Komatsu PC60-7 Hydraulic Excavator Operation and Maintenance Manual SEAM034106T

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM034106T

- Format: PDF

- Size: 9.0MB

- Number of Pages: 289

-

Model List:

- PC60-7 Hydraulic Excavator

- 1. COVER

- 2. FOREWORD

- 2.1. FOREWORD

- 2.2. SAFETY INFORMATION

- 2.3. INTRODUCTION

- 2.3.1. DIRECTIONS OF MACHINE

- 2.4. PRODUCT INFORMATION

- 2.4.1. MACHINE SERIAL NUMBER PLATE AND ITS LOCATION

- 2.4.2. ENGINE SERIAL NUMBER PLATE AND ITS LOCATION

- 2.4.3. SERVICE METER LOCATION

- 2.4.4. YOUR MACHINE SERIAL NUMBERS AND DISTRIBUTOR

- 2.5. ATTACHMENTS AND OPTIONS

- 3. SAFETY

- 3.1. SAFETY INFORMATION

- 3.2. WARNING LABELS AND PICTOGRAMS

- 3.2.1. WARNING LABELS AND PICTOGRAMS LOCATION

- 3.2.2. WARNING LABELS AND PICTOGRAMS ACTUAL

- 3.3. SAFETY INFORMATION

- 3.3.1. Safety Rules

- 3.3.2. If Abnormalities are Found

- 3.3.3. Working Wear and Personal Protective Items

- 3.3.4. Fire Extinguisher and First Aid Kit

- 3.3.5. Safety Equipment

- 3.3.6. Keep Machine Clean

- 3.3.7. Keep Operators Compartment Clean

- 3.3.8. Leaving Operators Seat with Lock

- 3.3.9. Handrails and Steps

- 3.3.10. Mounting and Dismounting

- 3.3.11. No Persons on Attachments

- 3.3.12. Burn Prevention

- 3.3.13. Fire Prevention and Explosion Prevention

- 3.3.14. Action If Fire Occurs

- 3.3.15. Windshield Washer Fluid

- 3.3.16. Falling Objects, Flying Objects a and Intruding Objects Prevention

- 3.3.17. Attachment Installation

- 3.3.18. Attachment Combinations

- 3.3.19. Cab Widow Glasses

- 3.3.20. Unauthorized Modifications

- 3.3.21. Safety at Jobsite

- 3.3.22. Working on Loose Ground

- 3.3.23. Distance to High Voltage Cables

- 3.3.24. Ensure Good Visibility

- 3.3.25. Ventilation for Enclosed Area

- 3.3.26. Signalmans Signal and Signs

- 3.3.27. Emergency Exit from Operators Cab

- 3.3.28. Asbestos Dust Hazard Prevention

- 3.4. SAFETY MACHINE OPERATION

- 3.4.1. BEFORE STARTING ENGINE

- 3.4.2. AFTER STARTING ENGINE

- 3.4.3. TRANSPORTATION

- 3.4.4. BATTERY

- 3.4.5. TOWING

- 3.4.6. LIFTING OBJECTS WITH BUCKET

- 3.5. SAFETY MAINTENANCE INFORMATION

- 3.5.1. Warning Tag

- 3.5.2. Keep Work Place Clean and Tidy

- 3.5.3. Appoint Leader when Working with Others

- 3.5.4. Stop Engine Before Carrying Out Maintenance

- 3.5.5. Two Workers for Maintenance when Engine is Running

- 3.5.6. Proper Tools

- 3.5.7. Accumulator

- 3.5.8. Personnel

- 3.5.9. Attachments

- 3.5.10. Work Under the Machine

- 3.5.11. Noise

- 3.5.12. When Using Hammer

- 3.5.13. Welding Works

- 3.5.14. Removing Battery Terminals

- 3.5.15. Safety First when Using Highpressure Grease to Adjust Track Tension

- 3.5.16. Do Not Disassemble Recoil Springs

- 3.5.17. Safety Rules for Highpressure Oil

- 3.5.18. Safety Handling Highpressure Hoses

- 3.5.19. Waste Materials

- 3.5.20. Air Conditioner Maintenance

- 3.5.21. Compressed Air

- 3.5.22. Periodic Replacement of Safety Critical Parts

- 4. OPERATION

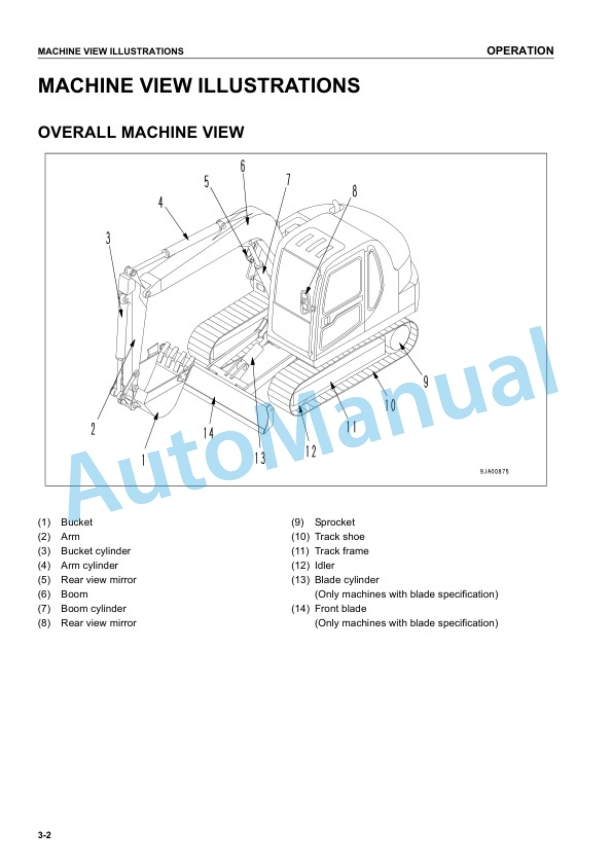

- 4.1. MACHINE VIEW ILLUSTRATIONS

- 4.1.1. OVERALL MACHINE VIEW

- 4.1.2. CONTROLS AND GAUGES

- 4.2. DETAILED CONTROLS AND GAUGES

- 4.2.1. MONITORING SYSTEM

- 4.2.2. SWITCHES

- 4.2.3. CONTROL LEVERS AND PEDALS

- 4.2.4. EMERGENCY EXIT FROM OPERATORS CAB

- 4.2.5. DOOR LOCK

- 4.2.6. CAP WITH LOCK

- 4.2.7. ASHTRAY

- 4.2.8. RADIO

- 4.2.9. FUSE

- 4.2.10. FUSIBLELINK

- 4.2.11. CONTROLLERS

- 4.2.12. OPERATION MANUAL STORAGE

- 4.2.13. TOOL BOX

- 4.2.14. GREASE GUN HOLDER

- 4.3. MACHINE OPERATIONS AND CONTROLS

- 4.3.1. BEFORE STARTING ENGINE

- 4.3.2. STARTING ENGINE

- 4.3.3. AFTER STARTING ENGINE

- 4.3.4. STOPPING THE ENGINE

- 4.3.5. CHECK AFTER SHUT OFF ENGINE

- 4.3.6. MACHINE OPERATION

- 4.3.7. STEERING THE MACHINE

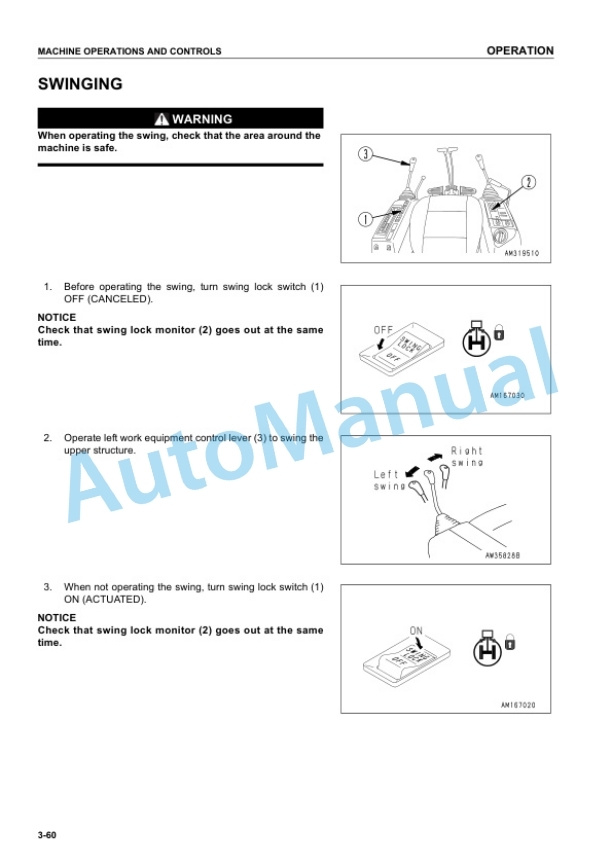

- 4.3.8. SWINGING

- 4.3.9. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 4.3.10. PROHIBITED OPERATIONS

- 4.3.11. GENERAL OPERATION INFORMATION

- 4.3.12. TRAVELING ON SLOPES

- 4.3.13. ESCAPE FROM MUD

- 4.3.14. RECOMMENDED APPLICATIONS

- 4.3.15. BUCKET REPLACEMENT AND INVERSION

- 4.3.16. PARKING MACHINE

- 4.3.17. MACHINE INSPECTION AFTER DAILY WORK

- 4.3.18. LOCKING

- 4.3.19. RUBBER SHOES AND ROAD LINERS

- 4.4. TRANSPORTATION

- 4.4.1. TRANSPORTATION PROCEDURE

- 4.4.2. LOADING AND UNLOADING WITH TRAILER

- 4.4.3. LIFTING MACHINE

- 4.5. COLD WEATHER OPERATION

- 4.5.1. COLD WEATHER OPERATION INFORMATION

- 4.5.2. AFTER DAILY WORK COMPLETION

- 4.5.3. AFTER COLD WEATHER SEASON

- 4.6. LONG TERM STORAGE

- 4.6.1. BEFORE STORAGE

- 4.6.2. DURING STORAGE

- 4.6.3. AFTER STORAGE

- 4.6.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 4.7. TROUBLES AND ACTIONS

- 4.7.1. RUNNING OUT OF FUEL

- 4.7.2. PHENOMENA THAT ARE NOT FAILURES

- 4.7.3. TOWING THE MACHINE

- 4.7.4. LIGHTWEIGHT TOWING HOOK

- 4.7.5. SEVERE JOB CONDITION

- 4.7.6. DISCHARGED BATTERY

- 4.7.7. OTHER TROUBLE

- 5. MAINTENANCE

- 5.1. MAINTENANCE INFORMATION

- 5.1.1. Service Meter Reading

- 5.1.2. Komatsu Genuine Replacement Parts

- 5.1.3. Komatsu Genuine Lubricants

- 5.1.4. Windshield Washer Fluid

- 5.1.5. Fresh and Clean Lubricants

- 5.1.6. Check Drained Oil and Used Filter

- 5.1.7. Fuel Strainer

- 5.1.8. Welding Instructions

- 5.1.9. Do Not Drop Things Inside Machine

- 5.1.10. Dusty Jobsite

- 5.1.11. Avoid Mixing Lubricants

- 5.1.12. Locking the Inspection Covers

- 5.1.13. Hydraulic System Air Bleeding

- 5.1.14. Hydraulic Hose Installation

- 5.1.15. Checks After Inspection and Maintenance Works

- 5.2. OUTLINE OF SERVICE

- 5.2.1. HANDLING OIL, FUEL, COOLANT, AND PERFORMING OIL CLINIC

- 5.2.2. ELECTRIC SYSTEM MAINTENANCE

- 5.3. WEAR PARTS

- 5.3.1. WEAR PARTS LIST

- 5.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 5.4.1. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 5.4.2. RECOMMENDED BRANDS, RECOMMENDED QUALITY FOR PRODUCTS OTHER THAN KOMATSU GENUINE OIL

- 5.5. TIGHTENING TORQUE SPECIFICATIONS

- 5.5.1. TIGHTENING TORQUE LIST

- 5.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 5.6.1. SAFETY CRITICAL PARTS

- 5.7. MAINTENANCE SCHEDULE

- 5.7.1. MAINTENANCE SCHEDULE CHART

- 5.7.2. MAINTENANCE INTERVAL FOR HYDRAULIC BREAKER

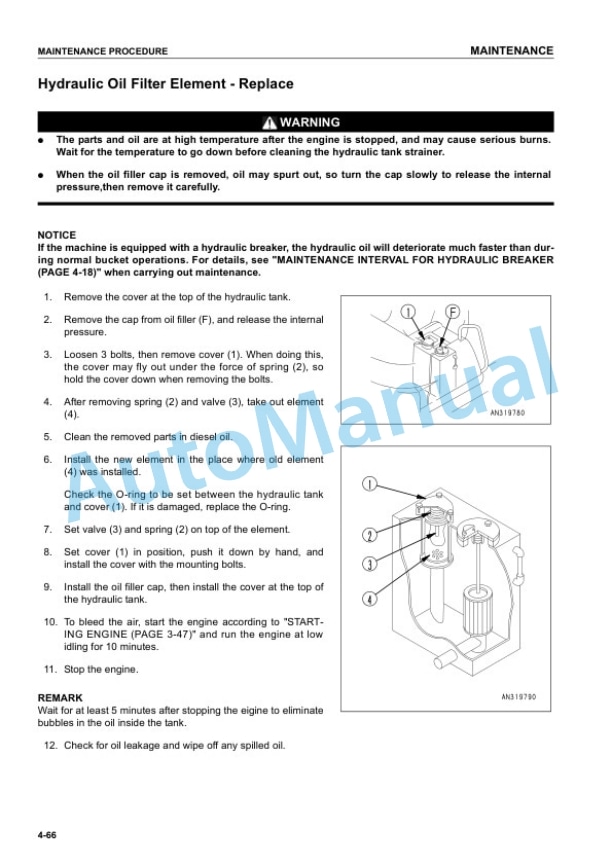

- 5.8. MAINTENANCE PROCEDURE

- 5.8.1. INITIAL 250 HOURS MAINTENANCE (ONLY AFTER THE FIRST 250 HOURS)

- 5.8.2. WHEN REQUIRED

- 5.8.3. CHECK BEFORE STARTING

- 5.8.4. EVERY 50 HOURS MAINTENANCE

- 5.8.5. EVERY 100 HOURS MAINTENANCE

- 5.8.6. EVERY 250 HOURS MAINTENANCE

- 5.8.7. EVERY 500 HOURS MAINTENANCE

- 5.8.8. EVERY 1000 HOURS MAINTENANCE

- 5.8.9. EVERY 2000 HOURS MAINTENANCE

- 5.8.10. EVERY 4000 HOURS MAINTENENCE

- 5.8.11. EVERY 5000 HOURS MAINTENANCE

- 6. SPECIFICATIONS

- 6.1. SPECIFICATIONS

- 7. ATTACHMENTS AND OPTIONS

- 7.1. ATTACHMENTS AND OPTIONS GENERAL INFORAMTION

- 7.1.1. SAFETY FIRST

- 7.1.2. ATTACHMENT INSTALLATION

- 7.2. BUCKET WITH HOOK

- 7.2.1. HOOK CONDITION

- 7.2.2. PROHIBITED OPERATIONS

- 7.3. AIR CONDITIONER

- 7.3.1. CONTROL PANEL

- 7.3.2. AIR CONDITIONER CONTROLS

- 7.3.3. AIR CONDITIONER MAINTENANCE

- 7.4. MACHINE READY FOR ATTACHMENT

- 7.4.1. LOCATIONS

- 7.4.2. HYDRAULIC CIRCUIT

- 7.4.3. ATTACHMENT OPERATIONS

- 7.4.4. ACCUMULATOR

- 7.4.5. LONG TERM STORAGE

- 7.4.6. SPECIFICATIONS

- 7.5. CHANGING MACHINE CONTROLL PATERN (IF PATTERN CHANGE VALVE EQUIPPED)

- 7.5.1. CONTROL PATTERN CHANGE PROCEDURE

- 7.5.2. MACHINE CONTROL PATTERNS

- 7.6. ATTACHMENT GUIDE

- 7.6.1. ATTACHMENT COMBINATIONS

- 7.6.2. SELECTION OF TRACK SHOES

- 7.7. AUTOMATIC GREASING SYSTEM

- 7.7.1. CONTROLLER

- 7.8. RECOMMENDED ATTACHMENT OPERATIONS

- 7.8.1. HYDRAULIC BREAKER

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800