- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA180PT-3MC Wheel Loader Operation and Maintenance Manual CEAM007602

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM007602

- Format: PDF

- Size: 2.6MB

- Number of Pages: 250

-

Model List:

- WA180PT-3MC Wheel Loader

- 1. INTRODUCTION

- 1.1. FORWARD

- 1.2. SAFETY INFORMATION

- 1.3. INTRODUCTION

- 1.3.1. INTENDED USE

- 1.3.2. FEATURES

- 1.3.3. BREAKING IN A NEW MACHINE

- 1.4. LOCATION OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.4.1. MACHINE SERIAL NO. PLATE POSITION

- 1.4.2. ENGINE SERIAL NO. PLATE POSITION

- 1.4.3. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 1.5. CONTENTS

- 2. SAFETY

- 2.1. GENERAL PRECAUTIONS

- 2.1.1. SAFETY RULES

- 2.1.2. SAFETY FEATURES

- 2.1.3. UNAUTHORIZED MODIFICATION

- 2.1.4. CLOTHING AND PERSONAL PROTECTIVE ITEMS

- 2.1.5. ALWAYS APPLY LOCK WHEN LEAVING OPERATORS SEAT

- 2.1.6. MOUNTING AND DISMOUNTING

- 2.1.7. FIRE PREVENTION FOR FUEL AND OIL

- 2.1.8. PRECAUTIONS WHEN HANDLING AT HIGH TEMPERATURES

- 2.1.9. ASBESTOS DUST HAZARD PREVENTION

- 2.1.10. CRUSHING OR CUTTING PREVENTION

- 2.1.11. FIRE EXTINGUISHER AND FIRST AID KIT

- 2.1.12. PRECAUTIONS WHEN USING ROPS

- 2.1.13. PRECAUTIONS FOR ATTACHMENTS

- 2.1.14. PRECAUTION WHEN HANDLING ACCUMULATOR

- 2.2. PRECAUTIONS DURING OPERATION

- 2.2.1. BEFORE STARTING ENGINE

- 2.2.2. AFTER STARTING ENGINE

- 2.2.3. TRANSPORTATION

- 2.2.4. BATTERY

- 2.2.5. TOWING

- 2.3. PRECAUTIONS FOR MAINTENANCE

- 2.3.1. BEFORE CARRYING OUT MAINTENANCE

- 2.3.2. DURING MAINTENANCE

- 2.3.3. TIRES

- 2.4. SAFETY LABELS

- 2.4.1. SAFETY LABEL LOCATIONS

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. EXTERIOR VIEW OF MACHINE

- 3.1.2. VIEW OF CONTROLS AND GAUGES

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. METERS AND LAMPS

- 3.2.2. SWITCHES (ALL MODELS)

- 3.2.3. SWITCHES (MODELS WITH CAB)

- 3.2.4. CONTROL LEVERS AND PEDALS

- 3.2.5. MISCELLANEOUS

- 3.2.6. FUSES

- 3.3. WALKAROUND CHECK

- 3.4. STARTING ENGINE PRECHECK

- 3.4.1. CHECK COOLANT LEVEL, ADD COOLANT

- 3.4.2. CHECK FUEL LEVEL, ADD FUEL

- 3.4.3. CHECK DUST INDICATOR

- 3.4.4. CHECK THE BRAKE OIL TANK

- 3.4.5. CHECK AND ADD ENGINE OIL

- 3.4.6. DRAIN THE FUELWATER SEPARATOR

- 3.4.7. DRAIN THE FUEL SEDIMENT STRAINER

- 3.4.8. CHECK THE ELECTRICAL WIRING

- 3.4.9. HANDLING TIRES

- 3.4.10. INSPECTING RIMS

- 3.4.11. CHECKING TIRE PRESSURE

- 3.4.12. CHECK MONITOR PANEL

- 3.4.13. CHECK EFFECT PARKING BRAKE

- 3.4.14. CHECK WHEEL BRAKES

- 3.4.15. CHECK SOUND OF HORN AND BACKUP ALARM

- 3.4.16. CHECK FLASHING OF LAMPS, CHECK FOR DIRT AND DAMAGE

- 3.4.17. CHECK ENGINE EXHAUST COLOR AND SOUND

- 3.4.18. CHECK OPERATION OF GAUGES

- 3.4.19. CHECK STEERING WHEEL PLAY, CHECK STEERING OPERATION

- 3.4.20. CHECK REAR VIEW MIRROR

- 3.4.21. CHECK LOCK OF CAB DOOR (MACHINES EQUIPPED WITH CAB)

- 3.4.22. OPERATORS SEAT

- 3.4.23. BEFORE STARTING ENGINE CHECK

- 3.5. STARTING ENGINE CHECK

- 3.5.1. NORMAL STARTING PROCEDURES (IN COLD AND WARM CONDITIONS)

- 3.5.2. STARTING PROCEDURES AFTER EXTENDED SHUTDOWN OR OIL CHANGE

- 3.5.3. STARTING PROCEDURES AFTER CHANGING FUEL FILTERS

- 3.5.4. STARTING PROCEDURES AFTER RUNNING OUT OF FUEL

- 3.5.5. AFTER STARTING ENGINE OPERATION CHECKS

- 3.6. OPERATING THE MACHINE

- 3.6.1. MOVING THE MACHINE

- 3.6.2. CHANGING GEAR SPEED

- 3.6.3. CHANGING DIRECTION (FORWARDREVERSE)

- 3.6.4. TURNING THE MACHINE

- 3.6.5. OPERATING THE WORK EQUIPMENT (WITH BUCKET TOOL)

- 3.6.6. OPERATING THE WORK EQUIPMENT (WITH FORK TOOL)

- 3.6.7. OPERATION OF WORK EQUIPMENT (WITH MULTIPURPOSE BUCKET)

- 3.6.8. OPERATION OF WORK EQUIPMENT (WITH MATERIAL HANDLING ARM)

- 3.6.9. HYDRAULIC QUICK COUPLER

- 3.6.10. UNCOUPLING FROM THE ATTACHMENT

- 3.6.11. TYPICAL WORK OPERATIONS

- 3.6.12. MULTIPURPOSE BUCKET

- 3.6.13. MATERIAL HANDLING ARM

- 3.6.14. PRECAUTIONS FOR OPERATION

- 3.6.15. ADJUSTING WORK EQUIPMENT POSTURE

- 3.6.16. STOPPING AND PARKING MACHINE

- 3.6.17. CHECKS AFTER COMPLETION OF OPERATION

- 3.6.18. STOPPING ENGINE

- 3.6.19. CHECKS AFTER STOPPING ENGINE

- 3.6.20. LOCKING THE MACHINE

- 3.7. TRANSPORTING THE MACHINE

- 3.7.1. LOADING AND UNLOADING

- 3.7.2. PRECAUTIONS FOR LOADING

- 3.7.3. PRECAUTIONS FOR LIFTING THE VEHICLE

- 3.8. COLD WEATHER OPERATIONS

- 3.8.1. PRECAUTIONS FOR LOW TEMPERATURE

- 3.8.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 3.8.3. AFTER COLD WEATHER

- 3.9. LONGTERM STORAGE

- 3.9.1. BEFORE STORAGE

- 3.9.2. DURING STORAGE

- 3.9.3. AFTER STORAGE

- 3.10. TROUBLESHOOTING

- 3.10.1. MACHINE RUNS OUT OF FUEL

- 3.10.2. TOWING THE MACHINE

- 3.10.3. IF BATTERY IS DISCHARGED

- 3.11. OTHER TROUBLE

- 3.11.1. ELECTRICAL SYSTEM

- 4. MAINTENANCE

- 4.1. GUIDES TO MAINTENANCE

- 4.2. OUTLINES OF SERVICE

- 4.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 4.2.2. FUEL INJECTION PUMP

- 4.2.3. OUTLINE OF ELECTRIC SYSTEM

- 4.3. WEAR PARTS LIST

- 4.4. USE OF FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 4.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 4.4.2. ENGINE OIL SPECIFICATIONS

- 4.4.3. DIESEL FUEL SPECIFICATIONS

- 4.4.4. COOLANT SPECIFICATIONS

- 4.5. STANDARD TIGHTENING TORQUE FOR BOLTS AND NUTS

- 4.5.1. INTRODUCTION OF NECESSARY TOOLS

- 4.5.2. TORQUE LIST

- 4.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 4.6.1. SAFETY CRITICAL PARTS

- 4.7. MAINTENANCE SCHEDULE CHART

- 4.7.1. MAINTENANCE SCHEDULE CHART

- 4.8. SERVICE PROCEDURES

- 4.8.1. INITIAL 250 HOURS SERVICE

- 4.8.2. WHEN REQUIRED

- 4.8.3. CHECK BEFORE STARTING

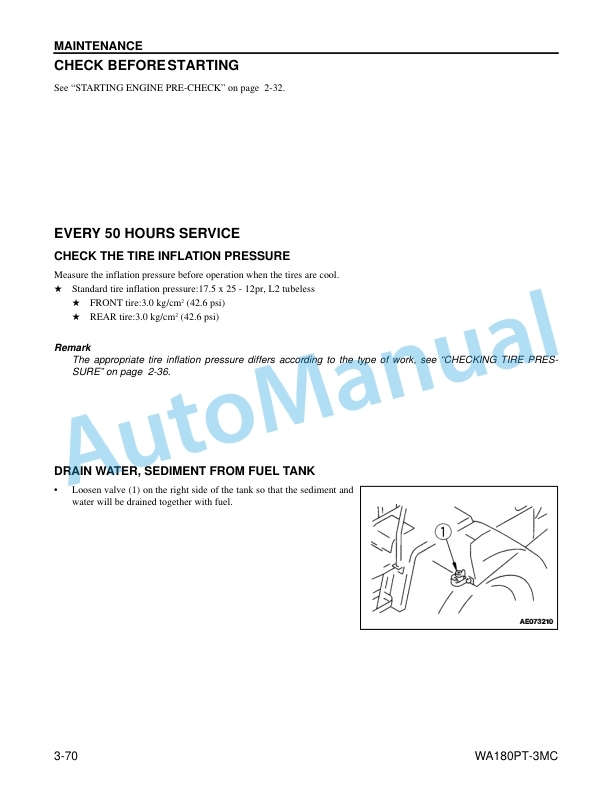

- 4.8.4. EVERY 50 HOURS SERVICE

- 4.8.5. EVERY 100 HOURS SERVICE

- 4.8.6. EVERY 250 HOURS SERVICE

- 4.8.7. EVERY 500 HOURS SERVICE

- 4.8.8. EVERY 1000 HOURS SERVICE

- 4.8.9. EVERY 2000 HOURS SERVICE

- 5. SPECIFICATIONS

- 5.1. WA180PT3MC WITH BUCKET ATTACHMENT

- 5.2. WA180PT3MC WITH FORK ATTACHMENT

- 5.3. WA180PT3MC WITH MATERIAL HANDLING ARM

- 6. OPTIONS, ATTACHMENTS

- 6.1. AVAILABLE ATTACHMENTS

- 6.2. BUCKETS AND TIRES SELECTION

- 6.3. AIR CONDITIONING

- 6.3.1. GENERAL LOCATIONS AND FUNCTION OF CONTROL PANEL

- 6.3.2. METHOD OF OPERATION

- 6.3.3. COOL BOX

- 6.4. ECSS (ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM)

- 6.4.1. STRUCTURE AND FUNCTION OF ECSS

- 6.4.2. METHOD OF OPERATING ECSS

- 6.4.3. PRECAUTIONS WHEN OPERATING ECSS SWITCH

- 6.4.4. ACCUMULATOR PRECAUTIONS

- 6.4.5. RADIO

- 7. Blank Page

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF