Komatsu D87E-2, D87P-2 Crawler Dozer Operation and Maintenance Manual CEAD007302

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAD007302

- Format: PDF

- Size: 9.1MB

- Number of Pages: 238

-

Model List:

- D87E-2 Crawler Dozer

- D87P-2 Crawler Dozer

- 1. MAIN MENU

- 2. COVER

- 3. INTRODUCTION

- 3.1. FORWARD

- 3.2. SAFETY INFORMATION

- 3.3. INTRODUCTION

- 3.3.1. INTENDED USE

- 3.3.2. FEATURES

- 3.3.3. BREAKING IN THE MACHINE

- 3.4. LOCATION OF PLATES, TABLE TO ENTER P.I.N. AND DISTRIBUTOR

- 3.4.1. PLATE LOCATION

- 3.4.2. ENGINE SERIAL NO. PLATE LOCATION

- 3.4.3. TABLE TO ENTER NUMBERS AND DISTRIBUTOR

- 3.4.4. ENGINE SERIAL NO. PLATE LOCATION

- 3.5. TABLE OF CONTENTS

- 4. SAFETY

- 4.1. WARNING LABELS

- 4.2. GENERAL PRECAUTIONS

- 4.2.1. SAFETY RULES

- 4.2.2. SAFETY FEATURES

- 4.2.3. UNAUTHORIZED MODIFICATION

- 4.2.4. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 4.2.5. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 4.2.6. MOUNTING AND DISMOUNTING

- 4.2.7. FIRE PREVENTION FOR FUEL AND OIL

- 4.2.8. CRUSHING OR CUTTING PREVENTION

- 4.2.9. PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURES

- 4.2.10. ASBESTOS DUST HAZARD PREVENTION

- 4.2.11. FIRE EXTINGUISHER AND FIRST AID KIT

- 4.2.12. PRECAUTIONS FOR ATTACHMENTS

- 4.2.13. PRECAUTIONS FOR ROPS

- 4.3. PRECAUTIONS DURING OPERATION

- 4.3.1. BEFORE STARTING ENGINE

- 4.4. OPERATING MACHINE

- 4.4.1. WHEN STARTING ENGINE

- 4.4.2. PRECAUTIONS WHEN MOVING FORWARD OR BACKWARD

- 4.4.3. VISIBILITY

- 4.4.4. TRAVELING ON SLOPES

- 4.4.5. OPERATE CAREFULLY ON SNOW

- 4.4.6. WORKING ON LOOSE GROUND

- 4.4.7. PARKING THE MACHINE

- 4.5. TRANSPORTATION

- 4.5.1. LOADING AND UNLOADING

- 4.5.2. SHIPPING

- 4.5.3. BATTERY

- 4.5.4. TOWING

- 4.6. PRECAUTIONS FOR MAINTENANCE

- 4.6.1. BEFORE CARRYING OUT MAINTENANCE

- 4.6.2. DURING MAINTENANCE

- 5. OPERATION

- 5.1. GENERAL

- 5.1.1. VIEW OF MACHINE

- 5.1.2. VIEWS OF CONTROLS AND GAUGES

- 5.1.3. VIEWS OF CONTROLS AND GAUGES

- 5.1.4. UNIVERSAL SYMBOLS

- 5.2. EXPLANATIONS OF COMPONENTS

- 5.2.1. GENERAL

- 5.2.2. GAUGES AND WARNING LIGHTS

- 5.2.3. SWITCHES

- 5.2.4. SEAT, SEAT BELT AND ARM RESTS

- 5.2.5. CONTROL LEVERS

- 5.2.6. PEDALS

- 5.2.7. LOCKING CAP

- 5.3. OPERATION

- 5.3.1. CHECKS BEFORE STARTING ENGINE

- 5.3.2. STARTING ENGINE

- 5.3.3. OPERATIONS AND CHECKS AFTER ENGINE STARTS

- 5.3.4. MOVING THE MACHINE

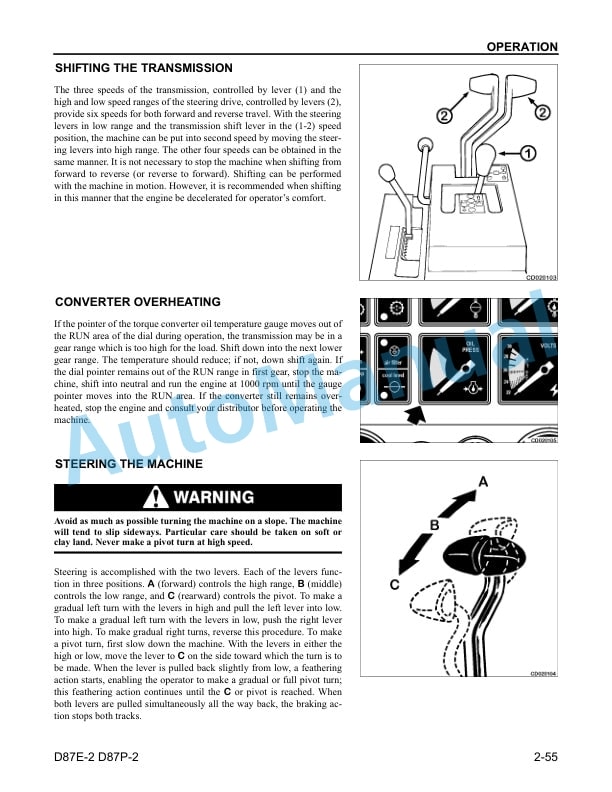

- 5.3.5. SHIFTING THE TRANSMISSION

- 5.3.6. CONVERTER OVERHEATING

- 5.3.7. STEERING THE MACHINE

- 5.3.8. DOWNGRADE OPERATION

- 5.3.9. OPERATING OVER AN OBSTRUCTION

- 5.3.10. ATTACHING TOWED EQUIPMENT

- 5.3.11. STOPPING THE MACHINE

- 5.3.12. PRECAUTIONS FOR OPERATION

- 5.3.13. PARKING THE MACHINE

- 5.3.14. CHECK AFTER FINISHING WORK

- 5.3.15. STOPPING THE ENGINE

- 5.3.16. CHECKS AFTER STOPPING ENGINE

- 5.3.17. LOCKING

- 5.3.18. WORK POSSIBLE USING MOUNTED EQUIPMENT

- 5.4. MOUNTED EQUIPMENT

- 5.4.1. SEMI U DOZER D87E2

- 5.4.2. STRAIGHT ANGLE DOZER D87E2

- 5.4.3. STRAIGHT DOZER D87P2

- 5.4.4. RIPPER

- 5.4.5. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 5.5. UTILITY BOX

- 5.6. TRANSPORTATION

- 5.6.1. LOADING, UNLOADING THE MACHINE

- 5.6.2. LIFTING THE MACHINE

- 5.6.3. SECURING THE MACHINE

- 5.6.4. PRECAUTIONS

- 5.7. COLD WEATHER OPERATIONS

- 5.7.1. PRECAUTIONS FOR LOW TEMPERATURE

- 5.7.2. AFTER COMPLETION OF WORK

- 5.7.3. AFTER COLD WEATHER

- 5.8. LONG TERM STORAGE

- 5.8.1. BEFORE STORAGE

- 5.8.2. DURING STORAGE

- 5.8.3. AFTER STORAGE

- 5.9. TROUBLESHOOTING

- 5.9.1. AFTER RUNNING OUT OF FUEL

- 5.9.2. IF BATTERY IS DISCHARGED

- 5.9.3. OTHER TROUBLE

- 5.9.4. METHODS OF TOWING MACHINE

- 6. MAINTENANCE

- 6.1. GUIDES TO MAINTENANCE

- 6.2. OUTLINES OF SERVICE

- 6.2.1. OUTLINE OF OIL, FUEL, COOLANT

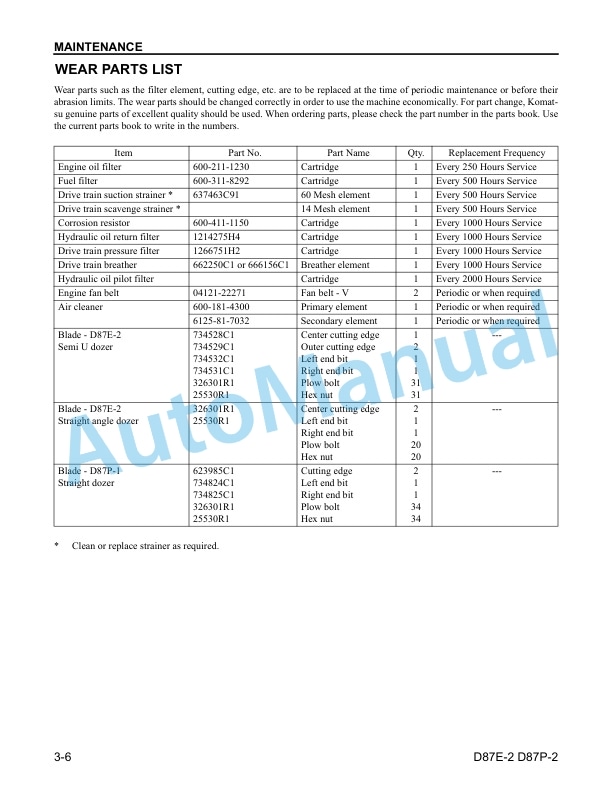

- 6.3. WEAR PARTS LIST

- 6.4. USE OF FUEL, COOLANT AND LUBRICANTS

- 6.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 6.4.2. ENGINE OIL SPECIFICATIONS

- 6.4.3. DRIVE TRAIN OIL SPECIFICATIONS

- 6.4.4. TRACK FRONT IDLER, TRACK ROLLER, TOP IDLER OIL SPECIFICATIONS

- 6.4.5. EQUIPMENT SYSTEM OIL SPECIFICATIONS

- 6.4.6. FINAL DRIVE OIL OR PIVOT SHAFT HOUSING SPECIFICATIONS

- 6.4.7. COOLING SYSTEM

- 6.4.8. FUEL SYSTEM

- 6.5. STANDARD TIGHTENING TORQUES

- 6.5.1. INTRODUCTION OF NECESSARY TOOLS

- 6.5.2. BOLT IDENTIFICATION CHART

- 6.6. PERIODIC REPLACEMENT OF CRITICAL PARTS

- 6.7. MAINTENANCE SCHEDULE CHART

- 6.8. SERVICE PROCEDURE

- 6.8.1. INITIAL 10 HOURS SERVICE

- 6.8.2. EVERY 10 HOURS SERVICE

- 6.8.3. EVERY 50 HOURS SERVICE

- 6.8.4. INITIAL 250 HOURS SERVICE

- 6.8.5. EVERY 250 HOURS SERVICE

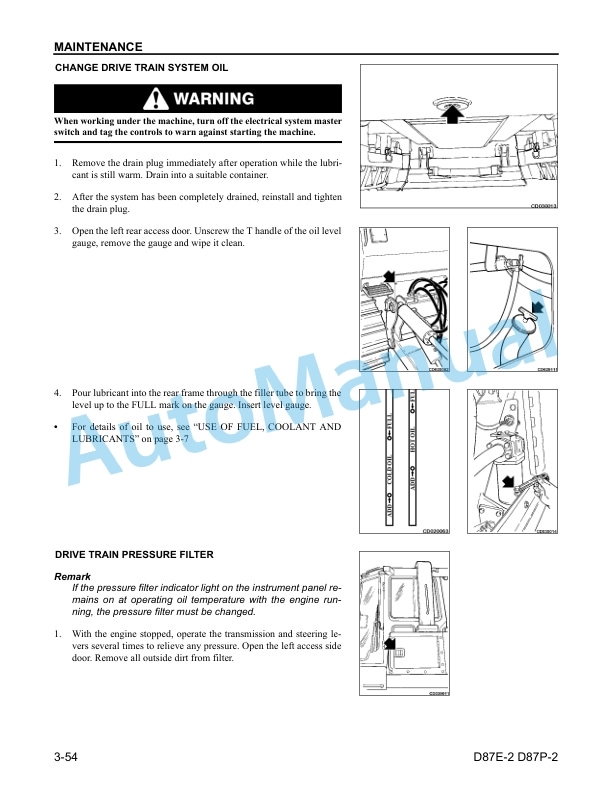

- 6.8.6. EVERY 500 HOURS SERVICE

- 6.8.7. EVERY 1000 HOURS SERVICE

- 6.8.8. EVERY 2000 HOURS SERVICE

- 6.8.9. EVERY 4000 HOURS SERVICE

- 6.8.10. WHEN REQUIRED

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS AND DIMENSIONS

- 7.1.1. SPECIFICATIONS

- 7.1.2. D87E2 DIMENSIONS

- 7.1.3. D87P2 DIMENSIONS

- 8. OPTIONS, ATTACHMENTS

- 8.1. PRECAUTIONS RELATED TO SAFETY

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534