Komatsu D275AX-5E0 Galeo Bull Dozer Operation and Maintenance Manual PEN00132-03

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: PEN00132-03

- Format: PDF

- Size: 9.1MB

- Number of Pages: 331

-

Model List:

- D275AX-5E0 Galeo Bull Dozer

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 2.3.2. VISIBILITY FROM OPERATORS SEAT

- 2.3.3. BREAKING IN THE MACHINE

- 2.4. NECESSARY INFORMATION

- 2.4.1. PRODUCT IDENTIFICATION NUMBER (PIN), MACHINE SERIAL NO. PLATE

- 2.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 2.4.3. BLADE SERIAL NO. PLATE POSITION

- 2.4.4. RIPPER SERIAL NO. PLATE POSITION

- 2.4.5. POSITION OF SERVICE METER

- 2.4.6. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 3. CONTENTS

- 4. SAFETY

- 4.1. SAFETY

- 4.2. SAFETY LABELS

- 4.2.1. POSITIONS OF SAFETY PICTOGRAMS

- 4.2.2. SAFETY LABELS

- 4.3. GENERAL PRECAUTIONS

- 4.3.1. SAFETY RULES

- 4.3.2. IF ABNORMALITIES ARE FOUND

- 4.3.3. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 4.3.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 4.3.5. SAFETY FEATURES

- 4.3.6. KEEP MACHINE CLEAN

- 4.3.7. INSIDE OPERATORS COMPARTMENT

- 4.3.8. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 4.3.9. HANDRAILS AND STEPS

- 4.3.10. PRECAUTIONS WHEN WORKING IN HIGH PLACES

- 4.3.11. MOUNTING AND DISMOUNTING

- 4.3.12. NO PEOPLE ON ATTACHMENTS

- 4.3.13. CRUSHING OR CUTTING PREVENTION

- 4.3.14. PREVENTION OF BURNS

- 4.3.15. FIRE PREVENTION

- 4.3.16. ACTION IF FIRE OCCURS

- 4.3.17. WINDOW WASHER LIQUID

- 4.3.18. PRECAUTIONS WHEN USING ROPS (ROLL OVER PROTECTIVE STRUCTURE)

- 4.3.19. PRECAUTIONS FOR ATTACHMENTS

- 4.3.20. CAB WINDOW GLASSES

- 4.3.21. UNAUTHORIZED MODIFICATION

- 4.3.22. SAFETY AT WORKSITE

- 4.3.23. WORKING ON LOOSE GROUND

- 4.3.24. DO NOT GO CLOSE TO HIGHVOLTAGE CABLES

- 4.3.25. ENSURE GOOD VISIBILITY

- 4.3.26. VENTILATION FOR ENCLOSED AREAS

- 4.3.27. CHECKING SIGNALMANS SIGNALS AND SIGNS

- 4.3.28. BE CAREFUL ABOUT ASBESTOS DUST

- 4.4. PRECAUTIONS FOR OPERATION

- 4.4.1. BEFORE STARTING ENGINE

- 4.4.2. OPERATION

- 4.4.3. TRANSPORTATION

- 4.4.4. BATTERY

- 4.4.5. TOWING

- 4.5. PRECAUTIONS FOR MAINTENANCE

- 4.5.1. WARNING TAG

- 4.5.2. KEEP WORK PLACE CLEAN AND TIDY

- 4.5.3. APPOINT LEADER WHEN WORKING WITH OTHERS

- 4.5.4. STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE

- 4.5.5. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 4.5.6. PROPER TOOLS

- 4.5.7. HANDLING ACCUMULATOR

- 4.5.8. PERSONNEL

- 4.5.9. ATTACHMENTS

- 4.5.10. WORK UNDER THE MACHINE

- 4.5.11. NOISE

- 4.5.12. PRECAUTIONS WHEN USING HAMMER

- 4.5.13. REPAIR WELDING

- 4.5.14. REMOVING BATTERY TERMINAL

- 4.5.15. PRECAUTIONS WHEN USING HIGHPRESSURE GREASE TO ADJUST TRACK TENSION

- 4.5.16. DO NOT DISASSEMBLE RECOIL SPRING

- 4.5.17. PRECAUTION WITH HIGHPRESSURE OIL

- 4.5.18. PRECAUTION FOR HIGH FUEL PRESSURE

- 4.5.19. HANDLING HIGHPRESSURE HOSES

- 4.5.20. PRECAUTION FOR HIGH VOLTAGE

- 4.5.21. WASTE MATERIAL

- 4.5.22. MAINTENANCE FOR AIR CONDITIONER

- 4.5.23. COMPRESSED AIR

- 4.5.24. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5. OPERATION

- 5.1. GENERAL VIEW

- 5.1.1. GENERAL VIEW OF MACHINE

- 5.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

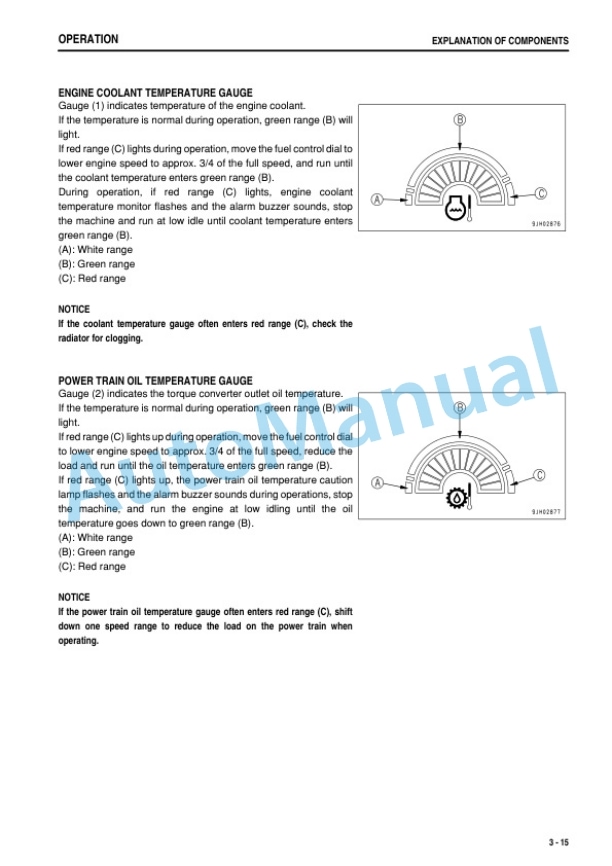

- 5.2. EXPLANATION OF COMPONENTS

- 5.2.1. FRONT PANEL

- 5.2.2. SWITCHES

- 5.2.3. CONTROL LEVERS, PEDALS

- 5.2.4. SASH GLASS INTERMEDIATE LOCK

- 5.2.5. DOOR POCKET

- 5.2.6. ASHTRAY

- 5.2.7. TOOL BOX

- 5.2.8. CAR STEREO, HANDLING

- 5.2.9. AIR CONDITIONER, HANDLING

- 5.3. OPERATION

- 5.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 5.3.2. STARTING ENGINE

- 5.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 5.3.4. STOPPING ENGINE

- 5.3.5. MOVING MACHINE

- 5.3.6. STOPPING MACHINE

- 5.3.7. SHIFTING GEAR

- 5.3.8. SHIFTING BETWEEN FORWARD AND REVERSE

- 5.3.9. STEERING MACHINE

- 5.3.10. PRECAUTIONS FOR OPERATION

- 5.3.11. PARKING MACHINE

- 5.3.12. CHECK AFTER STOPPING ENGINE

- 5.3.13. CHECK AFTER FINISHING WORK

- 5.3.14. LOCKING

- 5.3.15. WORK POSSIBLE USING BULLDOZER

- 5.3.16. EFFECTIVE USE OF MODE SELECTION SYSTEM

- 5.3.17. RIPPER OPERATION

- 5.3.18. OPERATING METHOD FOR RIPPING OPERATIONS

- 5.3.19. ADJUSTING POSTURE OF WORK EQUIPMENT

- 5.3.20. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 5.4. TRANSPORTATION

- 5.4.1. TRANSPORTATION PROCEDURE

- 5.4.2. LOADING, UNLOADING WORK

- 5.4.3. METHOD OF LIFTING MACHINE

- 5.4.4. TRAVELING ON ROADS

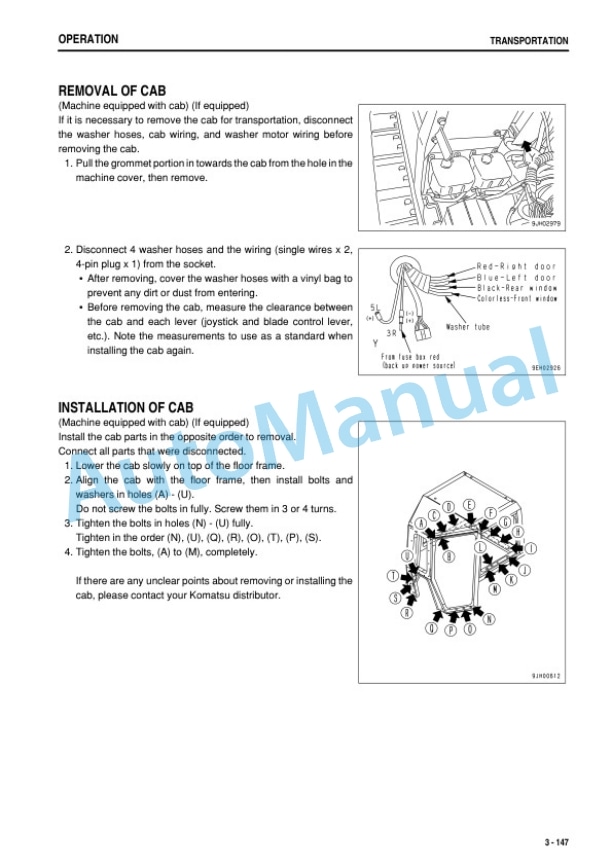

- 5.4.5. REMOVAL OF CAB

- 5.4.6. INSTALLATION OF CAB

- 5.5. COLD WEATHER OPERATION

- 5.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 5.5.2. AFTER COMPLETION OF WORK

- 5.5.3. AFTER COLD WEATHER

- 5.6. LONGTERM STORAGE

- 5.6.1. BEFORE STORAGE

- 5.6.2. DURING STORAGE

- 5.6.3. AFTER STORAGE

- 5.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 5.7. TROUBLESHOOTING

- 5.7.1. AFTER RUNNING OUT OF FUEL

- 5.7.2. METHOD OF TOWING MACHINE

- 5.7.3. IF BATTERY IS DISCHARGED

- 5.7.4. OTHER TROUBLE

- 5.7.5. WHEN MODE SELECTION SYSTEM FLASHES

- 6. MAINTENANCE

- 6.1. GUIDES TO MAINTENANCE

- 6.2. OUTLINES OF SERVICE

- 6.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 6.2.2. OUTLINE OF ELECTRIC SYSTEM

- 6.2.3. HANDLING HYDRAULIC RELATED EQUIPMENT

- 6.3. WEAR PARTS

- 6.3.1. WEAR PARTS LIST

- 6.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 6.4.1. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 6.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 6.5.1. TORQUE LIST

- 6.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 6.6.1. SAFETY CRITICAL PARTS

- 6.7. MAINTENANCE SCHEDULE CHART

- 6.7.1. MAINTENANCE SCHEDULE CHART

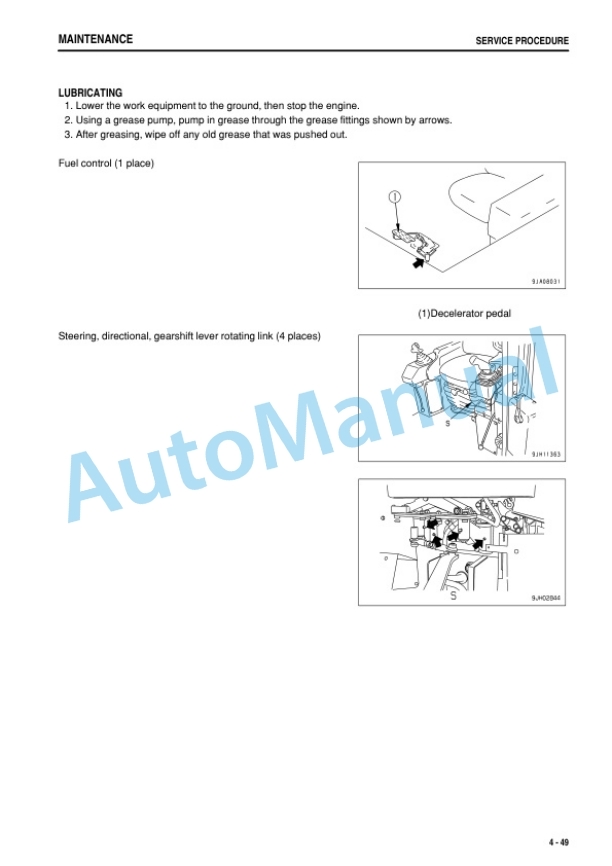

- 6.8. SERVICE PROCEDURE

- 6.8.1. INITIAL 250 HOURS SERVICE (ONLY AFTER THE FIRST 250 HOURS)

- 6.8.2. WHEN REQUIRED

- 6.8.3. CHECK BEFORE STARTING

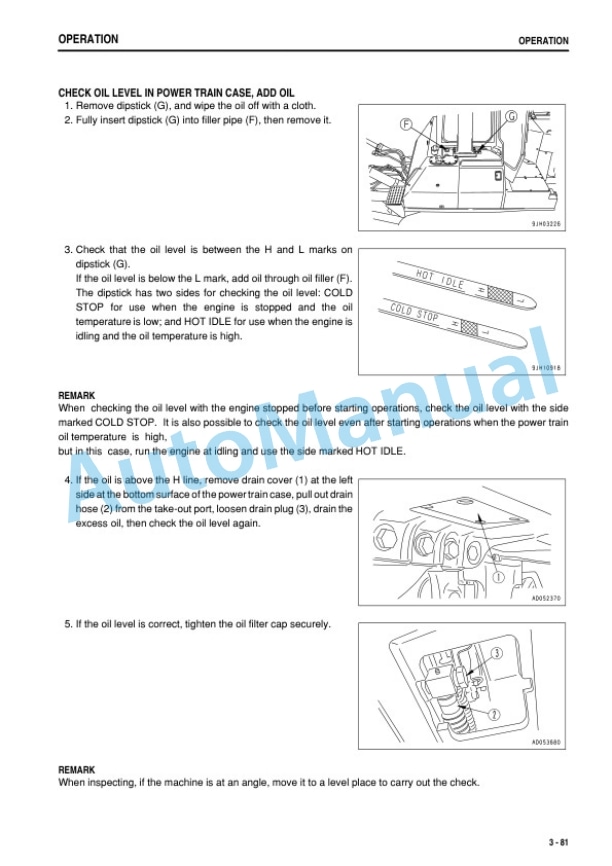

- 6.8.4. EVERY 250 HOURS SERVICE

- 6.8.5. EVERY 500 HOURS SERVICE

- 6.8.6. EVERY 1000 HOURS SERVICE

- 6.8.7. EVERY 2000 HOURS SERVICE

- 6.8.8. EVERY 4000 HOURS SERVICE

- 6.8.9. EVERY 8000 HOURS SERVICE

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS

- 8. ATTACHMENTS, OPTIONS

- 8.1. GENERAL PRECAUTIONS

- 8.1.1. PRECAUTIONS RELATED TO SAFETY

- 8.2. SELECTION OF TRACK SHOE

- 8.2.1. SELECTION OF TRACK SHOES

- 8.3. PROCEDURE FOR SELECTING RIPPER POINT

- 8.4. EFFECTIVE METHOD OF OPERATION FOR DUAL TILT DOZER

- 8.4.1. BLADE CONDITION

- 8.4.2. DOZING WORK

- 8.4.3. LEVELING (SPREADING) OPERATION

- 8.4.4. DITCHING OPERATION

- 8.4.5. BOULDER RAISING OPERATION

- 8.4.6. SIDECUTTING OPERATIONS

- 8.4.7. HORIZONTAL DOZING OPERATIONS FROM SIDE SLOPE (ROUGH GROUND)

- 8.5. SHOE SLIP CONTROL

- 8.5.1. MODE SELECTION SWITCH PANEL (SHOE SLIP CONTROL)

- 8.5.2. EFFECTIVE USE OF MODE SELECTION SYSTEM

- 8.5.3. IF MODE SELECTION SYSTEM FLASHES

- 8.6. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 8.6.1. BASIC PRECAUTIONS

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700