Komatsu D475A-8E0 Bull Dozer Operation and Maintenance Manual EENAM03952

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: EENAM03952

- Format: PDF

- Size: 86.7MB

- Number of Pages: 574

-

Model List:

- D475A-8E0 Bull Dozer

- 1. Foreword

- 1.1. Table of Contents

- 1.2. KOMATSU Machine Operator Privacy Policy

- 1.3. Foreword

- 1.3.1. Safety Information

- 1.3.2. Noise

- 1.3.3. Vibration Level

- 1.3.4. Introduction

- 1.3.5. Engine Technology to Conform Exhaust Gas Emission

- 1.3.6. Product Information

- 1.3.7. Abbreviation List

- 1.3.8. Serial Plate

- 1.3.9. Declaration of Conformity

- 2. Safety

- 2.1. Safety Labels

- 2.2. General Precautions Common to Operation and Maintenance

- 2.2.1. Precautions Before You Start Operation

- 2.2.2. Prepare for Safety Operation

- 2.2.3. Procedures If Fire Occurs

- 2.2.4. Precautions to Prevent Fire

- 2.2.5. Precautions When You Get on or Off Machine

- 2.2.6. Precautions for Machine and Jobsite

- 2.3. Precautions for Operation

- 2.3.1. Precautions for Jobsite

- 2.3.2. Start Engine

- 2.3.3. Precautions for Operation

- 2.3.4. Precautions for Transportation

- 2.3.5. Towing and being Towed

- 2.4. Precautions for Maintenance

- 2.4.1. Precautions Before Inspection and Maintenance

- 2.4.2. Precautions for Check and Maintenance

- 3. Operation

- 3.1. General View

- 3.1.1. Names of Machine Equipment

- 3.1.2. Control Levers and Pedals

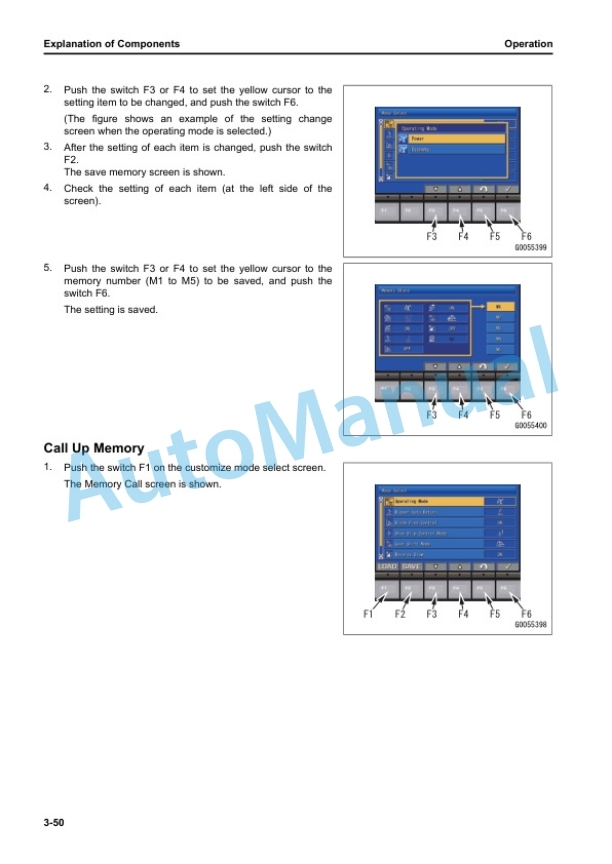

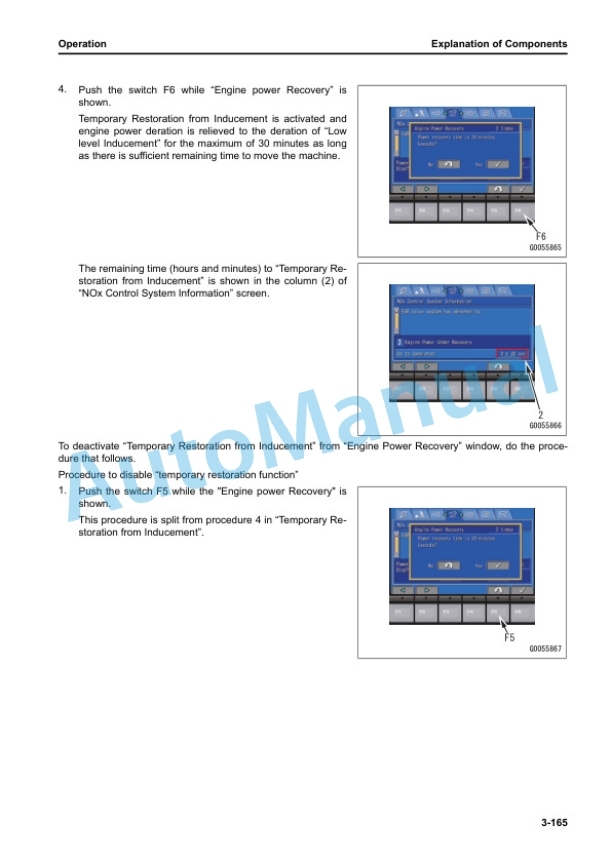

- 3.2. Explanation of Components

- 3.2.1. Machine Monitor Equipment

- 3.2.2. Switches

- 3.2.3. Control Levers and Pedals

- 3.2.4. Other Equipment

- 3.3. Machine Operations and Controls

- 3.3.1. Checks and Adjustment Before You Start Engine

- 3.3.2. How to Start Engine

- 3.3.3. Operations and Checks After You Start Engine

- 3.3.4. How to Stop Engine

- 3.3.5. How to Start Machine (Travel FORWARD and REVERSE) and Stop Machine

- 3.3.6. How to Shift Gears

- 3.3.7. How to Switch Between FORWARD and REVERSE

- 3.3.8. Steer Machine

- 3.3.9. Recommended Working Modes for Works

- 3.3.10. Precautions for Operation

- 3.3.11. Precautions When You Work on Slope

- 3.3.12. Precautions When You Use Brake

- 3.3.13. Do Not Open Door While You Operate Machine

- 3.3.14. Do Not Change CAB Glass in Any Way that Will Block the View

- 3.3.15. Precautions for Floating Operation

- 3.3.16. Precautions for Blind Areas Caused by CAB and ROPS Structures

- 3.3.17. Recommended Applications

- 3.3.18. Good Use of Ripper

- 3.3.19. Operating Method for Ripping Work

- 3.3.20. How to Adjust Work Equipment

- 3.3.21. Tips for Longer Undercarriage Life

- 3.3.22. Park Machine

- 3.3.23. How to Examine After You Complete Work

- 3.3.24. Lock

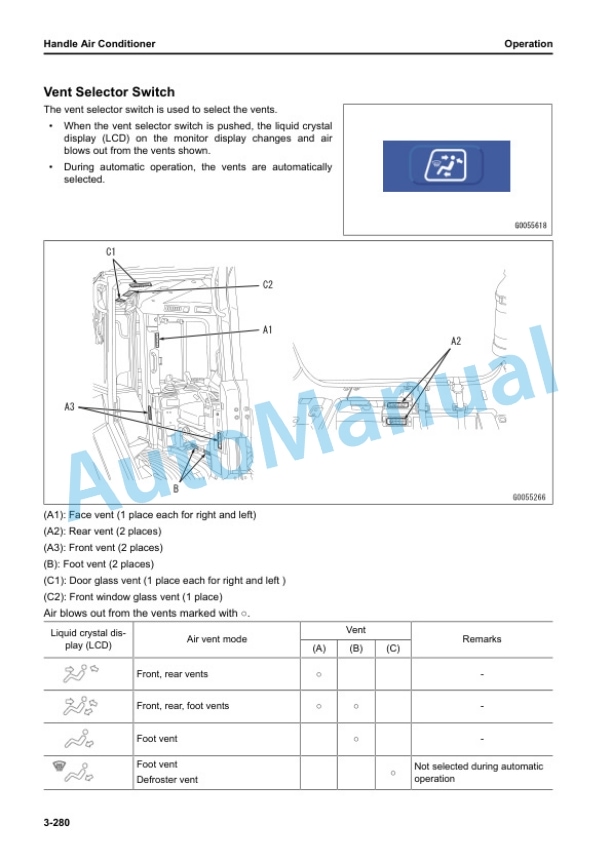

- 3.4. Handle Air Conditioner

- 3.4.1. Explanation of Air Conditioner Components

- 3.4.2. Operate Air Conditioner

- 3.5. Handle Radio

- 3.5.1. Explanation of Radio Equipment

- 3.5.2. Operate Radio

- 3.5.3. Radio Setting

- 3.6. Antenna

- 3.7. Transportation

- 3.7.1. Travel on Road

- 3.7.2. Precautions When You Transport Machine

- 3.7.3. Transportation

- 3.7.4. Remove CAB

- 3.7.5. Load onto and Unload from a Trailer

- 3.7.6. How to Lift Machine

- 3.8. Cold Weather Operation

- 3.8.1. Cold Weather Operation Information

- 3.8.2. Precautions After Daily Work Ends in Cold Weather

- 3.8.3. After Cold Weather Season

- 3.9. Precautions for LongTerm Storage

- 3.9.1. Prepare for LongTerm Storage

- 3.9.2. Maintenance During LongTerm Storage

- 3.9.3. Start Machine After LongTerm Storage

- 3.10. Troubles and Procedures

- 3.10.1. Procedures When You Run Out of Fuel

- 3.10.2. Precautions When You Tow Machine

- 3.10.3. Precautions for Discharged Battery

- 3.10.4. Other Trouble

- 4. Maintenance

- 4.1. Precautions for Maintenance

- 4.1.1. Examine Service Meter Reading

- 4.1.2. Komatsu Genuine Replacement Parts

- 4.1.3. Komatsu Genuine Lubricants

- 4.1.4. Always Use Clean Washer Fluid

- 4.1.5. Clean Lubricants

- 4.1.6. Check Drained Oil and Used Filter

- 4.1.7. Precautions When You Refill Oil or Fuel

- 4.1.8. Precautions for Welding

- 4.1.9. Do Not Drop Things Inside Machine

- 4.1.10. Precautions for KDPF

- 4.1.11. Dusty Jobsites

- 4.1.12. Avoid Mixing Oil

- 4.1.13. Lock Inspection Covers

- 4.1.14. Precautions When You Open and Close Engine Side Cover

- 4.1.15. Bleed Air from Hydraulic System

- 4.1.16. Precautions When You Install Hydraulic Hoses

- 4.1.17. Checks After Inspection and Maintenance

- 4.1.18. Select Fuel and Lubricants by Ambient Temperature

- 4.2. Outline of Maintenance

- 4.2.1. Handle Oil, Fuel, Coolant, and Do Oil Clinic

- 4.2.2. Electrical Components

- 4.2.3. Handle Hydraulic Components

- 4.3. Standard Tightening Torque for Bolts and Nuts

- 4.4. Maintenance Schedule

- 4.4.1. Maintenance Schedule Table

- 4.4.2. Maintenance Interval When Diesel Fuel Mixed with BioFuel is Used

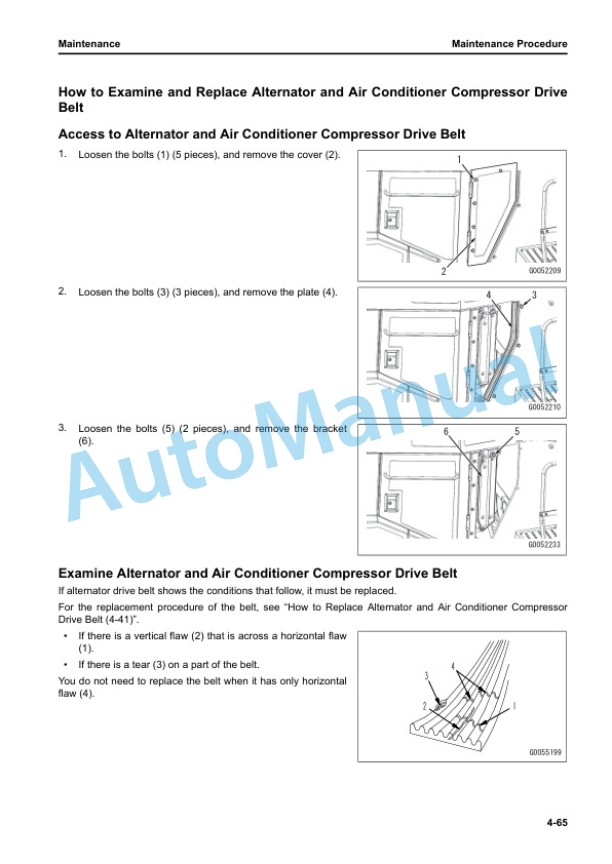

- 4.5. Maintenance Procedure

- 4.5.1. Initial 250 Hours Maintenance (Only After the First 250 Hours)

- 4.5.2. When Required

- 4.5.3. How to Examine Before You Start Operation

- 4.5.4. Every 250 Hours Maintenance

- 4.5.5. Every 500 Hours Maintenance

- 4.5.6. Every 1000 Hours Maintenance

- 4.5.7. Every 2000 Hours Maintenance

- 4.5.8. Every 4000 Hours Maintenance

- 4.5.9. Every 4500 Hours Maintenance

- 4.5.10. Every 8000 Hours Maintenance

- 4.5.11. Every 9000 Hours Maintenance

- 5. Specifications

- 5.1. Specifications

- 6. Attachments and Options

- 6.1. General Precautions

- 6.1.1. Precautions for Safety

- 6.2. Attachments and Options

- 6.2.1. Track Shoes Selection

- 6.3. Procedure to Select Ripper Point

- 6.4. Handle External Power Supply Engine Preheater

- 6.4.1. Install External Power Supply System for External Power Supply Engine Preheater

- 6.4.2. Make External Power Supply Cable

- 6.4.3. Install External Power Supply System

- 6.4.4. How to Start Engine in Cold Weather

- 6.5. How to Use Dual Tilt Dozer Effectively

- 6.5.1. Blade State

- 6.5.2. Dozing Work

- 6.6. Handle Hydraulic Type Ladder

- 6.6.1. Procedure to Operate Hydraulic Type Ladder

- 6.6.2. Procedures If Machine Does Not Move by Failure

- 6.6.3. When Required

- 6.6.4. Every 1000 Hours Maintenance

- 6.6.5. Every 4000 Hours Maintenance

- 6.7. Machine with Mining Specification

- 6.7.1. General Precautions Common to Operation and Maintenance

- 6.7.2. Switches

- 6.7.3. System Operating Lamp

- 6.7.4. Examine Before You Start Operation

- 6.7.5. KOWA (Komatsu Oil Wear Analysis)

- 6.7.6. When Required

- 6.7.7. Every 250 Hours Maintenance

- 6.7.8. Every 500 Hours Maintenance

- 6.7.9. Every 1000 Hours Maintenance

- 6.7.10. Every 2000 Hours Maintenance

- 6.7.11. Consumable Parts

- 7. Replacement Parts

- 7.1. Defined Life Parts

- 7.1.1. Defined Life Parts List

- 7.2. Consumable Parts

- 7.2.1. Consumable Parts List

- 7.3. Recommended Fuel, Coolant, and Lubricant

- 7.3.1. Lubrication Chart

- 7.3.2. How to Use Fuel, Coolant and Lubricants by Ambient Temperature

- 7.3.3. Recommended Brands and Qualities Other Than Komatsu Genuine Oils

- 8. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001