Bomag BF 700 C-2 Paver Service Manual 00840018

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840018

- Format: PDF

- Size: 40.2MB

- Number of Pages: 512

- Serial Number:

821892111001 and up

-

Model List:

- BF 700 C-2 Paver

- 1. Table of contents

- 2. General

- 2.1. Introduction Service Manual

- 2.2. Concerning your safety

- 2.2.1. Handling fuels and lubricants

- 2.2.1.1. Preliminary remarks

- 2.2.1.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 2.2.1.3. Safety regulations and environmental protection regulations for handling oil

- 2.2.1.4. Safety regulations and environmental protection regulations for handling hydraulic oil

- 2.2.1.5. Safety regulations and environmental protection regulations for handling coolants

- 2.2.1.6. Safety regulations and environmental protection regulations for handling battery acid

- 2.2.2. Working on hydraulic lines

- 2.2.3. Working on the engine

- 2.2.4. Maintenance work on electric components and battery

- 2.2.5. Working on heating elements

- 2.2.6. Cleaning work

- 2.2.7. Parking the machine in secured condition

- 2.3. Fuels and lubricants

- 2.3.1. Engine oil

- 2.3.1.1. Oil quality

- 2.3.1.2. Oil viscosity

- 2.3.1.3. Oil change intervals

- 2.3.2. Fuel

- 2.3.2.1. Fuel quality

- 2.3.2.2. Winter fuel

- 2.3.2.3. Storage

- 2.3.3. Coolant

- 2.3.3.1. General

- 2.3.3.2. Topping up coolant

- 2.3.3.3. Replacing coolant

- 2.3.4. Hydraulic oil

- 2.3.4.1. Mineral oil based hydraulic oil

- 2.3.4.2. Biodegradable hydraulic oil

- 2.3.5. Gear oil ISO VG 220

- 2.3.6. Lubrication grease

- 2.3.7. Hightemperature lubrication grease

- 2.4. List of fuels and lubricants

- 2.5. Repair notes for hydraulics

- 3. Technical data

- 4. Total overview of machine

- 4.1. Component overview electrics

- 4.2. Component overview Wiring looms

- 4.3. Component overview hydraulics

- 5. Troubleshooting

- 5.1. Overviews

- 5.1.1. Overview Travel system

- 5.1.2. Overview Material Transport

- 5.1.3. Overview Screed Functions

- 5.2. Codes General Information

- 5.3. Fault codes

- 5.3.1. Foreword

- 5.3.2. Fault code list

- 5.3.3. Fault Rectification

- 6. Electrics

- 6.1. Control units

- 6.1.1. Software Updating

- 6.2. Display

- 6.2.1. LCDisplay unit

- 6.3. Input codes

- 6.3.1. Resetting to factory settings

- 6.3.2. Travel Control (Travel Functions)

- 6.3.2.1. Automatic Calibration Of Currents In Travel System

- 6.3.2.2. Calibrating the travel system manually

- 6.3.2.3. Travel signal by push button for partial screed relief

- 6.3.2.4. Steering with toggle button for track control, should the steering encoder be defective

- 6.3.2.5. Changing the type of speed potentiometer

- 6.3.2.6. Driving against the closed brake

- 6.3.2.7. Activating/deactivating the screed heating in low idle speed

- 6.3.2.8. Activating/deactivating the cleaning function

- 6.3.2.9. Activating/deactivating the charge pressure relief valve

- 6.3.2.10. Managing settings

- 6.3.3. Screed control (screed functions)

- 6.3.3.1. Calibrating the LCSfunction

- 6.3.3.2. Activating/deactivating the twin LCS

- 6.3.3.3. Calibrating tamper pump currents

- 6.3.3.4. Changing the tamper start and stop ramp

- 6.3.3.5. Calibrating vibration pump currents

- 6.3.3.6. Managing settings

- 6.3.4. Material flow control

- 6.3.4.1. Activating/deactivating the hydraulic front hopper wing

- 6.3.4.2. Calibrating auger pump currents

- 6.3.4.3. Changing the auger start and stop ramp

- 6.3.4.4. Calibrating scraper belt pump currents

- 6.3.4.5. Enable/disable lifting the auger block together with the screed

- 6.3.4.6. Managing settings

- 6.3.5. Managing the fault log

- 6.3.6. Read out fault codes Deutz

- 6.4. Replacement of electrical components

- 6.4.1. Control system

- 6.4.2. Travel pump

- 6.4.3. Pump for the auger drive

- 6.4.4. Pump for the scraper belt drive

- 6.4.5. Pump for the tamper drive

- 6.4.6. Pump for the vibration drive

- 6.4.7. Components without adjustment/teach procedure

- 7. Engine

- 7.1. Diesel engine description

- 7.2. Engine maintenance

- 7.2.1. Checking the engine oil level

- 7.2.2. Change engine oil and oil filter cartridge

- 7.2.3. Checking, cleaning the water separator

- 7.2.4. Replacing the fuel filter, bleeding the fuel system

- 7.2.4.1. Preliminary remarks

- 7.2.4.2. Replacing the fuel filter

- 7.2.4.3. Replacing the fuel prefilter

- 7.2.4.4. Bleed the fuel system

- 7.2.5. Air filter maintenance

- 7.2.5.1. Replacing the safety element

- 7.2.6. Checking the coolant level

- 7.2.7. Changing the coolant

- 7.2.8. Servicing the Vbelt

- 7.2.8.1. Checking the Vbelt

- 7.2.8.2. Tensioning the generator Vbelt

- 7.2.8.3. Replacing the generator Vbelt

- 7.2.8.4. Tightening the Vbelt for coolant pump and fuel pump

- 7.2.8.5. Replacing coolant and fuel pump

- 7.2.9. Checking the engine mounts

- 7.2.10. Adjusting the valve clearance

- 7.2.11. Engine faults

- 7.3. Engine electrics

- 7.3.1. EMR3 system components

- 7.3.2. Rotary speed sensor for camshaft, B114

- 7.3.3. Crankshaft speed sensor, B130

- 7.3.4. Rail pressure sensor, B93

- 7.3.5. Fuel pressure sensor, B145

- 7.3.6. Fuel Control Unit Y137

- 7.3.7. Injectors, Y147, Y149, Y169 and Y170

- 7.3.8. Oil pressure sensor, B88

- 7.3.9. Charge air temperature/charge pressure sensor, B133

- 7.3.10. EMR coolant temperature sensor, B113

- 7.3.11. Glow plugs

- 7.3.12. Sensor, water in fuel, B124

- 7.3.13. Diagnose with Serdia

- 7.3.14. Diagnostics with CANbus

- 7.3.15. Diagnostics interface

- 7.3.16. Removing and installing the electric starter

- 8. Hydraulic system

- 8.1. Hydraulics fundamentals

- 8.2. Routing of hydraulic hoses

- 8.2.1. Hoses for travel functions

- 8.2.2. Hoses for radiator

- 8.2.3. Hoses for scraper belt

- 8.2.4. Hoses for auger

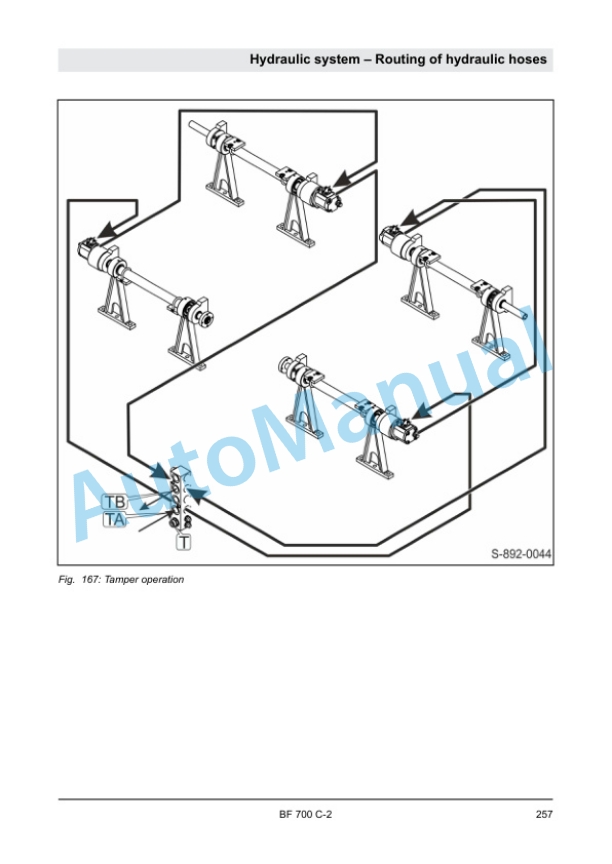

- 8.2.5. Hoses for tamper vibration

- 9. Assembly groups

- 9.1. Tractor

- 9.1.1. General

- 9.1.2. Travel system

- 9.1.3. Drivers stand

- 9.2. Material transport

- 9.2.1. Hopper

- 9.2.2. Scraper belt

- 9.2.3. Augers

- 9.2.4. Tunnel

- 9.2.5. Side plates

- 9.2.6. Inspection and maintenance work

- 9.2.6.1. Material transport

- 9.2.6.2. Every 250 operating hours

- 9.2.6.2.1. Servicing the scraper belt

- 9.2.6.2.2. Servicing the scraper belt drive chain

- 9.2.6.2.3. Servicing the auger

- 9.2.6.2.4. Checking scraper and rubber apron on material hopper

- 9.2.6.3. Every 500 operating hours

- 9.2.6.3.1. Checking the hydraulic lines

- 9.2.6.4. As required

- 9.2.6.4.1. Extending auger and tunnel

- 9.3. Screed S600

- 9.3.1. Description

- 9.3.2. Basic settings on the screed

- 9.3.2.1. To be observed before adjusting the screed

- 9.3.2.2. Basic settings screed S500/600

- 9.3.3. Assembling the screed extensions

- 9.4. Screed heating

- 9.4.1. Description

- 9.4.2. Screed heating commissioning

- 9.4.3. Faults in the electric heating

- 10. Appendix

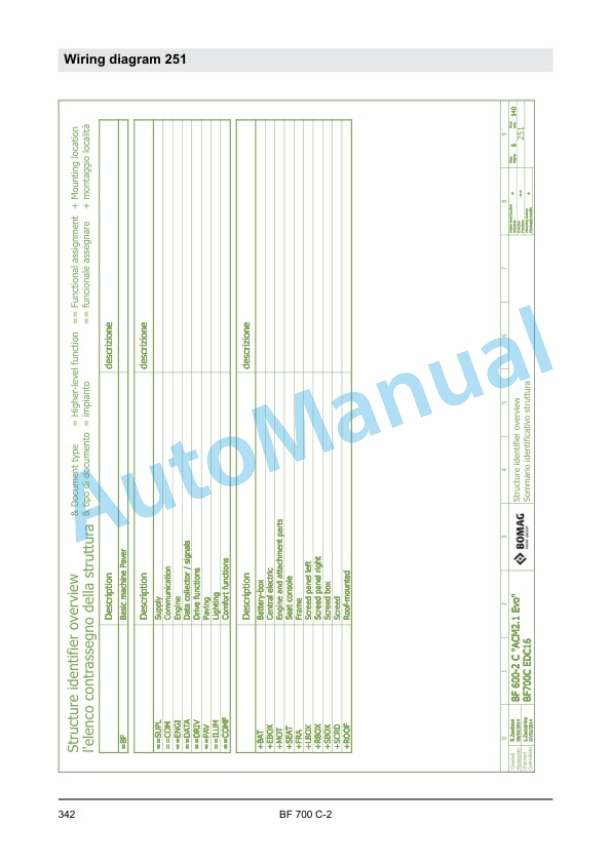

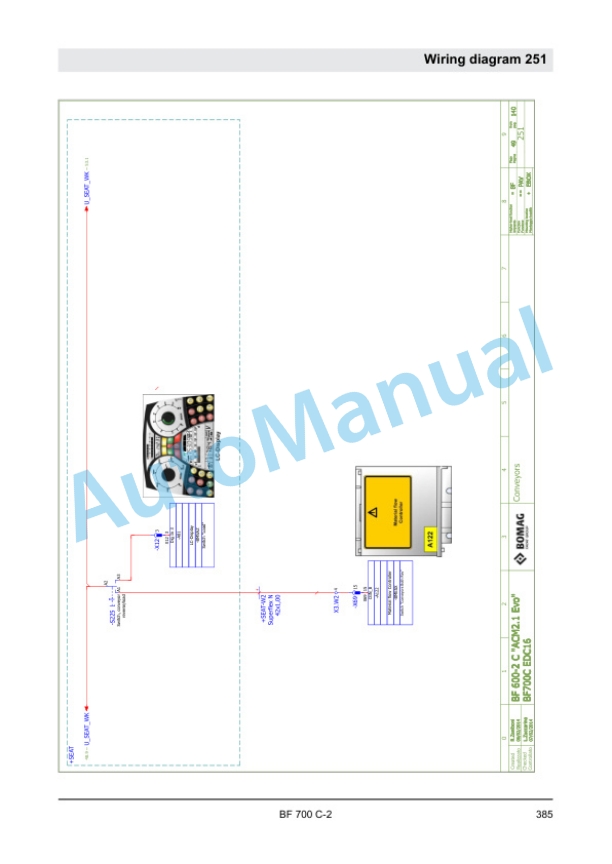

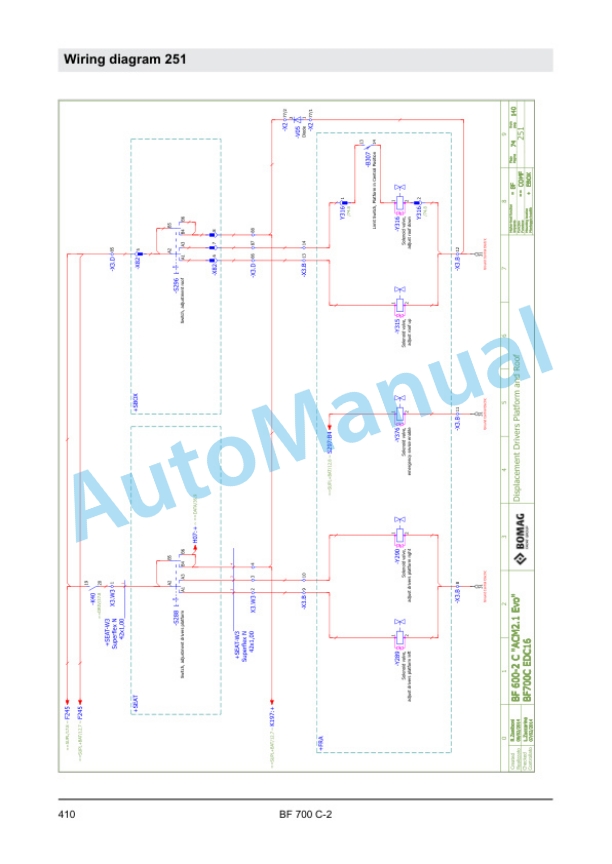

- 10.1. A Wiring diagram 251

- 10.2. B Wiring diagram screed S600

- 10.3. C Hydraulic diagram BF700C

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930051001 – 101930051010

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

Bomag Service Manual PDF

Bomag BC 472 RS Refuse Compactor Electric, Hydraulic Schematics Diagram 101930011002 – 101930011011

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 EB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930061001 – 101930061001