Komatsu PC1250-8, PC1250LC-8, PC1250SP-8 Hydraulic Excavator Operation and Maintenance Manual EENAM03011

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: EENAM03011

- Format: PDF

- Size: 10.4MB

- Number of Pages: 422

-

Model List:

- PC1250-8 Hydraulic Excavator

- PC1250LC-8 Hydraulic Excavator

- PC1250SP-8 Hydraulic Excavator

- 1. FOREWORD

- 1.1. BEFORE READING THIS MANUAL

- 1.2. SAFETY INFORMATION

- 1.2.1. Noise emission levels

- 1.2.2. Vibration levels

- 1.3. INTRODUCTION

- 1.3.1. USE OF MACHINE

- 1.3.2. DIRECTIONS OF MACHINE

- 1.3.3. VISIBILITY FROM OPERATORS SEAT

- 1.4. PRODUCT INFORMATION

- 1.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 1.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 1.4.3. SERVICE METER LOCATION

- 1.4.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 1.4.5. MACHINE SERIAL NUMBER PLATE (according directive 2006/42/EC)

- 1.4.6. Declaration according Directive 2006/42/EC Annex I point 1.7.4.2 (c)

- 1.4.7. ATTACHMENTS AND OPTIONS

- 1.4.8. LOCATION OF SAFETY LABELS

- 1.4.9. SAFETY LABELS

- 1.5. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 1.5.1. PRECAUTIONS BEFORE STARTING OPERATION

- 1.5.2. PREPARATIONS FOR SAFE OPERATION

- 1.5.3. FIRE PREVENTION

- 1.5.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 1.5.5. DO NOT GET CAUGHT IN WORK EQUIPMENT

- 1.5.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 1.5.7. PROTECTION AGAINST FALLING, FLYING, INTRUDING OBJECTS

- 1.5.8. UNAUTHORIZED MODIFICATION

- 1.5.9. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 1.5.10. PRECAUTIONS RELATED TO CAB GLASS

- 1.5.11. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 1.6. PRECAUTIONS FOR OPERATION

- 1.6.1. PRECAUTIONS FOR JOBSITE

- 1.6.2. STARTING ENGINE

- 1.6.3. OPERATION

- 1.6.4. TRANSPORTATION

- 1.6.5. TOWING

- 1.6.6. LIFTING OBJECTS WITH BUCKET

- 1.7. PRECAUTIONS FOR MAINTENANCE

- 1.7.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 1.7.2. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 2. OPERATION

- 2.1. MACHINE VIEW ILLUSTRATIONS

- 2.1.1. OVERALL MACHINE VIEW

- 2.1.2. CONTROLS AND GAUGES

- 2.1.3. Machine monitor

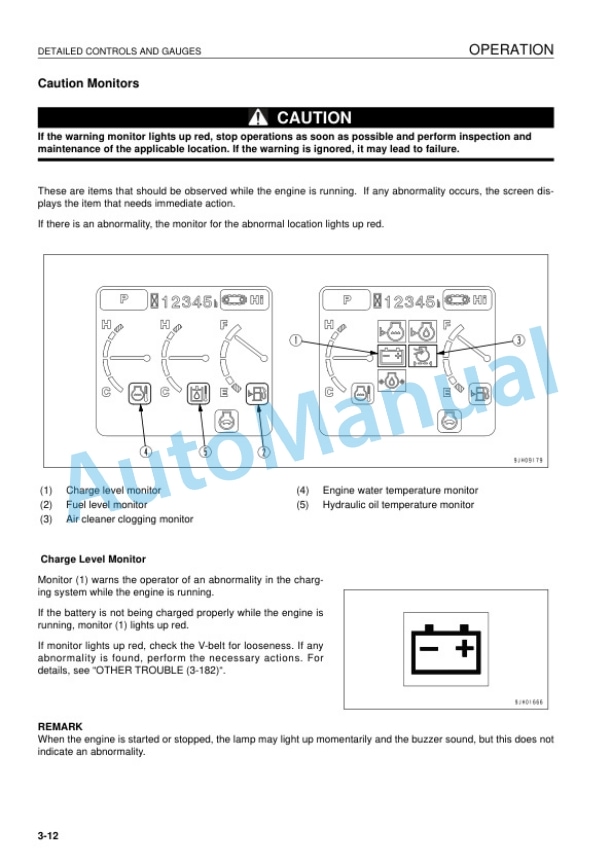

- 2.2. DETAILED CONTROLS AND GAUGES

- 2.2.1. MONITORING SYSTEM

- 2.2.2. SWITCHES

- 2.2.3. CONTROL LEVERS AND PEDALS

- 2.2.4. EMERGENCY EXIT FROM OPERATORS CAB

- 2.2.5. DOOR LOCK

- 2.2.6. CAP WITH LOCK

- 2.2.7. HOT AND COOL BOX

- 2.2.8. MAGAZINE BOX

- 2.2.9. ASHTRAY

- 2.2.10. FIRE EXTINGUISHER

- 2.2.11. AIR CONDITIONER CONTROLS

- 2.2.12. RADIO

- 2.2.13. AUXILIARY ELECTRIC POWER

- 2.2.14. BATTERY DISCONNECT SWITCH

- 2.2.15. FUSE

- 2.2.16. CIRCUIT BREAKER

- 2.2.17. CONTROLLER

- 2.2.18. TOOL BOX

- 2.2.19. GREASE PUMP

- 2.2.20. EXTERNAL POWER SOURCE TYPE ENGINE PREHEATING HEATER

- 2.2.21. HANDLING PORTABLE COMBUSTION TYPE PREHEATING HEATER

- 2.3. MACHINE OPERATIONS AND CONTROLS

- 2.3.1. BEFORE STARTING ENGINE

- 2.3.2. STARTING ENGINE

- 2.3.3. AFTER STARTING ENGINE

- 2.3.4. STOPPING THE ENGINE

- 2.3.5. MACHINE OPERATION

- 2.3.6. STEERING THE MACHINE

- 2.3.7. SWINGING

- 2.3.8. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 2.3.9. WORKING MODE

- 2.3.10. PROHIBITED OPERATIONS

- 2.3.11. GENERAL OPERATION INFORMATION

- 2.3.12. TRAVELLING ON SLOPES

- 2.3.13. ESCAPE FROM MUD

- 2.3.14. RECOMMENDED APPLICATIONS

- 2.3.15. BUCKET REPLACEMENT

- 2.3.16. PARKING MACHINE

- 2.3.17. MACHINE INSPECTION AFTER DAILY WORK

- 2.3.18. LOCKING

- 2.4. TRANSPORTATION

- 2.4.1. TRANSPORTATION PROCEDURE

- 2.4.2. PRECAUTIONS FOR TRANSPORTATION

- 2.4.3. LIFTING MACHINE

- 2.4.4. SHIPPING MACHINE INFORMATION

- 2.4.5. TRANSPORTATION POSTURE

- 2.5. COLD WEATHER OPERATION

- 2.5.1. COLD WEATHER OPERATION INFORMATION

- 2.5.2. AFTER DAILY WORK COMPLETION

- 2.5.3. AFTER COLD WEATHER SEASON

- 2.6. LONG TERM STORAGE

- 2.6.1. BEFORE STORAGE

- 2.6.2. DURING STORAGE

- 2.6.3. AFTER STORAGE

- 2.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

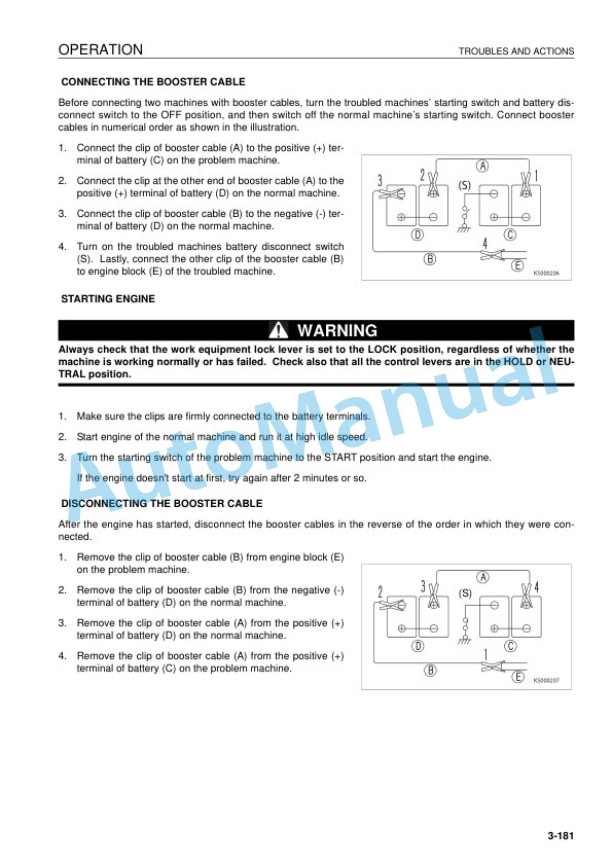

- 2.7. TROUBLES AND ACTIONS

- 2.7.1. RUNNING OUT OF FUEL

- 2.7.2. PHENOMENA THAT ARE NOT FAILURES

- 2.7.3. TOWING THE MACHINE

- 2.7.4. SEVERE JOB CONDITION

- 2.7.5. DISCHARGED BATTERY

- 2.7.6. OTHER TROUBLE

- 3. MAINTENANCE

- 3.1. MAINTENANCE INFORMATION

- 3.2. OUTLINE OF SERVICE

- 3.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 3.2.2. ELECTRIC SYSTEM MAINTENANCE

- 3.3. WEAR PARTS

- 3.3.1. WEAR PARTS LIST

- 3.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 3.4.1. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 3.5. TIGHTENING TORQUE SPECIFICATIONS

- 3.5.1. TIGHTENING TORQUE LIST

- 3.6. SAFETY CRITICAL PARTS

- 3.6.1. SAFETY CRITICAL PARTS LIST

- 3.7. MAINTENANCE SCHEDULE

- 3.7.1. MAINTENANCE SCHEDULE CHART

- 3.7.2. EXPANATION OF LUBRICATION CHART DECAL

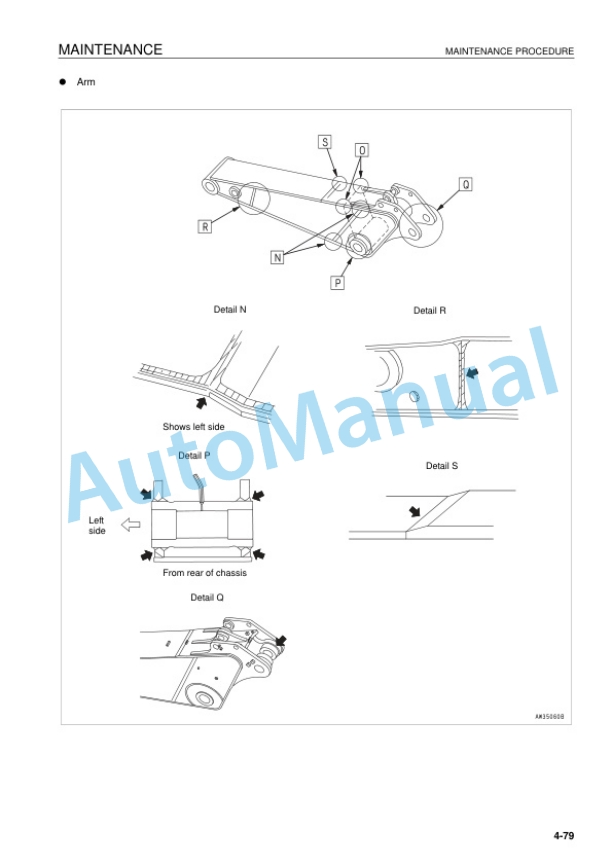

- 3.8. MAINTENANCE PROCEDURE

- 3.8.1. INITIAL 100 HOURS MAINTENANCE (ONLY AFTER THE FIRST 100 HOURS)

- 3.8.2. INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)

- 3.8.3. WHEN REQUIRED

- 3.8.4. CHECK BEFORE STARTING

- 3.8.5. EVERY 10 HOURS MAINTENANCE

- 3.8.6. EVERY 100 HOURS MAINTENANCE

- 3.8.7. EVERY 250 HOURS MAINTENANCE

- 3.8.8. EVERY 500 HOURS MAINTENANCE

- 3.8.9. EVERY 1000 HOURS MAINTENANCE

- 3.8.10. EVERY 2000 HOURS MAINTENANCE

- 3.8.11. EVERY 4000 HOURS MAINTENANCE

- 3.8.12. EVERY 5000 HOURS MAINTENANCE

- 3.8.13. EVERY 8000 HOURS MAINTENANCE

- 4. SPECIFICATIONS

- 4.1. SPECIFICATIONS

- 5. ATTACHMENTS AND OPTIONS

- 5.1. GENERAL PRECAUTIONS FOR SAFETY

- 5.1.1. PRECAUTIONS WHEN SELECTING

- 5.1.2. READ THE INSTRUCTION MANUAL THOROUGHLY

- 5.1.3. PRECAUTIONS WHEN REMOVING OR INSTALLING

- 5.1.4. PRECAUTIONS WHEN USING

- 5.2. ATTACHMENT GUIDE

- 5.2.1. COMBINATIONS OF WORK EQUIPMENT

- 5.3. SELECTION OF TRACK SHOES

- 5.4. AUTOGREASING SYSTEM

- 5.4.1. EXPLANATION OF COMPONENTS

- 5.4.2. OPERATION

- 5.4.3. TROUBLESHOOTING

- 5.4.4. MAINTENANCE

- 5.5. HANDLING MACHINES EQUIPPED WITH KOMTRAX Plus

- 5.5.1. KOMTRAX Plus INSTALLED, COMMUNICATIONS TERMINAL NOT INSTALLED

- 5.5.2. KOMTRAX Plus AND COMMUNICATIONS TERMINAL INSTALLED

- 6. LOADING SHOVEL

- 6.1. EXPLANATION OF COMPONENTS

- 6.1.1. SWITCHES

- 6.1.2. FUSE

- 6.2. OPERATIONS

- 6.2.1. OPERATION OF WORK EQUIPMENT

- 6.2.2. PRECAUTIONS DURING OPERATION

- 6.2.3. LOADING SHOVEL WORK

- 6.3. PRECAUTIONS WHEN DISASSEMBLING MACHINE

- 6.3.1. RELEASING PRESSURE

- 6.4. TRANSPORTATION

- 6.4.1. MACHINE CONFIGURATION FOR TRANSPORT

- 6.5. WEAR PARTS

- 6.5.1. WEAR PARTS LIST

- 6.6. MAINTENANCE

- 6.6.1. CHECK BEFORE STARTING

- 6.6.2. EVERY 10 HOURS MAINTENANCE

- 6.6.3. EVERY 5000 HOURS MAINTENANCE

- 6.7. SPECIFICATION

- 6.8. COMBINATION OF WORK EQUIPMENT

- 6.8.1. COMBINATION OF WORK EQUIPMENT

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF