Claas Disco 3600 Frc Fc Move Profil (F98) Mower Operator Manual EN

$50.00

- Model: Disco 3600 Frc Fc Move Profil (F98) Mower

- Type Of Manual: Operator Manual

- Language: EN

- Format: PDF(s)

- Size: 62.7 MB

File List:

00 1329 399 0.pdf

00 2308 940 4.pdf

00 2348 408 0.pdf

00 2348 427 0.pdf

00 2308 940 4.pdf:

DISCO 3600 FC MOVEDISCO 3600 FC PROFILDISCO 3600 FRC MOVEDISCO 3600 FRC PROFIL

Table of contents

1 Introduction

1.1 Notes on the manual

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.1.4 Optional equipment

1.1.5 Qualified specialist workshop

1.1.6 Maintenance notes

1.1.7 Warranty notes

1.1.8 Spare parts and technical questions

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Identifying warnings

2.1.1 Hazard signs

2.1.2 Signal word

2.2 Safety rules

2.2.1 Importance of Operator’s Manual

2.2.2 Observing safety decals and warnings

2.2.3 Requirements for all persons working with the machine

2.2.4 Children in danger

2.2.5 Hazard areas

2.2.6 Presence between tractor and machine

2.2.7 Hitching the tractor to the machine

2.2.8 Danger of injury from rotating shafts

2.2.9 Structural alterations

2.2.10 Optional equipment and spare parts

2.2.11 Control of the machine while it is running

2.2.12 Operation only after proper putting into operation

2.2.13 Technical condition

2.2.14 Danger from damage to the machine

2.2.15 Complying with technical limit values

2.2.16 Danger from continued running of machine parts

2.2.17 Keeping safety devices functional

2.2.18 Personal protective equipment

2.2.19 Wearing suitable clothing

2.2.20 Removing dirt and loose objects

2.2.21 Preparing the machine for road travel

2.2.22 Risks when driving on the road and in the field

2.2.23 Parking the machine safely

2.2.24 Unsupervised parking

2.2.25 Unsuitable operating utilities

2.2.26 Safe handling of operating and auxiliary utilities

2.2.27 Environmental protection and disposal

2.2.28 Fire prevention

2.2.29 Lethal electrocution from overhead lines

2.2.30 Behaviour in case of voltage flash-over from overhead lines and when lightning strikes

2.2.31 Noise may cause health damage

2.2.32 Pressurised fluids

2.2.33 Hot surfaces

2.2.34 Working on machine only after shutting it down

2.2.35 Maintenance work and repairs

2.2.36 Raised machine parts and loads

2.2.37 Danger from welding work

2.3 Safety markings on the DISCO MOVE

2.3.1 Structure of safety decals

2.3.2 Safety decals on the machine

2.4 Safety markings on the DISCO PROFIL

2.4.1 Structure of safety decals

2.4.2 Safety decals on the machine

3 Machine description

3.1 Overview and method of operation of the DISCO MOVE

3.1.1 Machine overview

3.1.2 Overview of the cutting disc direction of rotation

3.1.3 Function of machine

3.1.4 Function of machine

3.2 Overview and method of operation of the DISCO PROFIL

3.2.1 Machine overview

3.2.2 Overview of the cutting disc direction of rotation

3.2.3 Function of machine

3.2.4 Function of machine

3.3 Optional machine equipment

3.3.1 Double mirror*

3.3.2 Double mirror*

3.3.3 Limiting chains*

3.3.4

3.3.5 Hydraulic set for AXION 800 with five-tonne power lift*

3.3.6 Quick-release coupling three-point linkage*

3.3.7 Hydraulically folding safety frames*

3.3.8 Warning plates with lighting*

3.3.9 Legal technical equipment for France*

3.3.10 High-cut skids*

3.3.11 Double high-cut skids*

3.3.12 Wear skids*

3.3.13 Low-cut system*

3.3.14 Slip-on yoke for 8-piece universal drive shaft*

3.4 Identification plates and identification number

3.4.1 Machine identification plate

3.5 Information on the DISCO MOVE

3.5.1 Stickers on the machine

3.6 Information on the DISCO PROFIL

3.6.1 Stickers on the machine

4 Operating and display elements

4.1 DISCO MOVE operating elements

4.1.1 Attachable frame

4.2 DISCO MOVE display elements

4.2.1 Attachable frame

4.3 DISCO PROFIL operating elements

4.3.1 Attachable frame

4.4 DISCO PROFIL display elements

4.4.1 Attachable frame

5 Technical specifications

5.1 DISCO 3600 FC MOVE

5.1.1 Dimensions

5.1.2 Weights

5.1.3 Requirements for the tractor

5.1.4 Version

5.1.5 Sound pressure level

5.2 DISCO 3600 FC PROFIL

5.2.1 Dimensions

5.2.2 Weights

5.2.3 Requirements for the tractor

5.2.4 Version

5.2.5 Sound pressure level

5.3 DISCO 3600 FRC MOVE

5.3.1 Dimensions

5.3.2 Weights

5.3.3 Requirements for the tractor

5.3.4 Version

5.3.5 Sound pressure level

5.4 DISCO 3600 FRC PROFIL

5.4.1 Dimensions

5.4.2 Weights

5.4.3 Requirements for the tractor

5.4.4 Version

5.4.5 Sound pressure level

5.5 Operating utilities

5.5.1 Lubricants

6 Machine preparation

6.1 Switching off and securing the machine

6.1.1 Switching off and securing the tractor and machine

6.1.2 Securing the raised machine

6.2 Adapting the tractor for DISCO MOVE

6.2.1 Adapting the tractor to the machine

6.2.2 Checking the ballasting of the tractor

Calculating the minimum front ballast

Calculating the minimum rear ballast

Calculating the actual front axle load

Calculating the actual total weight

Calculating the actual rear axle load

Calculation table

6.2.3 Checking the protective guard on the tractor PTO shaft

6.2.4 Adjusting the front power lift

6.2.5 Attaching the holders for the limiting chains*

6.3 Adapting DISCO MOVE

6.3.1 Adapting the machine to the tractor

Adjustment work on the removed machine

Adjustment work on the attached machine

6.3.2 Adapting the machine to front PTO rotating anti-clockwise

6.3.3 Adapting the lower link category

6.3.4 Adapting the upper link category

6.3.5 Adjust the position of the upper link pin

6.3.6 Changing the conditioner speed

6.3.7 Adapting the hydropneumatic mower suspension to the tractor

6.3.8 Adapting the wiring loom for the warning plates* to the tractor

6.3.9 Checking the universal drive shaft length

Shortest working position of the universal drive shaft

Longest working position of the universal drive shaft

6.3.10 Adapting the universal drive shaft length

6.3.11 Adjusting the mounting frame

Checking the free space of universal drive shaft

6.3.12 Adjusting the length of limiting chains*

6.3.13 Adapting the machine to the quick-release coupling three-point linkage*

Adjusting the plate on the hitch block

Adjusting the coupling hook

6.3.14 Swathing plate adjustment with large tractor front tyres

6.3.15 Installing the high-cut skids*

6.3.16 Removing the high-cut skids*

6.3.17 Attaching the double high-cut skids*

6.3.18 Installing wear skids*

6.4 Attaching the DISCO MOVE

6.4.1 Attaching the machine to the tractor

Directly attaching the machine

Attaching the machine with quick-release coupling three-point linkage*

6.4.2 Detaching the safety guard

6.4.3 Fitting the lower link

6.4.4 Fitting the upper link

6.4.5 Mounting the machine with quick-release coupling three-point linkage*

6.4.6 Fitting the limiting chains*

6.4.7 Hooking in the safety guard

6.4.8 Checking the safety guard

6.4.9 Adjusting the upper link

6.4.10 Installing the universal drive shaft

6.4.11 Connecting the hydraulic hose lines

6.4.12 Attaching the hydraulically folding safety frame*

6.4.13 Plugging in the lighting cable*

6.5 Removing DISCO MOVE

6.5.1 Removing the machine from the tractor

Removing the machine without quick-release coupling three-point linkage*

Removing the machine with quick-release coupling three-point linkage*

6.5.2 Folding in the locks

6.5.3 Detaching the safety guard

6.5.4 Removing the limiting chains*

6.5.5 Unplugging the lighting cable*

6.5.6 Disconnecting the hydraulic hoses

6.5.7 Disconnecting the hydraulically folding safety frames*

6.5.8 Removing the universal drive shaft

6.5.9 Unhooking the upper link

6.5.10 Unhooking the lower link

6.5.11 Setting down the machine with quick-release coupling three-point linkage*

6.6 Adapting the tractor for DISCO PROFIL

6.6.1 Adapting the tractor to the machine

6.6.2 Checking the ballasting of the tractor

Calculating the minimum front ballast

Calculating the minimum rear ballast

Calculating the actual front axle load

Calculating the actual total weight

Calculating the actual rear axle load

Calculation table

6.6.3 Checking the protective guard on the tractor PTO shaft

6.6.4 Adjusting the front power lift

6.6.5 Fitting the holders for the floatation springs

6.6.6 Fitting the plates for the load relief springs

6.6.7 Attaching the holder for hydropneumatic mower suspension*

6.6.8 Attaching the plates for hydropneumatic mower suspension*

6.7 Adapting DISCO PROFIL

6.7.1 Adapting the machine to the tractor

Adjustment work on the removed machine

Adjustment work on the attached machine

6.7.2 Adapting the machine to front PTO rotating anti-clockwise

6.7.3 Changing the conditioner speed

6.7.4 Checking the universal drive shaft length

Shortest working position of the universal drive shaft

Longest working position of the universal drive shaft

6.7.5 Adapting the universal drive shaft length

6.7.6 Setting the hydropneumatic mower suspension*

6.7.7 Swathing plate adjustment with large tractor front tyres

6.7.8 Installing the high-cut skids*

6.7.9 Removing the high-cut skids*

6.7.10 Attaching the double high-cut skids*

6.7.11 Installing wear skids*

6.8 Attaching DISCO PROFIL

6.8.1 Attaching the machine to the tractor

6.8.2 Detaching the safety guard

6.8.3 Accommodating the machine

6.8.4 Adjusting the plate on the hitch block

6.8.5 Hooking in the safety guard

6.8.6 Checking the safety guard

6.8.7 Adjusting the upper link

6.8.8 Installing the universal drive shaft

6.8.9 Checking the free space of universal drive shaft

6.8.10 Checking the free space of universal drive shaft

6.8.11 Fitting the floatation springs

6.8.12 Fitting the hydropneumatic mower suspension*

Checking the fitting position

6.8.13 Attaching the hydraulically folding safety frame*

6.8.14 Plugging in the lighting cable*

6.9 Removing DISCO PROFIL

6.9.1 Removing the machine from the tractor

6.9.2 Folding in the lock

6.9.3 Detaching the safety guard

6.9.4 Unhinge the suspension springs

6.9.5 Unplugging the lighting cable*

6.9.6 Unhitching the hydropneumatic mower suspension*

6.9.7 Disconnecting the hydraulically folding safety frames*

6.9.8 Removing the universal drive shaft

6.9.9 Setting down the machine

6.10 Prepare road travel

6.10.1 Preparing the machine for road transport

6.10.2 Obtaining an exceptional permit

6.10.3 Marking the machine for road travel

6.10.4 Folding the safety frame up

6.10.5 Folding up the warning plates with lighting*

6.10.6 Raising to the transport position

6.10.7 Raising to the transport position

6.11 Preparing fieldwork

6.11.1 Preparing the machine for fieldwork

6.11.2 Lowering the machine to the working position

6.11.3 Lowering the machine to the working position

6.11.4 Folding down the warning plates with lighting*

6.11.5 Folding the safety frame down

6.12 Loading the machine

6.12.1 Lifting the machine

7 Operation

7.1 Driving on the road

7.1.1 Driving on public roads

7.2 Fieldwork settings

7.2.1 Unlocking and locking ground adaptation

7.2.2 Adjusting the cutting height

7.2.3 Adjusting the cutting height with the low-cut system*

7.2.4 Adjusting the tine conditioner

7.2.5 Adjusting the swathing plates

7.2.6 Mowing without conditioner effect

7.3 Fieldwork

7.3.1 To be observed during fieldwork

7.3.2 Machine use

7.3.3 Adapting the PTO shaft speed

7.3.4 Mowing methods

7.3.5 Instructions for mowing

7.3.6 Difficult conditions of use

7.3.7 Recommendation for environmental protection

8 Faults and remedies

8.1 Overview of problems

8.1.1 Overview of problems on the machine

8.2 Mower unit

8.2.1 The cutting disc no longer turns

9 Maintenance

9.1 Maintenance interval overview

9.1.1 Before the harvest

9.1.2 After the first 50 operating hours

9.1.3 Every 8 operating hours or daily

9.1.4 Every 20 operating hours

9.1.5 Every 50 operating hours

9.1.6 Every 100 operating hours

9.1.7 Every 250 operating hours

9.1.8 Every 500 operating hours or annually

9.1.9 Every 5 years

9.1.10 After the harvest

9.2 Gearbox

9.2.1 Checking the gearbox for leaks

9.2.2 Check the oil level in the main gearbox

9.2.3 Change the oil in the main gearbox

9.2.4 Checking the oil level in the angle drive

9.2.5 Change the oil in the angle drive

9.3 Clutch

9.3.1 Checking the overload clutch

9.3.2 Venting the friction clutch

9.3.3 Checking the friction discs

9.3.4 Clean the friction clutch on the universal drive shaft

9.3.5 Cleaning the free-wheel clutch on the universal drive shaft

9.4 Universal drive shafts

9.4.1 Servicing the universal drive shafts

9.5 Hydraulic system

9.5.1 Hydraulic system maintenance

9.5.2 Checking the hydraulic hoses

9.5.3 Checking the accumulator

9.5.4 Checking the accumulator*

9.5.5 Reducing the pressure in the hydraulic system

9.5.6 Reducing the pressure in the hydraulic system*

9.6 Mower unit

9.6.1 Checking the oil level and oil quality of the cutting disk

9.6.2 Changing the oil in the mower head

9.6.3 Check the mower knives

9.6.4 Replacing the mower knives

9.6.5 Check the mower knife holder

9.6.6 Check the adapters

9.6.7 Clean the drain opening of the feed drum

9.6.8 Check the feed drum wear bars

9.6.9 Check the cover plate on the feed drum

9.6.10 Check the sealing washer of the feed drum

9.6.11 Check the cutting discs

9.6.12 Replacing the cutting discs

9.6.13 Adjust the anti-wrap guard

9.7 Crop processing unit

9.7.1 Checking the conditioner drive belt

9.7.2 Tensioning the conditioner drive belt

9.7.3 Replacing the conditioner drive belt

9.7.4 Checking the tines

Replacing the tines

Replacing tines with tine screw terminal

Inserting the rubber spring

Align bent tines

9.7.5 Adjusting the roller conditioner

Adjusting the tension springs

Tensioning the tension springs

Relieving the tension of tension springs

Adjusting synchronous running

Adjusting the roller clearance

9.8 Frame

9.8.1 Adjusting the ground adaptation spring

9.8.2 Checking the low-cut system*

9.9 Assembly parts and machine body

9.9.1 Removing crop residues

9.9.2 Checking the safety guards

9.9.3 Check the safety guard holder

Front safety guard holder

Left and right safety guard holders

9.9.4 Clean the machine

9.9.5 Preserve the machine

9.9.6 Check the fittings

9.10 Lubrication chart for the DISCO MOVE

9.10.1 Lubricating the grease points every 20 operating hours

9.10.2 Lubricate lubrication points every 50 operating hours

9.10.3 Lubricating grease points every 100 operating hours

9.10.4 Lubricating grease points every 250 operating hours

9.11 Lubrication chart for the DISCO PROFIL

9.11.1 Lubricating the grease points every 20 operating hours

9.11.2 Lubricating grease points every 100 operating hours

9.11.3 Lubricating grease points every 250 operating hours

10 Putting out of operation and disposal

10.1 General information

10.1.1 Removal from service and disposal

11 EC declaration of conformity

11.1 DISCO 3600 FC/3600 FRC

12 Technical terms and abbreviations

12.1 Terms and explanations

12.1.1 Technical terms

12.1.2 Abbreviations

00 2348 408 0.pdf:

CEMIS 100

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 100

3.1.2 Function principle of CEMIS 100

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 100

4 Operating and display elements

4.1 CEMIS 100

4.1.1 User interface for LINER

4.1.2 User interface for ROLLANT

4.1.3 User interface for UNIWRAP

5 Technical specifications

5.1 CEMIS 100

5.1.1 Specification

6 Operation

6.1 CEMIS 100

6.1.1 Operating the CEMIS 100

6.1.2 Switching CEMIS 100 on

6.1.3 Switching CEMIS 100 off

7 Maintenance

7.1 CEMIS 100

7.1.1 Daily

8 Putting out of operation and disposal

8.1 General information

8.1.1 Removal from service and disposal

9 Technical terms and abbreviations

9.1 Terms and explanations

9.1.1 Technical words

9.1.2 Abbreviations

00 2348 427 0.pdf:

CEMIS 700

Table of contents

1 Introduction

1.1 General information

1.1.1 Validity of the manual

1.1.2 Information about this Operator’s Manual

1.1.3 Symbols and notes

1.2 Intended use

1.2.1 Intended use

1.2.2 Reasonably foreseeable misuse

2 Safety

2.1 Safety rules

2.1.1 General safety and accident prevention regulations

2.1.2 Interaction between terminal and machine or tractor

2.1.3 Electrocution by electrical system

3 Product description

3.1 Overview and method of operation

3.1.1 Overview of CEMIS 700

3.1.2 Function principle of CEMIS 700

3.2 Identification plates and identification numbers

3.2.1 Spare parts and technical questions

3.2.2 Identification plate of CEMIS 700

4 Information on the product

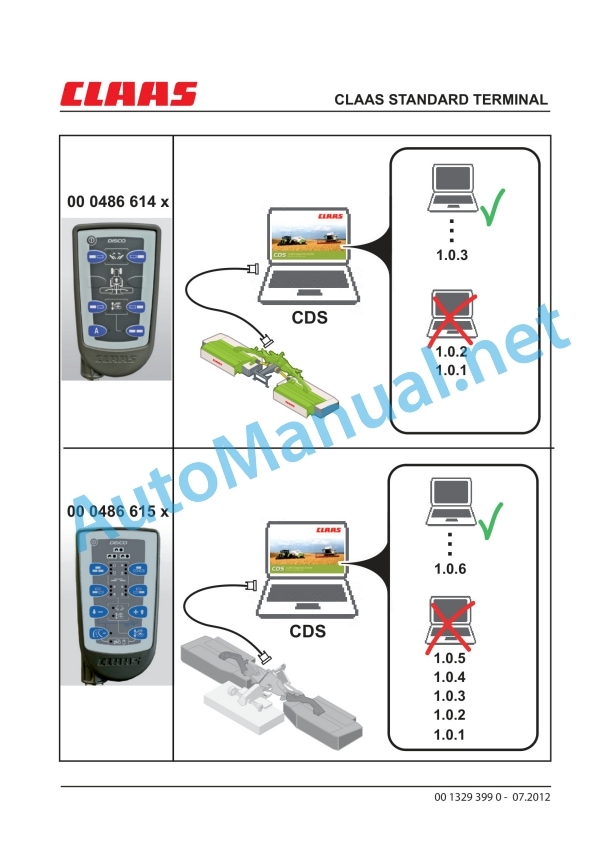

4.1 Software version

5 Operating and display elements

5.1 CEMIS 700

5.1.1 User interface

5.1.2 Terminal program

6 Technical specifications

6.1 CEMIS 700

6.1.1 Specification

7 Operation

7.1 CEMIS 700

7.1.1 Operating the CEMIS 700

7.1.2 Switching CEMIS 700 on

7.1.3 Switching CEMIS 700 off

7.2 Terminal settings

7.2.1 Making settings

Making settings with the rotary button

Making settings with the touch function

7.2.2 Setting the screen lighting

Daytime mode

Nighttime mode

Activating automatic key lighting

7.2.3 Setting the time and date

7.2.4 Displaying diagnosis information

On-board power supply voltage display

Display of CLAAS ISOBUS ECU address and name

7.2.5 Setting the language and display formats

Setting the language

Setting display formats

7.2.6 Setting the volume

7.2.7 Deleting an ISOBUS implement

8 Maintenance

8.1 Maintenance

8.1.1 Daily

9 Putting out of operation and disposal

9.1 General information

9.1.1 Removal from service and disposal

10 Technical terms and abbreviations

10.1 Terms and explanations

10.1.1 Technical words

10.1.2 Abbreviations

John Deere Repair Technical Manual PDF

John Deere Diesel Engines PowerTech 4.5L and 6.8L – Motor Base Technical Manual 07MAY08 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish