Bomag BM 1000-30 Service Manual 00840200

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840200

- Format: PDF

- Size: 72.2MB

- Number of Pages: 888

- Serial Number:

821836551001 and up

-

Model List:

- BM 1000-30

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.2.1. Handling fuels and lubricants

- 2.2.1.1. Preliminary remarks

- 2.2.1.2. Safety regulations and environmental protection regulations for handling diesel fuel

- 2.2.1.3. Safety regulations and environmental protection regulations for handling oil

- 2.2.1.4. Safety regulations and environmental protection regulations for handling hydraulic oil

- 2.2.1.5. Safety regulations and environmental protection regulations for handling coolants

- 2.2.1.6. Safety regulations and environmental protection regulations for handling battery acid

- 2.2.2. Parking the machine in secured condition

- 2.3. Fuels and lubricants

- 2.3.1. Engine oil

- 2.3.1.1. Oil quality

- 2.3.1.2. Oil viscosity

- 2.3.1.3. Oil change intervals

- 2.3.2. Fuel

- 2.3.2.1. Fuel quality

- 2.3.2.2. Winter fuel

- 2.3.2.3. Storage

- 2.3.3. Coolant

- 2.3.4. Hydraulic oil

- 2.3.4.1. Mineral oil based hydraulic oil

- 2.3.4.2. Biodegradable hydraulic oil

- 2.3.5. Gear oil ISO VG 220

- 2.3.6. Gear oil SAE 75W90

- 2.3.7. Lubrication grease

- 2.3.8. Hightemperature lubrication grease

- 2.4. List of fuels and lubricants

- 2.5. Notes on repair

- 2.5.1. General repair instructions

- 2.5.1.1. Repair notes for electrics

- 2.5.1.2. Repair notes for hydraulics

- 2.5.1.3. Repair notes for Common Rail engines

- 2.5.1.4. Repair notes for gaskets and mating surfaces

- 2.5.1.5. Repair notes for ball and roller bearings

- 2.5.1.6. Feather keys and keyways

- 2.5.1.7. Repair notes for cotter pins

- 2.5.1.8. Repair notes for screws and nuts

- 2.5.1.9. Strength classes, metric screws and nuts

- 2.5.1.10. Identification of UNFthreads

- 2.5.2. Tightening torques

- 3. Technical data

- 4. Total overview of machine

- 4.1. Outside view of machine

- 4.1.1. Overview of maintenance flaps and doors

- 4.1.2. Display field, pressure gauge, hydraulic pressure

- 4.2. Component overview Electrics

- 4.3. Component overview hydraulics

- 5. Trouble shooting

- 5.1. Preliminary remarks

- 5.2. Emergency procedures

- 5.2.1. Actuating the emergency stop switch

- 5.2.2. Disconnecting the battery

- 5.2.3. Towing the machine

- 5.3. Overviews

- 5.3.1. Travel system

- 5.3.2. Milling drive

- 5.3.3. Height adjustment

- 5.3.4. Steering

- 5.3.5. Conveyor belt

- 5.4. Troubleshooting, electrical systems

- 5.4.1. Preliminary remarks

- 5.4.2. Starting the engine with jump leads

- 5.4.3. Servicing the battery, checking the main battery isolation

- 5.4.3.1. Battery service

- 5.4.3.2. Checking the main battery shutoff

- 5.4.4. Fuse assignment

- 5.4.4.1. Notes on safety

- 5.4.4.2. Central electrics

- 5.4.4.3. Main fuses

- 5.4.5. Understanding electric circuit diagrams

- 5.4.5.1. Electric circuit diagrams

- 5.4.5.2. Circuit symbols in EPlan

- 5.4.5.3. Identification of switch blocks

- 5.4.6. Measuring method

- 5.4.7. ESX, checking the electric power supply

- 5.4.8. Diagnostics concept

- 5.5. Trouble shooting, hydraulics

- 5.5.1. Insufficient hydraulic power

- 5.5.2. Trouble shooting axial piston pumps

- 5.5.3. Trouble shooting axial piston motors

- 5.5.4. Fault table hydraulic components

- 6. Electric systems

- 6.1. Display

- 6.1.1. Description

- 6.1.2. Overview

- 6.1.3. Displays on the work screen

- 6.1.4. Switching between metric and imperial units

- 6.1.5. Setting the screen brightness/contrast

- 6.1.6. Fault code display

- 6.2. Central electrics

- 6.3. Fuse assignment

- 6.3.1. Notes on safety

- 6.3.2. Central electrics

- 6.3.3. Main fuses

- 6.4. Wiring looms

- 6.5. Display Levelling

- 6.6. Sensors

- 6.7. Telemecanique switch

- 6.8. Deutsch plug, series DT and DTM

- 6.9. Servicing the battery, checking the main battery isolation

- 6.9.1. Battery service

- 6.9.2. Checking the main battery shutoff

- 6.10. Starting the engine with jump leads

- 7. Diesel engine

- 7.1. Features

- 7.2. Electronic engine control unit

- 7.3. Engine electrics

- 7.3.1. Description of sensors

- 7.3.2. Generator

- 7.3.3. Trouble shooting Starter

- 7.3.4. Repair of starter

- 7.4. Engine diagnostics

- 7.5. Fuel

- 7.6. Cooling system

- 7.7. Inspection and maintenance work

- 7.7.1. Maintenance Table

- 7.7.2. Checks prior to start up

- 7.7.2.1. Notes on safety

- 7.7.2.2. Checking the engine oil level

- 7.7.2.3. Checking, cleaning the water separator

- 7.7.3. Every 250 operating hours

- 7.7.3.1. Cleaning the radiator module

- 7.7.3.2. Checking radiator hoses and hose clamps

- 7.7.3.3. Checking the belt for the travel pump drive

- 7.7.4. Every 500 operating hours

- 7.7.4.1. Change engine oil and oil filter cartridge

- 7.7.4.2. Replacing the fuel filter, bleeding the fuel system

- 7.7.4.3. Checking the antifreeze concentration and the condition of the coolant

- 7.7.4.4. Servicing the battery, checking the main battery isolation

- 7.7.5. Every 1000 operating hours

- 7.7.5.1. Checking, adjusting the valve clearance

- 7.7.5.2. Servicing the belt for the generator

- 7.7.6. Every 3000 operating hours

- 7.7.6.1. Changing the coolant

- 7.7.7. As required

- 7.7.7.1. Air filter maintenance

- 7.7.7.2. Checking the coolant level

- 7.7.7.3. Replacing the belt for the travel pump drive

- 7.7.7.4. Draining the fuel tank sludge

- 7.7.7.5. Taking an engine oil sample

- 8. Hydraulic system

- 8.1. Open and closed hydraulic circuit

- 8.2. Travel circuit

- 8.3. Height adjustment

- 8.4. Steering

- 8.5. Milling operation

- 8.6. Hydraulic units

- 8.6.1. External gear pumps

- 8.6.2. Description of fan pump

- 8.6.3. Working pump

- 8.6.3.1. Axial piston pumps, A10VO/VSO 18 to 100 DF1

- 8.6.4. Conveyor belt pump

- 8.6.5. Travel pump

- 8.6.6. Desxcription of travel motor BOSCH REXROTH

- 8.6.7. Hydraulic cylinder

- 8.6.7.1. Repairing hydraulic cylinders

- 8.6.7.2. Hydraulic cylinder with path measuring system

- 8.7. Inspection and maintenance work

- 8.7.1. Maintenance Table

- 8.7.2. Checks prior to start up

- 8.7.2.1. Notes on safety

- 8.7.2.2. Checking the hydraulic oil level

- 8.7.3. Every 500 operating hours

- 8.7.3.1. Checking the hydraulic lines

- 8.7.4. Every 1000 operating hours

- 8.7.4.1. Replacing the hydraulic oil filter

- 8.7.5. Every 2000 operating hours

- 8.7.5.1. Changing the hydraulic oil

- 9. Assembly groups

- 9.1. Milling drive

- 9.1.1. Description

- 9.1.2. Inspection and maintenance work

- 9.1.2.1. Maintenance Table

- 9.1.2.2. Every 250 operating hours

- 9.1.2.3. Every 500 operating hours

- 9.1.2.4. Every 1000 operating hours

- 9.1.2.5. As required

- 9.2. Milling unit

- 9.2.1. Description

- 9.2.2. Inspection and maintenance work

- 9.2.2.1. Maintenance Table

- 9.2.2.2. Checks prior to start up

- 9.2.2.3. As required

- 9.3. Levelling system

- 9.3.1. Control unit for levelling system

- 9.3.1.1. Buttons and displays

- 9.3.1.2. Display

- 9.4. Travel system

- 9.4.1. Description

- 9.4.2. Inspection and maintenance work

- 9.4.2.1. Maintenance Table

- 9.4.2.2. Checks prior to start up

- 9.4.2.3. Every 250 operating hours

- 9.4.2.4. Every 1000 operating hours

- 9.4.2.5. As required

- 9.4.3. Repairs

- 9.5. Conveyor belt

- 9.5.1. Description

- 9.5.2. Fold in conveyor belt

- 9.5.3. Unfold conveyor belt

- 9.5.4. Inspection and maintenance work

- 9.5.4.1. Maintenance Table

- 9.5.4.2. Checks prior to start up

- 10. List of special tools

- 11. Available special tools

- 11.1. Special tools, electrics

- 11.2. Special tools, hydraulic system

- 11.2.1. Special tools, tests and adjustments

- 11.2.2. Special tools for flushing

- 12. Index

- 13. Appendix

- 13.1. A Supplier documentation

- 13.1.1. Steering and working pump

- 13.1.2. Travel pump

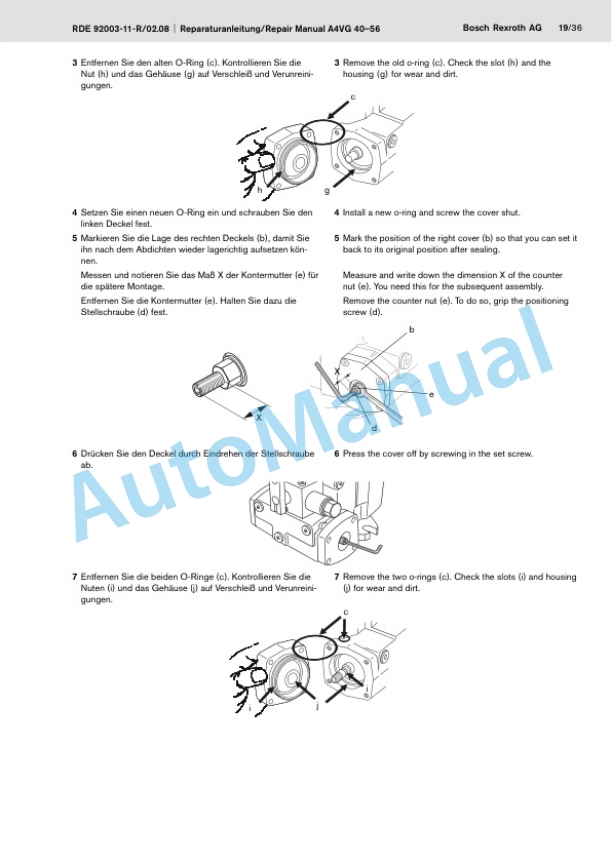

- 13.1.3. Travel motor

- 13.1.4. Conveyor belt pump

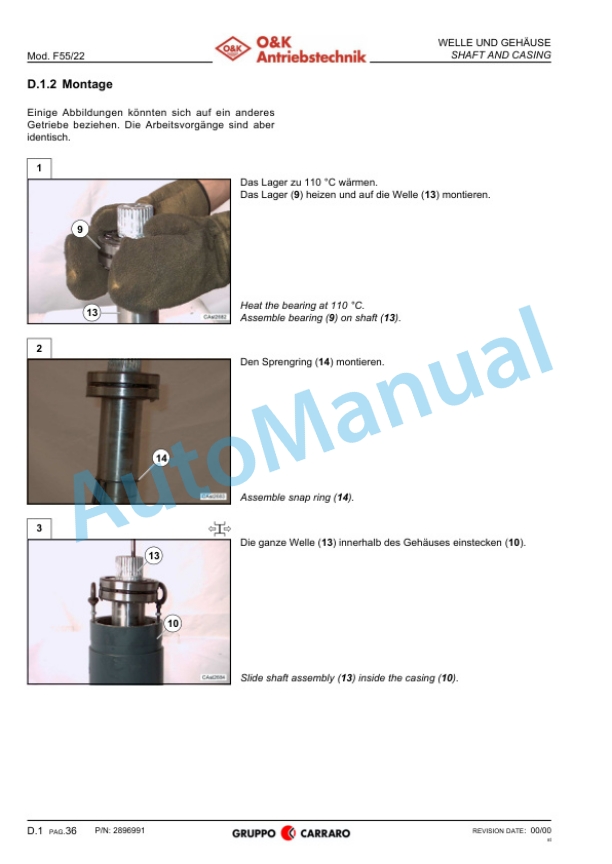

- 13.1.5. Fräsgetriebe

- 13.1.6. Fahrgetriebe

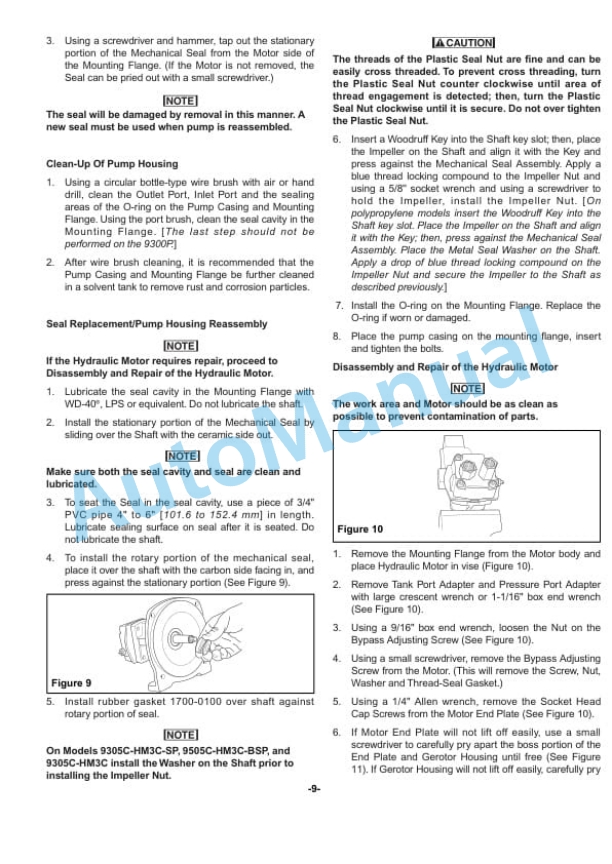

- 13.1.7. Hydraulic motor

- 13.1.8. Spraying pump

- 13.1.9. Steering valve

- 13.1.10. Clutch

- 13.2. B Circuit diagrams

- 13.2.1. Circuit diagram 410

- 13.2.2. Hydraulic diagram 00856155

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

Bomag Service Manual PDF

Bomag BC 473 EB-4 Refuse Compactor Electric Schematics Diagram 101930111001 – 101930119999

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

Bomag Service Manual PDF

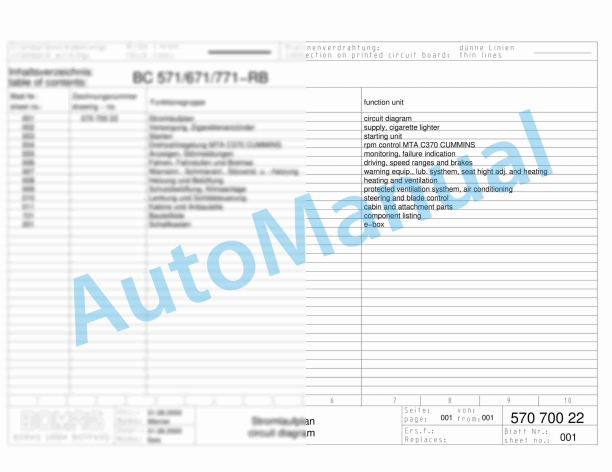

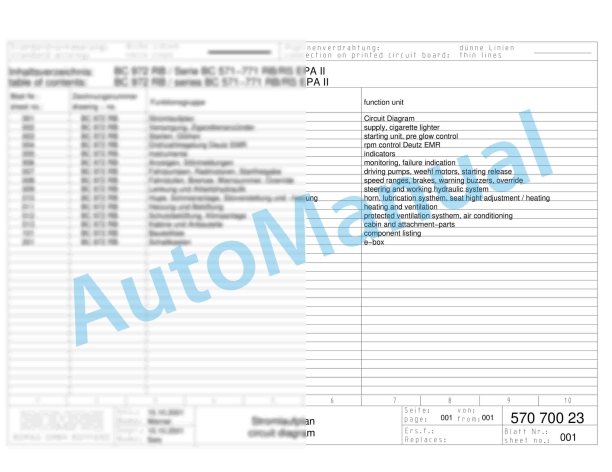

Bomag BC 571 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570621033 – 101570621062

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

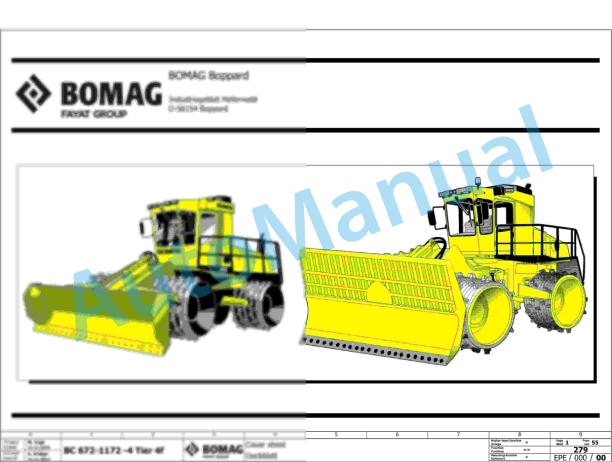

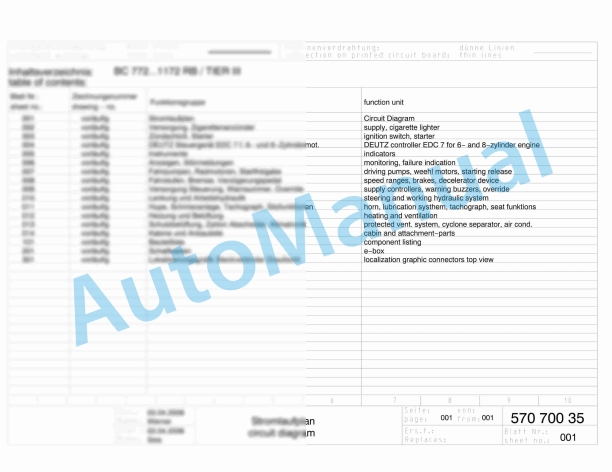

Bomag BC 572 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101570631001 – 101570631163

Bomag Service Manual PDF

Bomag Service Manual PDF