Bomag BM 2000-60 Cold Milling Machine Service Manual 00891036

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00891036

- Format: PDF

- Size: 56.5MB

- Number of Pages: 792

- Serial Number:

82183613

-

Model List:

- BM 2000-60 Cold Milling Machine

- 1. BM 2000/60

- 2. Cold Milling Machine

- 3. Introduction

- 4. Safety regulations

- 5. General repair instructions

- 6. Tightening torques

- 7. Technical data

- 8. Maintenance chart

- 9. Table of fuels and lubricants

- 10. Fuels and lubricants

- 11. Understanding circuit diagrams

- 12. Terminal designations

- 13. Current and voltage

- 14. Resistance

- 15. Series / parallel connection

- 16. Ohms law

- 17. Electrical energy

- 18. Formula diagram

- 19. Logical base gates

- 20. Metrology

- 21. Diodes, relays, fuses

- 22. Batteries

- 23. Threephase generator

- 24. Electric starter

- 25. Special tools, electrics

- 26. Component overview

- 27. Drivers stand

- 28. Control console, rear right

- 29. Control console, rear left

- 30. Control console, front right

- 31. Control console, front left

- 32. Control console for auxiliary control

- 33. Engine hood control console

- 34. Loading conveyor belt

- 35. Steering limitation, front

- 36. Middle position, rear steering

- 37. Operating conditions for rear steering

- 38. Height limitation, rear

- 39. Operating conditions for rear posts

- 40. High pressure sensors for travel/conveyor belt pump

- 41. Pressure sensor for steering / working hydraulics

- 42. Pressure sensor for clutch pressure

- 43. Pressure sensor for fan circuit

- 44. Differential pressure switch for hydraulic oil filter

- 45. Pressure switch for water sprinkling system

- 46. Operating condition for sprinkling system

- 47. Limit switch on scraper

- 48. Operating conditions for scraper

- 49. Rope sensors, height regulation

- 50. Inclination sensor for height regulation

- 51. Operating conditions for height regulation

- 52. Levelling control panel

- 53. Speed sensor

- 54. Operating conditions for travel drive

- 55. Terminal box

- 56. Pin assignment, ID4…..ID6

- 57. Battery compartment

- 58. Battery maintenance

- 59. Multifunction display, inputs/ outputs

- 60. TUNING PID Parameter

- 61. Digital inputs and outputs in the electric circuit diagram

- 62. Switching states, COMPACT (ID4)

- 63. Switching states, COMPACT (ID5)

- 64. Switching states, COMPACT (ID6)

- 65. Switching states, CGC MATRIX

- 66. Operating conditions for conveyor belt

- 67. Operating conditions for gathering foot

- 68. Operating conditions for grade shoes

- 69. Operating condition for milling rotor operation

- 70. General information on diesel engine

- 71. Engine attachment parts

- 72. Lubrication oil schematic

- 73. Electronic engine control EMR

- 74. Sensor data EMR

- 75. Plug assignment EMR

- 76. Connection diagram EMR engine control

- 77. Engine

- 78. Fault lamp

- 79. Diagnostics button

- 80. Overview of fault flashing codes

- 81. Possible diagnostics with the SERIDA software

- 82. Checking the engine speed

- 83. Disassembling and assembling the injection valves

- 84. Checking and adjusting the start of commencement

- 85. Replacement of radial seal on flywheel side

- 86. Replacement of radial seal on pump carrier

- 87. Replacing the thermostats

- 88. Replacing the coolant pump

- 89. Sealing / replacing the oil cooler

- 90. Replacing the cylinder head gasket

- 91. Check, adjust the valve clearance

- 92. Checking, replacing the generator Vbelt

- 93. Service the combustion air filter

- 94. Check the coolant level

- 95. Change the coolant

- 96. Check the engine oil level

- 97. Changing engine oil and oil filter cartridges

- 98. Check fastening of engine / turbocharger / combustion air hoses

- 99. Engine conservation

- 100. Cleaning the engine

- 101. Fuel prefilter / water separator (SEPAR filter)

- 102. Checking, cleaning the water separator

- 103. Changing the fuel prefilter element

- 104. Change the fuel filter cartridge

- 105. Special tools, Deutz engine (BF8M 1015C)

- 106. Explanation of symbols

- 107. Milling drive

- 108. Checking, replacing the milling drum Vbelt

- 109. Change the oil in the milling drum reduction gear

- 110. Oil change in milling drum bearing

- 111. Checking/replacing cutting tools, scraper

- 112. Replacing bases/holders

- 113. Lubricating the milling drum

- 114. Lubricating the dry clutch

- 115. Checking the wear of the friction lining

- 116. Friction lining / replacing the outer discs

- 117. Conveyor belts

- 118. Checking, tightening the conveyor belts

- 119. Checking the safety ropes

- 120. Lubricating the conveyor belts

- 121. Folding / unfolding the loading conveyor belt

- 122. Travel drive

- 123. Checking the track plates

- 124. Retightening the track shoe fastening screws

- 125. Checking the track drive

- 126. Lubricating the travel drive

- 127. Lubricating the steering system

- 128. Oil change in track drive gear

- 129. Transfer case

- 130. Check the oil level in the pump drive gear

- 131. Change the oil in the pump drive gear

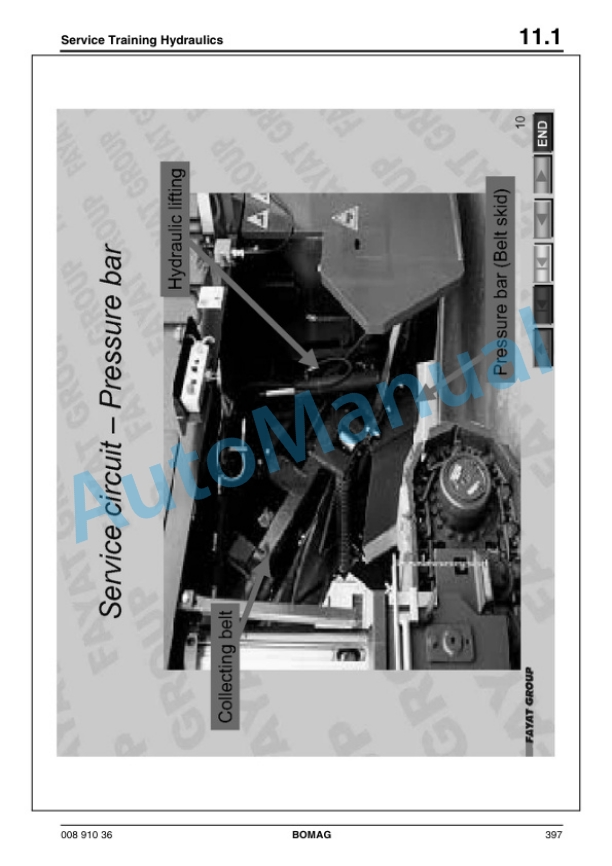

- 132. Service Training Hydraulics

- 133. Repairing hydraulic cylinders

- 134. Steering and working pump A10V ……

- 135. Travel pump A4VG 71 … 180

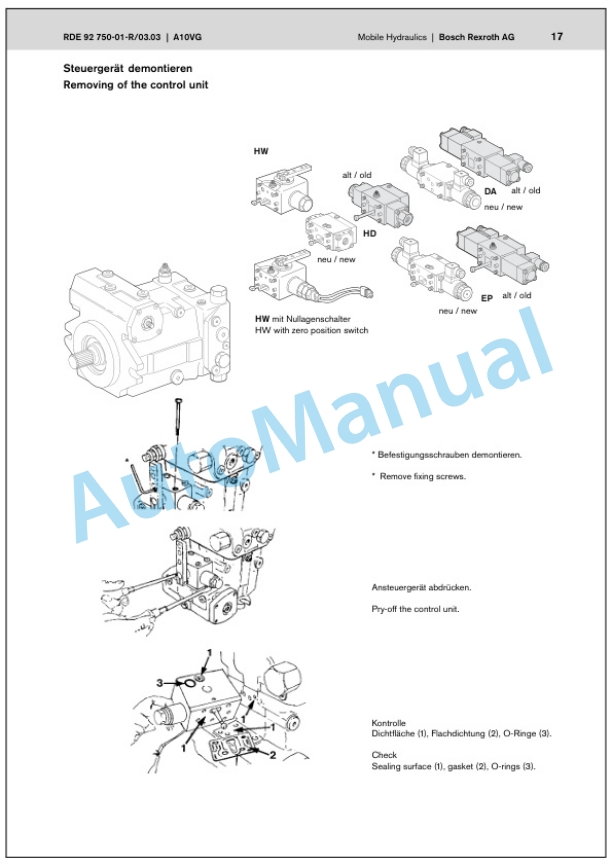

- 136. Conveyor belt pump A10VG 28 … 56

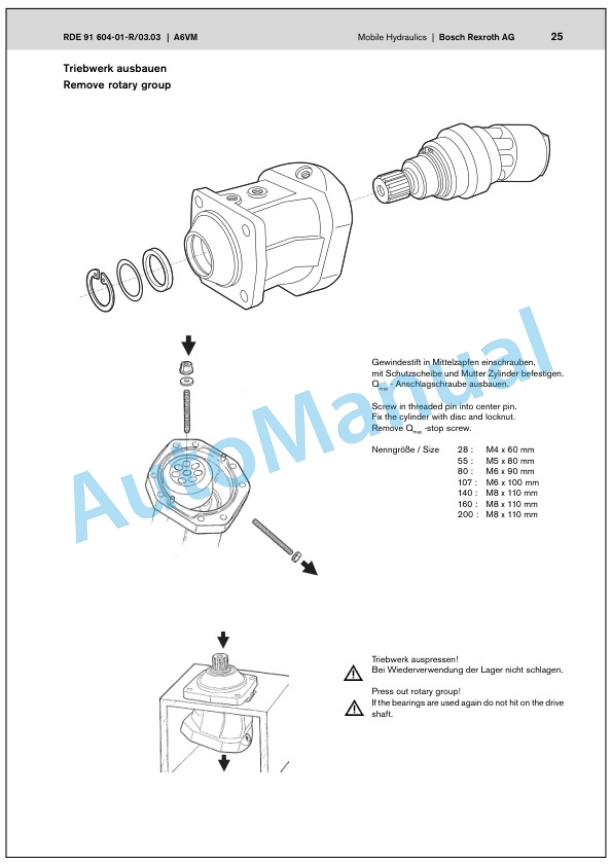

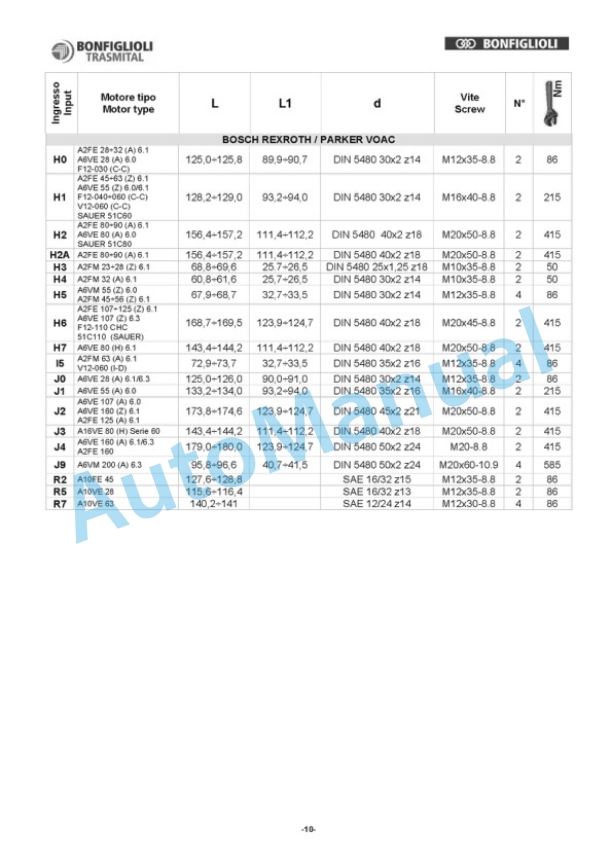

- 137. Travel motor A6VM/VE

- 138. Travel gear 705C3H10C80

- 139. Conveyor belt motor OMT

- 140. Sprinkling pump

- 141. Wiring diagram

- 142. Hydraulic diagram

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930021001 – 101930021018

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058