Bomag BW 226 DH-4 BVC Single Drum Roller Service Training 00891790

$30.00

- Type Of Manual: Service Training

- Manual ID: 00891790

- Format: PDF

- Size: 45.6MB

- Number of Pages: 746

- Serial Number:

101582861109 – 10158408

Category: Bomag Service Manual PDF

-

Model List:

- BW 226 DH-4 BVC Single Drum Roller

- 1. BW 226 DH4

- 1.1. BW 226 DH4

- 2. General

- 2.1. General

- 2.2. Introduction

- 2.3. General

- 2.4. General

- 2.5. Transport work with cranes and lifting tackle

- 2.6. Precautions and codes of conduct for welding work

- 2.7. Operation of highvoltage systems

- 2.8. Old oils

- 2.9. Hydraulics

- 2.10. Hot fuels

- 2.11. Synthetic rubber

- 2.12. Poisonous substances

- 2.13. Air conditioning system

- 2.14. Battery

- 2.15. Special safety regulations

- 2.16. The values specified in the table apply for screws

- 2.17. The values specified in the table apply for screws

- 2.18. The values specified in the table apply for screws

- 2.19. The values specified in the table apply for screws

- 2.20. The values specified in the table apply for screws

- 2.21. The values specified in the table apply for screws

- 2.22. The values specified in the table apply for screws

- 2.23. The values specified in the table apply for screws

- 2.24. The values specified in the table apply for screws

- 2.25. The values specified in the table apply for screws

- 2.26. The values specified in the table apply for screws

- 2.27. The values specified in the table apply for screws

- 2.28. The values specified in the table apply for screws

- 2.29. The values specified in the table apply for screws

- 2.30. The values specified in the table apply for screws

- 3. BOMAG single drum rollers

- 3.1. BOMAG single drum rollers

- 3.2. The vibration systems.

- 3.3. The vibration systems.

- 3.4. Infinitely variable, intelligent and flexible BOMAG VARIOCONTROL (BVC)

- 4. Technical data

- 4.1. Technical data

- 4.2.

- 4.3.

- 4.4.

- 5. Maintenance

- 5.1. Maintenance

- 5.2. General notes on maintenance

- 5.3. Fuels and lubricants

- 5.4. Coolant

- 5.5. Mineral oil based hydraulic oil

- 5.6. Biodegradable hydraulic oil

- 5.7. Oil for drive axle

- 5.8. Oil for Vario vibration unit

- 5.9. Lubrication grease

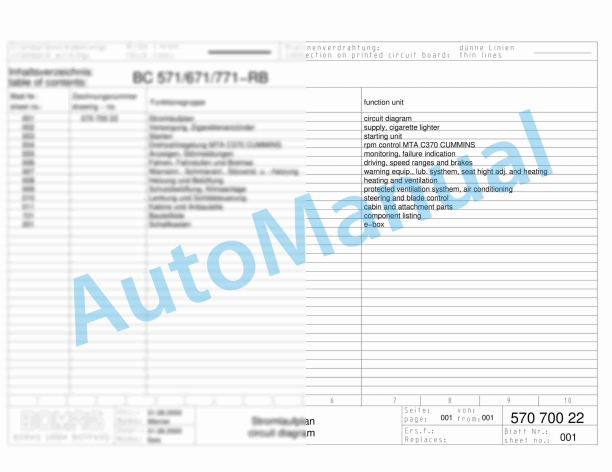

- 6. EPlan wiring diagrams

- 6.1. EPlan wiring diagrams

- 7. Electrics

- 7.1. Electrics

- 7.2. Battery service

- 7.3. Starting with jump wires

- 7.4.

- 7.5.

- 7.6.

- 7.7.

- 7.8. S00, starter switch

- 7.9.

- 7.10.

- 7.11.

- 7.12.

- 7.13.

- 7.14.

- 7.15.

- 7.16.

- 7.17.

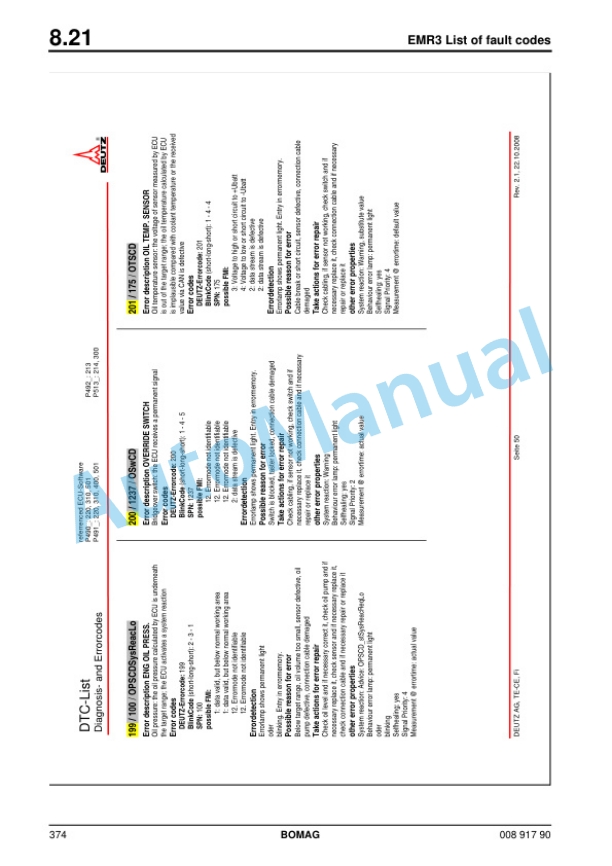

- 8. Electronic modules

- 8.1. Electronic modules

- 8.2.

- 8.3.

- 8.4.

- 8.5.

- 8.6.

- 8.7.

- 9. Engine electrics

- 9.1. Engine electrics

- 10. BOMAG, Variocontrol

- 10.1. BOMAG, Variocontrol

- 10.2. Infinitely variable, intelligent and flexible BOMAG VARIOCONTROL (BVC)

- 10.3. Infinitely variable, intelligent and flexible BOMAG VARIOCONTROL (BVC)

- 10.4. Exciter unit

- 10.5.

- 10.6. Automatic measuring and controlling

- 10.7. BVC/BTM05 settings before startup

- 10.8. BVC/BTM05 settings before startup

- 10.9. BVC/BTM05 settings before startup

- 10.10. BVC/BTM05 settings before startup

- 10.11. BVC/BTM05 settings before startup

- 10.12. BVC/BTM05 settings before startup

- 10.13. Variocontrol, selecting the operating mode

- 10.14. Measuring pass with Variocontrol

- 10.15. Teaching distance pulses

- 10.16. Amplitude limitation (BVC only)

- 11. Hydraulics

- 11.1. Hydraulics

- 11.2. Travel and vibration pump, H1

- 11.3. Travel and vibration pump, H1

- 11.4. Variable displacement pump, H1 P 078/100 RA

- 11.5.

- 11.6. Swash plate principle, pump

- 11.7. Swash plate motor with variable displacement, series 51

- 11.8. Swash plate motor with variable displacement, series 51

- 11.9. Description of function

- 11.10. Description of function

- 11.11. Flushing valve

- 11.12. Swash plate principle, motor

- 11.13. External gear pumps

- 11.14. External gear pumps

- 11.15. Multiple gear pumps

- 11.16. Slewing motor

- 11.17. Slewing motor

- 11.18. Brake control

- 11.19. Stopping the machine, operating the parking brake

- 11.20. Towing in case of an engine failure

- 11.21. Adjust the parking brake

- 11.22. Exciter unit

- 11.23. Exciter unit

- 11.24. Hydraulic diagram

- 11.25. Check the hydraulic oil level

- 11.26. Changing hydraulic oil and breather filter

- 11.27. Replace hydraulic oil filter

- 12. Electric steering

- 12.1. Electric steering

- 12.2. Articulated joint

- 12.3. Articulated joint

- 12.4. External gear pumps

- 12.5. Multiple gear pumps

- 13. Hydraulic steering (optional)

- 13.1. Hydraulic steering (optional)

- 13.2. Articulated joint

- 14. Tests and adjustments

- 14.1. Tests and adjustments

- 14.2. Activate service mode

- 14.3. Activate service mode

- 14.4. Driving against the closed brake

- 14.5. Turn the steering against an end stop.

- 14.6. Check the leakage rate of the vibration motor

- 14.7. Pressure test in steering circuit

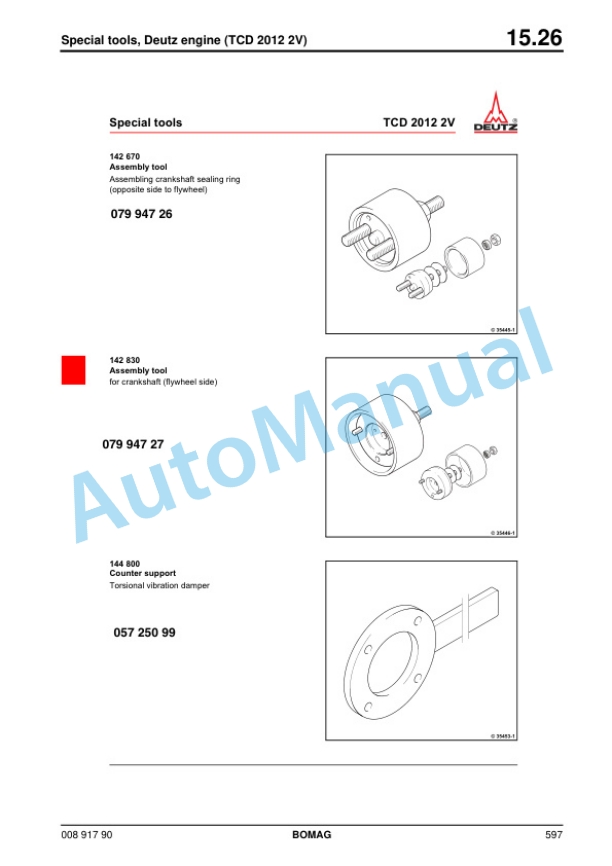

- 15. Flushing and bleeding

- 15.1. Flushing and bleeding

- 15.2. Special tools for flushing

- 15.3. Bleeding the vibration circuit

- 15.4. Bleeding the vibration circuit

- 15.5. Bleeding the vibration circuit

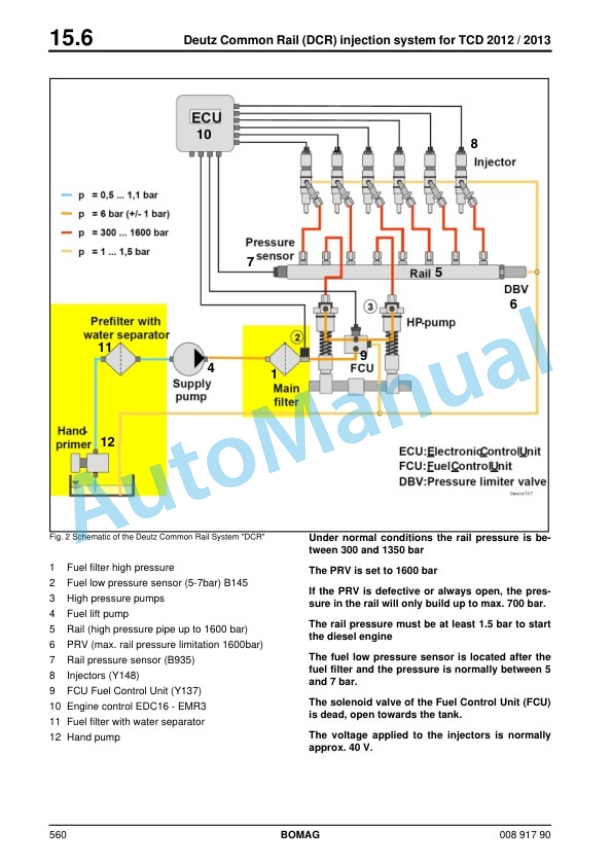

- 16. Engine

- 16.1. Engine

- 16.2. Check the engine oil level

- 16.3. Check the engine oil level

- 16.4. Change engine oil and oil filter cartridge

- 16.5. Change the fuel prefilter cartridge

- 16.6. Replace the fuel filter cartridge

- 16.7. Check, clean the water separator

- 16.8. Check the coolant level

- 16.9. Change the coolant

- 16.10. Service the combustion air filter

- 16.11. Service the combustion air filter

- 16.12. Check the dust separator

- 16.13. Cleaning the oil bath air filter

- 16.14. Adjust the valve clearance

- 16.15. Checking / replacing the ribbed Vbelt

- 16.16. Check the engine mounts

- 16.17. Replacing the crank case pressure ventilation valve

- 16.18. Engine conservation

- 17. Air conditioning system

- 17.1. Air conditioning system

- 17.2. Checking, replacing the refrigerant compressor Vbelt

- 17.3. Checking, replacing the refrigerant compressor Vbelt

- 17.4. Checking, replacing the refrigerant compressor Vbelt

- 17.5. Checking, replacing the refrigerant compressor Vbelt

- 17.6. Service the air conditioning

- 18. Drum

- 18.1. Drum

- 19. Circuit diagrams

- 19.1. Circuit diagrams

- 20.

- 20.1.

Rate this product

You may also like

Bomag Service Manual PDF

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 473 RB-3 Refuse Compactor Electric Schematics Diagram 101930131001 – 101930139999

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

$30.00