Komatsu PC290LL-11 Log Loader Operation and Maintenance Manual CEAM032002

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM032002

- Format: PDF

- Size: 55.3MB

- Number of Pages: 474

-

Model List:

- PC290LL-11 Log Loader

- 1. Contents

- 2. INTRODUCTION

- 2.1. Foreword

- 2.2. Safety Alert Symbol and Signal Words

- 2.3. Basic Machine Introduction

- 2.4. Exhaust Gas Regulations

- 2.5. Product Information

- 3. SAFETY

- 3.1. Safety Labels

- 3.2. General Precautions Common to Operation and Maintenance

- 3.3. Operation Precautions

- 3.4. Maintenance Precautions

- 4. OPERATION

- 4.1. Visual Overview of Machine

- 4.2. Machine Monitor Components

- 4.3. Warning Lamps

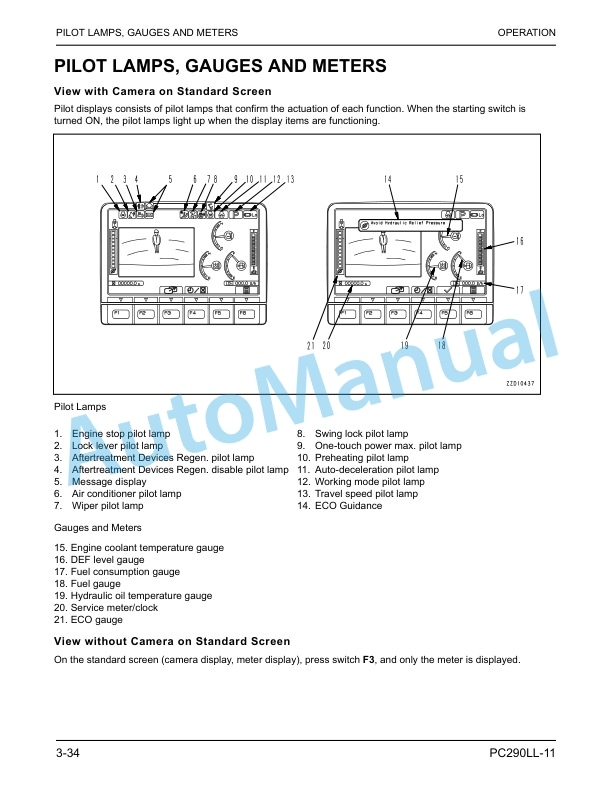

- 4.4. Pilot Lamps, Gauges and Meters

- 4.5. Monitor Gauges and Meters

- 4.6. Monitor Switches

- 4.7. User Menu

- 4.8. Operator Cab Switches

- 4.9. Control Levers and Pedals

- 4.10. Air Conditioner Operations

- 4.11. Radio Operations

- 4.12. Emergency Escape

- 4.13. Auxiliary Electric Power

- 4.14. Fuses

- 4.15. Cab Containers

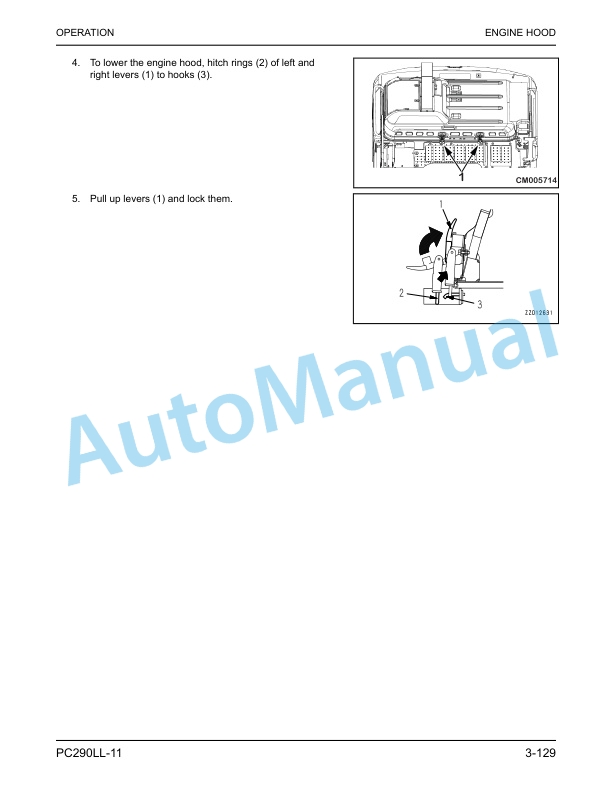

- 4.16. Engine Hood

- 4.17. Caps and Covers with Lock

- 4.18. Battery Disconnect Switch

- 4.19. System Operating Lamp

- 4.20. Komatsu Diesel Particulate Filter (KDPF)

- 4.21. Komatsu Closed Crankcase Ventilation (KCCV)

- 4.22. Urea SCR System

- 4.23. DEF Filter

- 4.24. KOMTRAX

- 4.25. Daily Checks and Preparations Before Starting Engine

- 4.26. Starting the Engine

- 4.27. Operations and Checks After Starting the Engine

- 4.28. Stopping the Engine

- 4.29. Moving and Steering Machine

- 4.30. Operating Work Equipment

- 4.31. Working Mode

- 4.32. Prohibited Operations

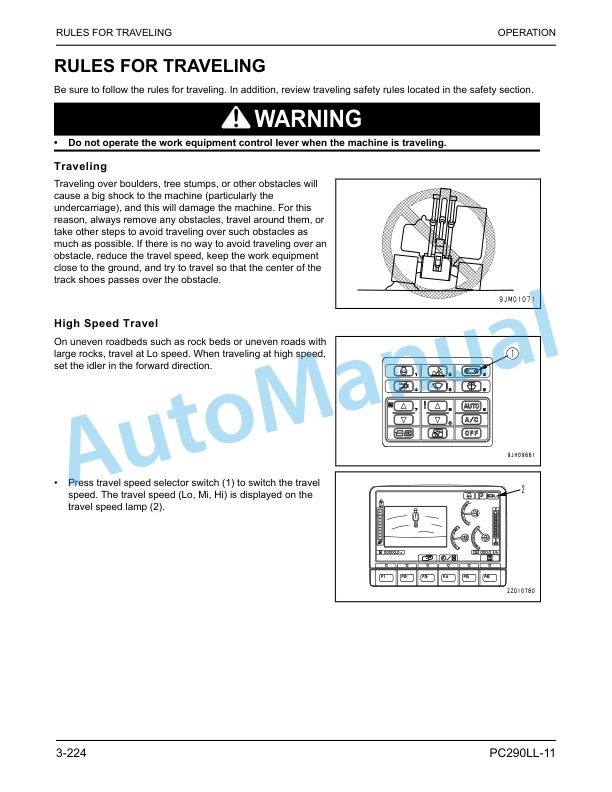

- 4.33. Rules for Traveling

- 4.34. Recommended Applications

- 4.35. Replacing and Inverting Bucket

- 4.36. Parking Machine

- 4.37. After Finishing Work

- 4.38. Transport the Machine

- 4.39. Cold Weather Operation

- 4.40. LongTerm Storage of Machine

- 4.41. Common Phenomena That are Not Failures

- 4.42. Towing Machine

- 4.43. Tow with Machine

- 4.44. Disconnect and Charge Battery

- 4.45. Jumper Cables to Start Engine

- 4.46. Troubleshooting Common Troubles and Actions to Take

- 5. MAINTENANCE

- 5.1. Rules for Maintenance

- 5.2. Outline of Service

- 5.3. Consumable Parts

- 5.4. Safety Critical Parts

- 5.5. Torque Specifications

- 5.6. Track Shoe Bolts

- 5.7. Recommended Fuel, Coolant, and Lubricant

- 5.8. Hydraulic Breaker Maintenance Interval

- 5.9. Maintenance Schedule

- 5.10. Maintenance Procedures as Required

- 5.11. Maintenance for First 500 Hours

- 5.12. Maintenance Every 100 Hours

- 5.13. Maintenance Every 250 Hours

- 5.14. Maintenance Every 500 Hours

- 5.15. Maintenance Every 1000 Hours

- 5.16. Maintenance Every 2000 Hours

- 5.17. Maintenance Every 4000 Hours

- 5.18. Maintenance Every 4500 Hours

- 5.19. Maintenance Every 5000 Hours

- 5.20. Maintenance Every 8000 Hours

- 5.21. Maintenance Every 9000 Hours

- 6. SPECIFICATIONS

- 6.1. Specifications PC290LL11

- 7. OPTIONS, ATTACHMENTS

- 7.1. General Attachment Safety Precautions

- 7.2. Machine Options

- 7.3. Machine Attachments

- 8. PROCESSOR OPTION

- 8.1. Introduction

- 8.2. Safety

- 8.3. Processor Operations

- 8.4. Processor Maintenance

- 9. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692