Bomag BW 211 D-40 to BW 213 PD-40 Single Drum Roller Service Manual 00840190

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840190

- Format: PDF

- Size: 111.7MB

- Number of Pages: 1392

- Serial Number:

101583481095 and up

861583551001 and up

861583561001 and up

101582421940 and up

101582432399 and up

101582441209 and up

101582471053 and up

101582481239 and up

101582491019 and up

Category: Bomag Service Manual PDF

-

Model List:

- BW 211 D-40 Single Drum Roller

- BW 211 PD-40 Single Drum Roller

- BW 212 D-40 Single Drum Roller

- BW 212 PD-40 Single Drum Roller

- BW 213 D-40 Single Drum Roller

- BW 213 PD-40 Single Drum Roller

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.3. Notes on repair

- 2.4. Fuels and lubricants

- 2.5. List of fuels and lubricants

- 3. Overview of machine

- 3.1. Diesel engine

- 3.2. Travel / vibration pump

- 3.3. Drum

- 4. Technical data

- 4.1. Technical data BW 211 D/PD40

- 4.2. Technical data BW 212 D/PD40 (58243, 58248, 58356)

- 4.3. Technical data BW 212 D40 (58348, 58356)

- 4.4. Technical data BW 213 D/PD40

- 4.5. Additional technical data

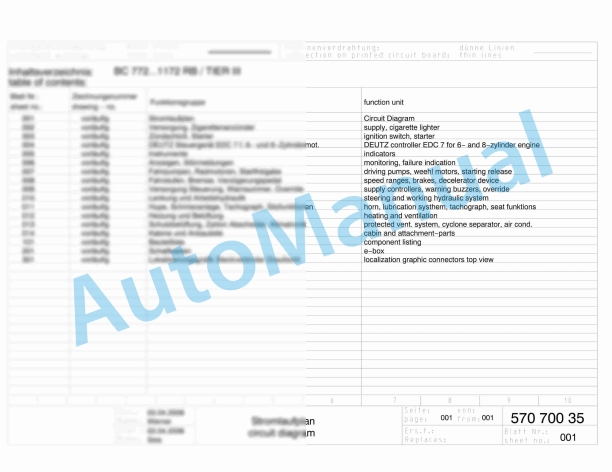

- 5. Electric systems

- 5.1. Table of fuels and lubricants

- 5.2. Central electrics

- 5.3. Fuse assignment

- 5.4. Operators stand

- 5.5. Wiring

- 5.6. Starting the engine with jump leads

- 5.7. Proximity switches on travel lever, B13 and B14

- 5.8. Differential pressure switch for hydraulic oil filter, B21

- 5.9. Level sensor in diesel tank, R03

- 5.10. Float switch, coolant tank, B55

- 5.11. Air filter vacuum switch, B03

- 5.12. Sensor for water in fuel, B124

- 5.13. Fuel preheating, R79

- 5.14. Oil pressure switch, B06

- 5.15. Coolant temperature switch, B30

- 5.16. Boost fuel solenoid valve, Y01

- 5.17. Solenoid actuator to shut down the engine, Y13

- 5.18. Engine solenoid actuator, Y120

- 5.19. Charge control light, engine tachometer

- 5.20. Heating flange on engine, R19

- 5.21. MESSX, A83

- 5.22. Acceleration transducer, B62

- 5.23. Control unit for air conditioning, A108

- 5.24. Module for seat contact monitoring, A68

- 5.25. Vibration module, K04

- 5.26. Speedometer module, A05

- 5.27. Telemecanique switch

- 5.28. Deutsch plug, series DT and DTM

- 5.29. Magnetic coil plug

- 5.30. Inspection and maintenance work

- 6. Diesel engine

- 6.1. Diesel engine, general

- 6.2. Service side

- 6.3. Starter side

- 6.4. Lubrication oil circuit

- 6.5. Coolant circuit

- 6.6. Replacing the thermostat

- 6.7. Fuel supply

- 6.8. Injection system

- 6.9. Injection pump replacement during service

- 6.10. Injection valve replacement during service

- 6.11. Checking / repairing injection valves

- 6.12. Checking the compression

- 6.13. Inspection and maintenance work

- 7. Hydraulic system

- 7.1. Overview of travel/vibration pump connections

- 7.2. Open and closed hydraulic circuit

- 7.3. Hydraulic units

- 7.4. Charge circuit

- 7.5. Travel circuit

- 7.6. Vibration circuit

- 7.7. Steering circuit

- 7.8. Tests and adjustments

- 7.9. Flushing and bleeding

- 7.10. Inspection and maintenance work

- 8. Air conditioning

- 8.1. Overview

- 8.2. Physical principles

- 8.3. Refrigerant R134a

- 8.4. Compressor oil / refrigeration oil

- 8.5. Working principle of the air conditioning system

- 8.6. Monitoring devices

- 8.7. Description of components

- 8.8. Compressor

- 8.9. Emptying in case of repair

- 8.10. Drying and evacuation

- 8.11. Filling instructions

- 8.12. Steam table for R134a

- 8.13. Inspection and maintenance work

- 9. Cabin assembly before initial commissioning

- 9.1. Preparations

- 9.2. Cabin assembly

- 9.3. Final function tests and checks

- 10. Replacing the cab window panes

- 10.1. Assembly of window panes

- 10.2. Auxiliary materials

- 10.3. Removing and installing the window pane

- 11. Oscillating articulated joint

- 11.1. Overview oscillating articulated joint

- 11.2. Removing and installing the oscillating articulated joint

- 11.3. Dismantling the oscillating articulated joint

- 11.4. Assembling the oscillating articulated joint

- 12. Drum

- 12.1. Assembly of padfoot shell

- 12.2. Overview drum

- 12.3. Removing and installing the drum

- 12.4. Dismantling the drum

- 12.5. Dismantling and assembling the changeover weight

- 12.6. Assembling the drum

- 12.7. Changing the rubber buffers, adjusting the pretension

- 12.8. Inspection and maintenance work

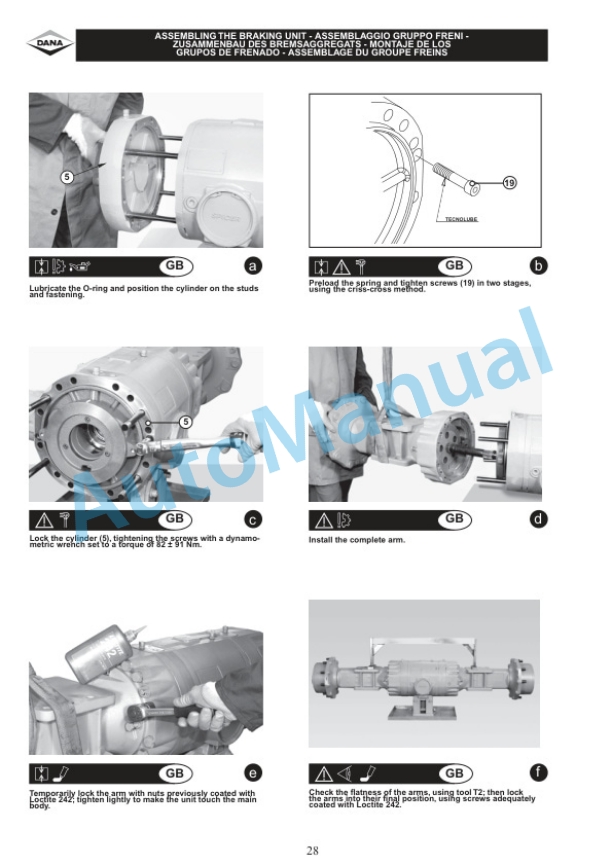

- 13. Drive axle

- 13.1. Drive axle

- 13.2. Checks prior to start up

- 13.3. Every 250 operating hours

- 13.4. Every 1000 operating hours

- 13.5. As required

- 14. Troubleshooting

- 14.1. Preliminary remarks

- 14.2. Emergency procedures

- 14.3. Troubleshooting, electrical systems

- 14.4. Troubleshooting, diesel engine

- 14.5. Trouble shooting, hydraulics

- 14.6. Trouble shooting, air conditioning system

- 15. Disposal

- 15.1. Final shutdown of machine

- 16. Special tools

- 16.1. Special tools, electrics

- 16.2. Special tools, hydraulic system

- 16.3. Special tools for oscillating articulated joint

- 16.4. Special tools, drum

- 17. Index

- 18. Appendix

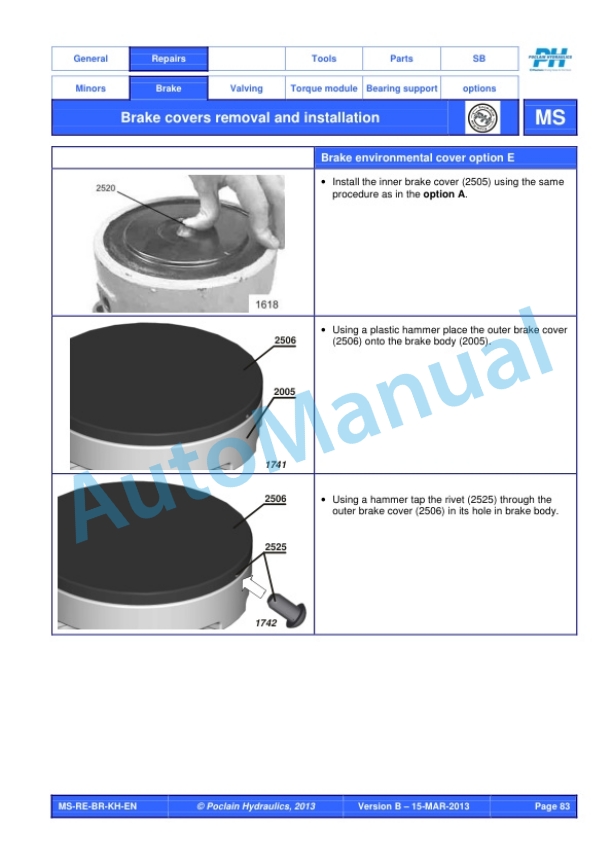

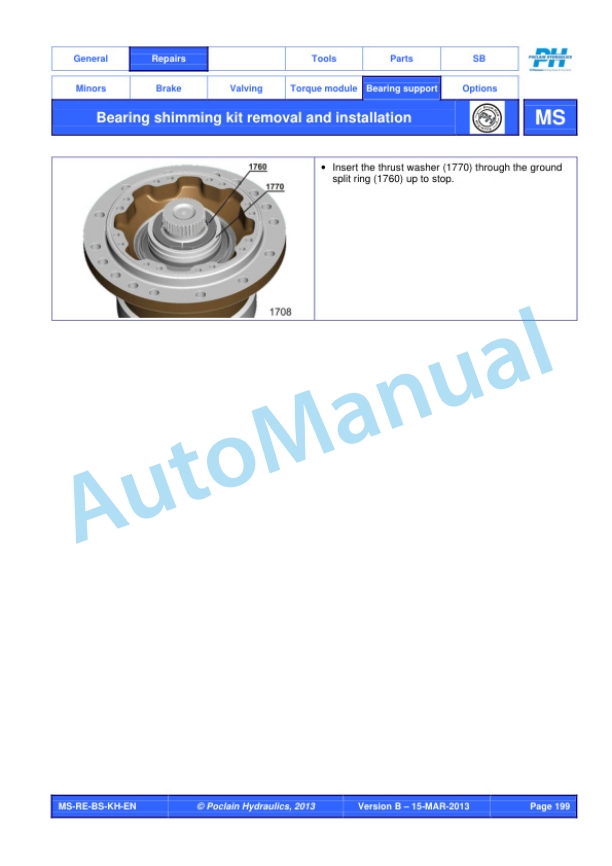

- 18.1. A Supplier documentation

- 18.2. B Circuit diagrams

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

$30.00

Bomag Service Manual PDF

$30.00