Komatsu MX352 Hydraulic Excavator Operation and Maintenance Manual SEAM061600T

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM061600T

- Format: PDF

- Size: 10.1MB

- Number of Pages: 273

-

Model List:

- MX352 Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER

- 3. FOREWORD

- 3.1. FOREWORD

- 3.2. SAFETY INFORMATION

- 3.3. INTRODUCTION

- 3.3.1. DIRECTIONS OF MACHINE

- 3.4. PRODUCT INFORMATION

- 3.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 3.4.2. ENGINE SERIAL NUMBER PLATE AND ITS LOCATION

- 3.4.3. EMISSION CONTROL INFORMATION LABEL AND ITS LOCATION

- 3.4.4. SERVICE METER LOCATION

- 3.4.5. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 3.5. CONTENTS

- 4. CONTENTS

- 5. SAFETY

- 5.1. SAFETY INFORMATION

- 5.2. SAFETY LABELS

- 5.2.1. LOCATION OF SAFETY LABELS

- 5.2.2. SAFETY LABELS

- 5.3. SAFETY INFORMATION

- 5.4. SAFETY MACHINE OPERATION

- 5.4.1. STARTING ENGINE

- 5.4.2. OPERATION

- 5.4.3. TRANSPORTATION

- 5.4.4. BATTERY

- 5.4.5. TOWING

- 5.4.6. LIFTING OBJECTS WITH BUCKET

- 5.5. SAFETY MAINTENANCE INFORMATION

- 6. OPERATION

- 6.1. MACHINE VIEW ILLUSTRATIONS

- 6.1.1. OVERALL MACHINE VIEW

- 6.1.2. CONTROLS AND GAUGES

- 6.2. DETAILED CONTROLS AND GAUGES

- 6.2.1. MONITORING SYSTEM

- 6.2.1.1. Emergency Monitors

- 6.2.1.2. Meter Display Portion

- 6.2.1.3. Pilot Lamps

- 6.2.1.4. Monitor Switches Portion

- 6.2.2. SWITCHES

- 6.2.3. CONTROL LEVERS AND PEDALS

- 6.2.4. WINDSHIELD

- 6.2.5. SLIDING DOOR

- 6.2.6. SLIDING WINDOW

- 6.2.7. EMERGENCY ESCAPE HAMMER

- 6.2.8. COVER WITH LOCK

- 6.2.8.1. Opening and Closing Covers with Lock

- 6.2.9. ENGINE REAR COVER

- 6.2.10. COOLING COVER

- 6.2.11. MUD COVER

- 6.2.12. METHOD OF OPENING (TILTING) FLOOR

- 6.2.13. FUSE

- 6.2.14. BLOCK FUSE

- 6.2.15. OPERATION MANUAL STORAGE

- 6.2.16. TOOL BOX

- 6.2.17. GREASE GUN HOLDER

- 6.2.18. ASHTRAY

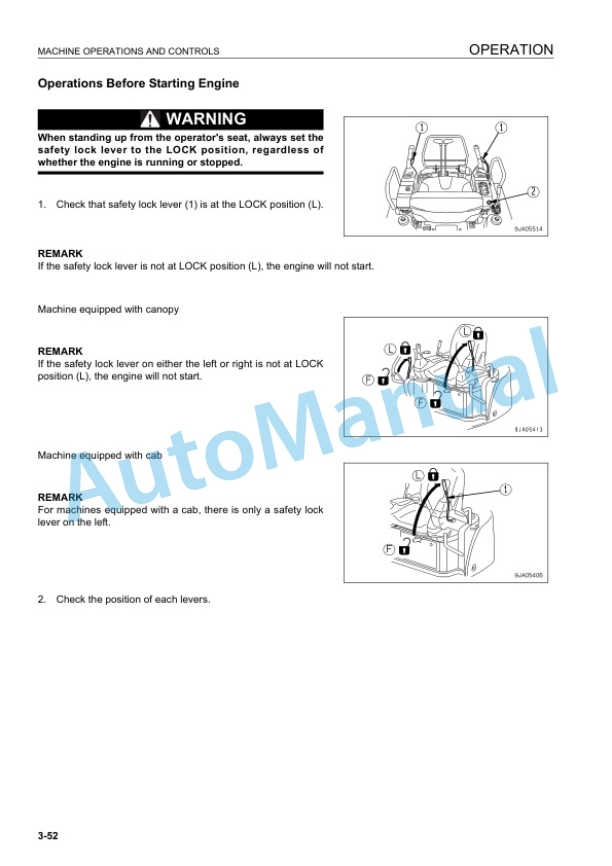

- 6.3. MACHINE OPERATIONS AND CONTROLS

- 6.3.1. BEFORE STARTING ENGINE

- 6.3.1.1. Walkaround Checks

- 6.3.1.2. Checks Before Starting

- 6.3.1.3. Adjustment

- 6.3.1.4. Seat Belt

- 6.3.1.5. Operations Before Starting Engine

- 6.3.2. STARTING ENGINE

- 6.3.2.1. Normal Starting

- 6.3.2.2. Starting Engine in Cold Weather

- 6.3.3. AFTER STARTING ENGINE

- 6.3.3.1. Breakingin the New Machine

- 6.3.3.2. Warmingup Operation

- 6.3.4. STOPPING THE ENGINE

- 6.3.5. MACHINE OPERATION

- 6.3.5.1. Preparations for Moving the Machine Off

- 6.3.5.2. Moving Machine Forward

- 6.3.5.3. Moving Machine Backward

- 6.3.5.4. Stopping Machine

- 6.3.6. STEERING THE MACHINE

- 6.3.6.1. Steering

- 6.3.7. SWINGING

- 6.3.8. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 6.3.9. PROHIBITED OPERATIONS

- 6.3.10. GENERAL OPERATION INFORMATION

- 6.3.11. TRAVELING ON SLOPES

- 6.3.12. ESCAPE FROM MUD

- 6.3.12.1. Stuck One Side of Track

- 6.3.12.2. Stuck Both Sides of Tracks

- 6.3.13. WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR

- 6.3.13.1. Backhoe work

- 6.3.13.2. Ditching work

- 6.3.13.3. Loading work

- 6.3.13.4. Smoothing work

- 6.3.13.5. Side ditching work

- 6.3.14. BUCKET REPLACEMENT

- 6.3.15. PARKING MACHINE

- 6.3.16. MACHINE INSPECTION AFTER DAILY WORK

- 6.3.16.1. Before stop engine

- 6.3.16.2. After stop engine

- 6.3.17. LOCKING

- 6.3.18. RUBBER SHOES AND ROAD LINERS

- 6.3.18.1. Rubber Shoes and Road Liners Information

- 6.3.18.2. Warranty for Rubber Shoes and Road Liners

- 6.3.18.3. Using Rubber Shoes and Road Liners

- 6.3.18.4. Long Life Operations

- 6.4. TRANSPORTATION

- 6.4.1. TRANSPORTATION PROCEDURE

- 6.4.2. LOADING AND UNLOADING WITH TRAILER

- 6.4.2.1. Loading

- 6.4.2.2. Securing Machine

- 6.4.2.3. Unloading

- 6.4.3. LIFTING MACHINE

- 6.5. COLD WEATHER OPERATION

- 6.5.1. COLD WEATHER OPERATION INFORMATION

- 6.5.1.1. Fuel and Lubricants

- 6.5.1.2. Cooling System Coolant

- 6.5.1.3. Battery

- 6.5.2. CAB HEATER IN COLD WEATHER

- 6.5.3. AFTER DAILY WORK COMPLETION

- 6.5.4. AFTER COLD WEATHER SEASON

- 6.6. LONG TERM STORAGE

- 6.6.1. BEFORE STORAGE

- 6.6.2. DURING STORAGE

- 6.6.3. AFTER STORAGE

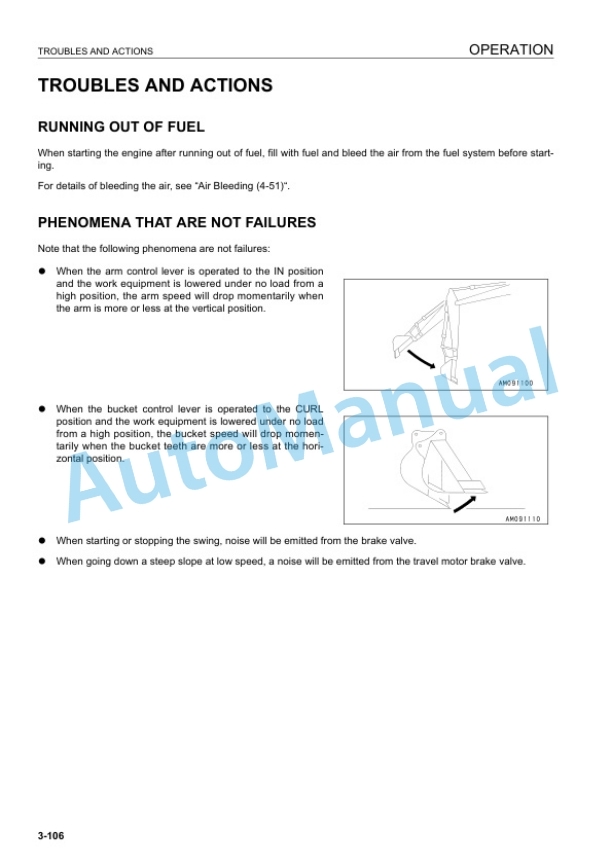

- 6.7. TROUBLES AND ACTIONS

- 6.7.1. RUNNING OUT OF FUEL

- 6.7.2. PHENOMENA THAT ARE NOT FAILURES

- 6.7.3. TOWING THE MACHINE

- 6.7.4. SEVERE JOB CONDITION

- 6.7.5. DISCHARGED BATTERY

- 6.7.5.1. Battery Removal and Installation

- 6.7.5.2. Battery Charges

- 6.7.5.3. Starting Engine with Booster Cables

- 6.7.6. OTHER TROUBLE

- 6.7.6.1. Electrical System

- 6.7.6.2. Chassis

- 6.7.6.3. Engine

- 7. MAINTENANCE

- 7.1. MAINTENANCE INFORMATION

- 7.2. LUBRICANTS, COOLANT AND FILTERS

- 7.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 7.2.1.2. Fuel

- 7.2.1.3. Cooling System Coolant

- 7.2.1.4. Grease

- 7.2.1.5. Carrying Out KOWA (Komatsu Oil Wear Analysis)

- 7.2.1.6. Oil and Fuel Storage

- 7.2.1.7. Filters

- 7.2.2. ELECTRIC SYSTEM MAINTENANCE

- 7.2.3. HANDLING HYDRAULIC SYSTEM

- 7.3. WEAR PARTS

- 7.3.1. WEAR PARTS LIST

- 7.4. LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS

- 7.5. TIGHTENING TORQUE SPECIFICATIONS

- 7.5.1. TIGHTENING TORQUE LIST

- 7.6. SAFETY CRITICAL PARTS

- 7.6.1. SAFETY CRITICAL PARTS LIST

- 7.7. MAINTENANCE SCHEDULE

- 7.7.1. MAINTENANCE SCHEDULE CHART

- 7.7.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 7.8. MAINTENANCE PROCEDURE

- 7.8.1. WHEN REQUIRED

- 7.8.1.1. CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT

- 7.8.1.2. CLEAN INSIDE OF COOLING SYSTEM

- 7.8.1.3. CHECK LEVEL OF BATTERY ELECTROLYTE

- 7.8.1.4. CLEAN WATER SEPARATOR ELEMENT

- 7.8.1.5. DRAIN WATER AND SEDIMENT FROM FUEL TANK

- 7.8.1.6. CHECK AND TIGHTEN TRACK SHOE BOLTS

- 7.8.1.7. CHECK AND ADJUST TRACK TENSION

- 7.8.1.8. CHECK, RUBBER SHOES OR ROAD LINERS

- 7.8.1.9. CHECK AND ADJUST RUBBER SHOE TENSION

- 7.8.1.10. REPLACE RUBBER SHOES

- 7.8.1.11. REPLACE ROAD LINERS

- 7.8.1.12. REPLACE BUCKET TEETH

- 7.8.1.13. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 7.8.1.14. CHECK, CLEAN AND LUBRICATE CAB SLIDE DOOR RAIL AND ROLLER

- 7.8.1.15. LUBRICATING

- 7.8.1.16. BLEEDING AIR FROM HYDRAULIC SYSTEM

- 7.8.2. CHECK BEFORE STARTING

- 7.8.3. EVERY 500 HOURS MAINTENANCE

- 7.8.3.1. LUBRICATING

- 7.8.3.2. CHANGE OIL IN ENGINE OIL PAN, REPLACE ENGINE OIL FILTER CARTRIDGE

- 7.8.3.3. REPLACE FUEL FILTER CARTRIDGE

- 7.8.3.4. CHECK OIL LEVEL IN FINAL DRIVE CASE, ADD OIL

- 7.8.3.5. CLEAN AND INSPECT RADIATOR FINS AND OIL COOLER FINS

- 7.8.3.6. CHECK AND ADJUST COOLING FAN BELT TENSION

- 7.8.4. EVERY 1000 HOURS MAINTENANCE

- 7.8.4.1. REPLACE HYDRAULIC OIL FILTER ELEMENT

- 7.8.4.2. CHANGE OIL IN FINAL DRIVE CASE

- 7.8.4.3. CHECK ENGINE VALVE CLEARANCE, ADJUST

- 7.8.5. EVERY 2000 HOURS MAINTENANCE

- 7.8.5.1. CHANGE OIL IN HYDRAULIC TANK, CLEAN STRAINER

- 7.8.5.2. CHECK ALTERNATOR, STARTING MOTOR

- 8. SPECIFICATIONS

- 8.1. SPECIFICATIONS

- 9. ATTACHMENTS AND OPTIONS

- 9.1. ATTACHMENTS AND OPTIONS GENERAL INFORAMTION

- 9.1.1. SAFETY FIRST

- 9.1.2. ATTACHMENT INSTALLATION

- 9.2. BUCKET WITH HOOK

- 9.2.1. PROHIBITED OPERATIONS

- 9.3. AIR CONDITIONER

- 9.3.1. CONTROL PANEL AND COMPONENTS

- 9.3.2. AIR CONDITIONER CONTROLS

- 9.3.3. AIR CONDITIONER MAINTENANCE

- 9.3.3.1. When Required

- 9.3.3.2. Every 250 Hours Maintenance

- 9.3.3.3. Every 500 Hours Maintenance

- 9.4. RADIO

- 9.4.1. CONTROL PANEL

- 9.4.2. CONTROLS OF RADIO

- 9.4.2.1. Listening to radio

- 9.4.2.2. Automatic Tuning

- 9.4.2.3. Manual Tuning

- 9.4.2.4. Preset Station Buttons

- 9.4.2.5. Using auto memory

- 9.4.2.6. Time Adjustment

- 9.4.2.7. Automatic selection of reception for monaural/stereo

- 9.4.2.8. Antenna

- 9.4.3. CARE FOR RADIO

- 9.5. WINDSHIELD WASHER

- 9.5.1. WINDSHIELD WASHER OPERATION

- 9.5.2. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 9.6. MACHINE READY FOR ATTACHMENT

- 9.6.1. LOCATIONS

- 9.6.2. HYDRAULIC CIRCUIT

- 9.6.2.1. Hydraulic Circuit Connection

- 9.6.3. ATTACHMENT OPERATIONS

- 9.6.3.1. When Using Breaker

- 9.6.3.2. When Using General Attachment Such as Crusher

- 9.6.4. LONG TERM STORAGE

- 9.6.5. SPECIFICATIONS

- 9.7. CHANGING MACHINE CONTROL PATTERN (IF PATTERN CHANGE VALVE EQUIPPED)

- 9.7.1. CONTROL PATTERN CHANGE PROCEDURE

- 9.7.2. MACHINE CONTROL PATTERNS

- 9.8. ATTACHMENT GUIDE

- 9.8.1. ATTACHMENT COMBINATIONS

- 9.9. RECOMMENDED ATTACHMENT OPERATIONS

- 9.9.1. HYDRAULIC BREAKER

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45