Komatsu PC210LCi-11 Hydraulic Excavator Operation and Maintenance Manual UENAM01300

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: UENAM01300

- Format: PDF

- Size: 50.5MB

- Number of Pages: 454

-

Model List:

- PC210LCi-11 Hydraulic Excavator

- 1. FOREWORD

- 1.1. BEFORE READING THIS MANUAL

- 1.2. SAFETY INFORMATION

- 1.3. INTRODUCTION

- 1.3.1. intelligent Machine Control

- 1.3.2. MAIN USE OF MACHINE

- 1.3.3. DEMOLITION WORK

- 1.4. AUTO TILT BUCKET SERIAL PLATE (IF EQUIPPED)

- 1.5. DECLARATION OF CONFORMITY

- 1.6. TABLE OF CONTENTS

- 2. SAFETY

- 2.1. SAFETY LABELS

- 2.1.1. LOCATION OF SAFETY LABELS

- 2.1.2. SAFETY LABELS

- 2.2. PRECAUTIONS FOR OPERATION

- 2.2.1. START ENGINE

- 2.2.2. PRECAUTIONS RELATED TO CONTROL BOX

- 2.2.3. PRECAUTIONS RELATED TO SEMIAUTO MODE

- 2.2.4. PRECAUTIONS FOR TRANSPORTATION

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. MACHINE EQUIPMENT NAME

- 3.1.2. GENERAL VIEW OF CAB

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. EXPLANATION OF MACHINE MONITOR EQUIPMENT

- 3.2.2. SWITCH

- 3.2.3. CONTROL LEVERS AND PEDALS

- 3.2.4. INTELLIGENT MACHINE CONTROL SYSTEM

- 3.2.5. OTHER EQUIPMENT

- 3.3. MACHINE OPERATIONS AND CONTROLS

- 3.3.1. CHECKS AND ADJUSTMENT BEFORE STARTING ENGINE

- 3.3.2. METHOD FOR STARTING ENGINE

- 3.3.3. HANDLING QUICK COUPLER PIN GRAB

- 3.3.4. METHOD FOR STOPPING ENGINE

- 3.3.5. PROHIBITED OPERATIONS

- 3.3.6. METHOD FOR PARKING MACHINE

- 3.3.7. METHOD FOR DISCONNECTING AND CONNECTING ELECTRICAL CONNECTION AT AUTO TILT BUCKET

- 3.3.8. METHOD FOR CONNECTING AND DISCONNECTING ELECTRICAL CONNECTION ON WORK EQUIPMENT FOR AUTO TILT BUCKET

- 3.4. HANDLING RADIO

- 3.5. TRANSPORTATION

- 3.5.1. REMOVE AND INSTALL GNSS ANTENNA

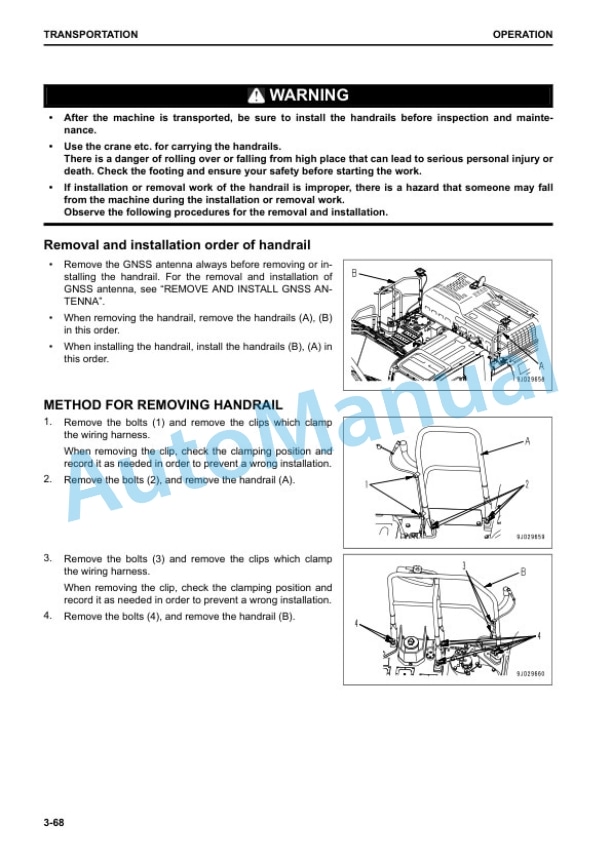

- 3.5.2. REMOVE AND INSTALL HANDRAIL

- 3.5.3. REMOVE AND INSTALL GNSS ANTENNA AND ANTENNA FOR NETWORK MODEM

- 3.6. PRECAUTIONS FOR LONGTERM STORAGE

- 3.6.1. STARTING MACHINE AFTER LONGTERM STORAGE

- 3.7. TROUBLES AND ACTIONS

- 3.7.1. IF ERROR INFORMATION IS DISPLAYED ON CONTROL BOX

- 3.7.2. OTHER TROUBLE

- 4. MAINTENANCE

- 4.1. MAINTENANCE SCHEDULE

- 4.1.1. MAINTENANCE SCHEDULE TABLE

- 4.2. MAINTENANCE PROCEDURE

- 4.2.1. MAINTENANCE INTERVAL FOR AUTO TILT BUCKET

- 4.2.2. EVERY 500 HOURS MAINTENANCE

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 5.1.1. SPECIFICATIONSPC210LCi11

- 6. ATTACHMENTS AND OPTIONS

- 6.1. PRECAUTIONS FOR USING ATTACHMENT AND OPTIONS

- 6.1.1. PRECAUTIONS WHEN SELECTING

- 6.1.2. READ THE OPERATION AND MAINTENANCE MANUAL THOROUGHLY

- 6.1.3. PRECAUTIONS WHEN REMOVING AND INSTALLING

- 6.1.4. PRECAUTIONS FOR USING

- 6.2. ATTACHMENTS AND OPTIONS

- 6.2.1. AUTO TILT BUCKET

- 6.3. RECOMMENDED ATTACHMENT OPERATIONS

- 6.3.1. HYDRAULIC BREAKER

- 6.4. KomVision

- 6.4.1. PRECAUTIONS WHEN USING KomVision

- 6.4.2. MACHINE MONITOR EQUIPMENT NAME

- 6.4.3. EXPLANATION OF MACHINE MONITOR EQUIPMENT

- 6.4.4. WARNING DISPLAY

- 6.4.5. CAMERA SYSTEM CAUTION LAMP

- 6.4.6. CAMERA CONTROLLER CAUTION LAMP

- 6.4.7. MONITOR DISPLAY

- 6.4.8. MONITOR DISPLAY SELECTOR SWITCH

- 6.4.9. CAMERA IMAGE SELECTOR SWITCH

- 6.4.10. METHOD FOR CHECKING BEFORE STARTING

- 6.4.11. METHOD FOR CHECKING CAMERA VISIBILITY

- 6.4.12. TROUBLES AND ACTIONS

- 7. SETTING

- 7.1. INTELLIGENT MACHINE CONTROL SETTINGS

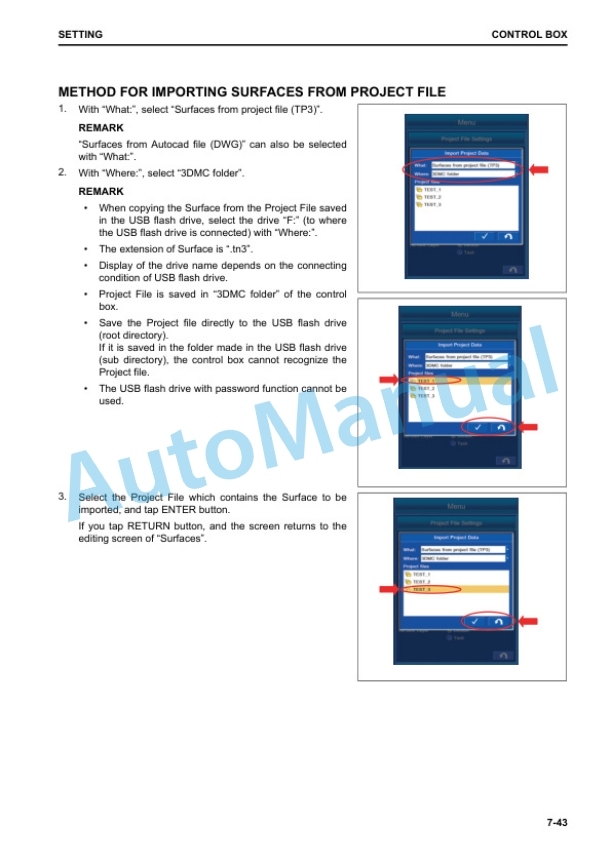

- 7.2. CONTROL BOX

- 7.2.1. METHOD FOR DISPLAYING MAIN MENU

- 7.3. MACHINE MONITOR

- 7.3.1. MACHINE SETTINGS

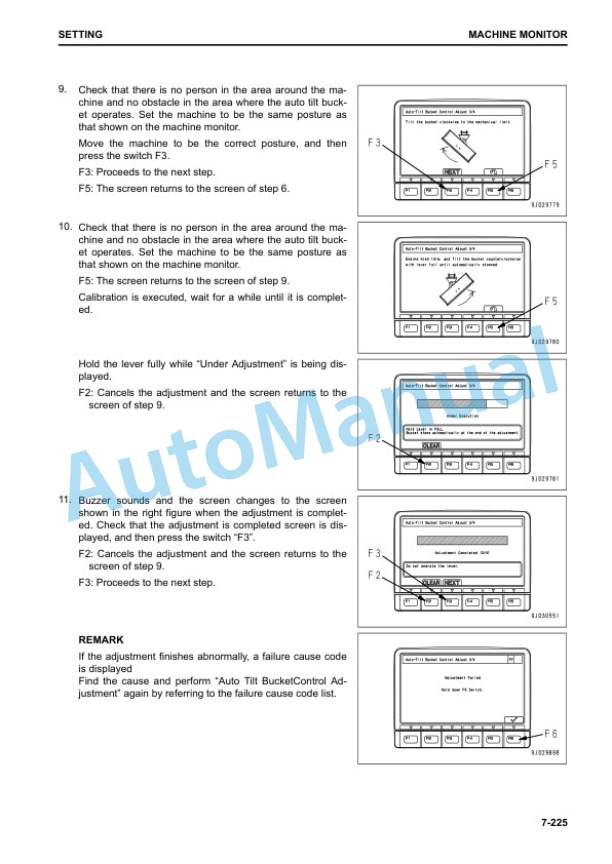

- 7.3.2. MC SETTING

- 8. EXECUTIONS

- 8.1. SEMIAUTO MODE

- 8.1.1. PRECAUTIONS FOR OPERATION

- 8.1.2. PRECAUTIONS FOR REPLACING PARTS AND FAILURES

- 8.1.3. WORKING MODE

- 8.1.4. WORKING MODE (WHEN AUTO TILT BUCKET IS EQUIPPED)

- 8.1.5. SEMIAUTO MODE SETTINGS

- 8.2. TRAVEL MODE

- 8.2.1. TRAVEL MODE SETTINGS

- 8.2.2. DISPLAY OF TRAVEL MODE

- 8.2.3. OFFSET MENU OF SURFACE

- 8.2.4. TEMPORARY DESIGN MENU

- 8.2.5. TARGET SURFACE SETTINGS

- 8.3. ROUGH DIGGING MODE

- 8.3.1. METHOD FOR SETTING ROUGH DIGGING SCREEN

- 8.4. FINE DIGGING MODE

- 8.4.1. METHOD FOR SETTING FINE DIGGING MODE SCREEN

- 8.5. TARGET SURFACE SETTINGS

- 8.5.1. TARGET SURFACE SETTING MENU

- 8.5.2. METHOD FOR SETTING TARGET SURFACE

- 8.6. BUCKET EDGE POSITION

- 8.6.1. DISPLAY BUCKET EDGE POSITION

- 8.6.2. METHOD FOR COMPARING WITH BENCHMARK

- 8.6.3. METHOD FOR CORRECTING BUCKET EDGE POSITION

- 8.7. DAILY CALIBRATION

- 8.7.1. WALKAROUND CHECKS OF INTELLIGENT MACHINE CONTROL EQUIPMENT

- 8.8. CHECK GNSS COMMUNICATION STATUS

- 8.8.1. METHOD FOR CHECKING GNSS COMMUNICATION STATUS

- 8.8.2. METHOD FOR CHECKING NUMBER OF SATELLITES AND ERROR OF POSITIONING

- 8.8.3. METHOD FOR DISPLAYING BUCKET EDGE COORDINATES

- 8.8.4. METHOD FOR SETTING SATELLITE POSITION DISPLAY AND ELEVATION ANGLE

- 8.8.5. METHOD FOR DISPLAYING GNSS RECEIVER INFORMATION

- 8.8.6. METHOD FOR CHECKING EXPECTANCY OF EDGE ACCURANCY

- 8.8.7. METHOD FOR SETTING GLONASS SATELLITE

- 8.8.8. METHOD FOR SETTING TILT SENSOR

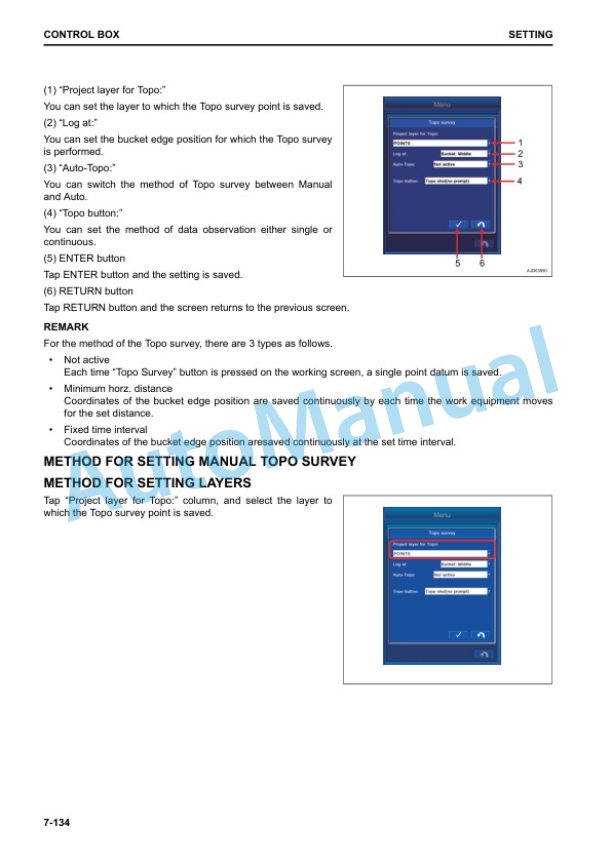

- 8.9. USE OF TOPO SURVEY

- 8.9.1. METHOD FOR PERFORMING TOPO SURVEY MANUALLY

- 8.9.2. METHOD FOR PERFORMING AUTOTOPO SURVEY

- 8.9.3. METHOD FOR CANCELING TOPOGRAPHIC SURVEYS

- 8.10. TROUBLESHOOTING

- 8.10.1. CONTROL BOX SCREEN DISPLAY

- 8.10.2. SEMIAUTO MODE

- 8.10.3. WORKING ACCURACY

- 8.10.4. AUTO TILT BUCKET

- 9. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E