- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu TD-25H Operation and Maintenance Manual OMTD25H00-1E

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OMTD25H00-1E

- Format: PDF

- Size: 2.2MB

- Number of Pages: 170

-

Model List:

- TD-25H

- 1. MAIN MENU

- 2. COVER

- 3. SECTION CONTENTS

- 4. INTRODUCTION

- 4.1. INTRODUCTION

- 4.2. SERIAL NUMBERS

- 5. SAFETY PRECAUTIONS

- 5.1. GENERAL

- 5.2. BEFORE STARTING THE ENGINE

- 5.3. OPERATION

- 5.4. MAINTENANCE

- 5.5. SHUTDOWN

- 5.6. SAFETY PRODUCT GRAPHIC LOCATION

- 5.6.1. SAFETY PRODUCT GRAPHIC

- 6. MACHINE TRANSPORT AND STORAGE

- 6.1. MACHINE TRANSPORT

- 6.1.1. GENERAL

- 6.1.2. TRUCK

- 6.1.3. RAILROAD FLAT CAR

- 6.2. LIFTING A MACHINE ON SLINGS

- 6.3. MOVING A DISABLED MACHINE

- 6.4. MACHINE STORAGE

- 6.4.1. PREPARING FOR STORAGE

- 6.4.2. SERVICING MACHINE DURING STORAGE

- 6.4.3. PREPARING FOR OPERATION AFTER STORAGE

- 7. OPERATING

- 7.1. MACHINE PRECAUTIONS

- 7.2. UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS

- 7.3. INSTRUMENT PANEL

- 7.4. CAB CONTROLS

- 7.5. CONTROLS AND ADJUSTMENT

- 7.5.1. SEAT

- 7.5.2. SEAT BELT

- 7.5.3. ENGINE SPEED AND SHUT DOWN LEVER

- 7.5.4. TRANSMISSION NEUTRAL LOCK LEVER

- 7.5.5. TRANSISSION SHIFT LEVER

- 7.5.6. HAND STEERING LEVERS

- 7.5.7. BRAKE AND DECELERATOR PEDAL

- 7.5.8. BRAKE AND DECELERATOR PEDAL LOCK

- 7.5.9. ELECTRIC SYSTEM MASTER SWITCH

- 7.5.10. EQUIPMENT CONTROL LEVERS

- 7.6. STARTING THE ENGINE

- 7.6.1. NORMAL START

- 7.6.2. ETHER INJECTION START

- 7.6.3. ENGINE START AFTER OIL CHANGE OR PROLONGED STANDSTILL

- 7.7. STOPPING THE ENGINE

- 7.8. TIPS FOR ENGINE SAFEGUARDING

- 7.9. DRIVING THE MACHINE

- 7.10. SHIFTING THE TRANSMISSION

- 7.11. CONVERTER OVERHEATING

- 7.12. STEERING THE MACHINE

- 7.12.1. GRADUAL TURN

- 7.12.2. PIVOT TURN

- 7.13. DOWNGRADE OPERATION

- 7.14. OPERATING OVER AN OBSTRUCTION

- 7.15. STOPPING THE MACHINE

- 7.16. PARKING THE MACHINE

- 7.17. OPERATING THE MOUNTED EQUIPMENT

- 7.17.1. BLADE CONTROL LEVER

- 7.17.1.1. HOLD

- 7.17.1.2. RAISE

- 7.17.1.3. LOWER

- 7.17.1.4. FLOAT

- 7.17.1.5. TILT

- 7.17.1.6. PITCH

- 7.17.2. RIPPER CONTROL LEVERS

- 7.17.2.1. RIPPER SHANK PITCH

- 7.17.2.2. RIPPER RAISE AND LOWER

- 7.17.2.3. PIN PULLER CONTROL LEVER

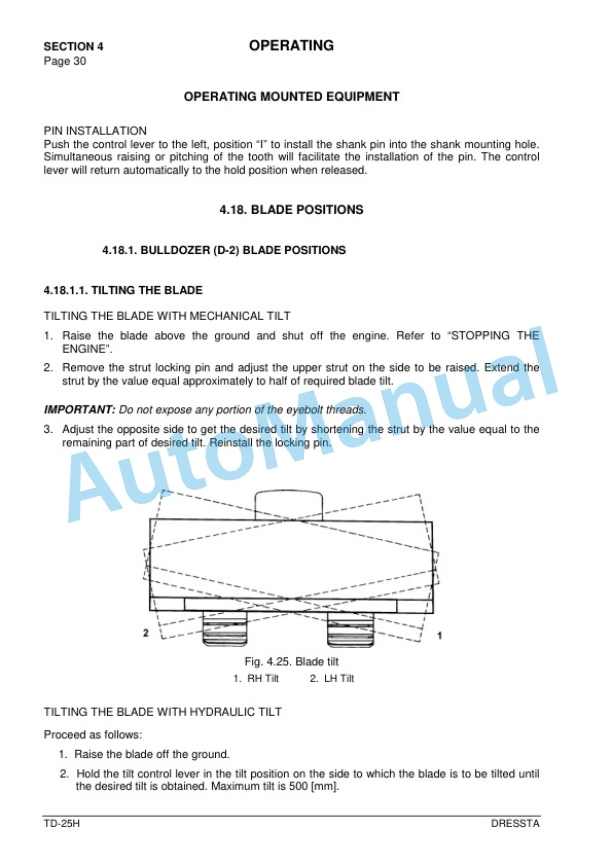

- 7.18. BLADE POSITIONS

- 7.18.1. BULLDOZER BLADE POSITIONS

- 7.18.1.1. TILTING THE BLADE

- 7.18.1.2. PITCHING THE BLADE

- 7.18.1.3. LEVELING THE BLADE

- 7.19. OPERATING TECHNIQUES

- 7.19.1. DIGGING AND CLEARING

- 7.19.2. TRANSPORTING, PILING OR LOADING

- 7.19.3. BREAKING PILES AND SPREADING

- 7.19.4. RIPPING

- 7.19.4.1. PRIOR TO OPERATION

- 7.19.4.2. RIPPING TECHNIQUES

- 7.19.4.3. COLD WEATHER OPERATION

- 7.20. ECONOMICAL OPERATION OF THE MACHINE

- 8. MAINTENANCE

- 8.1. SERVICE PRECAUTIONS

- 8.2. SCHEDULED MAINTENANCE GUIDE

- 8.2.1. GROUD LEVEL INSPECTION

- 8.3. MAINTENANCE AND SERVICE CHART

- 8.3.1. REFILL SPECIFICATIONS AND CAPACITIES CHART

- 8.4. LUBRICATION

- 8.4.1. WHEN SHIPPED

- 8.4.2. WHEN SERVICED

- 8.4.3. SELECTION

- 8.4.4. VISCOSITIES

- 8.4.5. RECOMMENDED LUBRICANT CHART

- 8.5. SEASONAL PREPARATION

- 8.5.1. FUEL SYSTEM

- 8.5.2. COOLING SYSTEM

- 8.5.3. ELECTRIC SYSTEM

- 8.6. AIR CLEANING SYSTEM

- 8.6.1. AIR PRECLEANER

- 8.6.2. AIR CLEANER

- 8.6.2.1. PRIMARY FILTER ELEMENT

- 8.6.2.2. SAFETY FILTER ELEMENT

- 8.6.3. CHECKING AIR INTAKE SYSTEM FOR LEAKS

- 8.7. BELTS

- 8.7.1. VISUAL INSPECTION

- 8.7.2. CHECKING TENSION AND ADJUSTMENT

- 8.7.2.1. CHECKING TENSION AND ADJUSTMENT OF A/C COMPRESSOR BELT

- 8.7.2.2. CHECKING AND ADJUSTMENT OF ALTERNATOR BELT

- 8.7.3. BELT REPLACEMENT

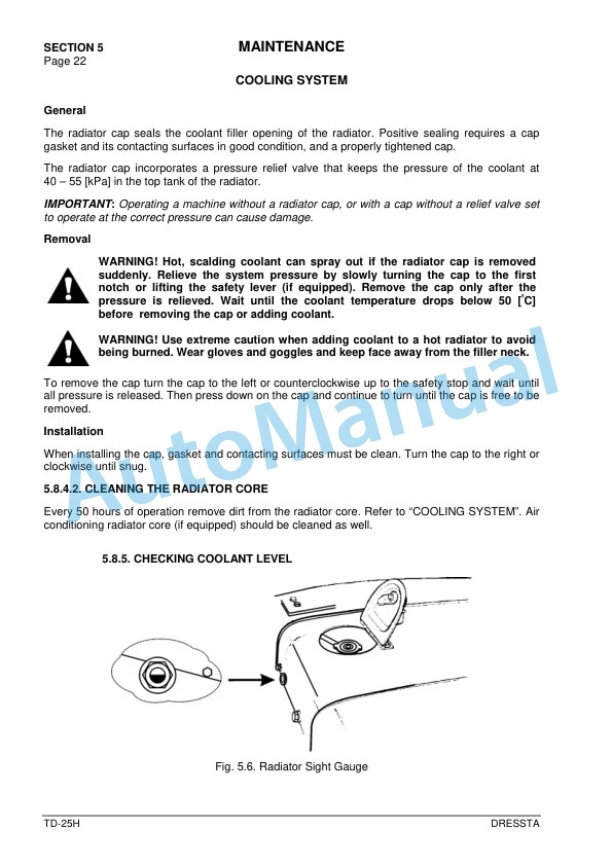

- 8.8. COOLING SYSTEM

- 8.8.1. WATER

- 8.8.2. ANTIFREEZE

- 8.8.3. INHIBITORS/CONDITIONERS

- 8.8.4. RADIATOR CAP

- 8.8.4.1. RADIATOR CAP COVER

- 8.8.4.2. CLEANING THE RADIATOR CORE

- 8.8.5. CHECKING COOLANT LEVEL

- 8.8.6. CHANGING COOLANT

- 8.8.6.1. DRAINING THE SYSTEM

- 8.8.6.2. FILLING THE DRAINED SYSTEM

- 8.8.7. CHANGING THE COOLANT FILTER

- 8.10. ELECTRICAL SYSTEM

- 8.10.1. ELECTRIC WIRES AND CONNECTIONS

- 8.10.2. AUTOMATIC RESET CIRCUIT BREAKER

- 8.10.3. BATTERIES

- 8.11. ENGINE

- 8.11.1. CHECKING THE CRANKCASE OIL

- 8.11.2. CHANGING THE CRANKCASE OIL AND OIL FILTER

- 8.11.3. ETHER INJECTOR

- 8.12. FUEL SYSTEM

- 8.12.1. FILLING THE FUEL TANK

- 8.12.2. FUEL TANK FILLER STRAINER

- 8.12.3. FUEL TANK SHUTOFF VALVE

- 8.12.4. FUEL FITLERS

- 8.12.4.1. FUEL FILTER WATER SEPARATOR DRAIN VALVE

- 8.12.4.2. REPLACING THE FUEL FILTERS

- 8.12.5. DRAINING THE FUEL TANK

- 8.13. HYDRAULIC SYSTEM

- 8.13.1. CHECKING THE OIL LEVEL

- 8.13.2. CHANGING HYDRAULIC OIL

- 8.13.3. REPLACEMENT OF THE RETURN FILTERS AND PILOT FILTER

- 8.13.4. SERVICING THE SUCTION STRAINER AND FILLER STRAINER

- 8.13.5. SERVICING THE RESERVOIR BREATHER

- 8.13.6. VENTING THE HYDRAULIC SYSTEM

- 8.14. LUBRICATING FITTINGS

- 8.15. MOUNTED EQUIPMENT

- 8.15.1. COMPLETE BLADE REMOVAL AND INSTALLATION

- 8.15.2. DIAGONAL STRUTS ADJUSTMENT

- 8.15.3. UPPER STRUT AND TILT CYLINDER ADJUSTMENT

- 8.15.4. PITCH CYLINDER CLEARANCE ADJUSTMENT

- 8.15.5. CHECKING THE BLADE CONDITION

- 8.15.5.1. TRUNNION AND CAP MOUNTING BOLTS

- 8.15.5.2. BLADE CUTTING EDGE AND END BITS MOUNTING BOLTS

- 8.15.5.3. ALLOWABLE WEAR OF CUTTING EDGE AND END BITS AND RIPPER POINTS

- 8.15.6. SERVICING THE RIPPER

- 8.16. SAFETY BELT

- 8.17. FINAL DRIVES

- 8.17.1. CHECKING THE OIL LEVEL

- 8.17.2. CHANGING THE OIL

- 8.18. TRANSMISSION SYSTEM

- 8.18.1. CHECKING THE OIL LEVEL IN REAR MAIN FRAME

- 8.18.2. CHANGING TRANSMISSION SYSTEM OIL

- 8.18.3. SERVICING THE TRANSMISSION SYSTEM PRESSURE FILTERS

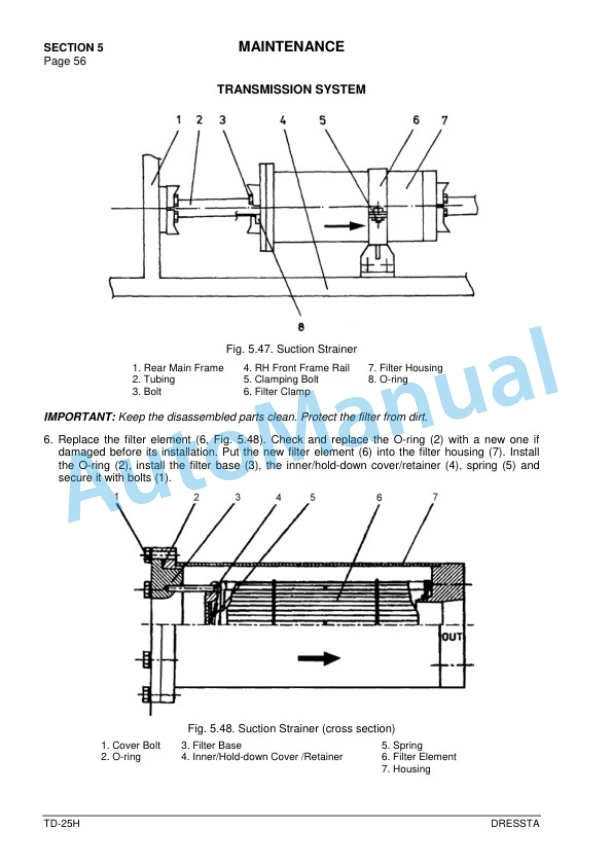

- 8.18.4. SERVICING THE SUCTION STRAINER

- 8.18.5. SERVICING THE TRANSMISSION SCAVENGER STRAINER

- 8.18.6. SERVICING THE BREATHER

- 8.19. UNDERCARRIAGE

- 8.19.1. TRACK SHOE BOLTS

- 8.19.2. EFFECT OF TRACK ADJUSTMENT ON UNDERCARRIAGE WEAR

- 8.19.3. CHECKING THE TENSION

- 8.19.4. ADJUSTING TENSION

- 8.19.5. TRACK FRAME GUIDE

- 8.19.6. PIVOT SHAFT HOUSING

- 8.19.7. FRONT WHEEL GUIDES

- 8.20. ADJUSTING HAND AND FOOT CONTROLS

- 8.21. CAB AND ROPS

- 8.21.1. ROPS CAB/CANOPY AND MOUNTED EQUIPMENT MOUNTING HARDWARE

- 8.21.2. AIR CONDITIONER FILTER CLEANING

- 8.21.3. WINDSHIELD WASHER RESERVOIR

- 9. SPECIFICATIONS

- 9.1. APPLICATION

- 9.2. TECHNICAL DESCRIPTION

- 9.3. SPECIFICATIONS

- 9.3.1. OVERALL DIMENSIONS OF DOZERS

- 9.3.2. ENGINE

- 9.3.3. ELECTRICAL SYSTEM

- 9.3.4. TORQUE CONVERTER

- 9.3.5. TRAVEL SPEEDS

- 9.3.6. TRANSMISSION

- 9.3.7. STEERING DRIVE

- 9.3.8. FINAL DRIVES OPERATION WEIGHTS

- 9.3.9. TRACK FRAMES

- 9.3.10. TRACK CHAINS

- 9.3.11. FUEL CONSUMPTION

- 9.3.12. WEIGHT (APPROXIMATE)

- 9.3.12.1. MAXIMUM PULL FORCE

- 9.3.13. BLADE

- 9.3.14. RIPPER

- 9.4. REFILL CAPACITIES

- 9.5. SPECIAL TORQUES

- 9.6. TORQUE VALUES FOR STANDARD METRIC FASTENERS

- 9.7. TORQUE VALUES FOR STANDARD ENGLISH FASTENERS

- 9.8. TORQUE VALUES FOR SPLIT FLANGE CONNECTIONS

- 9.9. TORQUE VALUES FOR HYDRAULIC TUBES AND FITTINGS

- 9.10. TORQUE VALUES FOR HOSE CLAMPS

- 9.11. TORQUE VALUES FOR AIR CONDITIONING TUBES AND FITTINGS

- 9.12. TORQUE VALUES FOR AIR CONDITIONING ORING CONNECTIONS

- 9.13. LIST OF SERVICE TOOLS

- 9.14. DRIVE TRAIN SCHEMATIC

- 9.15. DRIVE TRAIN HYDRAULIC SYSTEM DIAGRAM

- 9.16. EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 9.17. WIRING DIAGRAM

- 9.18. CAB WIRING DIAGRAM

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF