Komatsu FD200-7, FD250-7 Forklift Truck Operation and Maintenance Manual TEN00738-05

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: TEN00738-05

- Format: PDF

- Size: 9.9MB

- Number of Pages: 195

-

Model List:

- FD200-7 Forklift Truck

- FD250-7 Forklift Truck

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.1.1. ABOUT THIS MANUAL

- 2.1.2. ENGINE MOUNTED ON THIS LIFT TRUCK

- 2.1.2.1. EXHAUST GAS CONTROL

- 2.1.2.2. CERTIFICATION LABEL AFFIXING POSITION

- 2.1.3. FOR YOUR SAFETY

- 2.1.3.1. SIGNAL WORDS

- 2.1.3.2. SAFETY INDICATORS

- 2.1.4. APPLICABLE MODEL AND SERIAL NO.

- 2.1.5. GENERAL VIEW OF LIFT TRUCK

- 2.1.5.1. APPLICATION OF LIFT TRUCK

- 2.1.5.2. DIRECTION OF LIFT TRUCK

- 2.1.6. UNITS OF MEASURE

- 2.1.7. QUALIFICATIONS FOR OPERATION

- 2.1.8. RUNNING IN NEW LIFT TRUCKS

- 2.1.8.1. RUNNING IN NEW LIFT TRUCK

- 2.1.8.2. MAINTENANCE FOR NEW LIFT TRUCK

- 2.1.9. WARRANTY AND SERVICE

- 2.1.9.1. PERIODICAL EXCHANGE PARTS

- 2.1.9.2. USE OF GENUINE KOMATSU PARTS AND OILS

- 2.1.10. NECESSARY INFORMATION OF LIFT TRUCK

- 2.1.10.1. MEMORANDUM (TO BE FILLED BY KOMATSU DISTRIBUTOR)

- 2.1.10.2. MODEL AND SERIAL NO. PLATE LOCATION

- 2.1.10.3. ENGINE SERIAL NUMBER PLATE OR STAMPING LOCATION

- 2.1.10.4. HOUR METER LOCATION

- 2.1.11. CONTENTS

- 3. SAFETY

- 3.1. SAFETY

- 3.1.1. SAFETY LABELS

- 3.1.1.1. SAFETY LABEL LOCATION CHART

- 3.1.1.2. SAFETY LABELS

- 3.1.2. BASIC PRECAUTIONS

- 3.1.2.1. FOLLOW RULES

- 3.1.2.2. NEVER OPERATE THE FAILED LIFT TRUCK

- 3.1.2.3. WEAR ADEQUATE CLOTHES AND SAFETY EQUIPMENT FOR OPERATION

- 3.1.2.4. FIRE EXTINGUISHER AND FIRST AID KIT

- 3.1.2.5. CAUTIONS FOR SAFETYRELATED EQUIPMENT

- 3.1.2.6. PRACTICE SUFFICIENTLY BEFORE OPERATION

- 3.1.2.7. JUMPING ON AND OFF FROM THE LIFT TRUCK IS STRICTLY PROHIBITED

- 3.1.2.8. KEEP THE OPERATORS COMPARTMENT AND PLATFORM CLEAN AND TIDY

- 3.1.2.9. CAUTION WHEN WASHING LIFT TRUCK

- 3.1.2.10. TO AVOID BURN INJURY

- 3.1.2.11. FIRE PREVENTION

- 3.1.2.12. IF A FIRE BREAKS OUT

- 3.1.2.13. HANDLING OF FIRE EXTINGUISHER (OPTIONAL)

- 3.1.2.14. DO NOT MODIFY THE LIFT TRUCK

- 3.1.2.15. DO NOT REMOVE THE OVERHEAD GUARD AND LOAD BACKREST

- 3.1.2.16. SECURE SAFETY AT THE WORKING AREA

- 3.1.2.17. ENGINE EXHAUST GAS IS TOXIC

- 3.1.2.18. PRECAUTIONS RELATED TO SPECIAL ENVIRONMENT

- 3.1.2.19. ASBESTOS CAUTION

- 3.1.2.20. WINDOW WASHER CAUTION

- 3.1.3. STARTUP INSPECTION

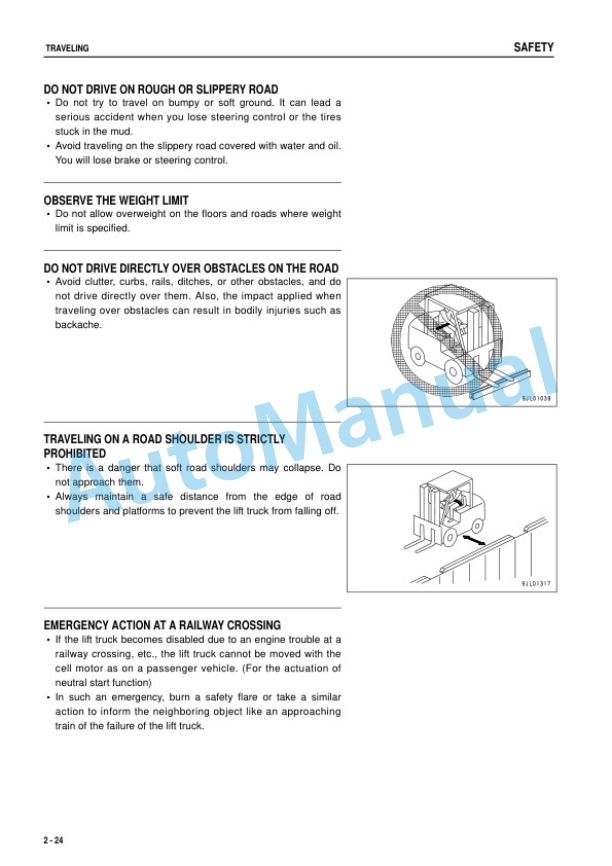

- 3.1.4. TRAVELING

- 3.1.4.1. PREPARATION BEFORE DRIVING THE LIFT TRUCK

- 3.1.4.2. WHILE DRIVING THE LIFT TRUCK

- 3.1.4.3. STOPPING AND PARKING

- 3.1.4.4. TOWING

- 3.1.5. LOAD HANDLING OPERATION

- 3.1.6. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 3.1.6.1. ALWAYS PERFORM THE STARTUP INSPECTION

- 3.1.6.2. PUT UP A WARNING SIGN DURING INSPECTION AND MAINTENANCE

- 3.1.6.3. KEEP THE WORKING AREA CLEAN AND TIDY

- 3.1.6.4. PRECAUTIONS BEFORE INSPECTION AND MAINTENANCE

- 3.1.6.5. KEEP UNAUTHORIZED PERSON OFF

- 3.1.6.6. USE OF RIGHT TOOLS AND EQUIPMENT

- 3.1.6.7. CAUTIONS WHEN WORKING UNDER WORK EQUIPMENT

- 3.1.6.8. AVOID GETTING CAUGHT UP BY THE MAST OR FALLING OFF

- 3.1.6.9. BE CAREFUL OF HIGHTEMPERATURE COOLANT

- 3.1.6.10. BE CAREFUL OF HIGH PRESSURE OIL

- 3.1.6.11. BE CAREFUL OF ROTATING COOLING FAN AND BELT

- 3.1.6.12. PRECAUTIONS FOR INSTALLING RADIO CONTROL SYSTEM

- 3.1.6.13. CAUTION WHEN REPAIRING THE ELECTRICAL SYSTEM

- 3.1.6.14. CAUTIONS FOR USING COMPRESSED AIR FOR CLEANING

- 3.1.6.15. CAUTIONS WHEN REPLACING THE SEAT

- 3.1.6.16. CAUTION WHEN HANDLING BATTERY

- 3.1.6.17. STRICTLY FOLLOW THE INSTRUCTIONS SHOWN BELOW TO AVOID GENERATION

- 3.1.6.18. CAUTION WHEN CHARGING A BATTERY

- 3.1.6.19. CAUTION WHEN HANDLING TIRES

- 3.1.6.20. CAUTION WHEN HANDLING ACCUMULATOR

- 3.1.6.21. CAUTION IN WASTE DISPOSAL

- 3.1.6.22. CAUTION AFTER INSPECTION AND REPAIR

- 3.1.6.23. PERIODIC REPLACEMENT OF DEFINED LIFE PARTS

- 3.1.7. HOISTING AND TRANSPORTING THE LIFT TRUCK

- 3.1.7.1. CAUTION WHEN HOISTING THE LIFT TRUCK

- 3.1.7.2. CAUTIONS FOR LOADING AND UNLOADING THE LIFT TRUCK

- 3.1.8. STRUCTURE AND STABILITY OF THE LIFT TRUCK (TO PREVENT LIFT TRUCK FROM TIPPING)

- 3.1.8.1. LONGITUDINAL STABILITY

- 3.1.8.2. CENTER OF GRAVITY OF A LOAD

- 3.1.8.3. COMBINED CENTER OF GRAVITY AND STABILITY ON THE LOADED LIFT TRUCK

- 3.1.8.4. ACTUAL CAPACITY

- 3.1.8.5. SERIAL NO. PLATE AND LOAD TABLE

- 3.1.8.6. INTRODUCTION OF OPTIONAL SAFETY AUXILIARY DEVICE

- 4. OPERATION

- 4.1. OPERATION

- 4.1.1. GENERAL VIEW

- 4.1.1.1. GENERAL VIEW OF LIFT TRUCK

- 4.1.1.2. INSTRUMENTS AND CONTROLS

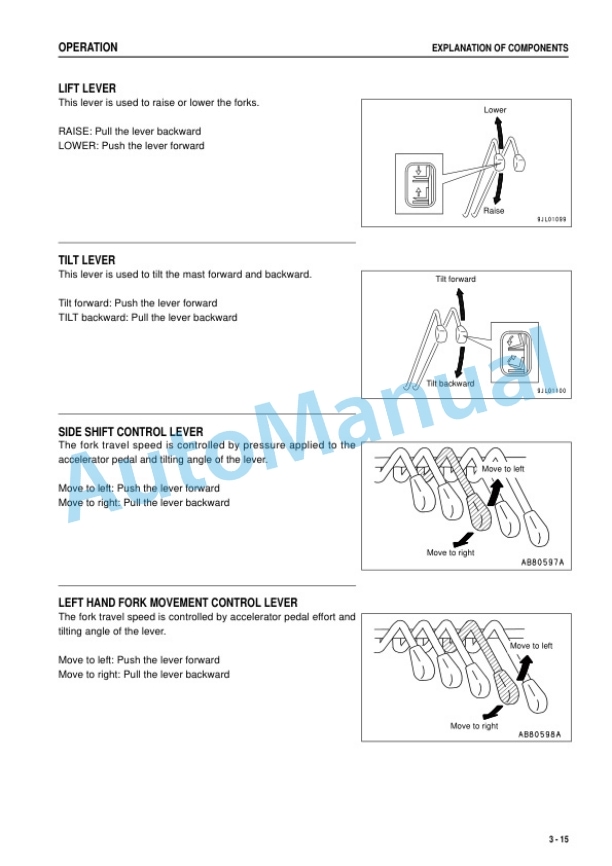

- 4.1.2. EXPLANATION OF COMPONENTS

- 4.1.2.1. INSTRUMENT PANEL

- 4.1.2.2. OPERATING DEVICES

- 4.1.3. OPERATION

- 4.1.3.1. STARTUP INSPECTION

- 4.1.3.2. GETTING ON/OFF THE LIFT TRUCK AND OPERATING POSTURE ADJUSTMENT

- 4.1.3.3. STARTING, GEAR SHIFTING, AND TRAVELING

- 4.1.3.4. STARTING AND STOPPING ON SLOPE

- 4.1.3.5. TRAVELING AT A SLOW SPEED (INCHING)

- 4.1.3.6. TURNING

- 4.1.3.7. OPERATION ON SNOWY AND FROZEN ROADS

- 4.1.3.8. TEMPORARY STOPPING, PARKING AND STOPPING

- 4.1.3.9. LOAD HANDLING OPERATION

- 4.1.3.10. CHECKING AFTER OPERATION

- 4.1.3.11. KOMTRAX

- 5. INSPECTION AND MAINTENANCE

- 5.1. INSPECTION AND MAINTENANCE

- 5.1.1. INSPECTION AND MAINTENANCE

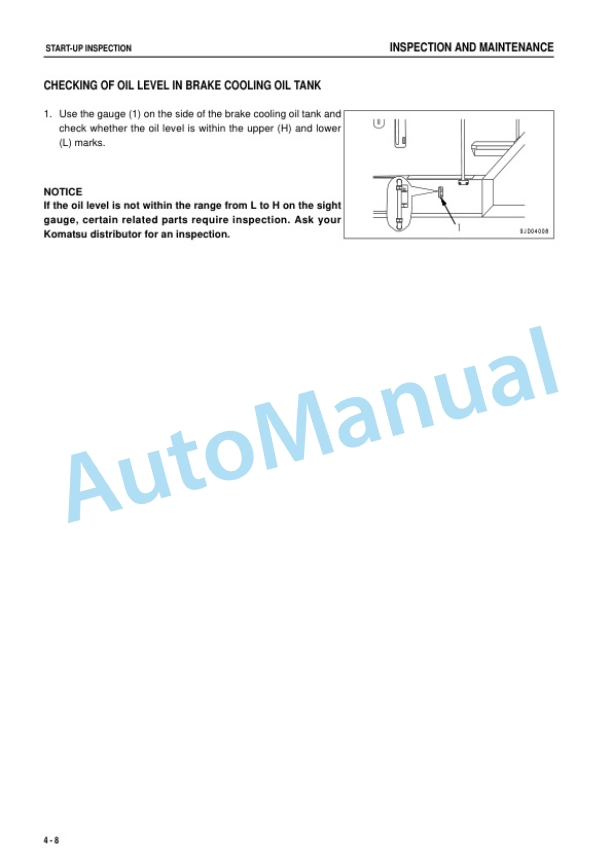

- 5.1.2. STARTUP INSPECTION

- 5.1.2.1. CHECKING ABNORMALITIES DETECTED ON THE PREVIOUS DAY

- 5.1.2.2. WALK AROUND A FORKLIFTT

- 5.1.2.3. INSPECTION BY OPENING COVER AND HOOD

- 5.1.2.4. CHECKING FROM THE OPERATORS SEAT

- 5.1.2.5. CHECK BY SETTING THE STARTING SWITCH TO THE ON POSITION

- 5.1.2.6. CHECKING WITH ENGINE STARTED

- 5.1.2.7. CHECKING THE BRAKE ACCUMULATOR

- 5.1.2.8. CHECKING WHILE TRAVELING SLOWLY

- 5.1.2.9. CHECKING BY OPERATING THE WORK EQUIPMENT CONTROL LEVER

- 5.1.2.10. CHECKING OF SAFETY FUNCTION

- 5.1.2.11. IINSPECTION OF LIFT TRUCK WITH CAB SPECIFICATION AND LIFT TRUCK WITH FRONT GLASS

- 5.1.2.12. CHECKING AND REPORTING AFTER OPERATION

- 5.1.3. INSPECTION AND MAINTENANCE

- 5.1.3.1. INSPECTION FOR EVERY 100 HOURS (2 WEEKS)

- 5.1.3.2. INSPECTION FOR EVERY 600 HOURS (3 MONTHS)

- 5.1.3.3. GREASES AND FUEL

- 5.1.3.4. AIR CLEANER ELEMENT CLEANING

- 5.1.3.5. FUEL PREFILTER AIR BLEEDING

- 5.1.3.6. REPLACING TIRES

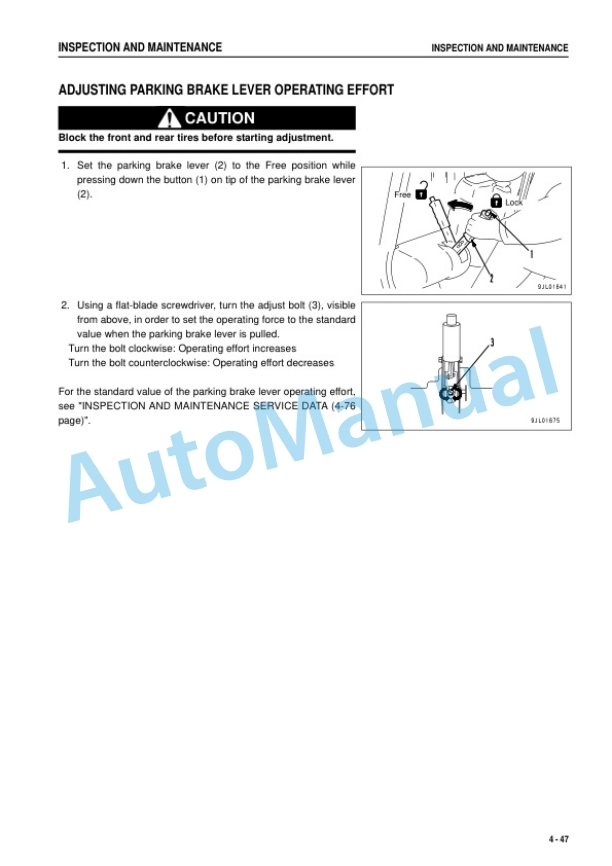

- 5.1.3.7. ADJUSTING PARKING BRAKE LEVER OPERATING EFFORT

- 5.1.3.8. REPLACING FUSE

- 5.1.3.9. REPLACING BULBS

- 5.1.3.10. INSPECTION OF HIGH PRESSURE PIPING CLAMP FOR LOOSENESS AND HARDENING OF RUBBER

- 5.1.3.11. CHECKING FOR MISSING FUEL SPRAY PREVENTION CAP, HARDENING OF RUBBER

- 5.1.4. PROCEDURE FOR A DOWN BATTERY

- 5.1.5. RUNNING IN COLD WEATHER

- 5.1.6. PROCEDURE WITH OVERHEATED ENGINE

- 5.1.7. OPERATING LIFT TRUCKS IN SPECIAL ENVIRONMENT OR IN FORCIBLE WAY

- 5.1.8. ACTION TO TAKE IF THE FORK FAILS TO LOWER

- 5.1.9. WASHING LIFT TRUCK

- 5.1.10. LONGTERM STORAGE

- 5.1.11. HOISTING LIFT TRUCK

- 5.1.12. LOADING AND UNLOADING OF LIFT TRUCK

- 5.1.13. HOW TO TOW THE LIFT TRUCK OR BE TOWED

- 5.1.14. INSPECTION AND MAINTENANCE SCHEDULE CHART

- 5.1.15. PERIODIC REPLACEMENT OF DEFINED LIFE PARTS

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF