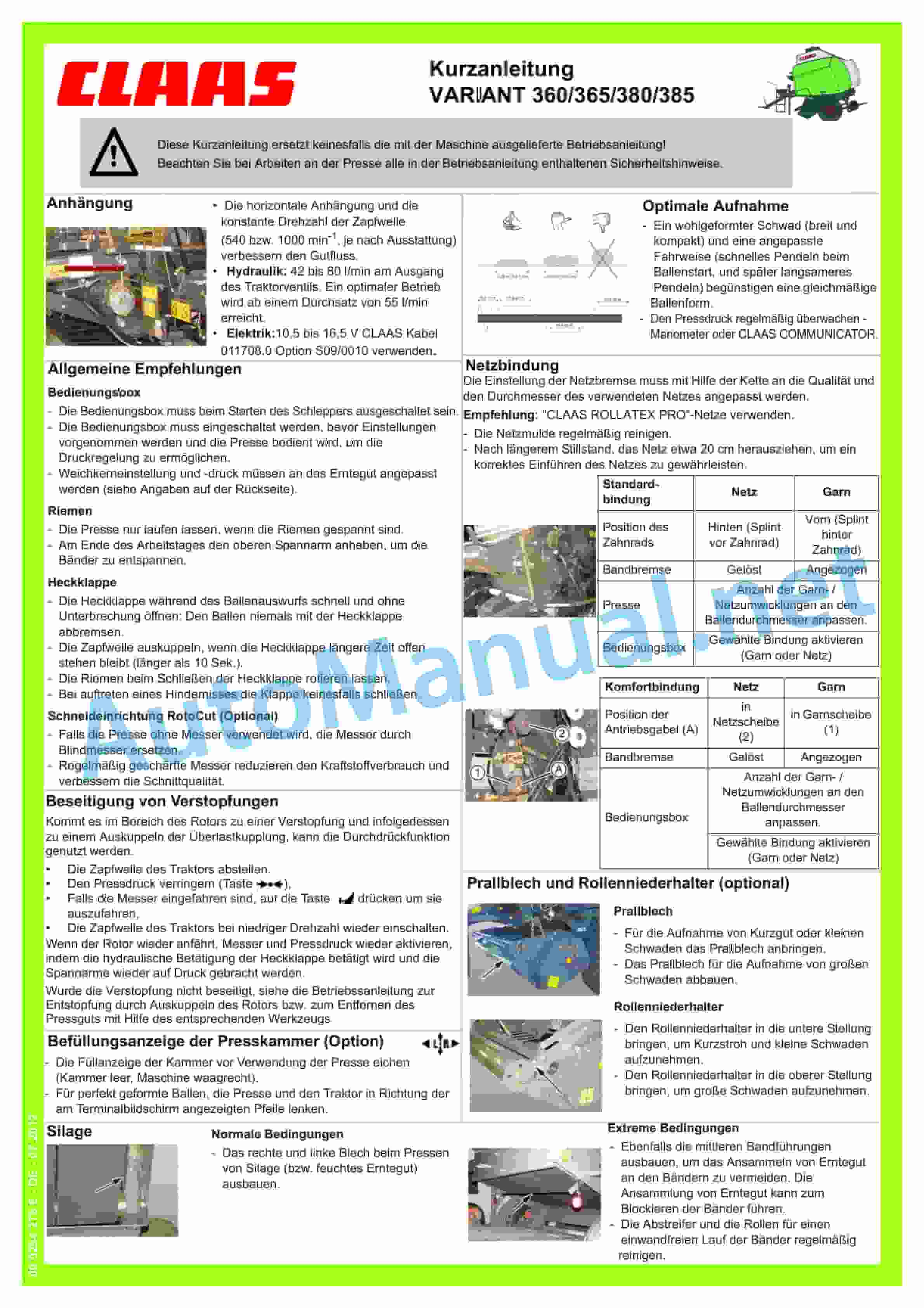

Claas VARIANT 465 460 365 360 RC RF (751) Baler Operator Manual DE

$50.00

- Model: VARIANT 465 460 365 360 RC RF (751) Baler

- Type Of Manual: Operator Manual

- Language: DE

- Format: PDF(s)

- Size: 146 MB

File List:

– 00 0290 518 0.pdf

– 00 0294 276 6.pdf

– 00 0294 601 0.pdf

– 00 0297 102 1.pdf

– 00 0301 090 0.pdf

– 00 0301 385 7.pdf

00 0290 518 0.pdf

Table of Contents:

2 1 Introduction

2.1 1.1 Generalities

2.2 1.2 Equipped machines

3 2 Security Consignments

3.1 2.1 Important

3.2 2.2 Security Consignments

4 3 Lot of pieces

4.1 3.1 VARIANT 3XX – 00 0857 722 0

5 4 Montage du garde-corps

5.1 4.1 Description

5.2 4.2 Press preparation

5.3 4.3 Mise en place du garde-corps

7 1 Introduction

7.1 1.1 General

7.2 1.2 Machines to be equipped

8 2 Safety regulations

8.1 2.1 Important

8.2 2.2 Safety regulations

9 3 Parts list

9.1 3.1 VARIANT 3XX – 00 0857 722 0

10 4 Installing the railing

10.1 4.1 Description

10.2 4.2 Preparing the press

10.3 4.3 Installation of the railing

12 1 Introduction

12.1 1.1 General points

12.2 1.2 Machines that can be fitted

13 2 Safety advice

13.1 2.1 Important

13.2 2.2 Safety instructions

14 3 parts kit

14.1 3.1 VARIANT 3XX – 00 0857 722 0

15 4 Fitting the guard rail

15.1 4.1 Description

15.2 4.2 Preparing the baler

15.3 4.3 Fitting the guard rail

17 1 Introduction

17.1 1.1 General

17.2 1.2 Equipment machine

18 2 Safety instructions

18.1 2.1 Important

18.2 2.2 Safety instructions

19 3 Lotto di pezzi

19.1 3.1 VARIANT 3XX – 00 0857 722 0

20 4 Monday of protection

20.1 4.1 Description

20.2 4.2 Preparation of the press

20.3 4.3 Monday of protection

22 1 Introduction

22.1 1.1 General information

22.2 1.2 Machines applicable

23 2 Standards of security

23.1 2.1 Important

23.2 2.2 Standards of security

24 3 Lot of pieces

24.1 3.1 VARIANT 3XX – 00 0857 722 0

25 4 Assembling the body protection

25.1 4.1 Description

25.2 4.2 Press preparation

25.3 4.3 Colocation of body protection

27 1 2 ??arking the machine

5.5 Utilization according to destination

6 FR_0200.pdf

6.1 Notice of assembly

6.2 Kit lin and lin court

7 FR_0508_V2.pdf

7.1 Utilization of the press for other products

8 FR_0507_V2.pdf

8.1 Utilization for the pressage du lin trs court

9 FR_0506_V2.pdf

9.1 Utilization for the pressage du lin court

10 FR_0505_V2.pdf

10.1 Utilization for the pressage of lin

11 FR_0504_V2.pdf

11.1 Before use

12 FR_0503_V2.pdf

12.1 Principle and function

13 FR_0502_V2.pdf

13.1 Introduction

14 FR_0500.pdf

14.1 Notice of use

15 FR_0404_V2.pdf

15.1 Preparation of the kit lin trs court

16 FR_0402_V2.pdf

16.1 Lot of parts (0844 809.0)

17 FR_0401_V2.pdf

17.1 Introduction

18 FR_0400.pdf

18.1 Notice of assembly

18.2 Kit lin tr

23 FR_0206_V2.pdf

23.1 Preassembly of the kit lin

24 FR_0205_V2.pdf

24.1 Preparation of the pick-up

25 FR_0204_V2.pdf

25.1 Reduction of the name of the courses

26 FR_0202_V2.pdf

26.1 Lot of parts (0844 801.0)

27 FR_0201_V2.pdf

27.1 Introduction

28 FR_0509_V2.pdf

28.1 Maintenance

29 RU_0100.pdf

29.1 ?? ????????? ?????? ???????? ????

41 RU_0402_V2.pdf

41.1 ?????? ??????? (0844 809.0)

42 RU_0401_V2.pdf

42.1 ????????

43 RU_0400.pdf

43.1 ?????????? ?? ??????

43.2 ???????? ?????? ???????? ????

44 RU_0210_V2.pdf

44.1 ???????????????????

45 RU_0209_V2.pdf

45.1 ???????? ??? ??????? ? ???

46 RU_0208_V2.pdf

46.1 ?????????? ????????? ????????? ????

47 RU_0207_V2.pdf

47.1 ?????? ????????? ?????

48 RU_0206_V2.pdf

48.1 ??????????????? ?????? ????????? ?????

49 RU_0205_V2.pdf

49.1 ?????????? ?????-??????????

50 RU_0204_V2.pdf

50.1 ?????????? ????? ????????? ??????

51 RU_0202_V2.pdf

51.1 ?????? ??????? (0843 001.0)

52 RU_0201_V2.pdf

52.1 ????????

53 RU_0200.pdf

53.1 ?????????? ?? ??????

53.2 ???????? ??? ???? ? ????????? ????

54 RU_0102b_V2.pdf

54.1 ?????? ??????????

54.2 ???????? ????????????????? ??????

54.3 ???? ???????? ?? ??????? ???????????? ? ????????????? ?????????? ???????

54.4 ??????? ??????

54.5 ????????????? ?? ?????????

55 RU_0101.pdf

55.1 ???????? ?? ??????? ????????????

56 RU_0509_V2.pdf

56.1 ??????????? ????????????

57 FR_0201_V2.pdf

57.1 Introduction

58 FR_0202_V2.pdf

58.1 Lot of parts (0844 801.0)

59 FR_0204_V2.pdf

59.1 Reduction of the name of the courses

60 FR_0205_V2.pdf

60.1 Preparation of the pick-up

61 FR_0206_V2.pdf

61.1 Preassembly of the kit lin

62 FR_0207_V2.pdf

62.1 Assembly of kit lin

63 FR_0208_V2.pdf

63.1 Preparation of the kit ?Lin court?

64 FR_0209_V2.pdf

64.1 Guides-ficelle et couteau

65 FR_0210_V2.pdf

65.1 Electric

66 FR_0400.pdf

66.1 Notice of assembly

66.2 Kit linen tr?s court

67 FR_0400.pdf

67.1 Notice of assembly

67.2 Kit linen tr?s court

68 FR_0401_V2.pdf

68.1 Introduction

69 FR_0402_V2.pdf

69.1 Lot of parts (0844 809.0)

70 FR_0404_V2.pdf

70.1 Preparation of the kit ? lin tr?s court ?

71 FR_0500.pdf

71.1 Notice of use

72 FR_0502_V2.pdf

72.1 Introduction

73 FR_0503_V2.pdf

73.1 Principle and function

74 FR_0504_V2.pdf

74.1 Before utilization

75 FR_0505_V2.pdf

75.1 Utilization for the pressage of lin

76 FR_0506_V2.pdf

76.1 Utilization for the pressage du lin court

77 FR_0507_V2.pdf

77.1 Utilization for the pressage du lin trs court

78 FR_0508_V2.pdf

78.1 Utilization of the press for other products

79 FR_0509_V2.pdf

79.1 Maintenance

80 RU_0100.pdf

80.1 an87.1 (0843 001.0)

88 RU_0204_V2.pdf

88.1 nnations

00 0301 090 0.pdf

Table of Contents:

1 VARIANT 360 / 360 RotoCutVARIANT 365 RotoCutVARIANT 380 / 380 RotoCutVARIANT 385 RotoCut

2 Table of Contents

3 1 About these operating instructions

3.1 1.1 General information

4 2 Security

4.1 2.1 General information

4.2 2.2 Warning symbol

4.3 2.3 Safety device

5 3 Machine description

5.1 3.1 Existing models

5.2 3.2 Overview and functions

5.3 3.3 Work and service areas

5.4 3.4 Type plate and serial number

5.5 3.5 General functional principle

5.6 3.6 Operating terminal

5.7 3.7 PTO shaft and drive

5.8 3.8 Good intake

5.9 3.9 Feeding unit

5.10 3.10 Pressing device

5.11 3.11 Binding system

5.12 3.12 Bale storage

5.13 3.13 Lubricating oil system

5.14 3.14 Lubrication system

5.15 3.15 Brake

5.16 3.16 Equipment

6 4 Control and display elements

6.1 4.1 OPERATOR

6.2 4.2 COMMUNICATOR II

6.3 4.3 ISOBUS Terminal

7 5 Technical data

7.1 5.1 Press

7.2 5.2 Safety devices

7.3 5.3 Tractor

8 6 Prepare machine

8.1 6.1 General information

8.2 6.2 Drive shaft

8.3 6.3 Attachment bracket

8.4 6.4 Hydraulic connections

8.5 6.5 Electrical connections

8.6 6.6 Brake

8.7 6.7 Yarn binding

8.8 6.8 Net binding

8.9 6.9 Cutting device

8.10 6.10 Load machine

9 7 Operation

9.1 7.1 General information

9.2 7.2 Movement of the press

9.3 7.3 Before each use

9.4 7.4 Field operation

9.5 7.5 Specific use

9.6 7.6 Pick-up

9.7 7.7 Feeding unit

9.8 7.8 Binding

9.9 7.9 Bale parameters

9.10 7.10 OPERATOR

9.11 7.11 COMMUNICATOR II

9.12 7.12 ISOBUS Terminal

9.13 7.13 Unclogging the press

9.14 7.14 After use

10 8 Malfunction and remedy

10.1 8.1 General information

10.2 8.2 Hydraulics

10.3 8.3 COMMUNICATOR II

10.4 8.4 Binding

10.5 8.5 Lubricating oil system

10.6 8.6 Lubrication system

10.7 8.7 Other functions

11 9 Maintenance

11.1 9.1 General maintenance instructions

11.2 9.2 Maintenance tables

11.3 9.3 Lubricant tables

11.4 9.4 Lubrication plan

11.5 9.5 Maintenance work gearbox

11.6 9.6 Maintenance work axle and wheels

11.7 9.7 Maintenance work brake

11.8 9.8 Maintenance work trailer hitch

11.9 9.9 Maintenance work hydraulic system

11.10 9.10 Maintenance work Pickup

11.11 9.11 Maintenance work on the pull-in unit

11.12 9.12 Maintenance work press chamber

11.13 9.13 Maintenance work Binding

11.14 9.14 Maintenance work bale storage

11.15 9.15 Maintenance work lubricating oil system

11.16 9.16 Maintenance work lubrication system

11.17 9.17 Maintenance work machine housing

11.18 9.18 Winterization

12 10 Decommissioning and disposal

12.1 10.1 General information

13 11 EC declaration of conformity

13.1 11.1 General information

00 0301 385 7.pdf

Table of Contents:

1 VARIANT 485 ROTO CUTVARIANT 480 / 480 ROTO CUTVARIANT 465 ROTO CUTVARIANT 460 / 460 ROTO CUT

2 Table of Contents

3 1 Introduction

3.1 1.1 General information

3.2 1.2 Intended use

4 2 Security

4.1 2.1 Recognize warnings

4.2 2.2 Safety instructions

4.3 2.3 Warning symbol

5 3 Machine description

5.1 3.1 Existing models

5.2 3.2 Overview and functions

5.3 3.3 Safety device

5.4 3.4 Work and service areas

5.5 3.5 Type plate and serial number

5.6 3.6 General functional principle

5.7 3.7 Information on the machine

5.8 3.8 Operating terminal

5.9 3.9 PTO shaft and drive

5.10 3.10 Hitch bracket

5.11 3.11 Receipt

5.12 3.12 Feeding unit

5.13 3.13 Pressing device

5.14 3.14 Binding system

5.15 3.15 Bale placement

5.16 3.16 Lubricating oil system

5.17 3.17 Lubrication system

5.18 3.18 Brake

5.19 3.19 Hydraulics

5.20 3.20 Equipment

6 4 Control and display elements

6.1 4.1 COMMUNICATOR II

6.2 4.2 OPERATOR

6.3 4.3 ISOBUS Terminal

6.4 4.4 EASY on board

7 5 Technical data

7.1 5.1 Press

7.2 5.2 Safety devices

7.3 5.3 Operating materials

7.4 5.4 Tractor

8 6 Prepare machine

8.1 6.1 Switch off and secure the machine

8.2 6.2 Adjust tractor

8.3 6.3 Adjust machine

8.4 6.4 Attach machine

8.5 6.5 Preparing for work

8.6 6.6 Yarn binding

8.7 6.7 Net binding

8.8 6.8 Cutting device

8.9 6.9 Loading the machine

9 7 Operation

9.1 7.1 General information

9.2 7.2 Movement of the press

9.3 7.3 Before each use

9.4 7.4 Field operation

9.5 7.5 Specific use

9.6 7.6 Pick-up

9.7 7.7 Feeding unit

9.8 7.8 Binding

9.9 7.9 Bale parameters

9.10 7.10 OPERATOR

9.11 7.11 OPERATOR with simplified menu

9.12 7.12 COMMUNICATOR II

9.13 7.13 ISOBUS Terminal

9.14 7.14 EASY on board

9.15 7.15 Unclogging the press

9.16 7.16 After Use

9.17 7.17 Detach machine

10 8 Malfunction and remedy

10.1 8.1 General information

10.2 8.2 Hydraulics

10.3 8.3 COMMUNICATOR II

10.4 8.4 Binding

10.5 8.5 Lubricating oil system

10.6 8.6 Lubrication system

10.7 8.7 Other functions

11 9 Maintenance

11.1 9.1 General maintenance instructions

11.2 9.2 Maintenance tables

11.3 9.3 Lubrication plan

11.4 9.4 Maintenance work gearbox

11.5 9.5 Maintenance work axle and wheels

11.6 9.6 Maintenance work brake

11.7 9.7 Maintenance work trailer hitch

11.8 9.8 Maintenance work hydraulic system

11.9 9.9 Maintenance work Pickup

11.10 9.10 Maintenance work on the pull-in unit

11.11 9.11 Maintenance work press chamber

11.12 9.12 Maintenance work Binding

11.13 9.13 Maintenance work bale storage

11.14 9.14 Maintenance work lubricating oil system

11.15 9.15 Maintenance work lubrication system

11.16 9.16 Maintenance work machine housing

11.17 9.17 Winterization

12 10 Decommissioning and disposal

12.1 10.1 General information

13 11 EC declaration of conformity

13.1 11.1 General information

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish