Komatsu PC160LC-7E0, PC180LC-7E0, PC180NLC-7E0 Hydraulic Excavator Operation and Maintenance Manual UEAM006705

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: UEAM006705

- Format: PDF

- Size: 9.7MB

- Number of Pages: 372

-

Model List:

- PC160LC-7E0 Hydraulic Excavator

- PC180LC-7E0 Hydraulic Excavator

- PC180NLC-7E0 Hydraulic Excavator

- 1. FOREWORD

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.2.1. Noise emission levels

- 1.2.2. Vibration levels

- 1.3. INTRODUCTION

- 1.3.1. DIRECTIONS OF MACHINE

- 1.3.2. BREAKINGIN THE NEW MACHINE

- 1.4. PRODUCT INFORMATION

- 1.4.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NO. PLATE

- 1.4.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 1.4.3. SERVICE METER LOCATION

- 1.4.4. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.4.5. MACHINE SERIAL PLATE

- 1.4.6. DECLARATION OF CONFORMITY

- 1.4.7. ATTACHMENTS AND OPTIONS

- 1.4.8. INDEX

- 1.4.9. COLOPHON

- 2. SAFETY

- 2.1. SAFETY INFORMATION

- 2.2. SAFETY LABELS

- 2.2.1. LOCATION OF SAFETY LABELS

- 2.2.2. SAFETY LABELS

- 2.3. SAFETY INFORMATION

- 2.4. SAFETY MACHINE OPERATION

- 2.4.1. STARTING ENGINE

- 2.4.2. OPERATION

- 2.4.3. TRANSPORTATION

- 2.4.4. Turn off the battery disconnect switch to the OFF position

- 2.4.5. BATTERY

- 2.4.6. TOWING

- 2.4.7. LIFTING OBJECTS WITH BUCKET

- 2.5. SAFETY MAINTENANCE INFORMATION

- 2.5.1. REMOVING BATTERY CABLES (for machines not fitted with battery disconnect switch only)

- 3. OPERATION

- 3.1. MACHINE VIEW ILLUSTRATIONS

- 3.1.1. OVERALL MACHINE VIEW

- 3.1.2. CONTROLS AND GAUGES

- 3.2. DETAILED CONTROLS AND GAUGES

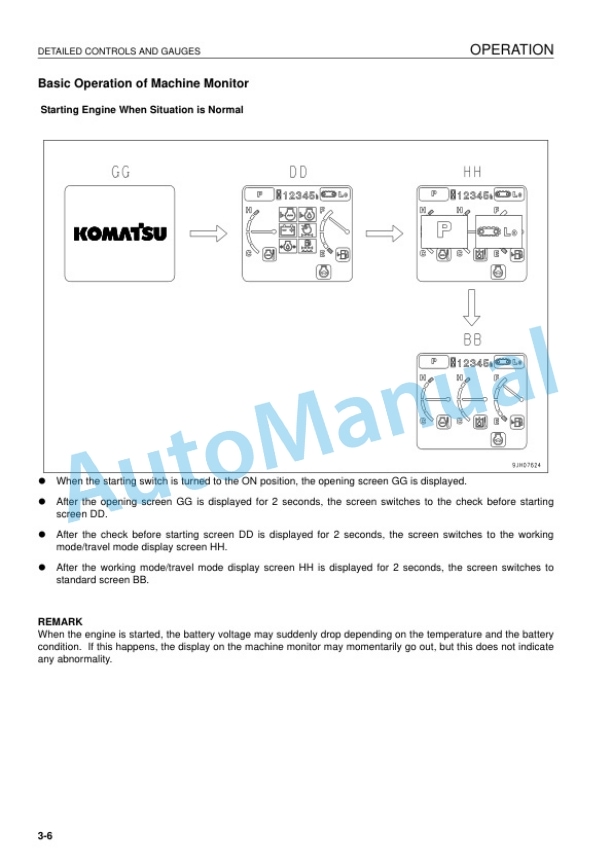

- 3.2.1. MONITORING SYSTEM

- 3.2.2. SWITCHES

- 3.2.3. CONTROL LEVERS AND PEDALS

- 3.2.4. SUN ROOF

- 3.2.5. WINDSHIELD

- 3.2.6. EMERGENCY EXIT FROM OPERATORS CAB

- 3.2.7. AIR CONDITIONER CONTROLS

- 3.2.8. AUXILIARY ELECTRIC POWER

- 3.2.9. FUSE

- 3.2.10. FUSIBLE LINK

- 3.2.11. CONTROLLER

- 3.2.12. TOOL BOX

- 3.2.13. GREASE GUN HOLDER

- 3.2.14. REFUELLING PUMP

- 3.3. MACHINE OPERATIONS AND CONTROLS

- 3.3.1. BEFORE STARTING ENGINE

- 3.3.2. STARTING ENGINE

- 3.3.3. AMBIENT TEMPERATURE RANGE FOR OPERATION AND STORAGE

- 3.3.4. AFTER STARTING ENGINE

- 3.3.5. STOPPING THE ENGINE

- 3.3.6. MACHINE OPERATION

- 3.3.7. STEERING THE MACHINE

- 3.3.8. SWINGING

- 3.3.9. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 3.3.10. WORKING MODE

- 3.3.11. PROHIBITED OPERATIONS

- 3.3.12. GENERAL OPERATION INFORMATION

- 3.3.13. TRAVELLING ON SLOPES

- 3.3.14. ESCAPE FROM MUD

- 3.3.15. RECOMMENDED APPLICATIONS

- 3.3.16. BUCKET REPLACEMENT AND INVERSION

- 3.3.17. PARKING MACHINE

- 3.3.18. MACHINE INSPECTION AFTER DAILY WORK

- 3.3.19. LOCKING

- 3.4. TRANSPORTATION

- 3.4.1. TRANSPORTATION PROCEDURE

- 3.4.2. LOADING AND UNLOADING WITH TRAILER

- 3.4.3. LIFTING MACHINE

- 3.5. COLD WEATHER OPERATION

- 3.5.1. COLD WEATHER OPERATION INFORMATION

- 3.5.2. AFTER DAILY WORK COMPLETION

- 3.5.3. AFTER COLD WEATHER SEASON

- 3.6. LONG TERM STORAGE

- 3.6.1. BEFORE STORAGE

- 3.6.2. DURING STORAGE

- 3.6.3. AFTER STORAGE

- 3.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 3.7. TROUBLES AND ACTIONS

- 3.7.1. RUNNING OUT OF FUEL

- 3.7.2. PHENOMENA THAT ARE NOT FAILURES

- 3.7.3. TOWING THE MACHINE

- 3.7.4. LIGHTWEIGHT TOWING HOLE

- 3.7.5. SEVERE JOB CONDITION

- 3.7.6. DISCHARGED BATTERY

- 3.7.7. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. MAINTENANCE INFORMATION

- 4.2. OUTLINE OF SERVICE

- 4.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 4.2.2. ELECTRIC SYSTEM MAINTENANCE

- 4.2.3. EXPLANATION OF LUBRICATION CHART DECAL

- 4.3. WEAR PARTS

- 4.3.1. WEAR PARTS LIST

- 4.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 4.4.1. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 4.5. TIGHTENING TORQUE SPECIFICATIONS

- 4.5.1. TIGHTENING TORQUE LIST

- 4.6. SAFETY CRITICAL PARTS

- 4.6.1. SAFETY CRITICAL PARTS LIST

- 4.7. MAINTENANCE SCHEDULE

- 4.7.1. MAINTENANCE SCHEDULE CHART

- 4.7.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

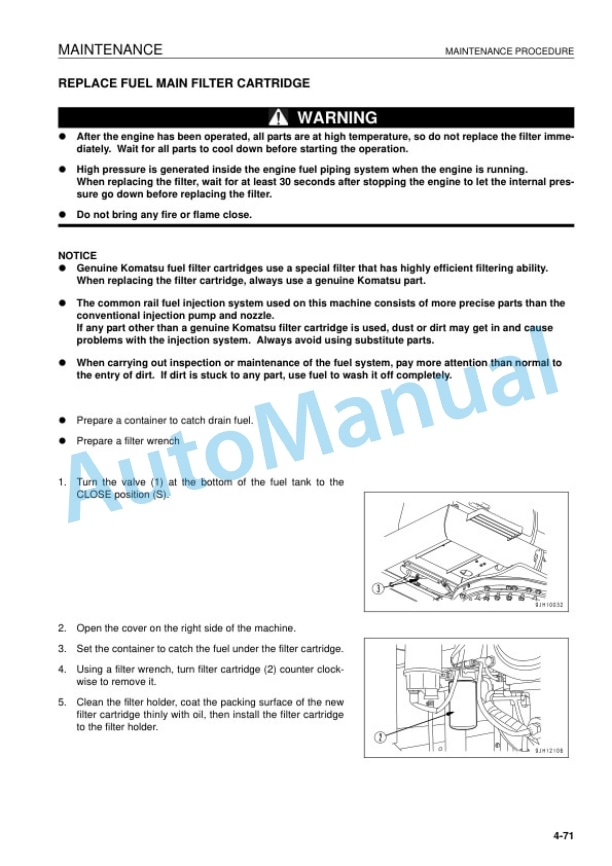

- 4.8. MAINTENANCE PROCEDURE

- 4.8.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 4.8.2. INITIAL 500 HOURS MAINTENANCE (ONLY AFTER THE FIRST 500 HOURS)

- 4.8.3. WHEN REQUIRED

- 4.8.4. CHECK BEFORE STARTING

- 4.8.5. EVERY 100 HOURS MAINTENANCE

- 4.8.6. EVERY 250 HOURS MAINTENANCE

- 4.8.7. EVERY 500 HOURS MAINTENANCE

- 4.8.8. EVERY 1000 HOURS MAINTENANCE

- 4.8.9. EVERY 2000 HOURS MAINTENANCE

- 4.8.10. EVERY 4000 HOURS MAINTENANCE

- 4.8.11. EVERY 5000 HOURS MAINTENANCE

- 4.8.12. EVERY 8000 HOURS MAINTENANCE

- 4.9. END OF SERVICE LIFE

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 5.1.1. PC160LC7E0, PC180LC7E0,PC180NLC7E0

- 5.1.2. WORKING RANGE 1PC BOOM

- 5.1.3. WORKING RANGE 2PC BOOM

- 5.2. EXPLANATION OF LIFTING CAPACITY CHART

- 5.2.1. MONOBOOM (PC160LC 7E0, PC180LC7E0, PC180NLC7E0)

- 5.3. EXPLANATION OF LIFTING CAPACITY CHART

- 5.3.1. PIECE BOOM (PC160LC 7E0, PC180lc7E0, PC180NLC7E0)

- 5.4. SPECIFICATIONS

- 5.4.1. PC160LGP7E0

- 6. ATTACHMENTS AND OPTIONS

- 6.1. ATTACHMENTS AND OPTIONS GENERAL INFORMATION

- 6.1.1. SAFETY FIRST

- 6.2. SPECIFICATIONS

- 6.2.1. Hydraulic specifications

- 6.2.2. ARM/PIN INFORMATION PC160/1807E0

- 6.2.3. ATTACHMENT INSTALLATION

- 6.3. BUCKET WITH HOOK

- 6.3.1. HOOK CONDITION

- 6.3.2. PROHIBITED OPERATIONS

- 6.4. MACHINES READY FOR ATTACHMENTS

- 6.4.1. EXPLANATION OF COMPONENTS

- 6.4.2. HYDRAULIC CIRCUIT

- 6.4.3. ATTACHMENT REMOVAL AND INSTALLATION

- 6.4.4. ATTACHMENT OPERATIONS

- 6.4.5. LONG TERM STORAGE

- 6.5. ATTACHMENT GUIDE

- 6.5.1. OTHER ATTACHMENTS

- 6.5.2. ATTACHMENT COMBINATIONS

- 6.5.3. BUCKET TEETH SELECTION

- 6.6. RECOMMENDED ATTACHMENT OPERATIONS

- 6.6.1. HYDRAULIC BREAKER

- 6.7. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 6.7.1. BASIC PRECAUTIONS

- 6.8. HYDRAULIC QUICK COUPLER PIPING

- 6.8.1. LOCATIONS

- 6.8.2. OPERATION

- 6.9. PC160LC7E0 PC180LC7E0 PC180NLC7E0 2PC BOOM

- 6.9.1. FEATURES OF 2PIECE BOOM ARM

- 6.9.2. OPERATION

- 6.9.3. TRANSPORTATION

- 6.9.4. LUBRICATING

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E