Bomag BM 500-15 Cold Planer Service Manual 00840024

$30.00

- Type Of Manual: Service Manual

- Manual ID: 00840024

- Format: PDF

- Size: 60.9MB

- Number of Pages: 882

- Serial Number:

101882021001 and up

101882041001 and up

Category: Bomag Service Manual PDF

-

Model List:

- BM 500-15 Cold Planer

- 1. Table of contents

- 2. General

- 2.1. Introduction

- 2.2. Concerning your safety

- 2.2.1. Basic prerequisites

- 2.2.2. Definition of responsible persons

- 2.2.3. Basic safety regulations for safe operation

- 2.2.4. Handling fuels and lubricants

- 2.2.5. Loading/transporting the machine

- 2.2.6. Start up procedure

- 2.2.7. Driving the machine, working operation

- 2.2.8. Refuelling

- 2.2.9. Regeneration of exhaust gas aftertreatment system

- 2.2.10. Emergency procedures

- 2.2.11. Maintenance work

- 2.2.12. Repair

- 2.2.13. Signage

- 2.3. Maintenance and repair

- 2.3.1. Preliminary remarks and safety notes

- 2.3.2. Notes on repair

- 2.3.3. Parking the machine in secured condition

- 3. Technical data

- 3.1. Fuels and lubricants

- 3.1.1. Engine oil

- 3.1.2. Fuel

- 3.1.3. Coolant

- 3.1.4. Hydraulic oil

- 3.1.5. Gear oil ISO VG 220

- 3.1.6. Lubrication grease

- 3.1.7. Hightemperature lubrication grease

- 3.2. List of fuels and lubricants

- 3.3. Terms and basis of calculation

- 4. Overview of machine

- 4.1. Component overview Electrics

- 4.2. Component overview hydraulics

- 4.3. Component overview machine assemblies

- 4.3.1. Engine

- 4.3.2. Drive unit

- 4.3.3. Height adjustment and steering

- 4.3.4. Milling unit

- 4.3.5. Milling drum

- 4.3.6. Conveyor system

- 4.3.7. Water system

- 4.4. Overview of maintenance flaps and doors

- 5. Electric systems

- 5.1. Basic principles

- 5.1.1. Deutsch plug, series DT and DTM

- 5.1.2. Clipon technology

- 5.1.3. Magnetic coil plug

- 5.1.4. Telemecanique switch

- 5.2. Operating consoles

- 5.3. Central electrics

- 5.4. Wiring

- 5.5. Description of electrical components

- 5.5.1. Pressure sensor for water spraying system

- 5.5.2. Crossslope sensor

- 5.5.3. Hydraulic oil temperature sensor

- 5.5.4. Side plate wire rope sensor

- 5.6. Fuse assignment

- 5.6.1. Notes on safety

- 5.6.2. Central electrics

- 5.6.3. Main fuses

- 5.7. Input codes

- 5.7.1. Display, layout and operation

- 5.7.2. Resetting to factory settings

- 5.7.3. Calibration of surge currents for height adjustment

- 5.7.4. Switching the unit system over

- 5.7.5. Water tank functions

- 5.7.6. Activation of relay in automatic mode

- 5.7.7. Conveyor belt ON via double and single buttons

- 5.7.8. Driving against the closed brake

- 5.7.9. Speed droop monitoring/display

- 5.7.10. Viscous fan

- 5.7.11. Software version

- 5.7.12. Milling clutch switching processes

- 5.7.13. Reversing with the milling drum switched ON

- 5.7.14. Showing the hydraulic oil temperature

- 5.7.15. 3way milling stage selector switch

- 5.7.16. Showing logged faults

- 5.7.17. Showing saved faults with operating hours

- 5.7.18. Deleting the error log

- 5.8. Replacement of components

- 5.9. Block diagrams

- 5.10. Inspection and maintenance work

- 5.10.1. Maintenance Table

- 5.10.2. Every 500 operating hours

- 5.10.3. As required

- 6. Hydraulic system

- 6.1. Basic principles

- 6.1.1. Open and closed hydraulic circuit

- 6.1.2. Swash plate principle, motor

- 6.1.3. Swash plate principle, pump

- 6.2. Hydraulic components position

- 6.3. Position of hydraulic pumps

- 6.4. Description of hydraulic components

- 6.4.1. Gear pump AZPF

- 6.4.2. Travel pump, A10VG1863 EP

- 6.4.3. Steering valve

- 6.4.4. Description of function

- 6.5. Repairs

- 6.5.1. Changing gear pumps on auxiliary drive of diesel engine

- 6.6. Tests and adjustments

- 6.6.1. Checking and adjusting the levelling

- 6.6.2. Checking and adjusting the roof adjustment

- 6.6.3. Checking and adjusting the clutch operating pressure

- 6.6.4. Checking and adjusting the brake releasing pressure

- 6.6.5. Checking and adjusting the steering pressure

- 6.6.6. Working hydraulics checking and adjusting the MP pressure

- 6.6.7. Checking and adjusting the scraper pressure

- 6.6.8. Checking and adjusting the conveyor belt pressure

- 6.6.9. Checking and adjusting the hydraulic breaker pressure

- 6.6.10. Checking and adjusting the maximum pressure of the travel pump

- 6.7. Inspection and maintenance work

- 6.7.1. Maintenance Table

- 6.7.2. Checks prior to start up

- 6.7.3. Every 250 operating hours

- 6.7.4. Every 500 operating hours

- 6.7.5. Every 1000 operating hours

- 6.7.6. Every 2000 operating hours

- 7. Machine assemblies

- 7.1. Engine

- 7.1.1. Diesel engine

- 7.2. Drive unit

- 7.2.1. Description

- 7.2.2. Repair

- 7.2.3. Inspection and maintenance work

- 7.3. Milling unit

- 7.3.1. Description

- 7.3.2. Repair

- 7.3.3. Inspection and maintenance work

- 7.4. Milling drum

- 7.4.1. Description

- 7.4.2. Repair

- 7.4.3. Inspection and maintenance work

- 7.5. Conveyor system

- 7.5.1. Description

- 7.5.2. Inspection and maintenance work

- 7.6. Water system

- 7.6.1. Description

- 7.6.2. Inspection and maintenance work

- 8. Troubleshooting

- 8.1. Preliminary remarks

- 8.2. Emergency procedures

- 8.2.1. Actuating the emergency stop switch

- 8.2.2. Disconnecting the battery

- 8.2.3. Towing the machine

- 8.3. Functional conditions

- 8.3.1. Functional conditions introduction

- 8.3.2. Functional conditions left side plate

- 8.3.3. Functional conditions right side plate

- 8.3.4. Functional conditions holddown

- 8.3.5. Functional conditions scraper

- 8.3.6. Functional conditions support wheel, rear left

- 8.3.7. Functional conditions support wheel, rear right

- 8.3.8. Functional conditions conveyor belt

- 8.3.9. Functional conditions milling

- 8.3.10. Functional conditions brake

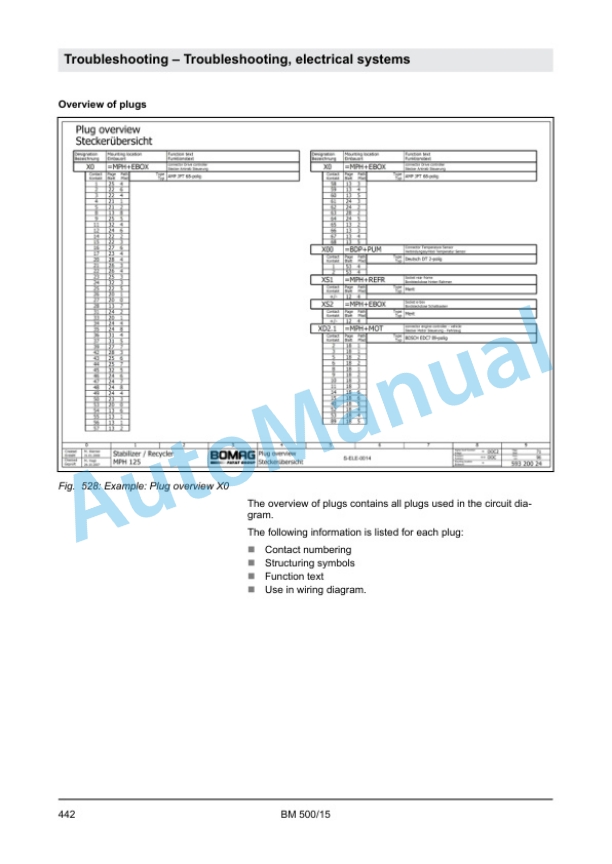

- 8.4. Troubleshooting, electrical systems

- 8.4.1. Measuring method

- 8.4.2. Diagnostics concept

- 8.4.3. Understanding electric circuit diagrams

- 8.4.4. ESX, checking the electric power supply

- 8.4.5. Codes General Information

- 8.4.6. Error codes

- 8.4.7. BOMAG DTC fault code list

- 8.4.8. Query codes

- 8.5. Trouble shooting, hydraulics

- 8.5.1. Troubleshooting table for hydraulic components

- 8.5.2. Troubleshooting axial piston motors

- 8.5.3. Troubleshooting axial piston pumps

- 8.5.4. Insufficient hydraulic power

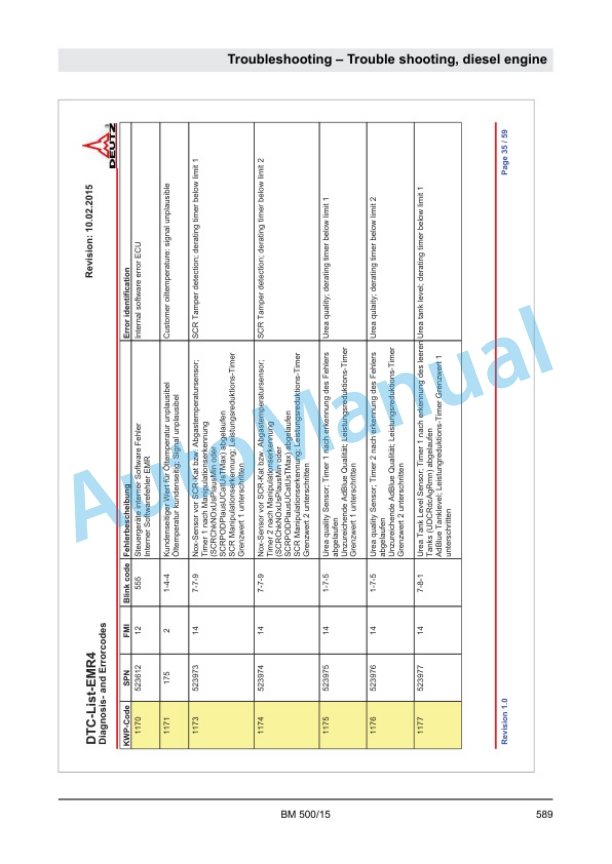

- 8.6. Trouble shooting, diesel engine

- 8.6.1. Starting the engine with jump leads

- 8.6.2. Bleed the fuel system

- 8.6.3. Engine malfunctions

- 8.6.4. Deutz DTC fault code list, EMR4

- 9. Special tools

- 9.1. Available special tools

- 9.1.1. Special tools, electrics

- 9.1.2. Special tools, hydraulic system

- 9.2. List of special tools

- 10. Index

- 11. Appendix

- 11.1. Appendices

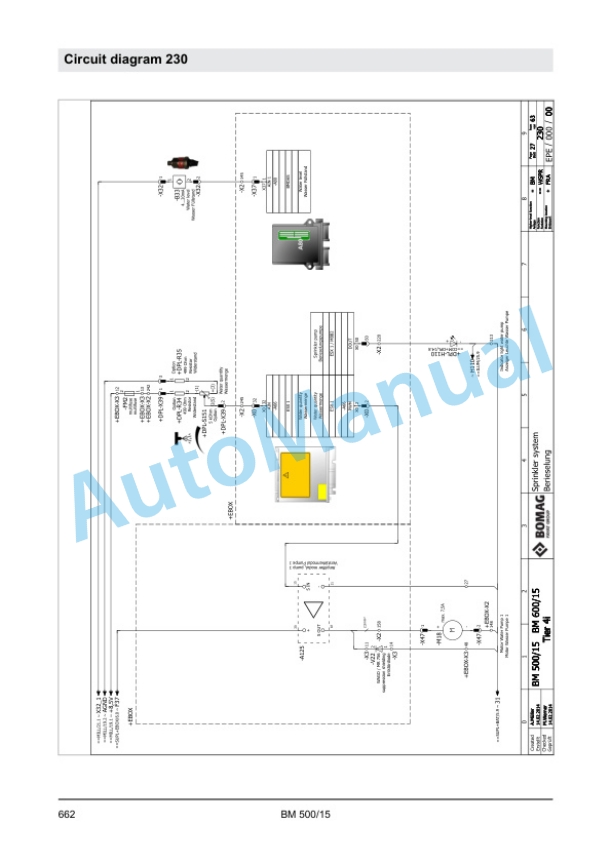

- 11.2. A Circuit diagram 230

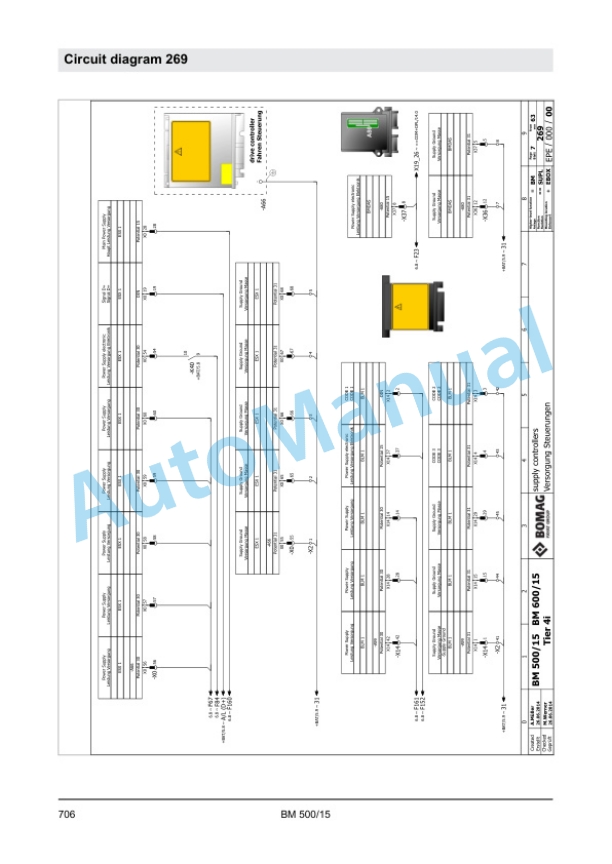

- 11.3. B Circuit diagram 269

- 11.4. C Wiring diagram 296

- 11.5. D Hydraulic diagram 264

- 11.6. E Hydraulic diagram 277

- 11.7. F Hydraulic diagram 343

Rate this product

You may also like

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00

Bomag Service Manual PDF

$30.00