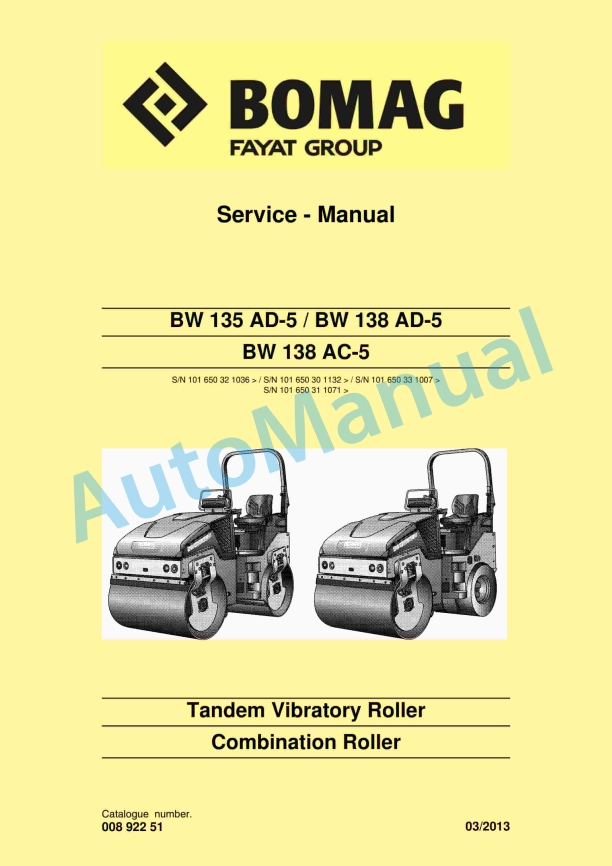

Bomag BW 135 AD-5, BW 138 AD-5, BW 138 AC-5 Tandem Vibratory Roller Service Manual 00892251

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00892251

- Format: PDF

- Size: 27.0MB

- Number of Pages: 540

- Serial Number:

101650321036 and up

101650301132 and up

101650331007 and up

101650311071 and up

Category: Bomag Service Manual PDF

-

Model List:

- BW 135 AD-5 Tandem Vibratory Roller

- BW 138 AD-5 Tandem Vibratory Roller

- BW 138 AC-5 Tandem Vibratory Roller

- 1. BW 135 AD5 / BW 138 AD5

- 1.1. BW 135 AD5 / BW 138 AD5

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Battery

- 2.14. Special safety regulations

- 2.15. The values specified in the table apply for screws

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 3. Technical data

- 3.1. Technical data

- 4. Maintenance

- 4.1. Maintenance

- 4.2. General notes on maintenance

- 4.3. Fuels and lubricants

- 4.4. Coolant

- 4.5. Mineral oil based hydraulic oil

- 4.6. Biodegradable hydraulic oil

- 5. Overall view of machine

- 5.1. Overall view of machine

- 6. Electrics

- 6.1. Electrics

- 6.2. Battery service

- 6.3. Starting with jump wires

- 6.4.

- 6.5.

- 6.6. Fuse assignment

- 6.7. Fuse assignment

- 6.8. Fuse assignment

- 6.9. Fuse assignment

- 6.10. Fuse assignment

- 6.11. Fuse assignment

- 6.12. Fuse assignment

- 6.13. Fuse assignment

- 6.14. Fuse assignment

- 6.15. Fuse assignment

- 6.16. Fuse assignment

- 6.17. Fuse assignment

- 6.18. Fuse assignment

- 6.19. Fuse assignment

- 6.20.

- 6.21.

- 7. Engine

- 7.1. Engine

- 7.2.

- 7.3. Check the engine oil level

- 7.4. Check the engine oil level

- 7.5. Change engine oil and oil filter cartridge

- 7.6. Checking the coolant level

- 7.7. Change the coolant

- 7.8. Check the antifreeze concentration and the condition of the coolant

- 7.9. Checking radiator hoses and hose clamps

- 7.10. Cleaning radiator and hydraulic oil cooler

- 7.11. Checking the Vbelt, tightening, if necessary replacing the Vbelt

- 7.12. Check, clean the air filter, replace if necessary

- 7.13. Check the air intake lines

- 7.14. Check, clean the water separator

- 7.15. Change the fuel filter

- 7.16. Check fuel lines and clamps

- 7.17. Replacing the fuel lines

- 7.18. Checking the engine mounts

- 7.19. Checking and adjusting the valve clearance

- 7.20. Checking and adjusting the valve clearance

- 7.21. Checking and adjusting the valve clearance

- 7.22. Checking and adjusting the valve clearance

- 7.23. Checking and adjusting the valve clearance

- 7.24. Checking and adjusting the valve clearance

- 7.25. Checking and adjusting the valve clearance

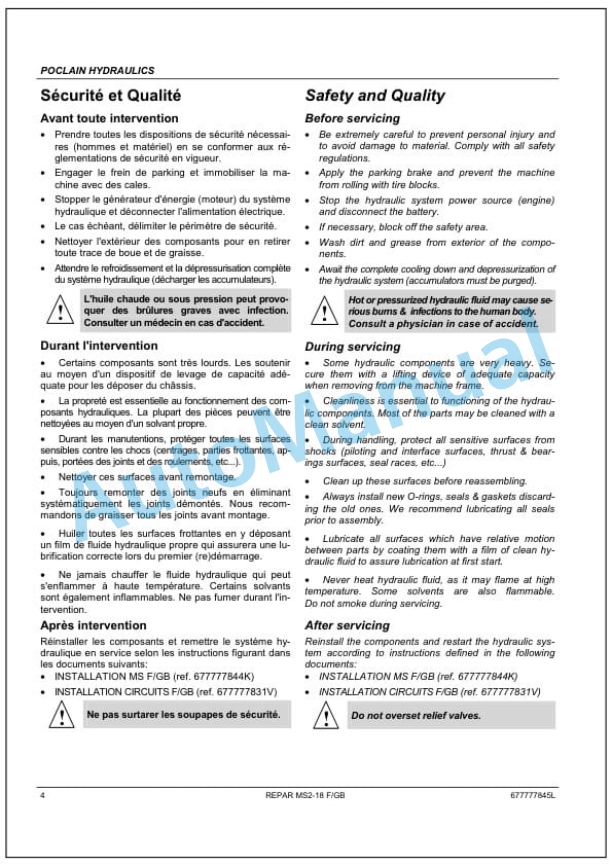

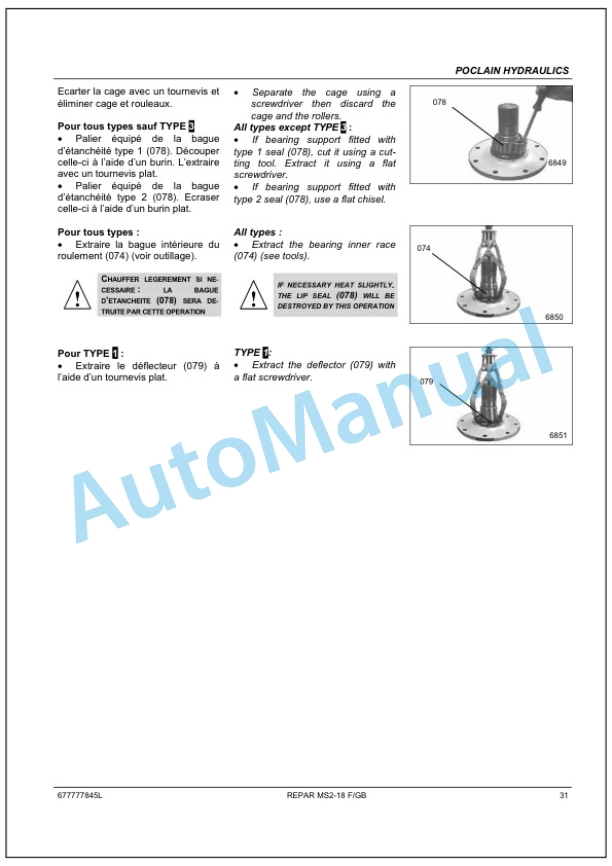

- 8. Hydraulics

- 8.1. Hydraulics

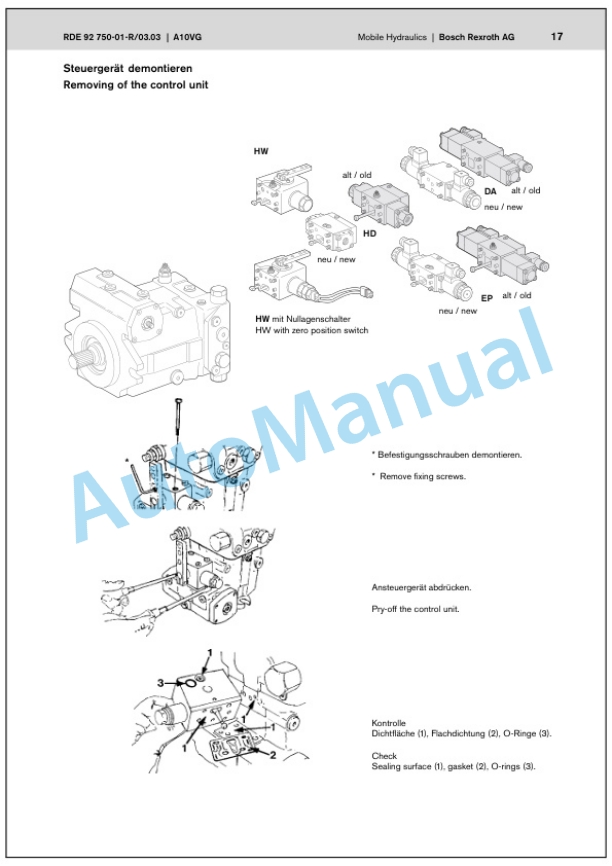

- 8.2. Variable displacement pump, A10VG45 HW

- 8.3. Variable displacement pump, A10VG45 HW

- 8.4. Variable displacement pump, A10VG45 HW

- 8.5. Swash plate principle, pump

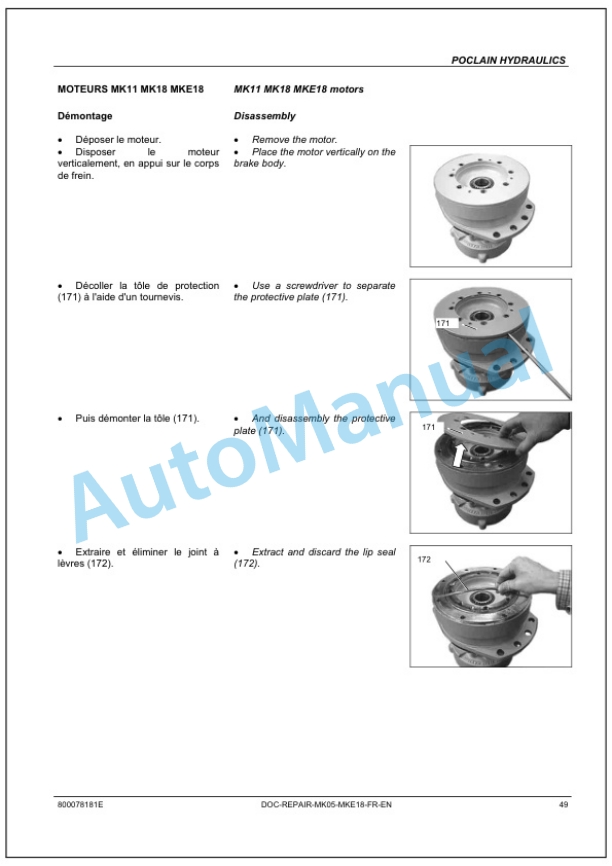

- 8.6. Operating principle of radial piston motor, MK

- 8.7. Operating principle of radial piston motor, MK

- 8.8. Functional principle radial piston motors, MS/MSE

- 8.9. Functional principle radial piston motors, MS/MSE

- 8.10. Outer gear motors nonreversible

- 8.11. Outer gear motors nonreversible

- 8.12. External gear pumps

- 8.13. External gear pumps

- 8.14. Multiple gear pumps

- 8.15. Towing

- 8.16. Towing

- 8.17. Towing

- 8.18. Towing

- 8.19. Checking the hydraulic oil level

- 8.20. Checking the hydraulic oil level

- 8.21. Checking the hydraulic oil level

- 8.22. Change hydraulic oil and breather filter

- 8.23. Checking the hydraulic oil filter element

- 8.24. Changing the hydraulic oil filter

- 9. Tests and adjustments

- 9.1. Tests and adjustments

- 9.2. Checking the rotation speeds

- 9.3. Checking the rotation speeds

- 9.4. Pressure tests in the travel circuit

- 9.5. Checking / adjusting the neutral positions of the travel pump

- 9.6. Pressure test in the vibration circuit

- 9.7. Checking the leakage rate of the vibration motor

- 9.8. Pressure test in steering circuit

- 10. Trouble shooting

- 10.1. Trouble shooting

- 11. Flushing and bleeding

- 11.1. Flushing and bleeding

- 11.2. Special tools for flushing

- 12. Drum

- 12.1. Drum

- 13. Oscillating articulated joint

- 13.1. Oscillating articulated joint

- 14. Suppliers documentation

- 14.1. Suppliers documentation

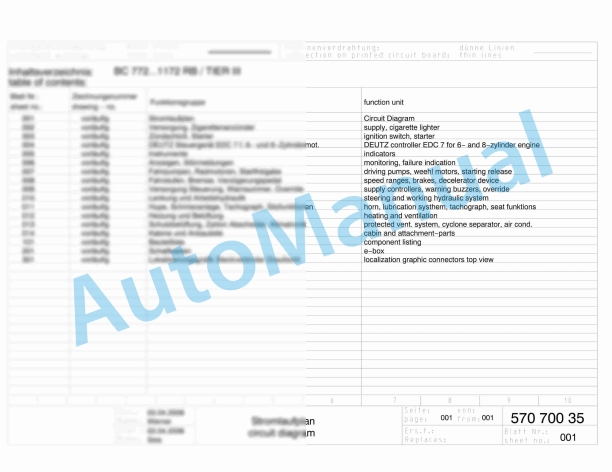

- 15. Circuit diagrams

- 15.1. Circuit diagrams

- 16.

- 16.1.

Rate this product

You may also like

Bomag Service Manual PDF

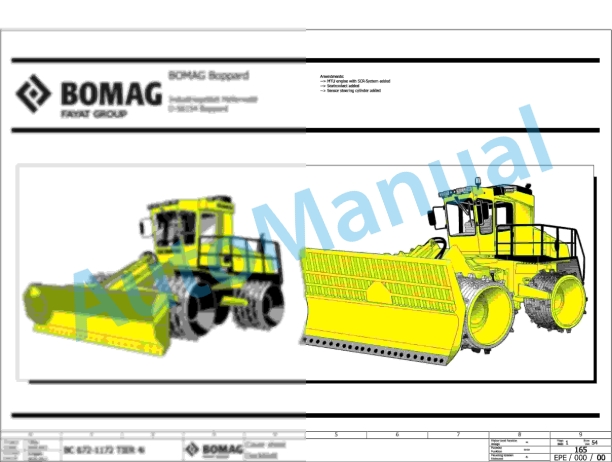

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

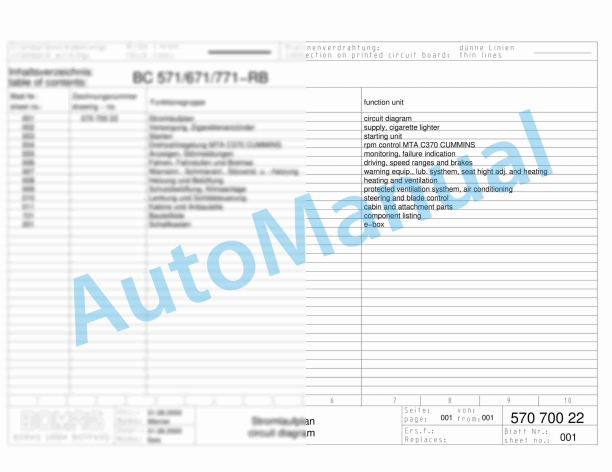

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

$30.00