Komatsu PC18MR-2 Galeo Hydraulic Excavator Operation and Maintenance Manual WEAM007300

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: WEAM007300

- Format: PDF

- Size: 6.5MB

- Number of Pages: 218

-

Model List:

- PC18MR-2 Galeo Hydraulic Excavator

- 1. FOREWORD

- 2. INFORMATION ON SAFETY

- 3. INTRODUCTION

- 3.1. INTENDED USES

- 3.2. IMPROPER OR UNAUTHORIZED USES

- 3.3. MAIN CHARACTERISTICS

- 3.4. BREAKINGIN THE NEW MACHINE

- 3.5. DIRECTIONS OF MACHINE

- 4. PRODUCT IDENTIFICATION

- 4.1. MACHINE SERIAL NUMBER

- 4.2. MACHINE IDENTIFICATION PLATE AND PRODUCT IDENTIFICATION NUMBER (PIN)

- 4.3. ENGINE SERIAL NUMBER AND EXHAUST GAS EMISSION PLATE

- 4.4. TRAVEL REDUCTION GEAR SERIAL NUMBER

- 4.5. SWING REDUCTION GEAR SERIAL NUMBER

- 4.6. SERIAL NUMBERS AND DEALERS ADDRESS

- 5. TABLE OF CONTENTS

- 6. SAFETY, NOISE AND VIBRATION PLATES

- 6.1. POSITION OF THE SAFETY PLATES

- 6.2. PICTOGRAMS AND RELEVANT MEANINGS

- 6.3. POSITION OF THE NOISE PLATES

- 6.4. VIBRATIONS TO WHICH THE OPERATOR IS SUBJECTED

- 7. GENERAL PRECAUTIONS

- 7.1. GENERAL SAFETY RULES

- 7.2. SAFETY DEVICES AND GUARDS

- 7.3. CLOTHING AND PERSONAL PROTECTION ITEMS

- 7.4. UNAUTHORIZED MODIFICATIONS

- 7.5. LEAVING THE OPERATORS SEAT

- 7.6. GETTING ON AND OFF THE MACHINE

- 7.7. PREVENTING FIRES DUE TO FUEL AND OIL

- 7.8. PREVENTING BURNS

- 7.9. PREVENTING DAMAGE DUE TO ASBESTOS POWDER

- 7.10. PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT

- 7.11. FIRE EXTINGUISHERS AND FIRST AID KIT

- 7.12. PRECAUTIONS CONCERNING THE ROPS STRUCTURE

- 7.13. PRECAUTIONS CONCERNING THE EQUIPMENT

- 8. PRECAUTIONS TO BE TAKEN BEFORE STARTING THE ENGINE

- 8.1. SAFETY ON THE WORK SITE

- 8.2. FIRE PREVENTION

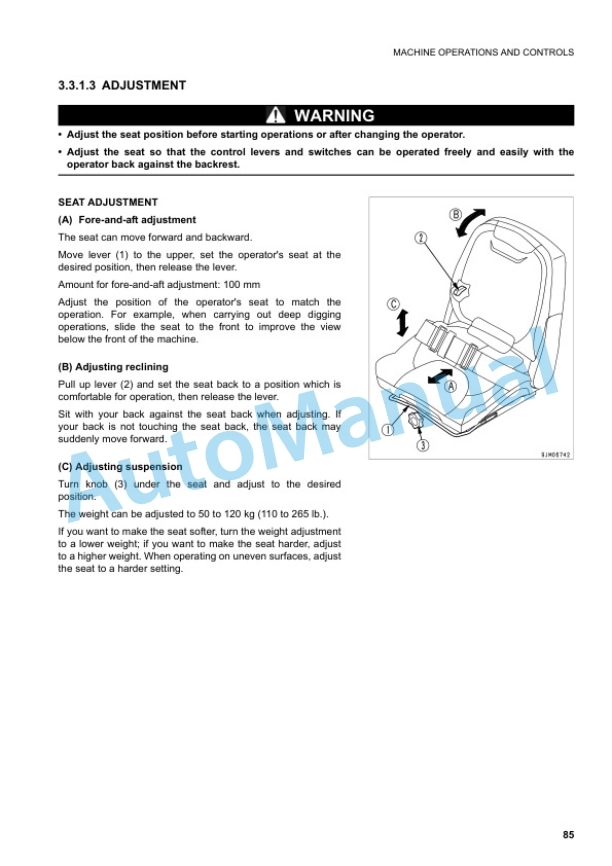

- 8.3. PRECAUTIONS CONCERNING THE OPERATOR SEAT

- 8.4. ROOM VENTILATION

- 8.5. PRECAUTIONS TO BE TAKEN FOR THE LIGHTS

- 9. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 9.1. STARTING THE ENGINE

- 9.2. CHECK THE DIRECTION BEFORE STARTING THE MACHINE

- 9.3. CHECKS FOR TRAVELLING IN REVERSE

- 9.4. MOVING THE MACHINE

- 9.5. MOVING ON SLOPES

- 9.6. WORKING ON SLOPES

- 9.7. UNAUTHORIZED OPERATIONS

- 9.8. PREVENTING ELECTROCUTION

- 9.9. VISIBILITY

- 9.10. WORKING ON ICY OR SNOWCOVERED SURFACES

- 9.11. PREVENTING DAMAGE CAUSED BY THE WORK EQUIPMENT

- 9.12. WORKING ON LOOSE GROUND

- 9.13. PARKING MACHINE

- 10. TRANSPORTING THE MACHINE ON MOTOR VEHICLES

- 10.1. LOADING AND UNLOADING

- 10.2. TRANSPORT

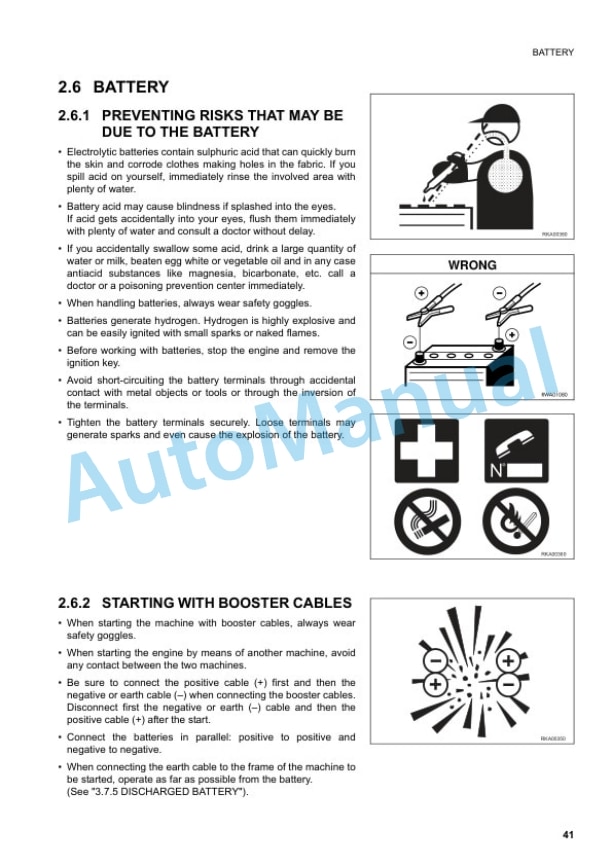

- 11. BATTERY

- 11.1. PREVENTING RISKS THAT MAY BE DUE TO THE BATTERY

- 11.2. STARTING WITH BOOSTER CABLES

- 12. PRECAUTIONS FOR THE REMOVAL

- 13. PRECAUTIONS FOR MAINTENANCE

- 13.1. WARNING PLATES

- 13.2. TOOLS

- 13.3. PERSONNEL

- 13.4. EQUIPMENT

- 13.5. WORKING UNDER THE MACHINE

- 13.6. CLEANING THE MACHINE

- 13.7. USE OF THE ENGINE DURING MAINTENANCE OPERATIONS

- 13.8. PERIODICAL CHANGE OF THE PARTS THAT ARE CRITICAL FOR SAFETY

- 13.9. STOP THE ENGINE BEFORE CARRYING OUT ANY MAINTENANCE OPERATION OR INSPECTION

- 13.10. RULES TO BE FOLLOWED DURING FUEL OR OIL TOPPING UP

- 13.11. CHECKING THE COOLANT LEVEL IN THE COOLING

- 13.12. USING LAMPS

- 13.13. PRECAUTIONS CONCERNING THE BATTERY AND THE ALTERNATOR

- 13.14. PRECAUTIONS CONCERNING THE STARTER

- 13.15. HANDLING HIGHPRESSURE PIPES

- 13.16. PRECAUTIONS TO BE TAKEN WHEN HANDLING HIGHPRESSURE OIL

- 13.17. PRECAUTIONS FOR MAINTENANCE OPERATIONS AT HIGH TEMPERATURES AND HIGH PRESSURE

- 13.18. PRECAUTIONS TO BE TAKEN WHEN USING HIGHPRESSURE GREASE TO ADJUST THE TRACK TENSION

- 13.19. DO NOT REMOVE THE SHOCK ABSORBING SPRING FROM THE SHOCK ABSORBER UNIT

- 13.20. HYDRAULIC ACCUMULATOR

- 13.21. COOLING FAN AND BELT

- 13.22. WASTE MATERIALS

- 13.23. COMPRESSED AIR

- 13.24. PRECAUTIONS FOR THE USE OF THE SYNTHETIC BIODEGRADABLE OIL TYPE HEES

- 14. MACHINE VIEW ILLUSTRATIONS

- 14.1. OVERALL MACHINE VIEW

- 14.2. CONTROLS AND GAUGES

- 15. DETAILED CONTROLS AND GAUGES

- 15.1. MONITORING SYSTEM

- 15.2. SWITCHES

- 15.3. CONTROL LEVERS AND PEDALS

- 15.4. COVERS WITH LOCK

- 15.5. ENGINE HOOD

- 15.6. COOLING COVER

- 15.7. BATTERY COVER

- 15.8. METHOD OF OPENING (TILTING) FLOOR

- 15.9. FUSE

- 15.10. BLOCK FUSE

- 15.11. OPERATION MANUAL STORAGE

- 15.12. TOOL BOX

- 16. MACHINE OPERATIONS AND CONTROLS

- 16.1. BEFORE STARTING ENGINE

- 16.2. AFTER STARTING ENGINE

- 16.3. STOPPING THE ENGINE

- 16.4. MACHINE OPERATION

- 16.5. STEERING THE MACHINE

- 16.6. SWINGING

- 16.7. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 16.8. PROHIBITED OPERATIONS

- 16.9. LONG LIFE OPERATIONS

- 16.10. TRAVELING ON SLOPES

- 16.11. ESCAPE FROM MUD

- 16.12. WORK POSSIBLE USING COMPACT HYDRAULIC EXCAVATOR

- 16.13. CHANGING THE BUCKET

- 16.14. PARKING MACHINE

- 16.15. CHECK AFTER SHUT OFF ENGINE

- 16.16. MACHINE INSPECTION AFTER DAILY WORK

- 16.17. LOCKING

- 16.18. RUBBER SHOES (Machine equipped with rubber shoes)

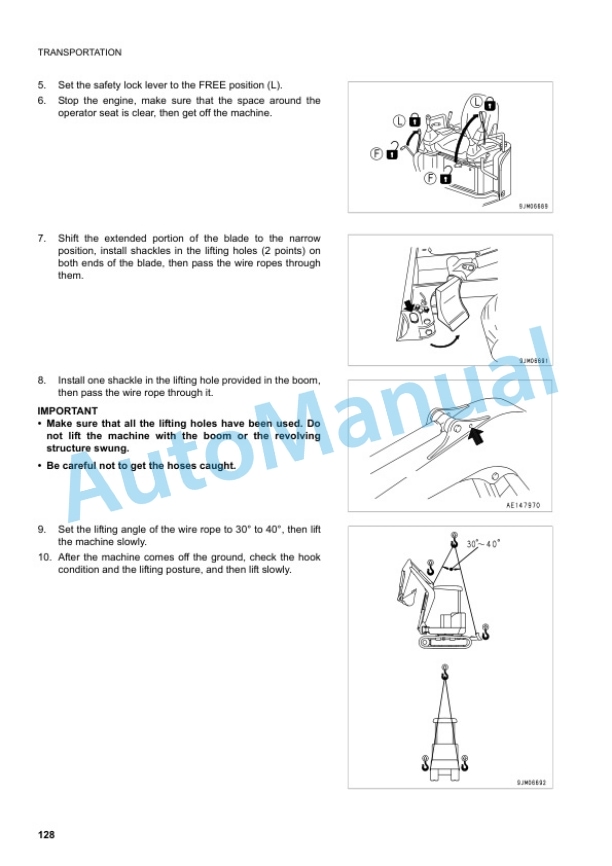

- 17. TRANSPORTATION

- 17.1. TRANSPORTATION PROCEDURE

- 17.2. LOADING AND UNLOADING WITH TRAILER

- 17.3. LIFTING MACHINE

- 18. COLD WEATHER OPERATION

- 18.1. COLD WEATHER OPERATION INFORMATION

- 18.2. AFTER DAILY WORK COMPLETION

- 18.3. AFTER COLD WEATHER SEASON

- 19. LONG TERM STORAGE

- 19.1. BEFORE STORAGE

- 19.2. DURING STORAGE

- 19.3. AFTER STORAGE

- 20. TROUBLES AND ACTIONS

- 20.1. RUNNING OUT OF FUEL

- 20.2. PHENOMENA THAT ARE NOT FAILURES

- 20.3. TOWING THE MACHINE

- 20.4. SEVERE JOB CONDITION

- 20.5. DISCHARGED BATTERY

- 20.6. OTHER TROUBLE

- 21. MAINTENANCE INFORMATION

- 22. LUBRICANTS, COOLANT AND FILTERS

- 22.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 22.2. ELECTRIC SYSTEM MAINTENANCE

- 22.3. HANDLING HYDRAULIC SYSTEM

- 23. WEAR PARTS

- 23.1. WEAR PARTS LIST

- 24. LUBRICANTS, FUEL AND COOLANT SPECIFICATIONS

- 24.1. HOMOLOGATED HEES SYNTHETIC BIODEGRADABLE LUBRICANTS

- 25. TIGHTENING TORQUE SPECIFICATIONS

- 25.1. TIGHTENING TORQUE LIST

- 26. LUBRICATION

- 26.1. LUBRICATION DIAGRAM

- 27. SAFETY CRITICAL PARTS

- 27.1. SAFETY CRITICAL PARTS LIST

- 28. MAINTENANCE SCHEDULE

- 28.1. MAINTENANCE SCHEDULE CHART

- 28.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

- 29. MAINTENANCE PROCEDURE

- 29.1. WHEN REQUIRED

- 29.2. CHECKS BEFORE STARTING

- 29.3. EVERY 500 HOURS MAINTENANCE

- 29.4. EVERY 1000 HOURS MAINTENANCE

- 29.5. EVERY 2000 HOURS MAINTENANCE

- 30. SPECIFICATIONS

- 31. LIFTING CAPACITIES

- 31.1. LIFTING CAPACITIES

- 32. ATTACHMENTS AND OPTIONS GENERAL INFORMATION

- 32.1. SAFETY FIRST

- 32.2. ATTACHMENT INSTALLATION

- 32.3. CHARACTERISTICS OF THE OPTIONAL EQUIPMENT

- 33. MACHINE READY FOR ATTACHMENT

- 33.1. LOCATIONS

- 33.2. HYDRAULIC CIRCUIT

- 34. ATTACHMENT OPERATIONS

- 34.1. LONG TERM STORAGE

- 34.2. SPECIFICATIONS

- 35. ATTACHMENT GUIDE

- 35.1. ATTACHMENT COMBINATIONS

- 36. RECOMMENDED ATTACHMENT OPERATIONS

- 36.1. HYDRAULIC BREAKER

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615