Table of Content:

1 ELECTRONIC MANUALS

2 FRONT COVER

3 INTRODUCTION

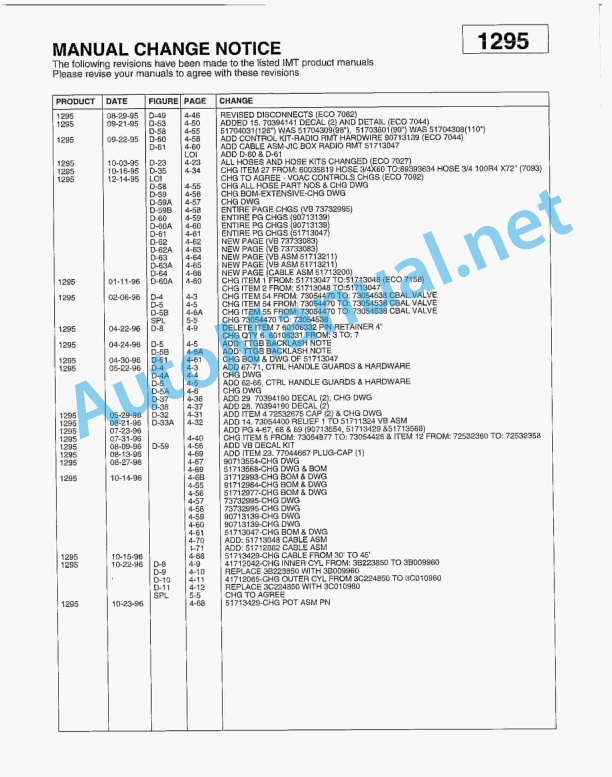

4 REVISIONS LIST

5 MAINTENANCE AND REPAIR MANUAL

6 REFERENCE TO SAFETY MANUAL

7 OTHER IMT PUBLICATIONS

8 TABLE OF CONTENTS

9 LIST OF ILLUSTRATIONS

10 OPERATION

10.1 1-1. GENERAL

10.2 1-2. VEHICLE CONTROLS

10.3 1-3. CRANE CONTROLS

10.4 Figure A-1. TYPICAL CRANE CONTROL DECALS

10.5 Figure A-2. TYPICAL REMOTE CONTROL DECALS

10.6 Figure A-3. TYPICAL WALLBOARD CRANE CONTROL DECAL

10.7 Figure A-4. TYPICAL LOADER CONTROL DECAL (TOE/HEEL)

10.8 Figure A-5. TYPICAL LOADER CONTROL DECAL (TOE/TOE)

10.9 1-3-1. REMOTE CONTROLS

10.10 1-3-2. GENERAL THEORY OF OPERATION

10.11 1-4. SAFETY FACTORS

10.12 1-4-1. LOAD LIMITS

10.13 1-4-2. EQUIPMENT INSPECTION

10.14 1-4-3. WORK STATION POSITIONING

10.15 1-4-4. OPERATING RESTRICTIONS

10.16 1-5. ENGINE SPEED REGULATION

10.17 Figure A-7. FORMULA – ENGINE RPM

10.18 1-6. LOAD LIFTING

10.19 1-7. STABILTY RATINGS

10.20 1-8. ANTI TWO BLOCKING SYSTEM

10.21 1-9. TASK PERFORMANCE

10.22 1-10. CRANE SHUTDOWN

10.23 1-11. OPERATORS

10.24 1-12. OPERATION IN ADVERSE CONDITIONS

10.25 1-12-1. DUSTY AND SANDY AREAS

10.26 1-12-2. HIGH HUMIDITY OR SALT AIR CONDITIONS

10.27 1-12-3. HIGH ALTITUDE

10.28 1-12-4. COLD WEATHER

10.29 1-13. HAND SIGNALS

10.30 Figure A-8. HAND SIGNALS

10.31 1-14. CRANE CAPACITY ALERT SYSTEM (ELECTRICALLY OPERATED)

10.32 Figure A-9. GENERAL CAPACITY ALERT SYSTEM WIRING DIAGRAM (ELECTRICAL)

10.33 1-15. CAPACITY ALERT SYSTEM (HYDRAULICALLY OPERATED)

10.34 Figure A-10.GENERAL CAPACITY ALERT SYSTEM DIAGRAM (HYDRAULIC)

10.35 1-16. CRANE CAPACITY AUDIBLE ALERT SYSTEM (ELECTRICALLY OPERATED)

10.36 Figure A-11. GENERAL CAPACITY AUDIBLE ALERT SYSTEM WIRING DIAGRAM

11 DECALS

11.1 Figure A1-1. DECAL LOCATIONS ON TELESCOPING CRANES

11.2 1A-1. DECAL PLACEMENT-TELESCOPING CRANES

11.3 Figure A1-2. DECAL LOCATIONS ON ARTICULATING CRANES

11.4 1A-2. DECAL PLACEMENT -ARTICULATING CRANES

11.5 1A-3. “DANGER” DECAL DESCRIPTIONS

11.6 1A-4. INSTRUCTIONAL DECALS

12 MAINTENANCE

12.1 2-1. GENERAL

12.2 2-2. LUBRICANTS

12.3 2-3. LUBRICATION

12.4 2-4. HYDRAULIC FLUID SPECIFICATION

12.5 Figure B-2. LUBRICATION PRODUCT & SCHEDULE

12.6 Figure B-3. HYDRAULIC FLUID SPECIFICATIONS

12.7 Figure B-1. GREASE WEEKLY DECAL

12.8 Figure B-4. TYPICAL GREASE ZERK LOCATIONS-TELESCOPING CRANES

12.9 Figure B-5. TYPICAL GREASE ZERK LOCATIONS-ARTICULATING CRANES

12.10 Figure B-6. TYPICAL GREASE ZERK LOCATIONS-WALLBOARD CRANES

12.11 Figure B-7. TYPICAL GREASE ZERK LOCATIONS-SPIDER LEG OUTRIGGERS

12.12 Figure B-8. TYPICAL GREASE ZERK LOCATIONS-LOG LOADERS

12.13 Figure B-9. HYDRAULIC FLUID PRECAUTIONS

12.14 2-5. HYDRAULIC OIL DETERIORATION

12.15 2-6. HYDRAULIC SYSTEM PURGING

12.16 2-7. PURGING AIR FROM THE SYSTEM

12.17 2-8. SYSTEM RELIEF PRESSURE

12.18 2-9. CYLINDER HOLDING CAPABILITIES

12.19 2-10. FILTER ELEMENT REPLACEMENT

12.20 2-11. WIRE ROPE MAINTENANCE

12.21 Figure B-10. SWIVEL HOOK GREASE ZERK

12.22 2-12. HOOK MAINTENANCE

12.23 Figure B-11. ROPE ATTACHMENTS

12.24 2-13. PERIODIC VEHICLE INSPECTION

12.25 2-14. PERIODIC CRANE INSPECTION

12.26 2-15. ADDITIONAL INSPECTIONS

12.27 2-16. REMOTE CONTROL INSPECTION

12.28 2-17. CORROSION CONTROL

12.29 2-18. LONG TERM STORAGE

12.30 2-19. PROPORTIONAL REMOTE CONTROL TROUBLESHOOTING

12.31 Figure B-14. VALVEBANK-PROPORTIONAL REMOTE CONTROL

13 REPAIR

13.1 3-1. GENERAL

13.2 3-2. MAINTENANCE PRECAUTIONS

13.3 3-3. GENERAL PRECAUTIONS

13.4 3-4. REPAIR PROCEDURE

13.5 3-5. CLEANLINESS

13.6 3-6. HYDRAULIC SYSTEMS

13.7 3-7. FASTENERS AND TORQUE VALUES

13.8 3-8. LABEL PARTS WHEN DISASSEMBLING

13.9 3-9. BOOM WEAR PADS

13.10 3-10. PIN AND BEARING INSPECTION AND INSTALLATION

13.11 3-10-1. PIN INSPECTION

13.12 3-10-2. PIN BEARING INSPECTION

13.13 3-10-3. INSTALLATION

13.14 3-11. TURNTABLE GEAR – REMOVAL AND REPLACEMENT

13.15 Figure C-1. TURNTABLE GEAR BEARING INSTALLATION

13.16 Figure C-2. BUSHING REMOVAL

13.17 Figure C-3. BUSHING INSTALLATION

13.18 3-12. PINION AND DRIVE GEAR BUSHINGS – REMOVAL AND REPLACEMENT

13.19 3-13. REMOVAL AND REPLACEMENT OF OUTRIGGER ARMS

13.20 3-14. VERTICAL OUTRIGGER CYLINDERS – REMOVAL AND REPLACEMENT

13.21 Figure C-4. POWER DOWN OUTRIGGER

13.22 3-15. EXTERNAL HORIZONTAL OUTRIGGER CYLINDERS – REMOVAL AND REPLACEMENT

13.23 3-16. FOLD-DOWN OUTRIGGER CYLINDER-REMOVAL AND REPLACEMENT

13.24 3-17. EXTENSION CYLINDER-REMOVAL AND REPLACEMENT

13.25 3-17-1. EXTERNAL CYLINDER

13.26 Figure C-5. FOLD-DOWN OUTRIGGER

13.27 3-17-2. INTERNAL CYLINDER

13.28 3-17-3. BOLT-ON EXTENSION CYLINDER

13.29 Figure C-6. EXTERNAL EXTENSION CYLINDER

13.30 Figure C-8. BOLT-ON EXTENSION CYLINDER

13.31 Figure C-7. INTERNAL EXTENSION CYLINDER

13.32 3-18. REMOVAL AND REPLACEMENT OF OPERATOR CONTROL VALVE

13.33 3-19. OUTER BOOM -REMOVAL AND REPLACEMENT

13.34 3-20. OUTER CYLINDER -REMOVAL AND REPLACEMENT

13.35 3-21. INNER CYLINDER -REMOVAL AND REPLACEMENT

13.36 3-22. INNER BOOM -REMOVAL AND REPLACEMENT

13.37 3-23. ROTATION MOTOR, COUNTERBALANCE VALVE AND BRAKE – REMOVAL AND REPLACEMENT

13.38 3-24. ‘KICKOUT’ A-FRAME OUTRIGGER CYLINDER- REMOVAL AND REPLACEMENT

13.39 Figure C-9. ‘KICKOUT’ A-FRAME OUTRIGGER REFERENCE

14 CYLINDER REPAIR

14.1 3A-1. CYLINDER DISASSEMBLY

14.2 Figure C1-1. TYPICAL CYLINDER AND SEAL KIT COMPONENTS

14.3 Figure C1-2. SEAL INSTALLATION GUIDELINES

14.4 3A-2. CYLINDER ASSEMBLY

14.5 3A-3. TELESCOPING CYLINDER DISASSEMBLY

14.6 3A-4. TELECOPING CYLINDER ASSEMBLY

14.7 Figure C1-3. TELESCOPING EXTENSION CYLINDER COMPONENTS

14.8 APPENDIX: PISTON & HEAD SPANNER WRENCH ATTACHMENT PART NUMBERS

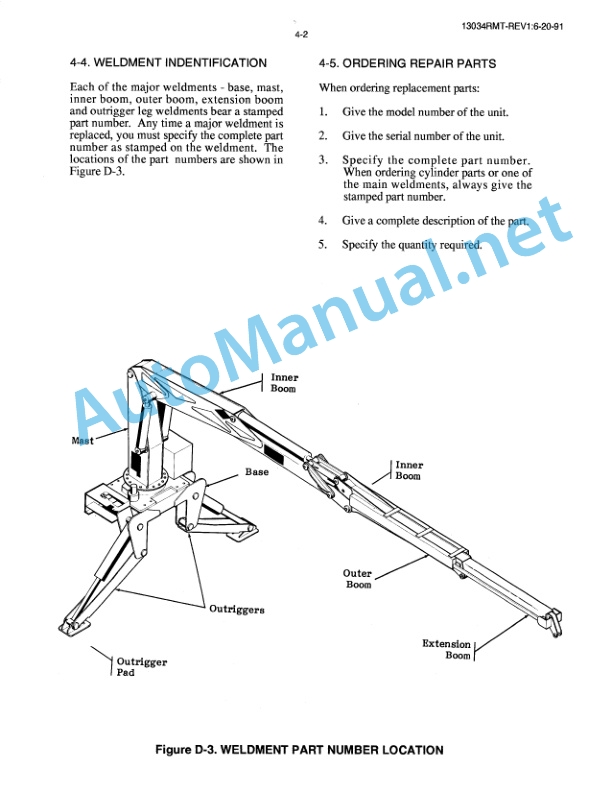

15 CHASSIS PREP FOR INSTALLATION

15.1 4-1. GENERAL

15.2 4-2. CHASSIS PREPARATION

15.3 4-2-1. FRAME STRENGTH

15.4 4-2-2. FRONT MOUNTED CRANE APPLICATION

15.5 4-2-3. REAR MOUNTED CRANE APPLICATION

15.6 4-2-4. FRAME REINFORCEMENT

15.7 Figure D-1. TYPICAL TORSIONAL SUB-FRAME

15.8 Figure D-2. FRAME REINFORCEMENT

15.9 4-3. PTO AND PUMP

15.10 4-3-1. PTO INSTALLATION

15.11 4-3-2. PUMP INSTALLATION

15.12 Figure D-3. PTO/PUMP INSTALLATION

15.13 4-3-3. DRIVELINE APPLICATION

15.14 Figure D-4. DRIVELINE APPLICATION

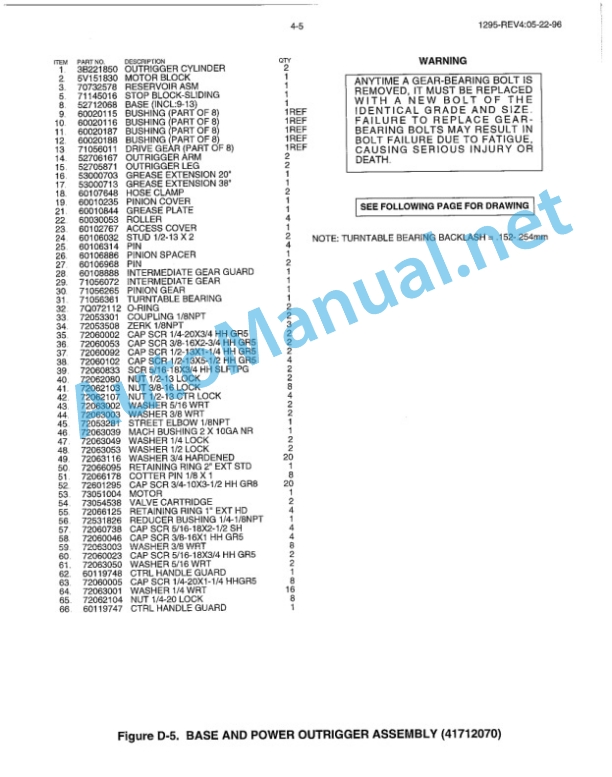

16 GENERAL REFERENCE

16.1 INSPECTION CHECKLIST

16.2 WIRE ROPE INSPECTION

16.3 HOOK INSPECTION

16.4 ANTI-TWO BLOCKING DEVICE INSPECTION

16.5 HOLDING VALVE INSPECTION

16.6 ANTI-TWO BLOCKING DEVICE INSPECTION

16.7 TORQUE DATA CHART – DOMESTIC

16.8 TORQUE DATA CHART – METRIC

16.9 TURNTABLE BEARING FASTENER TIGHTENING SEQUENCE

16.10 TURNTABLE BEARING INSPECTION FOR REPLACEMENT

16.11 CONVERSION FACTORS

16.12 LIMITED WARRANTY