Bomag BW 211 D-3 Single Drum Wheel Drive Vibratory Roller Repair Instructions 00819360

$30.00

- Type Of Manual: Repair Instructions

- Manual ID: 00819360

- Format: PDF

- Size: 36.5MB

- Number of Pages: 390

-

Model List:

- BW 211 D-3 Single Drum Wheel Drive Vibratory Roller

- 1. BW 211 D3

- 2. Single drum wheel drive vibratory roller

- 2.1. General

- 3. Foreword

- 3.1. Introduction

- 4. Safety regulations

- 4.1. Important notes

- 4.2. General

- 4.3. Special safety regulations

- 4.4. Hydraulics

- 5. General repair instructions

- 5.1. General

- 5.2. Hydraulic system

- 5.3. Electrical system

- 5.4. Seals and gaskets

- 6. Tightening torques

- 6.1. Tightening torques

- 7. Connecting plan

- 7.1. Fig. 1 Drive pump

- 7.2. Tests and adjustments

- 8. Technical Data

- 9. Special tools

- 10. Checking the rotary speeds

- 10.1. Checking the vibrator shaft speed

- 10.2. Checking the engine speed

- 11. Checking / adjusting the neutral positions of the travel pump

- 11.1. Mechanical neutral position

- 11.2. Hydraulic neutral position

- 12. Pressure tests in the travel circuit

- 13. Adjusting the high pressure relief valves in the travel system

- 13.1. Adjusting the pressure override

- 14. Adjusting the vibrator shaft speed

- 15. Pressure tests in the vibration circuit

- 16. Adjusting the high pressure relief valves in the vibration system

- 16.1. Adjusting the pressure override

- 17. Checking the leak oil rate of the vibration motor

- 18. Pressure tests in the steering circuit

- 18.0.1. Flushing

- 19. Special tools for flushing

- 20. Spülschema Fahrantrieb

- 20.1. After changing a component

- 20.2. With extreme oil contamination (abrasion)

- 20.3. Before flushing

- 20.4. Flushing filter installation (Fig. 1)

- 20.5. Flushing the hoses

- 20.6. Flushing the entire system

- 20.7. Bleeding

- 21. Flushing the travel circuit

- 21.1. Cleaning the hydraulic oil tank

- 21.2. Filter installation for flushing the travel system

- 21.3. Bleeding the travel circuit

- 21.4. Flushing the hoses in the travel circuit

- 21.5. Flushing the drum drive motor

- 21.5.1. Fig. 10

- 21.6. Flushing the axle drive motor

- 21.6.1. Fig. 11

- 21.7. Function test

- 21.7.1. Fig. 12

- 21.8. Maintenance of the flushing kit

- 22. Flushing diagram vibration circuit

- 22.1. After changing a component

- 22.2. In case of excessive oil contamination (abrasion)

- 22.3. Before flushing

- 22.4. Installation of the flushing filter (Fig. 1)

- 22.5. Flushing the hoses

- 22.6. Flushing the system

- 22.7. Bleeding

- 22.8. Function test

- 23. Flushing the vibration circuit

- 23.1. Cleaning the hydraulic oil tank

- 23.2. Filter installation for flushing the vibration system

- 23.3. Bleeding the vibration circuit

- 23.4. Flushing the hoses

- 23.5. Flushing the vibration motor

- 23.5.1. Fig. 10

- 23.6. Function test

- 23.6.1. Fig. 11

- 23.7. Maintenance of the flushing kit

- 23.7.1. Trouble shooting

- 24. General

- 24.1. General notes on trouble shooting in hydraulic systems

- 24.2. Important points for trouble shooting and fault rectification

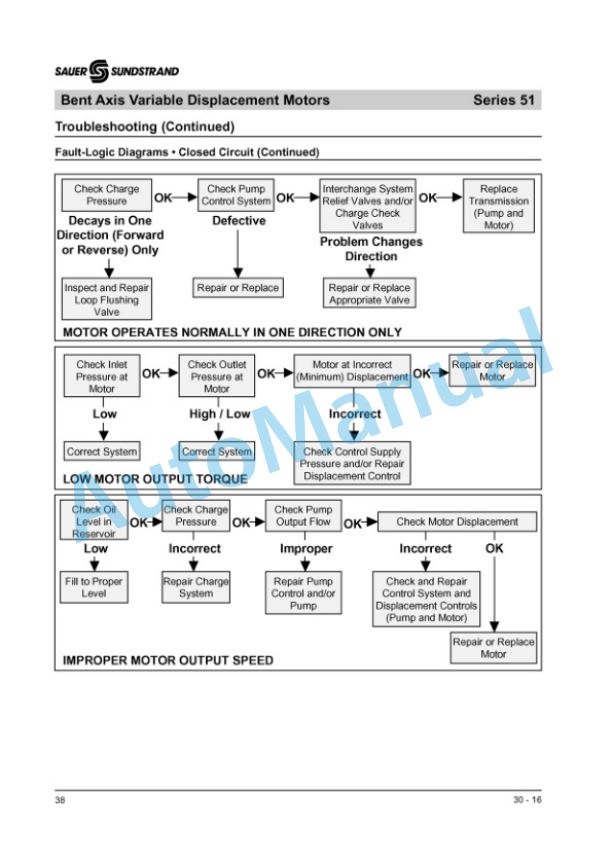

- 25. Trouble shooting diagram

- 25.1. Steering pressure OK

- 25.2. Valve OK

- 25.3. High pressure OK

- 25.4. High pressure valves OK

- 25.5. Nozzles OK

- 25.6. Speed OK

- 25.7. Steering pressure OK

- 25.8. Valve OK

- 25.9. Pilot pressure OK

- 25.10. Voltage / current OK

- 25.11. High pressure OK

- 25.12. Valve OK

- 25.13. High pressure valves OK

- 25.14. Nozzles OK

- 25.15. Steering pressure OK

- 26. Special tools

- 27. Drum repair overview

- 28. Removing and installing the drum

- 28.1. Removing the drum

- 28.2. Installing the drum

- 28.2.1. Fig. 10

- 28.2.2. Fig. 11

- 28.2.3. Fig. 12

- 28.2.4. Fig. 13

- 28.2.5. Fig. 14

- 29. Repairing the drum

- 29.1. Removing the travel motor

- 29.2. Removing the vibrator unit (travel motor side)

- 29.3. Dismantling the vibrator unit (travel motor side)

- 29.3.1. Fig. 10

- 29.3.2. Fig. 11

- 29.3.3. Fig. 12

- 29.3.4. Fig. 13

- 29.3.5. Fig. 14

- 29.3.6. Fig. 15

- 29.3.7. Fig. 16

- 29.3.8. Fig. 17

- 29.3.9. Fig. 18

- 29.3.10. Fig. 19

- 29.3.11. Fig. 20

- 29.4. Removing the vibrator unit (vibration motor side)

- 29.4.1. Fig. 21

- 29.4.2. Fig. 22

- 29.4.3. Fig. 23

- 29.4.4. Fig. 24

- 29.4.5. Fig. 25

- 29.4.6. Fig. 26

- 29.4.7. Fig. 27

- 29.4.8. Fig. 28

- 29.5. Removing, dismantling the side

- 29.5.1. Fig. 29

- 29.5.2. Fig. 30

- 29.5.3. Fig. 31

- 29.5.4. Fig. 32

- 29.5.5. Fig. 33

- 29.5.6. Fig. 34

- 29.6. Dismantling the vibrator unit (vibration motor side)

- 29.6.1. Fig. 35

- 29.6.2. Fig. 36

- 29.6.3. Fig. 37

- 29.6.4. Fig. 38

- 29.6.5. Fig. 39

- 29.6.6. Fig. 40

- 29.6.7. Fig. 41

- 29.6.8. Fig. 42

- 29.6.9. Fig. 43

- 29.6.10. Fig. 44

- 29.6.11. Fig. 45

- 29.7. Assembling the vibrator unit (vibration motor side)

- 29.7.1. Fig. 46

- 29.7.2. Fig. 47

- 29.7.3. Fig. 48

- 29.7.4. Fig. 49

- 29.7.5. Fig. 50

- 29.7.6. Fig. 51

- 29.7.7. Fig. 52

- 29.7.8. Fig. 53

- 29.7.9. Fig. 54

- 29.7.10. Fig. 55

- 29.7.11. Fig. 56

- 29.7.12. Fig. 57

- 29.7.13. Fig. 58

- 29.7.14. Fig. 59

- 29.7.15. Fig. 60

- 29.7.16. Fig. 61

- 29.7.17. Fig. 62

- 29.7.18. Fig. 63

- 29.7.19. Fig. 64

- 29.7.20. Fig. 65

- 29.7.21. Fig. 66

- 29.7.22. Fig. 67

- 29.8. Assembling and installing the side plate

- 29.8.1. Fig. 68

- 29.8.2. Fig. 69

- 29.8.3. Fig. 70

- 29.8.4. Fig. 71

- 29.8.5. Fig. 72

- 29.8.6. Fig. 73

- 29.8.7. Fig. 74

- 29.8.8. Fig. 75

- 29.8.9. Fig. 76

- 29.8.10. Fig. 77

- 29.8.11. Fig. 78

- 29.8.12. Fig. 79

- 29.9. Assembling the vibrator unit (travel motor side)

- 29.9.1. Fig. 80

- 29.9.2. Fig. 81

- 29.9.3. Fig. 82

- 29.9.4. Fig. 83

- 29.9.5. Fig. 84

- 29.9.6. Fig. 85

- 29.9.7. Fig. 86

- 29.9.8. Fig. 87

- 29.9.9. Fig. 88

- 29.9.10. Fig. 89

- 29.9.11. Fig. 90

- 29.9.12. Fig. 91

- 29.9.13. Fig. 92

- 29.9.14. Fig. 93

- 29.9.15. Fig. 94

- 29.9.16. Fig. 95

- 29.9.17. Fig. 96

- 29.9.18. Fig. 97

- 29.10. Installing the vibrator unit (travel motor side)

- 29.10.1. Fig. 98

- 29.10.2. Fig. 99

- 29.10.3. Fig. 100

- 29.10.4. Fig. 101

- 29.10.5. Fig. 102

- 29.11. Installing the travel motor

- 29.11.1. Fig. 103

- 29.11.2. Fig. 104

- 29.11.3. Fig. 105

- 29.11.4. Fig. 106

- 29.12. Installing the vibrator unit (vibration motor side)

- 29.12.1. Fig. 107

- 29.12.2. Fig. 108

- 29.12.3. Fig. 109

- 29.12.4. Fig. 110

- 29.12.5. Fig. 111

- 29.12.6. Fig. 112

- 29.12.7. Fig. 113

- 29.12.8. Fig. 114

- 29.12.9. Fig. 115

- 29.12.10. Fig. 116

- 29.12.11. Fig. 117

- 30. Disassembling and assembling the changeover weight

- 30.1. Dismantling the changeover weight

- 30.2. Assembling the changeover weight

- 31. Changing the rubber buffers

- 31.0.1. Oscillating articulated joint

- 32. Special tools

- 33. Oscillating articulated joint repair

- 34. Removing and installing the oscillating articulated joint

- 35. Dismantling the oscillating articulated joint

- 36. Assembling the oscillating articulated joint

- 36.0.1. Suppliers documentation

- 37. Travel drive series 51

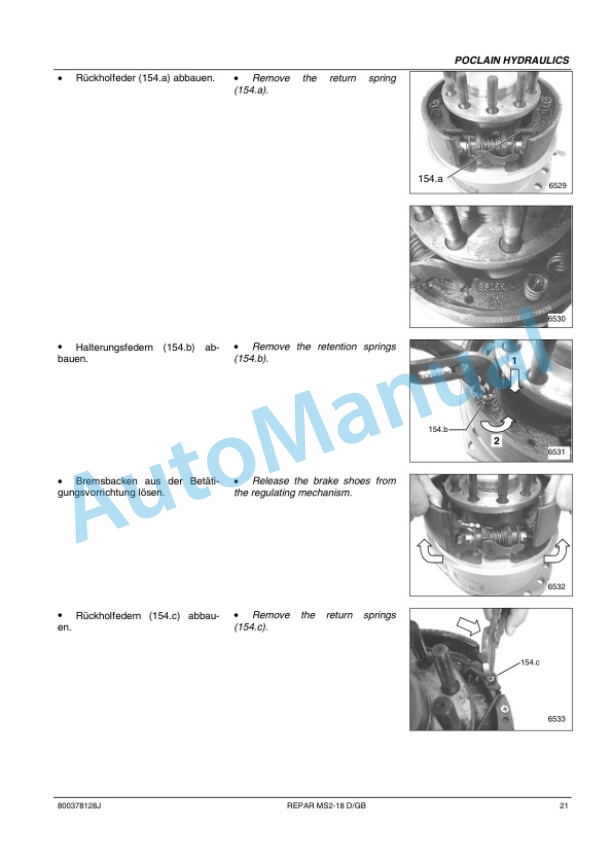

- 38. MS/MSE 02 to 18

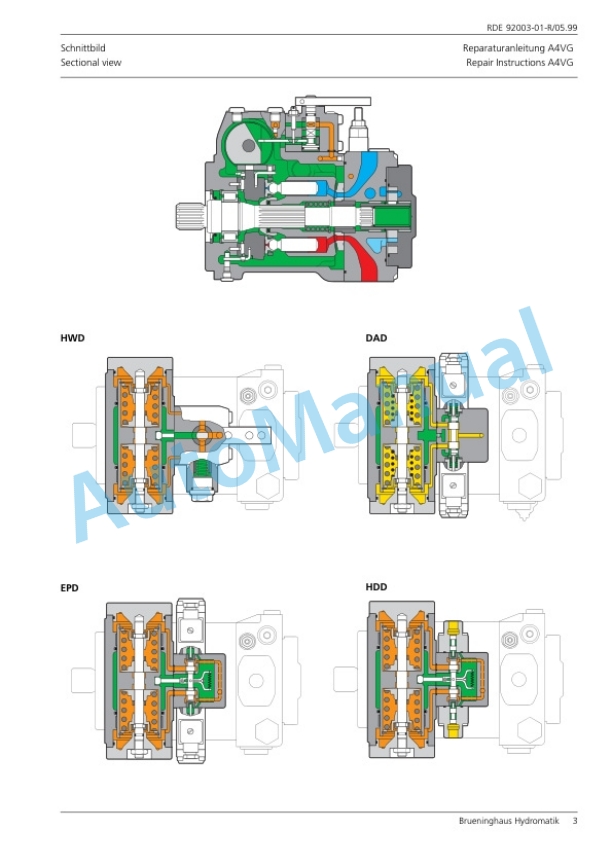

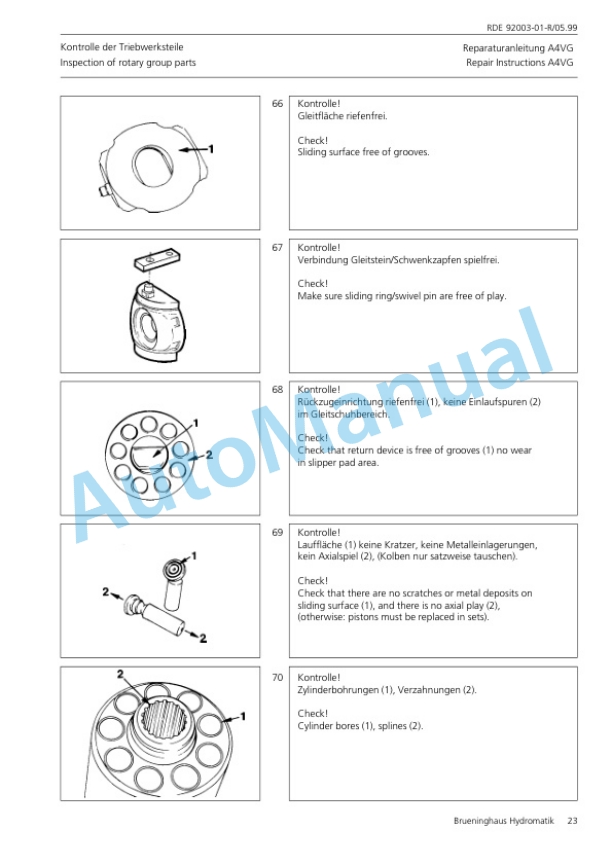

- 39. A4VG

- 40. A10VG

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930001002 – 101930001058

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 473 EB-3 Refuse Compactor Electric Schematics Diagram 101930151001 – 101930159999

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930031001 – 101930031042

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 462 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930071001 – 101930071002

Bomag Service Manual PDF

Bomag Service Manual PDF

Bomag BC 472 RB Refuse Compactor Electric, Hydraulic Schematics Diagram 101930041001 – 101930041022