Komatsu D39EX-12, D39PX-12 Bull Dozer Operation and Maintenance Manual SEAM040200

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM040200

- Format: PDF

- Size: 5.6MB

- Number of Pages: 211

-

Model List:

- D39EX-12 Bull Dozer

- D39PX-12 Bull Dozer

- 1. MAIN MENU

- 2. COVER

- 3. FOREWORD

- 3.1. FOREWORD

- 3.2. SAFETY INFORMATION

- 3.3. INTRODUCTION

- 3.3.1. FRONT/REAR, LEFT/RIGHT DIRECTIONS OF MACHINE

- 3.4. NECESSARY INFORMATION

- 3.4.1. MACHINE SERIAL NO. PLATE AND POSITION

- 3.4.2. ENGINE SERIAL NO. PLATE AND POSITION

- 3.4.3. EMISSION CONTROL INFORMAITON LABEL AND POSITION

- 3.4.4. POSITION OF SERVICE METER

- 3.4.5. TABLE TO ENTER SERIAL NO. AND DISTRIBUTION

- 3.5. CONTENTS

- 4. SAFETY

- 4.1. SAFETY

- 4.2. SAFETY LABELS

- 4.2.1. POSITIONS OF SAFETY PICTOGRAMS

- 4.2.2. SAFETY LABELS

- 4.3. GENERAL PRECAUTIONS

- 4.3.1. SAFETY RULES

- 4.3.2. IF ABNORMALITY ARE FOUND

- 4.3.3. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 4.3.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 4.3.5. SAFETY FEATURES

- 4.3.6. KEEP MACHINE CLEAN

- 4.3.7. INSIDE OPERATORS COMPARTMENT

- 4.3.8. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 4.3.9. HANDRAILS AND STEPS

- 4.3.10. MOUNTING AND DISMOUNTING

- 4.3.11. NO PEOPLE ON ATTACHMENTS

- 4.3.12. CRUSHING OR CUTTING PREVENTION

- 4.3.13. PREVENTION OF BURNS

- 4.3.14. FIRE PREVENTION

- 4.3.15. ACTION IF FIRE OCCURS

- 4.3.16. WINDOW WASHER LIQUID

- 4.3.17. PRECAUTIONS WHEN USING ROPS

- 4.3.18. PRECAUTIONS FOR ATTACHMENTS

- 4.3.19. UNAUTHORIZED MODIFICATION

- 4.3.20. SAFETY AT WORKSITE

- 4.3.21. WORKING ON LOOSE GROUND

- 4.3.22. DO NOT GO CLOSE TO HIGHVOLTAGE CABLES

- 4.3.23. ENSURE GOOD VISIBILITY

- 4.3.24. VENTILATION FOR ENCLOSED AREA

- 4.3.25. CHECKING SIGNALMANS SIGNALS AND SIGNS

- 4.3.26. EMERGENCY EXIT FROM OPERATORS CAB

- 4.3.27. BE CAREFUL ABOUT ASBESTOS DUST

- 4.4. PRECAUTIONS FOR OPERATIONS

- 4.4.1. STARTING ENGINE

- 4.4.1.1. CHECKS BEFORE STARTING ENGINE

- 4.4.1.2. PRECAUTIONS WHEN STARTING

- 4.4.1.3. PRECAUTIONS IN COLD AREAS

- 4.4.2. OPERATION

- 4.4.2.1. CHECKS BEFORE OPERATION

- 4.4.2.2. PRECAUTIONS FOR MOVING MACHINE FORWARD OR IN REVERSE

- 4.4.2.3. PRECAUTIONS WHEN TRAVELING

- 4.4.2.4. TRAVELING ON SLOPES

- 4.4.2.5. OPERATE CAREFULLY ON SNOW

- 4.4.2.6. PARKING MACHINE

- 4.4.3. TRANSPORTATION

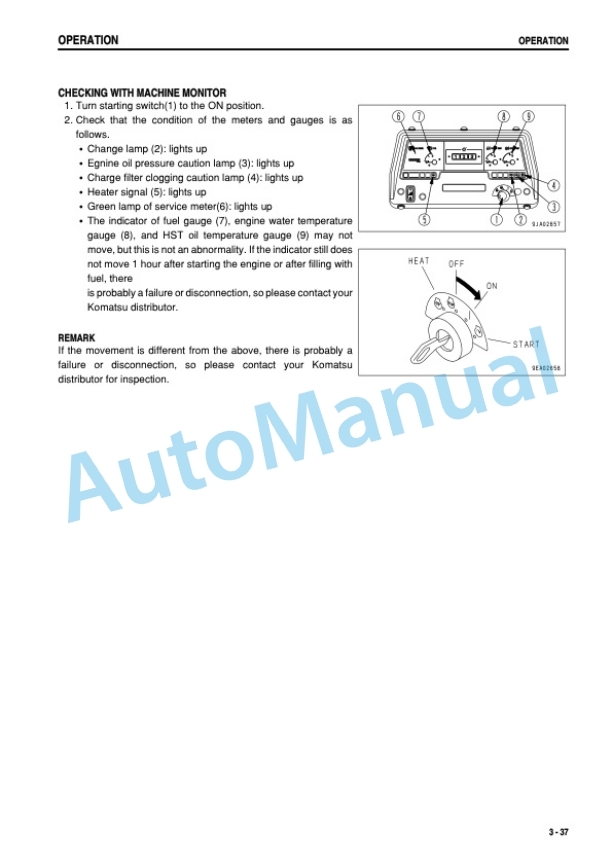

- 4.4.3.1. LOADING AND UNLOADING

- 4.4.3.2. SHIPPING

- 4.4.4. BATTERY

- 4.4.4.1. BATTERY HAZARD PREVENTION

- 4.4.4.2. STARTING WITH BOOSTER CABLE

- 4.4.5. TOWING

- 4.4.5.1. WHEN TOWING

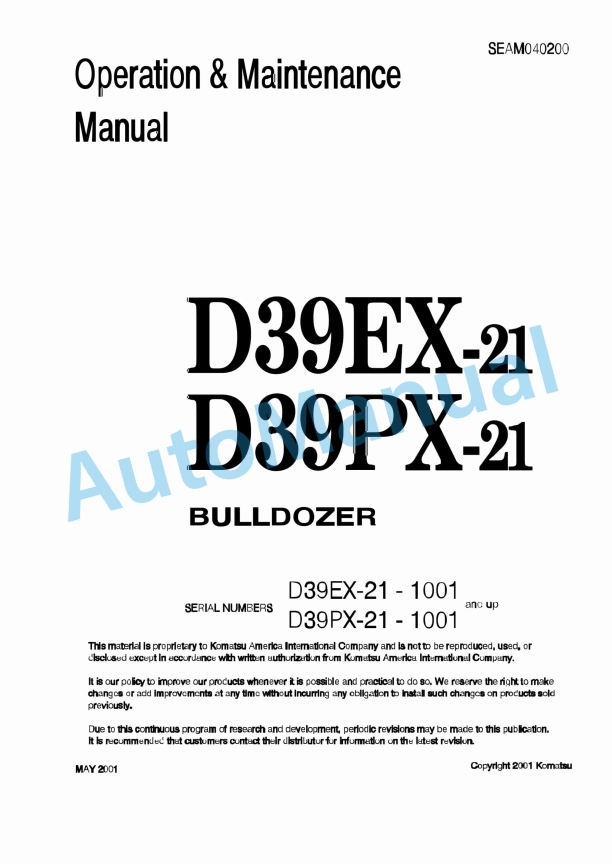

- 4.5. PRECAUTIONS FOR MAINTENANCE

- 4.5.1. WARNING TAG

- 4.5.2. KEEP WORK PLACE CLEAN AND TIDY

- 4.5.3. APPOINT LEADER WHN WORKING WITH OTHERS

- 4.5.4. STOP ENGINE BEFORE CARRYING OUT INSPECTION AND MAINTENANCE

- 4.5.5. TWO WORKERS FOR MAINTENANCE WHEN ENGINE IS RUNNING

- 4.5.6. PROPER TOOLS

- 4.5.7. NO UNAUTHORIZED PERSONNEDL INTO AREA

- 4.5.8. ATTACHMENTS

- 4.5.9. WORK UNDER THE MACINE

- 4.5.10. NOISE

- 4.5.11. PRECAUTIONS WHEN USING HAMMER

- 4.5.12. REPAIR WELDING

- 4.5.13. REMOVING BATTERY TERMINAL

- 4.5.14. PRECAUTIONS WHEN USING HIGHPRESSURE GREASE TO ADJUST TRACK TENSION

- 4.5.15. DO NOT DISASSEMBLE RECOIL SPRING

- 4.5.16. PRECAUTION WITH HIGHPRESSURE OIL

- 4.5.17. HANDLING HIGHPRESSURE HOSES

- 4.5.18. WASTE MATERIAL

- 4.5.19. MAINTENANCE FOR AIR CONDITIONER

- 4.5.20. COMPRESSED AIR

- 4.5.21. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5. OPERATION

- 5.1. GENERAL VIEW

- 5.1.1. GENERAL VIEW OF MACHINE

- 5.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 5.2. EXPLANATION OF COMPONENTS

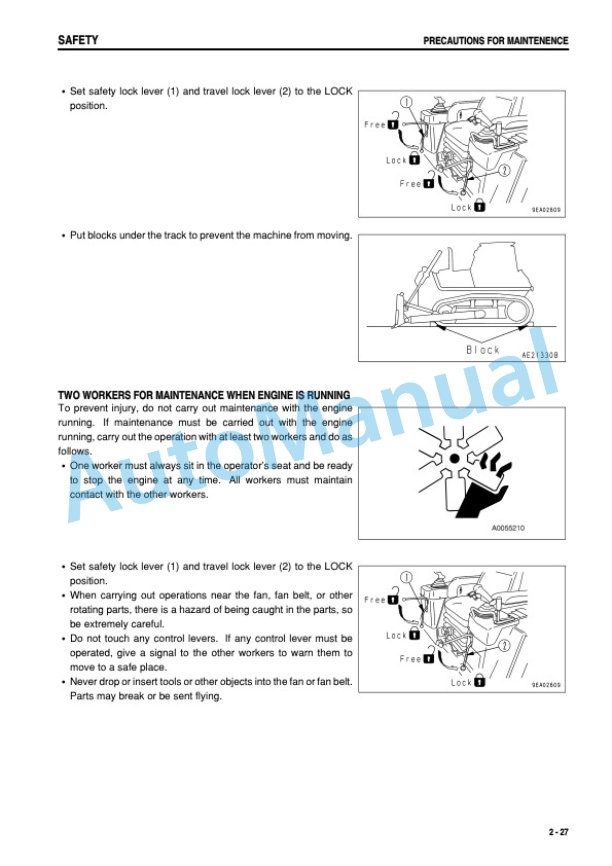

- 5.2.1. MONITOR PANEL

- 5.2.2. SWITCHES

- 5.2.3. CONTROL LEVERS AND PEDALS

- 5.2.4. FUSE

- 5.2.5. ELECTRIC POWER TAKEOUT ADAPTER

- 5.2.6. DOOROPEN LOCK

- 5.2.7. SASH GLASS INTERMEDIATE LOCK

- 5.2.8. CAP, COVER WITH LOCK

- 5.2.9. DOOR POCKET

- 5.2.10. ASHTRAY

- 5.2.11. LUNCHBOX HOLDER BELT

- 5.2.12. CUP HOLDER

- 5.2.13. TOOL BOX

- 5.2.14. GREASE PUMP HOLDER

- 5.2.15. CAR STEREO, HANDLING

- 5.2.16. AIR CONDITIONER, HANDLING

- 5.3. OPERATION

- 5.3.1. CHECK BEFORE STARTING ENGINE, ADJUST

- 5.3.2. STARTING ENGINE

- 5.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 5.3.4. STOPPING ENGINE

- 5.3.5. CHECK AFTER STOPPING ENGINE

- 5.3.6. MACHINE OPERATION

- 5.3.7. STOPPING MACHINE

- 5.3.8. SHIFTING GEAR

- 5.3.9. SHIFTING BETWEEN FORWARD AND REVERSE

- 5.3.10. STEERING MACHINE

- 5.3.11. PRECAUTIONS FOR OPERATION

- 5.3.12. WORK POSSIBLE USING BULLDOZER

- 5.3.13. PARKING MACHINE

- 5.3.14. CHECK AFTER FINISHING WORK

- 5.3.15. LOCKING

- 5.3.16. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 5.4. TRANSPORATION

- 5.4.1. TRANSPORATION MEANS

- 5.4.2. REMOVING CAB

- 5.4.3. PRECAUTIONS WHEN REMOVING WORK EQUIPMENT

- 5.4.4. LOADING, UNLOADING WORK

- 5.4.5. LIFTING MACHINE

- 5.5. COLD WEATHER OPERATION

- 5.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 5.5.2. AFTER COMPLETION OF WORK

- 5.5.3. AFTER COLD WEATHER

- 5.6. LONGTERM STORAGE

- 5.6.1. BEFORE STORAGE

- 5.6.2. DURING STORAGE

- 5.6.3. AFTER STORAGE

- 5.7. TROUBLESHOOTING

- 5.7.1. AFTER RUNNING OUT OF FUEL

- 5.7.2. MACHINE TOWING METHOD

- 5.7.3. IF BATTERY IS DISCHARGED

- 5.7.4. WHEN ENGINE DOES NOT STOP

- 5.7.5. OTHER TROUBLE

- 6. MAINTENANCE

- 6.1. GUIDE TO MAINTENANCE

- 6.2. OUTLINE OF SERVICE

- 6.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 6.2.2. RELATING TO ELECTRIC SYSTEM

- 6.3. WEAR PARTS LIST

- 6.3.1. WEAR PARTS LIST

- 6.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 6.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 6.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 6.5.1. TROQUE LIST

- 6.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 6.6.1. SAFETY CRITICAL PARTS

- 6.7. MAINTENANCE SCHEDULE CHART

- 6.7.1. MAINTENANCE SCHEDULE CHART

- 6.7.2. SERVICE PROCEDURE

- 6.7.2.1. WHEN REQUIRED

- 6.7.2.1.1. CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT

- 6.7.2.1.2. CLEAN INSIDE OF COOLING SYSTEM

- 6.7.2.1.3. CHECK TRACK TENSION

- 6.7.2.1.4. CHECK AND TIGHTEN TRACK SHOE BOLTS

- 6.7.2.1.5. CHECK ELECTRICAL INTAKE AIR HEATER

- 6.7.2.1.6. REVERSE AND REPLACE END BITS AND CUTTING EDGES

- 6.7.2.1.7. ADJUST IDLER CLEARANCE

- 6.7.2.1.8. CHECK, ADJUST AIR CONDITIONER

- 6.7.2.1.9. GREASE DOOR HINGE

- 6.7.2.1.10. CHECK DOOR LOCK STRIKER

- 6.7.2.1.11. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 6.7.2.1.12. REPLACE WIPER BLADE

- 6.7.2.1.13. CHECK IDLER OIL LEVEL, ADD OIL

- 6.7.2.1.14. ADJUST PLAY IN CENTER BALL

- 6.7.2.1.15. PROCEDURE FOR BLEEDING AIR IN HYDRAULIC SYSTEM

- 6.7.2.1.16. PROCEDURE FOR RELEASING INTERNAL PRESSURE OF HYDRAULIC SYSTEM

- 6.7.2.2. CHECK BEFORE STARTING

- 6.7.2.3. EVERY 50 HOURS SERVICE

- 6.7.2.3.1. DRAIN WATER, SEDIMENT FROM FUEL TANK

- 6.7.2.4. EVERY 250 HOURS SERVICE

- 6.7.2.4.1. LUBRICATING

- 6.7.2.4.2. CHECK OIL LEVEL IN FINAL DRIVE CASE , ADD OIL

- 6.7.2.4.3. CHECK LEVEL OF BATTERY ELECTROLYTE

- 6.7.2.4.4. CHECK BRAKE PERFORMANCE

- 6.7.2.4.5. CLEAN AIR CONDITIONER AIR FILTER (FRESH/RECIRC FILTER)

- 6.7.2.5. EVERY 500 HOURS SERVICE

- 6.7.2.5.1. REPLACE FUEL FILTER CARTRIDGE

- 6.7.2.5.2. CHANGE OIL IN ENGINE OIL PAN, RPLACE ENGINE OIL FILTER CARTRIDGE

- 6.7.2.5.3. REPLACE CORROSION RESISTOR CARTRIDGE

- 6.7.2.5.4. CHECK, CLEAN RADIATOR FINS

- 6.7.2.6. EVERY 1000 HOURS SERVICE

- 6.7.2.6.1. CHANGE OIL IN FINAL DRIVE CASE

- 6.7.2.6.2. CHECK FAN BELT TENSION, ADJUST

- 6.7.2.6.3. CHECK ALL TIGHTENING PARTS OF TURBOCHARGER

- 6.7.2.6.4. CHECK PLAY OF TURBOCHARGER ROTOR

- 6.7.2.6.5. CHECK FOR LOOSE ROPS MOUNT BOLTS

- 6.7.2.7. EVERY 2000 HOURS SERVICE

- 6.7.2.7.1. CHANGE OIL IN HYDRAULIC TANK, REPLACE OIL FILTER CARTRIDGE AND CLEAN SUCTION STRAINER

- 6.7.2.7.2. CLEAN, CHECK TURBOCHARGER

- 6.7.2.7.3. CHECK VIBRATION DAMPER

- 6.7.2.7.4. CHECK ALTERNATOR, STARTING MOTOR

- 6.7.2.7.5. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 6.7.2.8. EVERY 4000 HOURS SERVICE

- 6.7.2.8.1. CHECK WATER PUMP

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS

- 8. ATTACHMENTS, OPTIONS

- 8.1. GENERAL PRECAUTIONS

- 8.1.1. PRECAUTIONS RELATED TO SAFETY

- 8.2. SUSPENSION SEAT

- 8.3. HEADREST

- 8.4. EQUIPPING FIRE EXTINGUISHER AND FIRST AID KIT

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E