Komatsu PC1250-8, PC1250LC-8, PC1250SP-8 Hydraulic Excavator Field Assembly Instruction GEN00055-08

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: GEN00055-08

- Format: PDF

- Size: 12.1MB

- Number of Pages: 205

-

Model List:

- PC1250-8 Hydraulic Excavator

- PC1250LC-8 Hydraulic Excavator

- PC1250SP-8 Hydraulic Excavator

- 1. COVER

- 2. FOREWARD

- 3. CONTENTS

- 4. SPECIFICATIONS

- 5. PRECAUTIONS FOR FIELD ASSEMBLY

- 6. ASSEMBLING PROCEDURES, APPLICABLE EQUIPMENT AND SCHEDULE

- 7. KIT LAYOUT DIAGRAM

- 8. TRANSPORTATION

- 9. LIST OF TOOLS FOR FIELD ASSEMBLING

- 10. TIGHTENING TORQUE

- 11. COATING MATERIALS

- 12. LIST OF PARTS SENT INDIVIDUALLY

- 13. ASSEMBLY OF CHASSIS

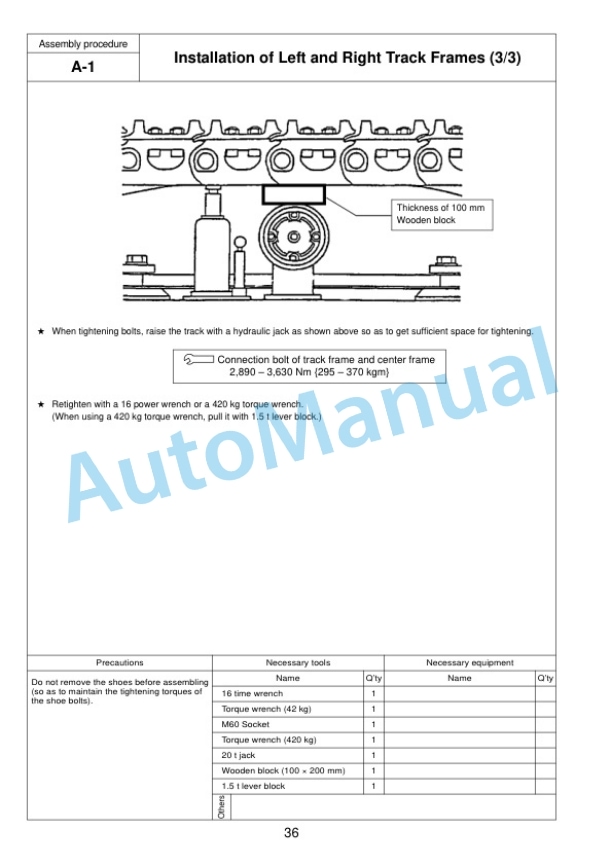

- 13.1. A 1. Installation of Left and Right Track Frames

- 13.2. A 2. Installation of Travel Piping

- 13.3. A 3. Installation of Travel Piping Covers

- 13.4. A 4. Installation of Steps

- 13.5. A 5. Filling Swing Circle with Grease

- 13.6. A 6. Assembly of Upper Structure and Undercarriage

- 13.7. A 7. Installation of Right Side Steps

- 13.8. A 8. Installation of Handrails

- 13.9. A 9. Installation of Swivel Travel Piping

- 13.10. A10. Sticking Sheet to Counterweight (EU specification)

- 13.11. A11. Installation of Cover board (To the Counterweight)

- 13.12. A12. Installation of Counterweight

- 13.13. A13. Installation of Left Side Steps (Including handrails)

- 13.14. A14. Installation of Radiator Cover (Standard specification)

- 13.15. A14. Installation of Radiator Cover (EU specification)

- 13.16. A15. Installation of Muffler Tail Pipe

- 13.17. A16. Changing of Mounting Position of Step Light

- 13.18. A17. Installation of Handrail to the Cab

- 13.19. A18. Installation of Left Rearview Mirror

- 13.20. A19. Installation of Right Rearview Mirrors

- 13.21. A20. Installation of Rearview Mirror (On the Counterweight) (EU specification)

- 13.22. A21. Preparation for Bleeding Air from Travel Motor

- 13.23. A22. Procedure for Bleeding Air From Hydraulic Circuit

- 13.24. A23. Permanent Tightening of Swing Circle Mounting Bolts

- 13.25. A24. Testing Track Shoe Tension

- 13.26. A25. Check Fuel, Coolant and Oil Levels

- 13.27. A26. Parts to be Touched up after Field Assembly

- 14. ASSEMBLING OF WORK EQUIPMENT OF BACKHOE

- 14.1. B 1. Installation of Arm Cylinder

- 14.2. B 2. Installation of Arm Cylinder Hoses

- 14.3. B 3. Installation of Boom Cylinder Foot

- 14.4. B 4. Installation of Boom Cylinder Hoses

- 14.5. B 5. Installation of Boom Foot Dust Seal

- 14.6. B 6. Installation of Boom Assembly

- 14.7. B 7. Installation of Boom Cylinder

- 14.8. B 8. Installation of Boom Hoses (Between machine and boom)

- 14.9. B 9. Installation of Arm Assembly

- 14.10. B10. Installation of Bucket Cylinder Hoses between Boom and Bucket Cylinder

- 14.11. B11. Installation of Bucket Assembly

- 14.12. B12. Clearance Standard for Installation of Work Equipment

- 14.13. B13. Installation of Work Equipment Grease Piping

- 14.14. B14. Procedure for Bleeding Air From Travel Motor

- 14.15. B15. Bleeding Air from Swing Motor

- 14.16. B16. Bleeding Air from Cylinder

- 14.17. B17. Installation of Work Equipment Wiring

- 14.18. B18. Greasing after Assembling Work Equipment

- 15. PROCEDURE FOR INSPECTION AND MAINTENANCE AFTER COMPLETION OF ASSEMBLY

- 15.1. M 1. Replacement of Return Filter (Standard Filter to Flushing Filter)

- 15.2. M 2. Relieving Remaining Pressure from Hydraulic Circuit

- 15.3. M 3. Installation of Flushing Tubes

- 15.4. M 4. Flushing of Hydraulic Circuit

- 15.5. M 5. Replacement of Pilot Filter (Flushing filter to Standard filter)

- 16. PROCEDURE FOR ASSEMBLING WORK EQUIPMENT OF LOADING SHOVEL

- 16.1. Transportation posture (only work equipment)

- 16.2. List of parts sent individually

- 16.3. Procedure for assembling work equipment of loading shovel

- 16.3.1. C 1. Installation of Arm Cylinder Bottoms

- 16.3.2. C 2. Connection of Boom and Arm

- 16.3.3. C 3. Pulling out Boom Foot Pin and Boom Cylinder Foot Pin

- 16.3.4. C 4. Installation of Boom and Arm Assembly

- 16.3.5. C 5. Replacement of Return Filter (Standard Element to Flushing Element)

- 16.3.6. C 6. Releasing Residual Pressure in Hydraulic Circuit

- 16.3.7. C 7. Installation of Boom Hoses (Between Chassis and Boom)

- 16.3.8. C 8. Installation of Flushing Tube for Boom Cylinder Hoses

- 16.3.9. C 9. Installation of Flushing Tube for Arm Cylinder Hoses

- 16.3.10. C10. Installation of Flushing Tube for Bucket Cylinder Hoses

- 16.3.11. C11. Installation of Hoses Between Boom and Arm (Bottom Dump)

- 16.3.12. C12. Installation of Flushing Tube for Bottom Dump Cylinder Hoses

- 16.3.13. C13. Installation of Hydraulic Circuit

- 16.3.14. C14. Replacement of Pilot Filter (Flushing Element to Standard Element)

- 16.3.15. C15. Installation of Boom Cylinder Bottoms

- 16.3.16. C16. Installation of Boom Cylinder Hoses

- 16.3.17. C17. Installation of Boom Cylinder Head Pin

- 16.3.18. C18. Installation of Arm Cylinder Hoses

- 16.3.19. C19. Installation of Bucket Cylinder

- 16.3.20. C20. Installation of Bucket Cylinder Hos

- 16.3.21. C21. Installation of Bucket Assembly

- 16.3.22. C22. Installation of Bottom Dump Cylinder Hoses

- 16.3.23. C23. Maintenance Standard

- 16.3.24. C24. Installation of Working Lamp

- 16.3.25. C25. Installation of Work Equipment Greasing Piping

- 16.3.26. C26. Bleeding Air from Work Equipment Circuit

- 16.3.27. C27. Checking Oil Level in Hydraulic Tank and Adding Oil

- 16.3.28. C28. Greasing After Assembling Work Equipment

- 16.4. Inspection of each part after assembly of loader

- 17. Field Assembly Inspection Report (Backhoe)

- 18. Field Assembly Inspection Report (Loading shovel)

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300