Komatsu D375A-6R Bull Dozer Field Assembly Instruction GEN00098-06

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: GEN00098-06

- Format: PDF

- Size: 13.4MB

- Number of Pages: 220

-

Model List:

- D375A-6R Bull Dozer

- 1. COVER

- 2. Preface

- 3. CONTENTS

- 4. Specifications

- 5. Precautions for field assembly

- 6. Disposal of removed parts

- 7. Assembly procedure, necessary equipment, and schedule

- 8. Layout of kit

- 9. Style for transportation

- 10. Table of tools for field assembly

- 11. Tightening torque

- 12. Coating materials list

- 13. Selection of wire ropes used for assembly

- 14. Assembly

- 14.1. A1 Installation of chassis

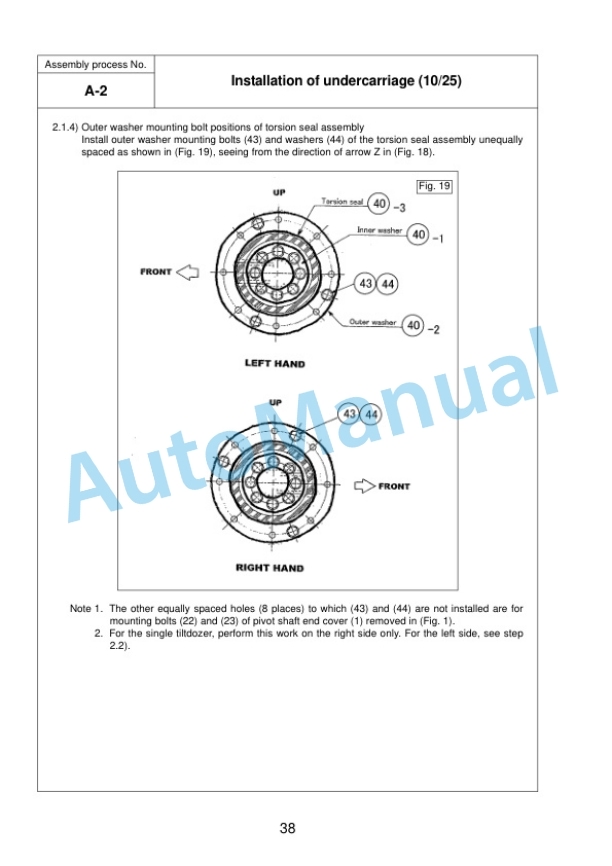

- 14.2. A2 Installation of undercarriage

- 14.3. A3 Adding oil to recoil chamber and pivot chamber

- 14.4. A4.1 Installation of engine air inlet hood

- 14.5. A4.2 Installation of engine air precleaner (if equipped)

- 14.6. A5 Installing direction of exhaust pipe

- 14.7. A6 Installation of blade lift cylinder

- 14.8. A7 Installation of ripper

- 14.9. A8 Installation of track

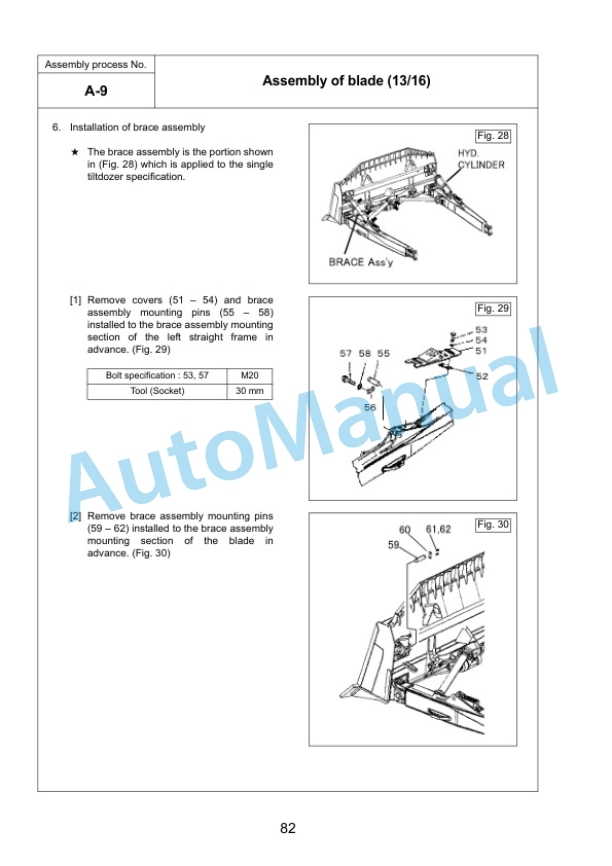

- 14.10. A9 Assembly of blade

- 14.11. A10 Installation of blade

- 14.12. A11 Installation of operators cab

- 14.13. A12 Installation of rear monitor camera (if equipped)

- 14.14. A13 Installation of additional cab lights (if equipped)

- 14.15. A14 Installation of ROPS guard

- 14.16. A15 Installation of VHMS, ORBCOMM antenna

- 14.17. A16 Installation of revolving warning lamp to top of ROPS (if equipped)

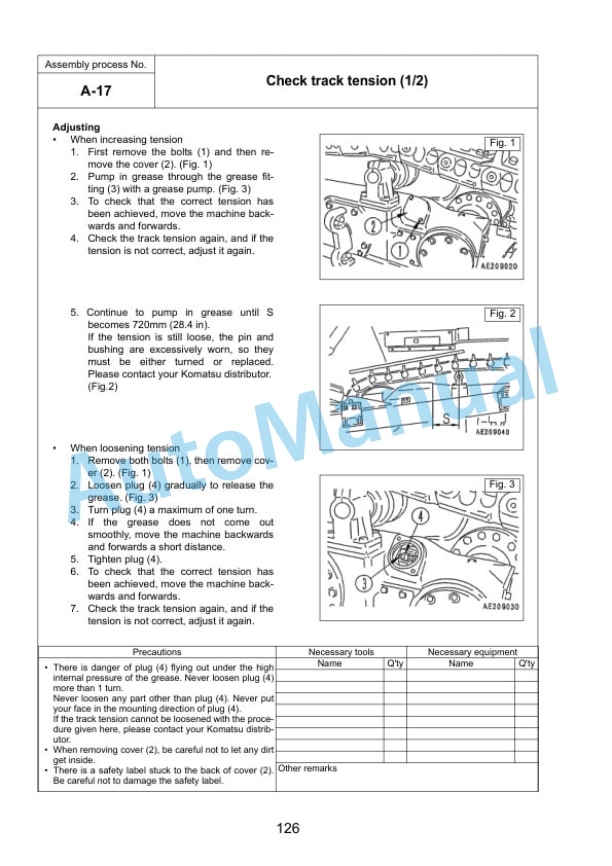

- 14.18. A17 Check track tension

- 14.19. A18 Check fuel, coolant and lubricants

- 14.20. A19 Bleeding air from hydraulic cylinders

- 14.21. A20 Lubricating

- 14.22. A21 Installation of fuel quick charge piping (if equipped)

- 15. Check and maintenance procedures after completion of assembly

- 15.1. M1 Check and adjustment of operators cab

- 15.2. M2 Inspection of machine monitor

- 15.3. M3 Checking operation of dual tilt mechanism (If equipped)

- 15.4. M4 Setting procedure for USER ADJUST MODE

- 15.5. M5 Setting procedure for maximum cooling fan speed

- 15.6. M6 Replacement of return filter (Replacement of standard filter > special flushing parts)

- 15.7. M7 Flushing of hydraulic circuit, and bleeding air from hydraulic cylinders (Part 1)

- 15.8. M8 Replacement of return filter (Replacement of special flushing parts > standard filter)

- 15.9. M9 Bleeding air from hydraulic cylinders (Part 2)

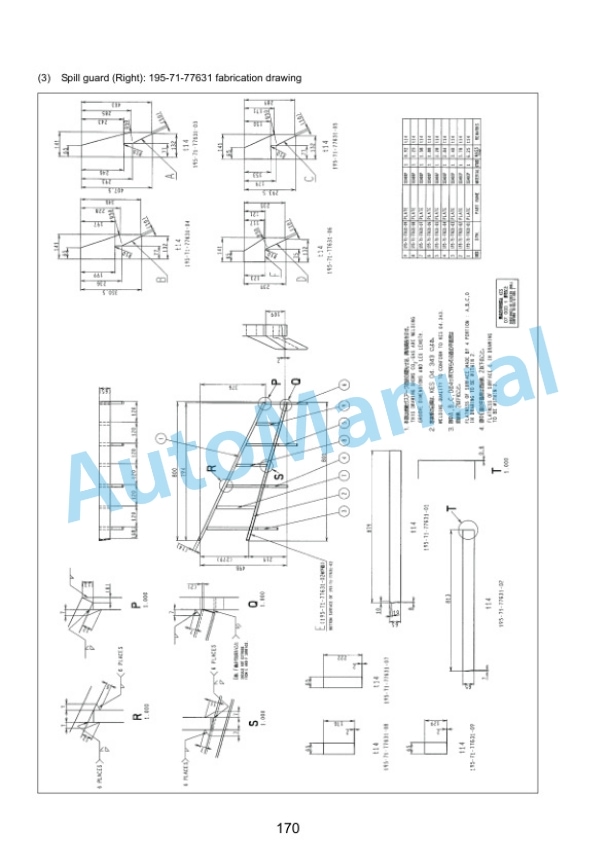

- 16. APPENDIX 1. Installation procedure for spill guard (Installation by welding)

- 17. APPENDIX 2. Precautions for initialization procedures for VHMS controller

- 18. Field assembly inspection report

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700