- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA420-1LC Wheel Loader Operation and Maintenance Manual SEAMU424KD10

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAMU424KD10

- Format: PDF

- Size: 10.7MB

- Number of Pages: 171

-

Model List:

- WA420-1LC Wheel Loader

- 1. MAIN MENU

- 2. CONTENTS

- 3. OPERATION

- 3.1. GENERAL LOCATIONS AND SPECIFICATIONS

- 3.1.1. GENERAL LOCATIONS

- 3.1.2. PERFORMANCE

- 3.1.3. ENGINE

- 3.2. INSTRUMENTS AND CONTROLS

- 3.2.1. MONITOR PANEL

- 3.2.1.1. CHECK MONITOR GROUP

- 3.2.1.2. CAUTION MONITOR GROUP

- 3.2.1.3. CAUTION MONITOR GROUP

- 3.2.1.4. METER GROUP PILOT DISPLAY

- 3.2.2. SWITCHES

- 3.2.2.1. TRANSMISSION CUTOFF SELECTOR SWITCH

- 3.2.2.2. ETHER START SWITCH

- 3.2.2.3. HORN BUTTON

- 3.2.2.4. HAZARD LAMP SWITCH

- 3.2.2.5. PARKING BRAKE SWITCH

- 3.2.2.6. WORKING LAMP SWITCH

- 3.2.2.7. STARTING SWITCH

- 3.2.2.8. LAMP SWITCHES

- 3.2.2.9. ROOM LAMP SWITCH

- 3.2.2.10. CIGARETTE LIGHTER

- 3.2.2.11. KICKDOWN SWITCH

- 3.2.2.12. FRONT WIPER SWITCH

- 3.2.2.13. REAR WlPER SWITCH

- 3.2.2.14. LEVERS AND PEDALS

- 3.2.2.15. DIRECTIONAL LEVER

- 3.2.2.16. SPEED CONTROL LEVER

- 3.2.2.17. SPEED CONTROL LEVER STOPPER

- 3.2.2.18. STEERING COLUMN TILT LEVER

- 3.2.2.19. ACCELERATOR PEDAL

- 3.2.2.20. BRAKE PEDALS

- 3.2.2.21. LIFT ARM CONTROL LEVER

- 3.2.2.22. BUCKET CONTROL LEVER

- 3.2.2.23. SAFETY LOCK

- 3.2.2.24. AIR CLEANER SERVICE INDICATOR

- 3.2.2.25. SAFETY BAR

- 3.2.2.26. WORK EQUIPMENT CONTROL LEVER

- 3.2.2.27. CIRCUIT BREAKER (MAIN)

- 3.2.2.28. DOOROPEN LOCK

- 3.2.2.29. HOOD TILT LOCK

- 3.2.2.30. FUSE BOX

- 3.2.2.31. OPERATORS SEAT

- 3.2.2.32. RIGHT SIDE ARMREST

- 3.2.3. SEAT BELT

- 3.3. CHECK BEFORE STARTING

- 3.3.1. WALKAROUND CHECK

- 3.3.2. CHECK MONITOR PANEL

- 3.3.3. CHECK AND REFILL COOLANT

- 3.3.4. CHECK OIL LEVEL AND REFIL IN THE ENGINE OIL PAN

- 3.3.5. CHECK FUEL LEVEL AND REFILL FUEL

- 3.3.6. CHECK AIR CLEANER SERVICE INDICATOR

- 3.3.7. DRAIN WATER FROM AIR TANK

- 3.3.8. CHECK FOR SEDIMENT AND WATER IN THE WATER SEDIMENTOR

- 3.3.9. FUELWATER SEPARATOR DRAINING WATER AND SEDIMENT

- 3.3.10. DRIVE BELT INSPECTION

- 3.3.11. FAN INSPECTlON

- 3.4. OPERATlNG YOUR MACHINE

- 3.4.1. BEFORE STARTING THE ENGINE

- 3.4.2. TO START THE ENGINE

- 3.4.2.1. SPECIAL STARTING

- 3.4.3. CHECKS AFTER STARTING

- 3.4.4. TO MOVE THE MACHINE OFF

- 3.4.5. CHANGING GEAR SPEED

- 3.4.6. CHANGING DIRECTION

- 3.4.7. TURNING

- 3.4.8. TO STOP THE MACHINE

- 3.4.9. TO STOP THE ENGINE

- 3.4.10. MAXIMUM DEPTH OF WATER

- 3.4.11. IF WHEEL BRAKE DOES NOT WORK

- 3.4.12. PRECAUTIONS WHEN DRIVING UP OR DOWN SLOPES

- 3.4.12.1. LOWER THE CENTER OF GRAVIIY WHEN TURNING

- 3.4.12.2. BRAKING ON DOWNHU SLOPES

- 3.4.12.3. IF ENGINE STOPS

- 3.4.13. PROPER BUCKET AND TIRE

- 3.5. ADJUSTMENT OF WORK EQUIPMENT

- 3.5.1. ADJUSTING BOOM KICKOUT

- 3.5.2. ADJUSTING BUCKET POSITIONER

- 3.5.3. BUCKET LEVEL INDICATOR

- 3.6. HANDLING THE TIRES

- 3.6.1. PRECAUTIONS WHEN HANDLING ilRES

- 3.6.2. PRECAUTIONS WHEN DRIVING MACHINE

- 3.6.3. TIRE PRESSURE

- 3.6.3.1. INFLATING TIRES

- 3.7. TOWING

- 3.7.1. TOWING THE MACHINE

- 3.7.1.1. WHEN ENGINE CAN BE USED

- 3.7.1.2. WHEN ENGINE CANNOT BE USED

- 3.7.2. RELEASING PARKING BRAKE

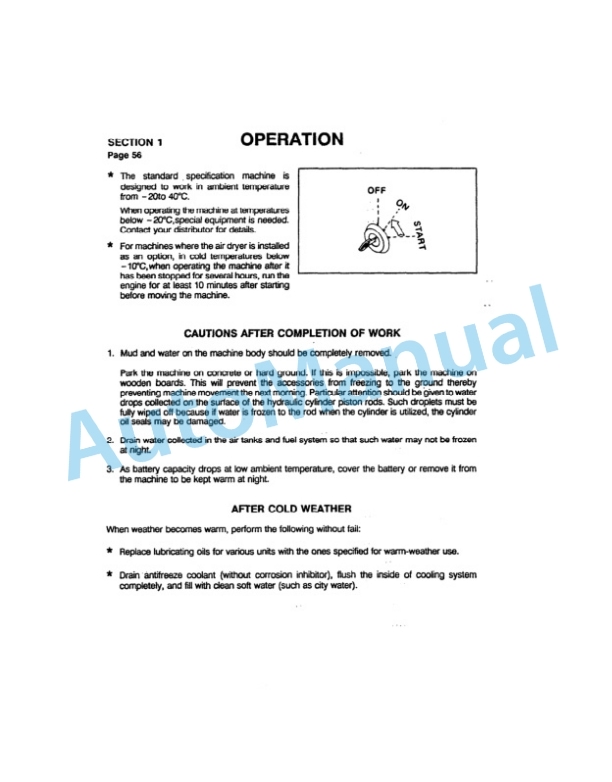

- 3.8. COLD WEATHER OPERATION

- 3.8.1. PREPARATION FOR LOW TEMPERATURE

- 3.8.1.1. FUEL AND LUBRICANTS

- 3.8.1.2. COOLANT

- 3.8.1.3. BATTERY

- 3.8.2. STARTING IN COLD WEATHER

- 3.8.3. CAUTIONS AFTER COMPLETION OF WORK

- 3.8.4. AFTER COLD WEATHER

- 4. MAINTENANCE

- 4.1. PERIODIC MAINTENANCE

- 4.2. BLEEDING AIR FROM CIRCUIT

- 4.2.1. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 4.2.2. BLEEDING AIR FROM FUEL SYSTEM

- 4.2.2.1. LOW PRESSURE LINES AND FUEL FILTER(S) VENTING

- 4.2.2.2. HIGH PRESSURE LINESVENTING

- 4.3. PERIODICAL PART REPLACEMENT

- 4.4. MAINTENANCE TABLE

- 4.5. OIL FILLER AND LEVEL GAUGE POSITIONS

- 4.6. CHECK BEFORE STARTING

- 4.7. EVERY 50 HOURS SERVICE

- 4.7.1. FUEL TANK

- 4.7.2. TIRE

- 4.8. EVERY 100 HOURS SERVICE

- 4.8.1. HYDRAULIC TANK

- 4.8.2. LUBRICATING

- 4.8.3. AIR CONDITIONER FILTERIF EQUIPPED

- 4.9. INITIAL 250 HOURS SERVICE

- 4.9.1. TRANSMlSSlON OIL FILTER

- 4.10. EVERY 250 HOURS SERVICE

- 4.10.1. ENGINE OIL PAN AND FfLTER

- 4.10.2. AIR INTAKE SYSTEM INSPECTION

- 4.10.3. AIR CONDlTlONER COMPRESSOR BELTIF EQUIPPED

- 4.10.4. WHEEL HUB NUTS

- 4.10.5. LUBRICATING

- 4.10.6. CHECK ELECTROLYTE LEVEL IN BATTERY

- 4.11. EVERY 500 HOURS SERVICE

- 4.11.1. FUEL FILTERS

- 4.11.2. TRANSMISSION OIL FILTER

- 4.11.3. LUBRICATING

- 4.11.4. AIR DRYER

- 4.11.5. ANTIFREEZE CONCENTRATION CHECK

- 4.11.6. COOLANT ADDITIVE CONCENTRATION

- 4.11.7. COOLANT FILTER

- 4.12. EVERY 1000 HOURS SERVICE

- 4.12.1. TRANSMISSION CASE AND STRAINER

- 4.12.2. TRANSMISSION CASE BREATHER

- 4.12.3. LUBRICATING

- 4.12.4. ENGINE VALVES

- 4.12.5. DRIVE BELT TENSION CHECK

- 4.12.6. DRIVE BELT, TENSIONER BEARING AND FAN HUB INSPECTION

- 4.13. EVERY 2000 HOURS SERVICE

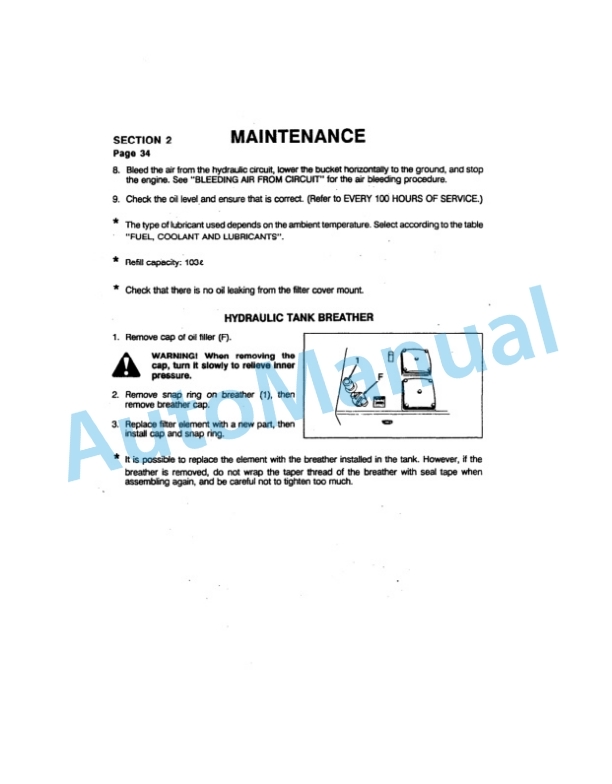

- 4.13.1. HYDRAULIC TANK AND FILTER

- 4.13.2. HYDRAULlC TANK BREATHER

- 4.13.3. DRIVE AXLES

- 4.13.4. AIR CONDITIONER FILTER IF EQUIPPED

- 4.13.5. BRAKE DISC

- 4.13.6. INTERNAL PART OF AIR DRYER

- 4.13.7. COOLANT CHANGE AND FLUSHING THE SYSTEM

- 4.13.7.1. COOLANT

- 4.13.7.2. DCA4 UNIT MAINTENANCE GUIDE

- 4.13.8. VlBRATlON DAMPER INSPECTION.

- 4.13.9. AIR COMPRESSOR INSPECTlON

- 4.13.9.1. AIR COMPRESSOR DISCHARGE INSPECTION

- 4.13.9.2. AIR COMPRESSOR lNTAKE INSPECTION

- 4.14. WHEN REQUIRED

- 4.14.1. CHECK, CLEAN AND REPLACE AIR CLEANER ELEMENT

- 4.14.1.1. CHECKING

- 4.14.1.2. CLEANING OR REPLACING OUTER ELEMENT

- 4.14.1.3. REPLACING INNER ELEMENT

- 4.14.1.4. CLEANING OUTER ELEMENT

- 4.14.2. CHECK AND REFILL TRANSMISSION OIL

- 4.14.3. CLEAN RADlATOR TIRES

- 4.14.4. CHECK AND REFILL DRIVE AXLE OIL

- 4.14.5. CLEAN DRIVE AXLE HOUSING BREATHER

- 4.14.6. CLEAN AIR CONDlTlONER CONDENSERIF EQUIPPED

- 4.14.7. CHECK AIR CONDlTlONER REFRIGERANT CHARGEIF EQUIPPED

- 4.14.8. LUBRICATING

- 4.14.9. CHECK AND REFILL WINDOW WASHING FLUID

- 4.14.10. WATER SEDIMENTOR

- 4.14.11. REPLACING BUCKET TEETH

- 4.14.11.1. IF THE BUCKET IS EQUIPPED WITH BOLTON TOOTH

- 4.14.11.2. IF THE BUCKET IS EDUIPPED WITH BOLTON TOOTH

- 4.14.11.3. IF THE BUCKET IS EQUIPPED WITH TIP TOOTH

- 4.15. ADJUSTMENT

- 4.15.1. ADJUSTING PARKING BRAKE

- 4.15.2. ADJUSTING LENGTH OF LEVER

- 4.16. TROUBLE SHOOTING GUIDE

- 4.16.1. ELECTRICAL SYSTEM

- 4.16.1.1. HYDRAULIC SYSTEM

- 4.17. SERVICE METER

- 4.18. MACHINE AND ENGINE SERIAL NUMBERS

- 4.19. FUEL, COOLANT AND LUBRICANTS

- 4.20. MEMORANDA

- 5. SAFETY AND OPERATION

- 5.1. SAFETY HINTS

- 5.1.1. OPERATION

- 5.1.1.1. GENERAL

- 5.1.1.2. CHECKING JOBSITE CONDITIONS

- 5.1.2. BEFORE STARTING OPERATION

- 5.1.2.1. CHECK BEFORE STARTING

- 5.1.2.2. PRECAUTIONS WHEN GETTING ON THE MACHINE

- 5.1.2.3. PRECAUTIONS WHEN STARTING THE ENGINE

- 5.1.2.4. CHECKS AFTER STARTING THE ENGINE

- 5.1.3. DURING OPERATION

- 5.1.3.1. ATTENTlON TO SURROUNDINGS

- 5.1.3.2. RESTRICTIONS CREATED BY JOBSITE

- 5.1.4. PARKING

- 5.2. PRECAUTIONS FOR MAINTENANCE

- 5.2.1. GENERAL

- 5.2.2. BEFORE MAINTENANCE

- 5.2.3. DURING MAINTENANCE

- 5.2.4. MISCELLANEOUS

- 5.3. BUCKET OPERATION

- 5.3.1. EXCAVATION

- 5.3.1.1. PRECAUTIONS WHEN SCOOPING UP MATERIALS

- 5.3.2. LEVELING

- 5.3.3. LOAD AND CARRY OPERATIONS

- 5.3.4. LOADING

- 5.3.4.1. CROSS DRIVE LOADING

- 5.3.4.2. VSHAPE LOADING

- 5.4. OPERATING THE CAB HEATER

- 5.4.1. EQUIPMENT ON CONTROL PANEL

- 5.4.1.1. FAN SPEED SWITCH

- 5.4.1.2. TEMPERATURE CONTROL LEVER

- 5.4.1.3. AIR INTAKE SELECTOR LEVER

- 5.5. METHOD OF OPERATlON

- 5.6. OPERATING THE AIR CONDITIONERIF EQUIPPED

- 5.6.1. EQUIPMENT ON CONTROL PANEL

- 5.6.1.1. FAN SPEED SWITCH

- 5.6.1.2. AIR CONDITIONER SWITCH

- 5.6.1.3. AIR INTAKE SELECTOR LEVER

- 5.6.1.4. TEMPERATURE CONTROL LEVER

- 5.6.1.5. PRECAUTIONS FOR USING AIR CONDITIONER

- 5.6.1.6. HANDLING THE AIR CONDITIONER IN SEASON

- 5.6.1.7. HANDLING THE AIR CONDITIONER IN OFFSEASONS

- 5.7. LOCKING CAP

- 5.8. HANDLING OF BATTERY

- 5.8.1. PRECAUTIONS FOR CHARGING BATTERY

- 5.8.2. REMOVAL AND INSTALLATION OF BATTERY

- 5.8.3. STARTING ENGINE WITH A BOOSTER CABLE

- 5.9. COOLANT AND LUBRICANTS

- 5.10. MEMORANDA

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF