Komatsu PC170LC-10 Hydraulic Excavator Operation and Maintenance Manual WENAM00020

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: WENAM00020

- Format: PDF

- Size: 34.8MB

- Number of Pages: 448

-

Model List:

- PC170LC-10 Hydraulic Excavator

- 1. FOREWORD

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.2.1. NOISE

- 1.2.2. VIBRATION LEVELS

- 1.2.3. GUIDE TO REDUCE VIBRATION LEVELS ON MACHINE

- 1.3. INTRODUCTION

- 1.3.1. USE OF MACHINE

- 1.3.2. DEMOLITION WORK

- 1.3.3. DIRECTIONS OF MACHINE

- 1.3.4. OPERATOR PROTECTIVE STRUCTURE

- 1.3.5. VISIBILITY FOR OPERATOR

- 1.4. BREAKING IN THE NEW MACHINE

- 1.5. PRODUCT INFORMATION

- 1.5.1. PRODUCT IDENTIFICATION NUMBER (PIN)/MACHINE SERIAL NUMBER PLATE

- 1.5.2. EPA REGULATIONS, ENGINE NUMBER PLATE

- 1.5.3. SERVICE METER LOCATION

- 1.5.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 1.5.5. SERIAL PLATE

- 1.5.6. DECLARATION OF CONFORMITY

- 1.6. CONTENTS

- 2. SAFETY

- 2.1. SAFETY

- 2.2. SAFETY LABELS

- 2.2.1. LOCATION OF SAFETY LABELS

- 2.2.2. SAFETY LABELS

- 2.3. GENERAL PRECAUTIONS COMMON TO OPERATION AND MAINTENANCE

- 2.3.1. PRECAUTIONS BEFORE STARTING OPERATION

- 2.3.2. PREPARATIONS FOR SAFE OPERATION

- 2.3.3. FIRE PREVENTION

- 2.3.4. PRECAUTIONS WHEN GETTING ON OR OFF MACHINE

- 2.3.5. DO NOT GET CAUGHT IN WORK EQUIPMENT

- 2.3.6. PRECAUTIONS RELATED TO PROTECTIVE STRUCTURES

- 2.3.7. PROTECTION AGAINST FALLING, FLYING, OR INTRUDING OBJECTS

- 2.3.8. UNAUTHORIZED MODIFICATION

- 2.3.9. PRECAUTIONS RELATED TO ATTACHMENTS AND OPTIONS

- 2.3.10. PRECAUTIONS RELATED TO CAB GLASS

- 2.3.11. PRECAUTIONS WHEN RUNNING ENGINE INSIDE BUILDING

- 2.4. PRECAUTIONS FOR OPERATION

- 2.4.1. PRECAUTIONS FOR JOBSITE

- 2.4.2. STARTING ENGINE

- 2.4.3. OPERATION

- 2.4.4. TRANSPORTATION

- 2.4.5. TOWING

- 2.4.6. LIFTING OBJECTS WITH BUCKET LINK LIFTING DEVICE (OPTIONAL EQUIPMENT)

- 2.4.7. SAFETY RULES FOR LIFTING OBJECTS

- 2.4.8. LIFTING OBJECTS WITH BUCKETS

- 2.5. PRECAUTIONS FOR MAINTENANCE

- 2.5.1. PRECAUTIONS BEFORE STARTING INSPECTION AND MAINTENANCE

- 2.5.2. PRECAUTIONS FOR INSPECTION AND MAINTENANCE

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. GENERAL VIEW OF MACHINE

- 3.1.2. GENERAL VIEW OF CAB

- 3.1.3. GENERAL VIEW OF CONTROLS AND GAUGES

- 3.2. EXPLANATION OF COMPONENTS

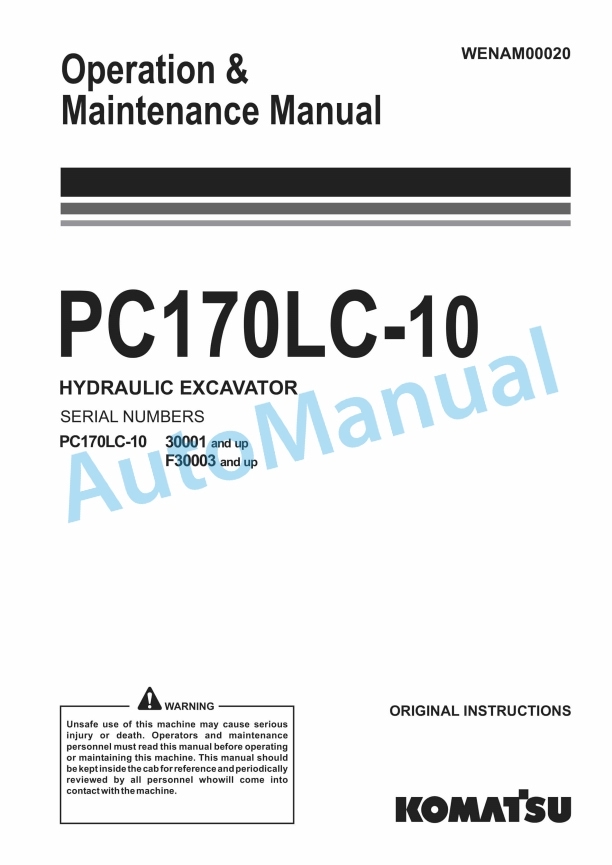

- 3.2.1. MACHINE MONITOR

- 3.2.2. SWITCHES

- 3.2.3. CONTROL LEVERS AND PEDALS

- 3.2.4. CEILING WINDOW

- 3.2.5. OPENING AND CLOSING CAB FRONT WINDOW

- 3.2.6. EMERGENCY ESCAPE HAMMER

- 3.2.7. DOOR LOCK

- 3.2.8. CAB DOOR HINGE

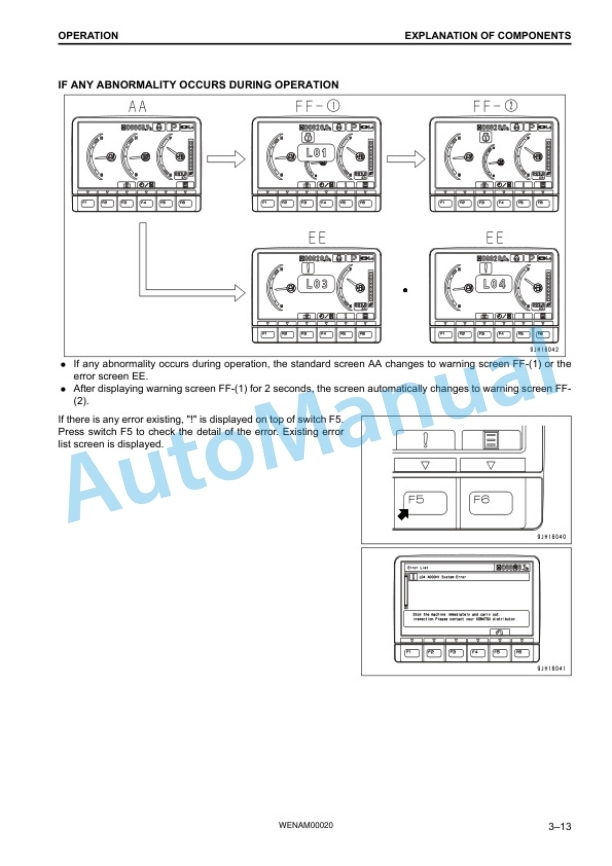

- 3.2.9. OPEN AND CLOSE ENGINE HOOD

- 3.2.10. CAPS AND COVERS WITH LOCK

- 3.2.11. DRINK BOX

- 3.2.12. MAGAZINE BOX

- 3.2.13. CUP HOLDER

- 3.2.14. ASHTRAY

- 3.2.15. HANDLING AIR CONDITIONER

- 3.2.16. HANDLING RADIO

- 3.2.17. AUXILIARY ELECTRIC POWER

- 3.2.18. FUSE

- 3.2.19. FUSIBLE LINK

- 3.2.20. TOOLBOX

- 3.2.21. GREASE PUMP HOLDER

- 3.2.22. FIRE EXTINGUISHER

- 3.2.23. BATTERY DISCONNECT SWITCH

- 3.2.24. SYSTEM OPERATING LAMP

- 3.2.25. HANDLING Komatsu Closed Crankcase Ventilation (KCCV)

- 3.2.26. HANDLING AUTOGREASING SYSTEM

- 3.2.27. HANDLING MACHINES EQUIPPED WITH KOMTRAX

- 3.3. MACHINE OPERATIONS AND CONTROLS

- 3.3.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 3.3.2. STARTING ENGINE

- 3.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 3.3.4. STOPPING ENGINE

- 3.3.5. MACHINE OPERATION

- 3.3.6. STEERING MACHINE

- 3.3.7. SWINGING MACHINE

- 3.3.8. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 3.3.9. WORKING MODE

- 3.3.10. PROHIBITED OPERATIONS

- 3.3.11. RULES FOR OPERATION

- 3.3.12. TRAVELING ON SLOPES

- 3.3.13. ESCAPE FROM MUD

- 3.3.14. RECOMMENDED APPLICATIONS

- 3.3.15. REPLACING AND INVERTING BUCKET

- 3.3.16. WHEN PARKING MACHINE

- 3.3.17. AFTER DAILY WORK COMPLETION

- 3.3.18. LOCKING

- 3.4. TRANSPORTATION

- 3.4.1. TRANSPORTATION PROCEDURE

- 3.4.2. LOADING AND UNLOADING WITH TRAILER

- 3.4.3. LIFTING MACHINE

- 3.5. COLD WEATHER OPERATION

- 3.5.1. COLD WEATHER OPERATION INFORMATION

- 3.5.2. AFTER DAILY WORK COMPLETION

- 3.5.3. AFTER COLD WEATHER SEASON

- 3.6. LONGTERM STORAGE

- 3.6.1. BEFORE STORAGE

- 3.6.2. DURING STORAGE

- 3.6.3. AFTER STORAGE

- 3.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 3.7. TROUBLES AND ACTIONS

- 3.7.1. RUNNING OUT OF FUEL

- 3.7.2. PHENOMENA THAT ARE NOT FAILURES

- 3.7.3. TOWING MACHINE

- 3.7.4. LIGHTWEIGHT TOWING HOLE

- 3.7.5. SEVERE JOB CONDITION

- 3.7.6. DISCHARGED BATTERY

- 3.7.7. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. RULES FOR MAINTENANCE

- 4.1.1. SERVICE METER READING

- 4.1.2. KOMATSU GENUINE REPLACEMENT PARTS

- 4.1.3. KOMATSU GENUINE LUBRICANTS

- 4.1.4. ALWAYS USE CLEAN WASHER FLUID

- 4.1.5. FRESH AND CLEAN LUBRICANTS

- 4.1.6. CHECK DRAINED OIL AND USED FILTER

- 4.1.7. CAUTION FOR REFILLING OIL OR FUEL

- 4.1.8. WELDING INSTRUCTIONS

- 4.1.9. DO NOT DROP THINGS INSIDE MACHINE

- 4.1.10. DUSTY JOBSITES

- 4.1.11. AVOID MIXING OIL

- 4.1.12. LOCKING INSPECTION COVERS

- 4.1.13. BLEED AIR FROM HYDRAULIC CIRCUIT

- 4.1.14. PRECAUTIONS WHEN INSTALLING HYDRAULIC HOSES

- 4.1.15. CHECKS AFTER INSPECTION AND MAINTENANCE

- 4.1.16. FUEL AND LUBRICANTS TO MATCH THE AMBIENT TEMPERATURE

- 4.1.17. CLOSE ENGINE HOOD SECURELY

- 4.2. OUTLINE OF MAINTENANCE

- 4.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 4.2.2. HANDLING ELECTRICAL COMPONENTS

- 4.3. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 4.3.1. TIGHTENING TORQUE LIST

- 4.4. MAINTENANCE SCHEDULE

- 4.4.1. MAINTENANCE SCHEDULE TABLE

- 4.4.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

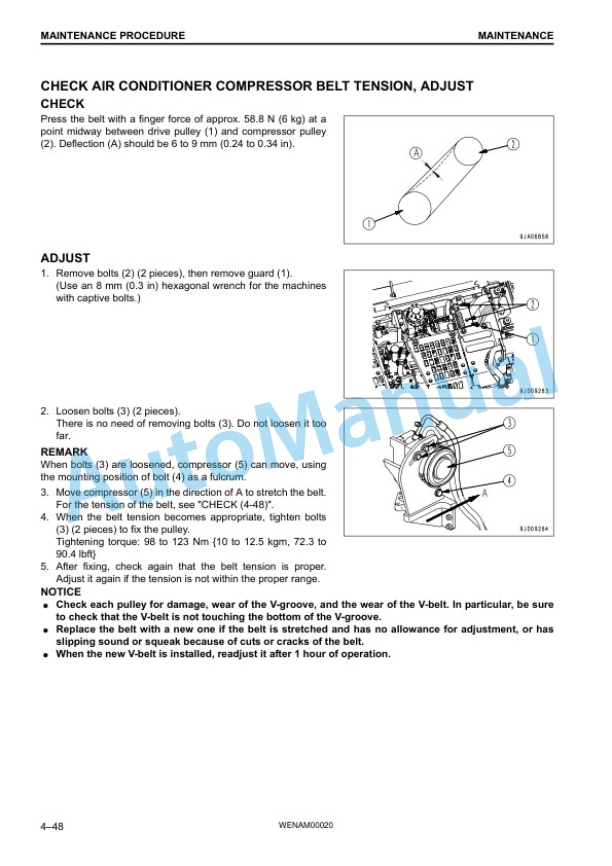

- 4.5. MAINTENANCE PROCEDURE

- 4.5.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 4.5.2. WHEN REQUIRED

- 4.5.3. CHECKS BEFORE STARTING

- 4.5.4. EVERY 100 HOURS MAINTENANCE

- 4.5.5. EVERY 250 HOURS MAINTENANCE

- 4.5.6. EVERY 500 HOURS MAINTENANCE

- 4.5.7. EVERY 1000 HOURS MAINTENANCE

- 4.5.8. EVERY 2000 HOURS MAINTENANCE

- 4.5.9. EVERY 4000 HOURS MAINTENANCE

- 4.5.10. EVERY 5000 HOURS MAINTENANCE

- 4.5.11. EVERY 8000 HOURS MAINTENANCE

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 5.1.1. specifications pc170lc10

- 5.1.2. specifications pc170lGP10

- 5.2. EXPLANATION OF LIFTING CAPACITY CHART

- 5.2.1. LIFTING CAPACITY CHART pc170lc10

- 5.3. EXPLANATION OF LIFTING CAPACITY CHART

- 5.3.1. LIFTING CAPACITY CHART pc170lGP10

- 6. ATTACHMENTS AND OPTIONS

- 6.1. GENERAL PRECAUTIONS FOR SAFETY

- 6.1.1. PRECAUTIONS WHEN SELECTING

- 6.1.2. READ THE OPERATION AND MAINTENANCE MANUAL THOROUGHLY

- 6.1.3. PRECAUTIONS WHEN REMOVING OR INSTALLING

- 6.1.4. PRECAUTIONS WHEN USING

- 6.2. HYDRAULIC QUICK COUPLER PIPING

- 6.3. BUCKET WITH HOOK

- 6.3.1. HOOK CONDITION

- 6.3.2. PROHIBITED OPERATIONS

- 6.4. MACHINE READY FOR INSTALLATION OF ATTACHMENT

- 6.4.1. EXPLANATION OF COMPONENTS

- 6.4.2. HYDRAULIC CIRCUIT

- 6.4.3. REMOVAL AND INSTALLATION OF ATTACHMENT

- 6.4.4. OPERATION

- 6.4.5. LONGTERM STORAGE

- 6.4.6. SPECIFICATIONS

- 6.5. ATTACHMENTS AND OPTIONS

- 6.5.1. ATTACHMENT COMBINATIONS

- 6.5.2. TRACK SHOES SELECTION

- 6.5.3. BUCKET TEETH SELECTION

- 6.6. RECOMMENDED ATTACHMENT OPERATIONS

- 6.6.1. HYDRAULIC BREAKER

- 7. REPLACEMENT PARTS

- 7.1. SAFETY CRITICAL PARTS

- 7.1.1. SAFETY CRITICAL PARTS LIST

- 7.2. CONSUMABLE PARTS

- 7.2.1. CONSUMABLE PARTS LIST

- 7.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 7.3.1. LUBRICATION CHART

- 7.3.2. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 8. INDEX

- 8.1. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713