Claas VARIANT 350 (770) Baler Operator Manual DE

$50.00

- Model: VARIANT 350 (770) Baler

- Type Of Manual: Operator Manual

- Language: DE

- Format: PDF(s)

- Size: 134 MB

File List:

– 00 0288 351 6.pdf

– 00 0288 352 0.pdf

– 00 0290 518 0.pdf

– 00 0294 519 7.pdf

– 00 0295 235 5.pdf

– 00 0300 306 0.pdf

00 0288 351 6.pdf

Table of Content:

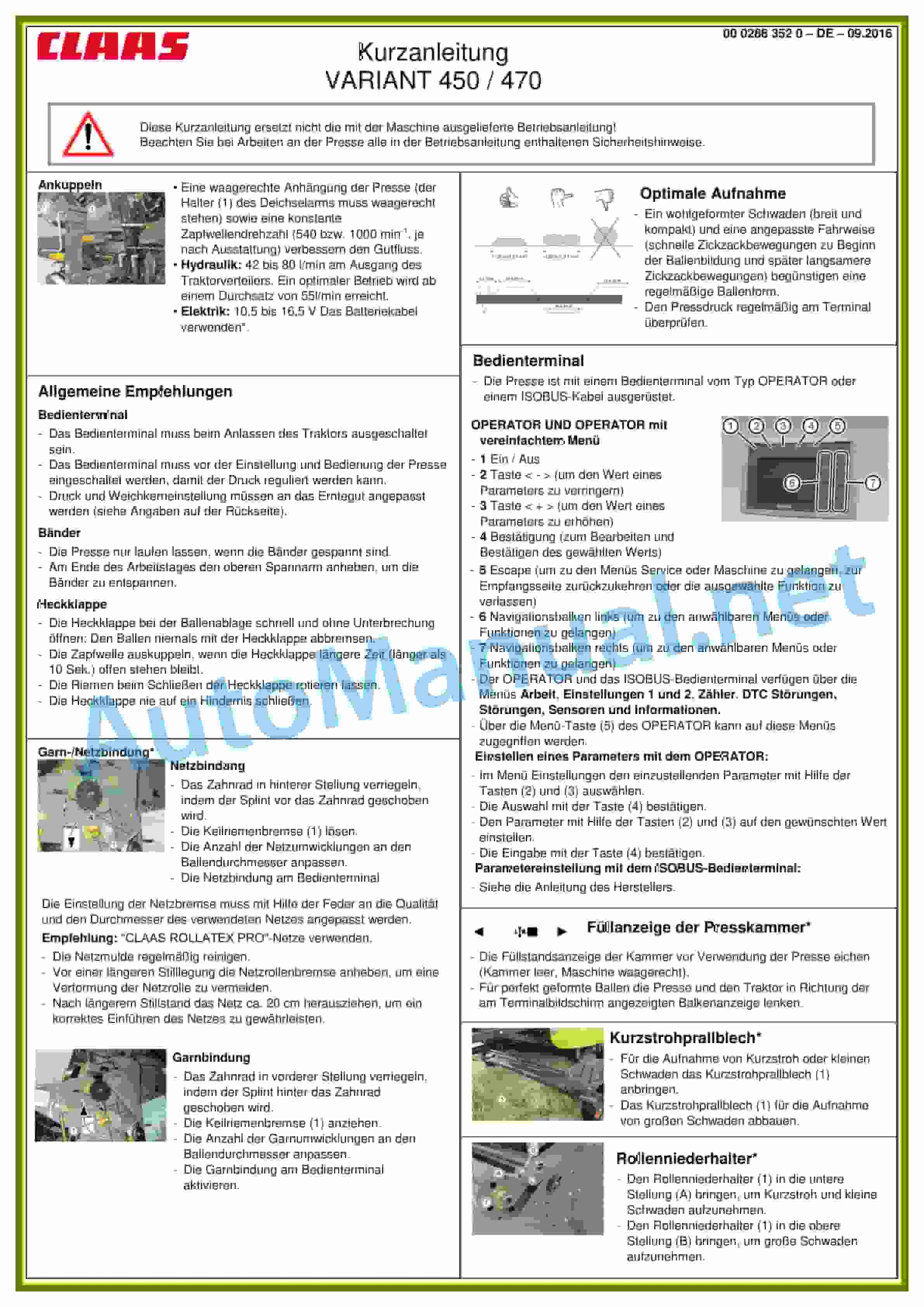

1 VARIANT 450VARIANT 470

2 Table of Contents

3 1 Introduction

3.1 1.1 General information

3.2 1.2 Intended use

4 2 Security

4.1 2.1 Recognize warnings

4.2 2.2 Safety instructions

4.3 2.3 Warning symbol

5 3 Machine description

5.1 3.1 Existing models

5.2 3.2 Overview and functions

5.3 3.3 Safety device

5.4 3.4 Work and service areas

5.5 3.5 Type plate and serial number

5.6 3.6 General functional principle

5.7 3.7 Information on the machine

5.8 3.8 Operating terminal

5.9 3.9 PTO shaft and drive

5.10 3.10 Hitch bracket

5.11 3.11 Receipt

5.12 3.12 Feeding unit

5.13 3.13 Pressing device

5.14 3.14 Binding system

5.15 3.15 Bale placement

5.16 3.16 Lubricating oil system

5.17 3.17 Hydraulics

5.18 3.18 Equipment

6 4 Control and display elements

6.1 4.1 OPERATOR

7 5 Technical data

7.1 5.1 Press

7.2 5.2 Safety devices

7.3 5.3 Operating materials

7.4 5.4 Tractor

8 6 Prepare machine

8.1 6.1 Switch off and secure the machine

8.2 6.2 Adjust tractor

8.3 6.3 Adjust machine

8.4 6.4 Attach machine

8.5 6.5 Preparing for work

8.6 6.6 Yarn binding

8.7 6.7 Net binding

8.8 6.8 Loading the machine

9 7 Operation

9.1 7.1 General information

9.2 7.2 Movement of the press

9.3 7.3 Before each use

9.4 7.4 Field operation

9.5 7.5 Specific use

9.6 7.6 Pick-up

9.7 7.7 Binding

9.8 7.8 Bale parameters

9.9 7.9 OPERATOR

9.10 7.10 OPERATOR with simplified menu

9.11 7.11 Unclogging the press

9.12 7.12 After use

9.13 7.13 Detach machine

10 8 Malfunction and remedy

10.1 8.1 General information

10.2 8.2 Hydraulics

10.3 8.3 OPERATOR

10.4 8.4 Binding

10.5 8.5 Lubricating oil system

10.6 8.6 Lubrication system

10.7 8.7 Other functions

11 9 Maintenance

11.1 9.1 General maintenance instructions

11.2 9.2 Maintenance tables

11.3 9.3 Lubrication plan

11.4 9.4 Maintenance work gearbox

11.5 9.5 Maintenance work axle and wheels

11.6 9.6 Maintenance work trailer hitch

11.7 9.7 Maintenance work hydraulic system

11.8 9.8 Maintenance work Pickup

11.9 9.9 Maintenance work on the pull-in unit

11.10 9.10 Maintenance work press chamber

11.11 9.11 Maintenance work Binding

11.12 9.12 Maintenance work bale storage

11.13 9.13 Maintenance work lubricating oil system

11.14 9.14 Maintenance work on the lubrication system

11.15 9.15 Maintenance work machine housing

11.16 9.16 Winterization

12 10 Decommissioning and disposal

12.1 10.1 General information

13 11 EC declaration of conformity

13.1 11.1 General information

00 0290 518 0.pdf

Table of Content:

2 1 Introduction

2.1 1.1 Generalities

2.2 1.2 Equipped machines

3 2 Security Consignments

3.1 2.1 Important

3.2 2.2 Security Consignments

4 3 Lot de pices

4.1 3.1 VARIANT 3XX – 00 0857 722 0

5 4 Montage du garde-corps

5.1 4.1 Description

5.2 4.2 Press preparation

5.3 4.3 Mise en place du garde-corps

7 1 Introduction

7.1 1.1 General

7.2 1.2 Machines to be equipped

8 2 Safety regulations

8.1 2.1 Important

8.2 2.2 Safety regulations

9 3 Parts list

9.1 3.1 VARIANT 3XX – 00 0857 722 0

10 4 Installing the railing

10.1 4.1 Description

10.2 4.2 Preparing the press

10.3 4.3 Installation of the railing

12 1 Introduction

12.1 1.1 General points

12.2 1.2 Machines that can be fitted

13 2 Safety advice

13.1 2.1 Important

13.1 VARIANT 3XX – 00 0857 722 0

15 4 Fitting the guard rail

15.1 4.1 Description

15.2 4.2 Preparing the baler

15.3 4.3 Fitting the guard rail

17 1 Introduction

17.1 1.1 Generalit

17.2 1.2 Equipment machine

18 2 Istruzioni di sicurezza

18.1 2.1 Importante

18.2 2.2 Istruzioni di sicurezza

19 3 Lotto di pezzi

19.1 3.1 VARIANT 3XX – 00 0857 722 0

20 4 Monday of protection

20.1 4.1 Description

20.2 4.2 Preparation of the press

20.3 4.3 Monday of protection

22 1 Introduction

22.1 1.1 General information

22.2 1.2 Machines applicable

23 2 Standards of security

23.1 2.1 Importante

23.2 2.2 Standards of security

24 3 Lote de piezas

24.1 3.1 VARIANT 3XX – 00 0857 722 0

25 4 Montaje de la body protection

25.1 4.1 Description

25.2 4.2 Press preparation

25.3 4.3 Colocation of body protection

27 1 3.?????

28.2 2.2 ???????? ?? ????? ????????????

29 3 ???????? ???????

29.1 3.1 VARIANT 3XX – 00 0857 722 0

30 4 ?????? ?????

30.1 4.1 ????????

30.2 4.2 ?????????? ?????-??????????

30.3 4.3 ????????? ?????

00 0294 519 7.pdf

Table of Content:

1 VARIANT 350VARIANT 370VARIANT 370 POWER

2 Table of Contents

3 1 About these operating instructions

3.1 1.1 General information

4 2 Security

4.1 2.1 General information

4.2 2.2 Warning symbol

4.3 2.3 Safety device

5 3 Machine description

5.1 3.1 Existing models

5.2 3.2 Overview and functions

5.3 3.3 Work and service areas

5.4 3.4 Type plate and serial number

5.5 3.5 General functional principle

5.6 3.6 Operating terminal

5.7 3.7 PTO shaft and drive

5.8 3.8 Good intake

5.9 3.9 Feeding unit

5.10 3.10 Pressing device

5.11 3.11 Binding system

5.12 3.12 Bale storage

5.13 3.13 Lubricating oil system

5.14 3.14 Lubrication system

5.15 3.15 Hydraulics

5.16 3.16 Equipment

6 4 Control and display elements

6.1 4.1 CLAAS STANDARD TERMINAL

6.2 4.2 CLAAS Medium Terminal

6.3 4.3 ISOBUS Terminal

7 5 Technical data

7.1 5.1 Press

7.2 5.2 Safety devices

7.3 5.3 Tractor

8 6 Prepare machine

8.1 6.1 General information

8.2 6.2 Drive shaft

8.3 6.3 Attachment bracket

8.4 6.4 Hydraulic connections

8.5 6.5 Electrical connections

8.6 6.6 Yarn binding

8.7 6.7 Net binding

8.8 6.8 Loading the machine

9 7 Operation

9.1 7.1 General information

9.2 7.2 Movement of the press

9.3 7.3 Before each use

9.4 7.4 Field operation

9.5 7.5 Specific use

9.6 7.6 Pick-up

9.7 7.7 Binding

9.8 7.8 Bale parameters

9.9 7.9 CLAAS STANDARD TERMINAL

9.10 7.10 CLAAS Medium Terminal

9.11 7.11 ISOBUS Terminal

9.12 7.12 Unclogging the press

9.13 7.13 After use

10 8 Malfunction and remedy

10.1 8.1 General information

10.2 8.2 Hydraulics

10.3 8.3 CLAAS STANDARD TERMINAL

10.4 8.4 CLAAS Medium Terminal

10.5 8.5 ISOBUS Terminal

10.6 8.6 Binding

10.7 8.7 Lubricating oil system

10.8 8.8 Lubrication system

10.9 8.9 Other functions

11 9 Maintenance

11.1 9.1 General maintenance instructions

11.2 9.2 Maintenance tables

11.3 9.3 Lubricant tables

11.4 9.4 Lubrication plan

11.5 9.5 Maintenance work gearbox

11.6 9.6 Maintenance work axle and wheels

11.7 9.7 Maintenance work trailer hitch

11.8 9.8 Maintenance work hydraulic system

11.9 9.9 Maintenance work Pickup

11.10 9.10 Maintenance work on the pull-in unit

11.11 9.11 Maintenance work press chamber

11.12 9.12 Maintenance work Binding

11.13 9.13 Maintenance work bale storage

11.14 9.14 Maintenance work lubricating oil system

11.15 9.15 Maintenance work lubrication system

11.16 9.16 Maintenance work machine housing

11.17 9.17 Winterization

12 10 Decommissioning and disposal

12.1 10.1 General information

13 11 EC declaration of conformity

13.1 11.1 General information

00 0300 306 0.pdf

Table of Content:

1 VARIANT 350VARIANT 370VARIANT 370 POWER

2 Table of Contents

3 1 About these operating instructions

3.1 1.1 General information

4 2 Security

4.1 2.1 General information

4.2 2.2 Warning symbol

4.3 2.3 Safety device

5 3 Machine description

5.1 3.1 Existing models

5.2 3.2 Overview and functions

5.3 3.3 Work and service areas

5.4 3.4 Type plate and serial number

5.5 3.5 General functional principle

5.6 3.6 Operating terminal

5.7 3.7 PTO shaft and drive

5.8 3.8 Good intake

5.9 3.9 Feeding unit

5.10 3.10 Pressing device

5.11 3.11 Binding system

5.12 3.12 Bale storage

5.13 3.13 Lubricating oil system

5.14 3.14 Lubrication system

5.15 3.15 Hydraulics

5.16 3.16 Equipment

6 4 Control and display elements

6.1 4.1 CLAAS STANDARD TERMINAL

6.2 4.2 OPERATOR

6.3 4.3 ISOBUS Terminal

7 5 Technical data

7.1 5.1 Press

7.2 5.2 Safety devices

7.3 5.3 Tractor

8 6 Prepare machine

8.1 6.1 General information

8.2 6.2 Drive shaft

8.3 6.3 Attachment bracket

8.4 6.4 Hydraulic connections

8.5 6.5 Electrical connections

8.6 6.6 Yarn binding

8.7 6.7 Net binding

8.8 6.8 Loading the machine

9 7 Operation

9.1 7.1 General information

9.2 7.2 Movement of the press

9.3 7.3 Before each use

9.4 7.4 Field operation

9.5 7.5 Specific use

9.6 7.6 Pick-up

9.7 7.7 Binding

9.8 7.8 Bale parameters

9.9 7.9 CLAAS STANDARD TERMINAL

9.10 7.10 OPERATOR

9.11 7.11 ISOBUS Terminal

9.12 7.12 Unclogging the press

9.13 7.13 After use

10 8 Malfunction and remedy

10.1 8.1 General information

10.2 8.2 Hydraulics

10.3 8.3 CLAAS STANDARD TERMINAL

10.4 8.4 OPERATOR

10.5 8.5 Binding

10.6 8.6 Lubricating oil system

10.7 8.7 Lubrication system

10.8 8.8 Other functions

11 9 Maintenance

11.1 9.1 General maintenance instructions

11.2 9.2 Maintenance tables

11.3 9.3 Lubricant tables

11.4 9.4 Lubrication plan

11.5 9.5 Maintenance work gearbox

11.6 9.6 Maintenance work axle and wheels

11.7 9.7 Maintenance work trailer hitch

11.8 9.8 Maintenance work hydraulic system

11.9 9.9 Maintenance work Pickup

11.10 9.10 Maintenance work on the pull-in unit

11.11 9.11 Maintenance work press chamber

11.12 9.12 Maintenance work Binding

11.13 9.13 Maintenance work bale storage

11.14 9.14 Maintenance work lubricating oil system

11.15 9.15 Maintenance work lubrication system

11.16 9.16 Maintenance work machine housing

11.17 9.17 Winterization

12 10 Decommissioning and disposal

12.1 10.1 General information

13 11 EC declaration of conformity

13.1 11.1 General information

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF