- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Claas Disco 3100 Fc Frc (639) Mower Operator Manual EN

$50.00

- Model: Disco 3100 Fc Frc (639) Mower

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 42.5 MB

File List:

00 0294 036 5.pdf

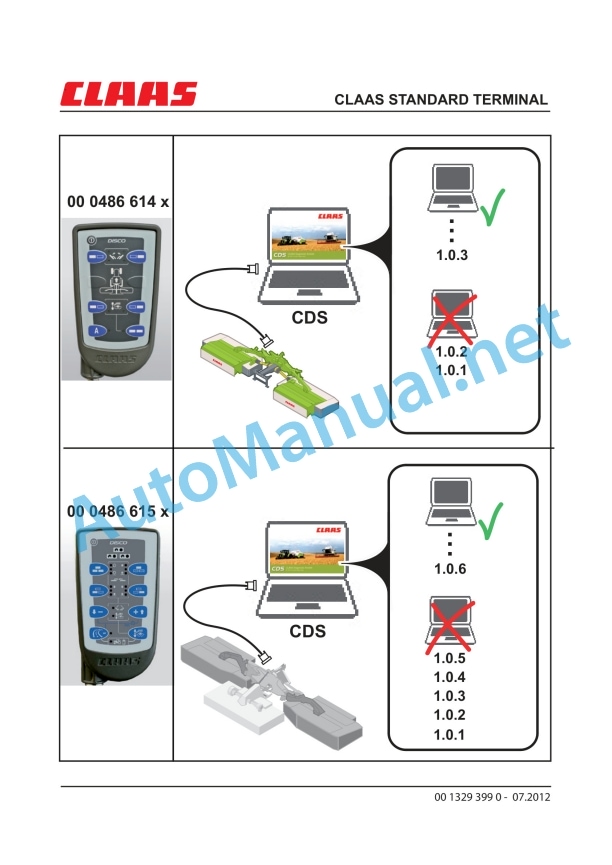

00 1329 399 0.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 0294 036 5.pdf:

DISCO 3100 F Profil

DISCO 3100 FC Profil

DISCO 3100 FRC Profil

Table of contents

1 To this operator’s manual

1.1 Notes on the manual

1.1.1 General instructions

1.1.2 Using the manual

Directions

1.1.3 Validity of manual

1.1.4 Symbols and notes

1.1.5 Technical specifications

2 Safety

2.1 Safety rules

2.1.1 Particularly important

2.1.2 Qualification of drivers and maintenance personnel

2.1.3 Intended use

2.1.4 Reasonably foreseeable misuse

2.1.5 Safety and accident prevention regulations

2.1.6 First aid measures

2.1.7 Danger of injury from hydraulic liquid

2.2 Safety decals on the machine

2.2.1 Safety decals

2.2.2 Position of hazard warning signs

3 Machine description

3.1 Overview and method of operation

3.1.1 Overview of DISCO 3100 F Profil

3.1.2 Overview of DISCO 3100 FC Profil / FRC Profil

3.1.3 Function of DISCO 3100 F Profil

3.1.4 Function of DISCO 3100 FC Profil

3.1.5 Function of DISCO 3100 FRC Profil

3.2 Optional machine equipment

3.2.1 High-cut skids

3.2.2 Low-cut skids

3.2.3 Bolted wear skids

3.2.4 Slip-on yoke for 8-piece universal drive shaft

3.2.5 Three point extension

3.2.6 Hydraulically folding safety frames

3.2.7 Hydraulic front load relief ACTIVE FLOAT“

3.2.8 Hydraulics kit – AXION 800 with 5 tons lifting unit

3.2.9 Legal equipment for France

3.3 Identification plate and vehicle identification number

3.3.1 Spare parts and technical questions

3.3.2 Position of identification plate

3.3.3 Position of identification number

3.3.4 Explanation of machine identification plate

4 Operating and control elements

4.1 Mower unit

4.1.1 Lock

4.1.2 Lock

4.2 Conditioner

4.2.1 Lever

4.2.2 Star handle

5 Technical specifications

5.1 DISCO 3100 F Profil – Type 623

5.1.1 Dimensions

5.1.2 Weights

.1.3 Requirements for the tractor

5.1.4 Version

5.1.5 Sound pressure level

5.1.6 Operating utilities and filling quantities

5.2 DISCO 3100 FC Profil – Type 639

5.2.1 Dimensions

5.2.2 Weights

5.2.3 Requirements on the tractor

5.2.4 Version

5.2.5 Sound pressure level

5.2.6 Operating utilities and filling quantities

5.3 DISCO 3100 FRC Profil – Type 639

5.3.1 Dimensions

5.3.2 Weights

5.3.3 Requirements on the tractor

5.3.4 Version

5.3.5 Sound pressure level

5.3.6 Operating utilities and filling quantities

6 Assembling the machine

6.1 DISCO 3100 F Profil – Type 623

6.1.1 Unpacking

6.1.2 Installing the left / right safety frame

6.1.3 Installing the front / rear safety frame

6.1.4 Installing the left / right safety guards

6.1.5 Installing the front / rear safety guards

6.2 DISCO 3100 FC Profil – Type 639

6.2.1 Unpacking

6.2.2 Installing the left / right safety frame

6.2.3 Installing the safety frame at the front

6.2.4 Installing the left / right safety guards

6.2.5 Installing the safety guard at the front

6.2.6 Installing the left / right swathing plates

6.2.7 Installing the baffle plates

6.2.8 Installation the rear safety guard

6.3 DISCO 3100 FRC Profil – Type 639

6.3.1 Unpacking

6.3.2 Installing the left / right safety frame

6.3.3 Installing the safety frame at the front

6.3.4 Installing the left / right safety guards

6.3.5 Installing the safety guard at the front

6.3.6 Installation the left / right swathing plates

6.3.7 Installation the rear safety guard

6.4 Knives

6.4.1 Installing the mower knives

7 Machine preparation

7.1 Adapting the tractor

7.1.1 Axle loads, minimum ballast, total weight

7.1.2 Calculating the minimum front ballast

7.1.3 Calculating the minimum rear ballast

7.1.4 Calculating the actual front axle load

7.1.5 Calculating the actual total weight

7.1.6 Calculating the actual rear axle load

7.1.7 Calculation table

7.1.8 Adjusting the front power lift

7.1.9 Attaching the three-point extension*

7.1.10 Fitting the brackets for load relief springs

7.1.11 Fitting the plates for the floatation springs

7.1.12 Bracket – fitting recommendations for floatation springs

CLAAS AXION 840

CLAAS ARES 836 RZ

CLAAS ARES 836 RZ

CLAAS ARES 696 RZ

CLAAS ARES 696 RZ

CLAAS CELTIS 446 RX

Fendt Vario Favorit 716

7.1.13 Bracket installation kits for suspension springs

CLAAS AXION 800

CLAAS ARES

CLAAS ARION 600 / 600 C / 500

CLAAS ARION 400

CLAAS AXOS

CLAAS ELIOS

CLAAS CELTIS

Fendt 900 Vario (new)

Fendt 800 Vario (new)

Fendt 800 Vario (old) / 700 Vario / 400 Vario

Fendt 309 Vario / 309 Ci / 307 Vario

Fendt 300 Vario

7.1.14 Mounting the hydraulic front load relief bracket

7.1.15 Mounting the hydraulic front load relief mounting plates

7.1.16 Recommendations for fitting the hydraulic front load relief brackets

CLAAS AXION 800

CLAAS ARION 600 / 600 C / 500

CLAAS ARION 600

CLAAS ARION 400

CLAAS AXOS 300

CLAAS ELIOS

Fendt 900 Vario (new)

Fendt 800 Vario (new)

Fendt 800 Vario (old) / 700 Vario / 400 Vario

Fendt 309 Vario / 309 Ci / 307 Vario

Fendt 300 Vario

Fendt 600 Vario (old)

7.2 Shutting down and securing the machine

7.2.1 Shutting down and securing the machine

7.2.2 Securing the lifted machine

7.3 Adapting the machine

7.3.1 Adapting to front PTO shaft rotating anti- clockwise

7.3.2 Universal drive shaft for CLAAS Celtis 446 RX

7.3.3 Universal drive shaft – Checking the length

7.3.4 Universal drive shaft – Adapting the length

7.3.5 Fitting the universal drive shaft to the machine

7.3.6 Conditioner speed

7.3.7 Adjusting the hydraulic load relief*

7.4 Hitch the machine

7.4.1 Preparing for installation

7.4.2 Accommodating the machine

7.4.3 Checking/adjusting the locking mechanism

7.4.4 Hooking in the safety guard

7.4.5 Checking the safety guard

7.4.6 Folding the lock out

7.4.7 Folding the lock out

7.4.8 Installing the universal drive shaft

7.4.9 Adjusting the upper link

7.4.10 Fitting the floatation springs

7.4.11 Fitting the hydraulic front load relief*

Checking the fitting position

7.4.12 Connecting the hydraulically folding safety frames*

7.5 Unhitching the machine

7.5.1 Folding in the lock

7.5.2 Folding in the lock

7.5.3 Detaching the safety guard

7.5.4 Unhinge the suspension springs

7.5.5 Removing the hydraulic front load relief*

7.5.6 Disconnecting the hydraulically folding safety frames*

7.5.7 Removing the universal drive shaft

7.5.8 Setting down the machine

7.6 Prepare road travel

7.6.1 Folding the safety frame up

7.6.2 Raising into transport position

7.7 Prepare field work

7.7.1 Folding the safety frame down

7.8 Loading the machine

7.8.1 Loading / unloading the machine

7.8.2 Loading / unloading the machine

8 Operation

8.1 General safety precautions

8.1.1 Prior to operation

8.2 Driving on the road

8.2.1 Road travel

8.2.2 Marking the machine for road travel

8.3 Fieldwork settings

8.3.1 Adjusting ground contour following

8.3.2 Adjusting the cutting height

8.3.3 Adjusting the tine conditioner

8.3.4 Adjusting the swath width

8.3.5 Adjusting the crop spreader

8.3.6 Mowing without conditioner effect

8.4 Fieldwork

8.4.1 Fieldwork

8.4.2 Machine use

Optimum PTO speed

8.4.3 Mowing methods

8.4.4 Instructions for mowing

8.4.5 Difficult conditions of use

8.4.6 Recommendation for environmental protection

9 Faults and remedies

9.1 Causes and remedies

9.1.1 General warnings

9.1.2 General trouble and remedy

10 Maintenance

10.1 Maintenance Information

10.1.1 General warnings

10.1.2 Electrical system

10.1.3 Protective guards

10.1.4 Spare parts

10.1.5 Unbalance

10.1.6 Compressed air and water

10.1.7 Burn prevention

10.1.8 Oils

10.1.9 Fire prevention and explosion prevention

10.1.10 Lines, tubes and hoses

10.2 Overview maintenance intervalls

10.2.1 Handling maintenance intervals

10.2.2 Before the harvest

10.2.3 After the first 50 operating hours

10.2.4 Every 8 operating hours

10.2.5 Every 20 operating hours

10.2.6 Every 100 operating hours

10.2.7 Every 250 operating hours

10.2.8 Every 500 operating hours or annually

10.2.9 As needed

10.2.10 After the harvest

10.3 Maintenance operations in general

10.3.1 Clean machine

10.3.2 Preserve the machine

10.3.3 Fastening material

10.4 Maintenance operations gearbox

10.4.1 Check gearbox tightness

10.4.2 Main gearbox

10.4.3 Main gearbox

10.4.4 Angle drive

10.5 Maintenance operations clutch

10.5.1 Adjusting the friction clutch

10.5.2 Venting the friction clutch

10.5.3 Replacing the friction discs

10.6 Maintenance operations drive shaft

10.6.1 Maintaining drive shafts

10.7 Mower unit maintenance work

10.7.1 Checking the mower head oil level

10.7.2 Changing the mower head oil

10.7.3 Removing the mower knife box

10.7.4 Observe direction of rotation of mower discs

10.7.5 Checking the knives

10.7.6 Replacing the knives

10.7.7 Checking the mower knife holder

10.7.8 Maintaining the cutting disc

10.7.9 Replacing the cutting discs

10.7.10 Installing the pinion units

10.7.11 Adjusting the anti-wrap guard

10.8 Conditioner maintenance work

10.8.1 Tensioning the drive belt

10.8.2 Changing the drive belts

10.8.3 Fitting / removing conditioner tines

10.8.4 Adjusting the roller conditioner

10.9 Swathing disc maintenance work

10.9.1 Adjusting the right swathing disc

10.10 Maintenance work on safety devices

10.10.1 Adjusting the safety device

Front safety guard holder

Left / right safety guard holder

10.11 Frame maintenance work

10.11.1 Adjusting the lock for fitting and removal

10.11.2 Adjusting ground contour following

10.11.3 Adjusting ground contour following

10.12 Lubrication chart

10.12.1 Grease points – 8 h

10.12.2 Grease points – 20 h

10.12.3 Grease points – 100 h

10.12.4 Grease points – 250 h

11 Placing out of operation and disposal

11.1 General Information

11.1.1 Removal from service and disposal

12 EC-declaration of conformity

12.1 DISCO 3100 F Profil / FC Profil / FRC Profil

12.1.1 EC Declaration of Conformity

13 Technical terms and shortcuts

13.1 Terms and explanations

13.1.1 Technical terms

13.1.2 Abbreviations

00 2348 408 0.pdf:

CEMIS 100

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 100

3.1.2 Function principle of CEMIS 100

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 100

4 Operating and display elements

4.1 CEMIS 100

4.1.1 User interface for LINER

4.1.2 User interface for ROLLANT

4.1.3 User interface for UNIWRAP

5 Technical specifications

5.1 CEMIS 100

5.1.1 Specification

6 Operation

6.1 CEMIS 100

6.1.1 Operating the CEMIS 100

6.1.2 Switching CEMIS 100 on

6.1.3 Switching CEMIS 100 off

7 Maintenance

7.1 CEMIS 100

7.1.1 Daily

8 Putting out of operation and disposal

8.1 General information

8.1.1 Removal from service and disposal

9 Technical terms and abbreviations

9.1 Terms and explanations

9.1.1 Technical words

9.1.2 Abbreviations

00 2348 427 0.pdf:

CEMIS 700

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF