- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA600-6 Wheel Loader Field Assembly Manual GEN00036-06

$20.00

- Type Of Manual: Field Assembly Manual

- Manual ID: GEN00036-06

- Format: PDF

- Size: 34.2MB

- Number of Pages: 113

-

Model List:

- WA600-6 Wheel Loader

- 1. Cover

- 2. Block outline

- 3. Principal component dimension table

- 4. Work space layout

- 5. General assembly schedule

- 6. List of equipment, jigs, tools and consumables

- 7. Oil, grease and paints

- 8. Assembly procedure

- 8.1. Oil and coolant

- 8.2. Oil and coolant capacity

- 8.3. Setting the front axle and bare machine to stationary position

- 8.4. Installing the front axle

- 8.5. Connecting the drive shaft

- 8.6. Connecting the brake pipe

- 8.7. Connecting the brake pipe (Brake cooling specification)

- 8.8. Installing tire and rim assembly

- 8.9. Installing step

- 8.10. Installing cab (1)

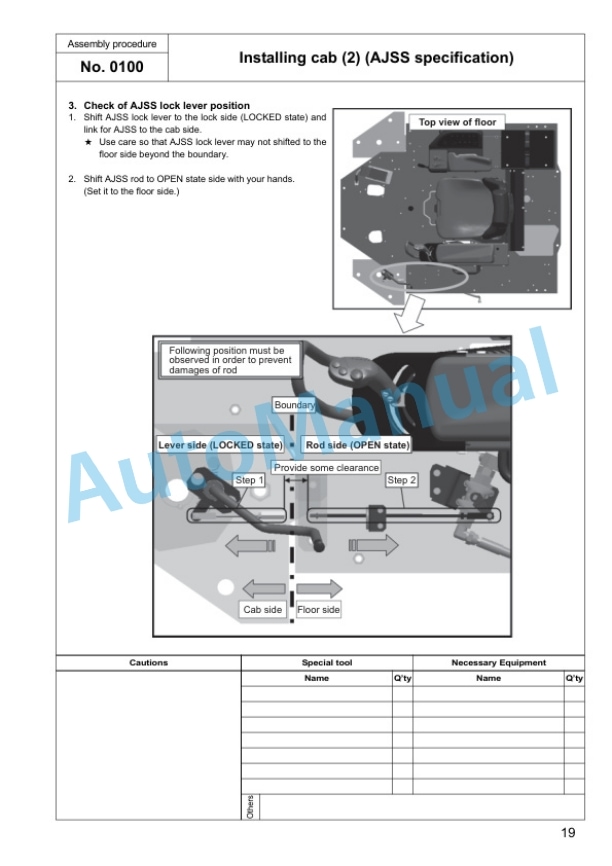

- 8.11. Installing cab (2) (AJSS specification)

- 8.12. Installing cab (2) (Steering wheel specification)

- 8.13. Installing cab (2) (AJSS and steering wheel specification)

- 8.14. Installing cab (3)

- 8.15. Installing cab (4) (AJSS specification)

- 8.16. Installing cab (4) (Steering wheel specification)

- 8.17. Installing cab (5) (Steering wheel specification)

- 8.18. Installing cab (6) (AJSS and steering wheel specification)

- 8.19. Installing cab harness (1/2)

- 8.20. Installing cab harness (2/2)

- 8.21. Installing cab duct (1/4)

- 8.22. Installing cab duct (2/4)

- 8.23. Installing cab duct (3/4)

- 8.24. Installing cab duct (4/4)

- 8.25. Installation of yellow rotary lamp

- 8.26. Installation of undercab cover

- 8.27. Installing front fender

- 8.28. Installing front light support and connection

- 8.29. Installing muffler stack and mirror

- 8.30. Installing counterweight (Standard and 1 ton heavier counterweight specifications)

- 8.31. Installing counterweight (Load and carry specification)

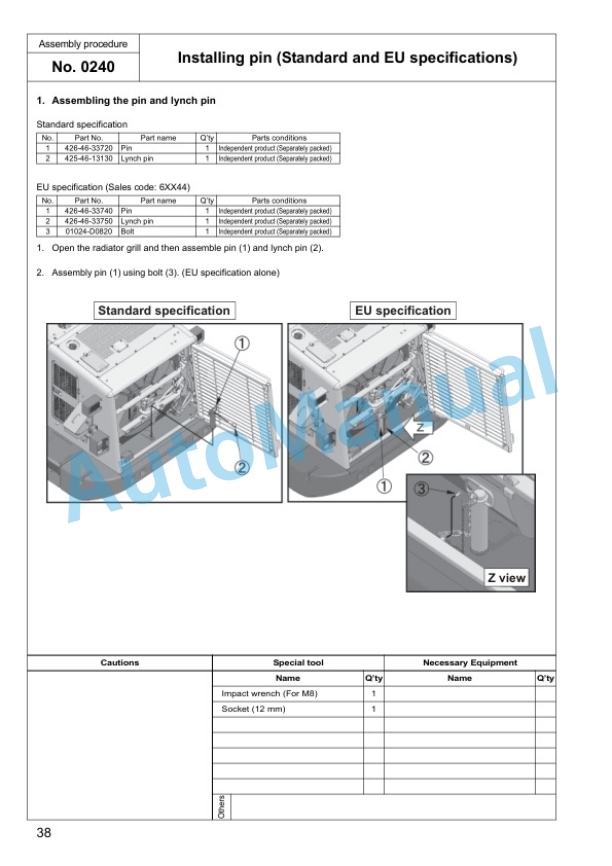

- 8.32. Installing pin (Standard and EU specifications)

- 8.33. Installing rear access ladder and L.H. platform

- 8.34. Installation of platform (R.H.) support

- 8.35. Installing the left handrail

- 8.36. Installing right platform and R.H. handrail

- 8.37. Installing fire extinguisher

- 8.38. Installing the rear fender mudguard plate

- 8.39. Installing rear fender

- 8.40. Installing cab undercover

- 8.41. Checking of sections

- 8.42. Air bleeding of work equipment hydraulic circuit and respective cylinders

- 8.43. Starting engine (1/2)

- 8.44. Starting engine (2/2)

- 8.45. Bleeding air from brake system

- 8.46. Installation of boom and bell crank assembly (Preparation for connection of bucket cylinder)

- 8.47. Installation of boom and bell crank assembly (Preparation for connection of lift cylinder)

- 8.48. Installation of boom and bell crank assembly (1)

- 8.49. Installation of boom and bell crank assembly (2)

- 8.50. Connection of autogreasing boom piping (Autogreasing spec.)

- 8.51. Preparation for connection of bucket cylinder

- 8.52. Installing bucket cylinder (Bell crank side)

- 8.53. Preparation for installation of bucket

- 8.54. Installation of bucket (1/3)

- 8.55. Installation of bucket (1) (Autogreasing spec.)

- 8.56. Installing bucket (2/3)

- 8.57. Installation of bucket (2) (Autogreasing spec.)

- 8.58. Installation of bucket (2) (Autogreasing spec.)

- 8.59. Installation of bucket (3/3)

- 8.60. Greasing (1st time)

- 8.61. Greasing (1st time) Autogreasing spec.

- 8.62. Installing lift arm positioner

- 8.63. Contents of adjustment items

- 8.64. Setting of machine monitor

- 8.65. Adjustment of work equipment controller lift arm angle

- 8.66. Adjustment of work equipment EPC starting current (1/2)

- 8.67. Adjustment of work equipment EPC starting current (2/2)

- 8.68. Adjustment of bucket positioner (1/2)

- 8.69. Adjustment of bucket positioner (2/2)

- 8.70. Adjustment of load meter lift arm angle

- 8.71. Load meter noload calibration

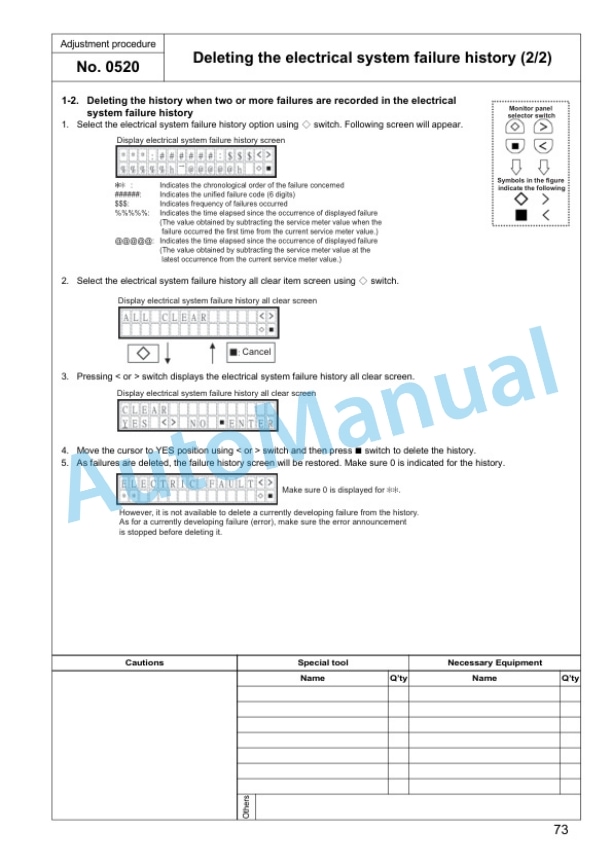

- 8.72. Deleting the electrical system failure history (1/2)

- 8.73. Deleting the electrical system failure history (2/2)

- 8.74. Installing the floor mat (AJSS specification)

- 8.75. Installing the floor mat (Steering wheel specification)

- 8.76. Runningin procedure (1/2)

- 8.77. Runningin procedure (2/2)

- 8.78. Greasing (2nd time)

- 8.79. Greasing (2nd time) Autogreasing spec.

- 8.80. Adding grease with autogreasing pump Autogreasing spec.

- 8.81. Setting of autogreasing pump controller Autogreasing spec.

- 8.82. Touch up work

- 8.83. On use of starter kit (dummy harness) and precaution on its use

- 8.84. Starter kit (dummy harness) assembling procedure

- 8.85. Check tire pressure and inflate tire

- 9. Appendix Machine check sheet for field assembly

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF