Claas Lexion 570 580 R (585) Combines Repair Manual EN

$300.00

- Model: Lexion 570 580 R (585) Combines

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 191 MB

File List:

00 0288 975 0.pdf

00 0290 380 0.pdf

00 0293 109 0.pdf

00 0295 424 0.pdf

00 0296 400 0.pdf

00 0302 218 2.pdf

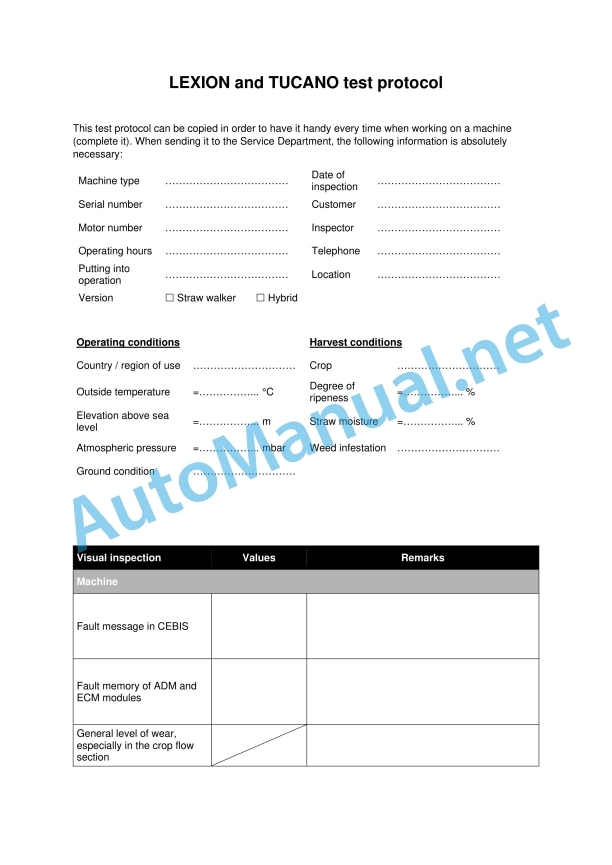

Test protocol LEXION and TUCANO.pdf

00 0288 975 0.pdf:

LEXION 770-405

Table of contents

Introduction

General information

Validity of manual

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

General information

Important

Hazard signs

Signal word

General safety and accident prevention regulations

Combine-harvester safety and accident prevention regulations

First aid measures

Leaving the machine

Battery isolating switch

Putting the machine out of operation

02 Gearbox / Clutch / Universal drive shaft

0210 Oscillation damper

Oscillation damper

Technical specifications

Work preparation

Installation

Oscillation damper

Technical specifications

Work preparation

Installation

Oscillation damper

Technical specifications

Work preparation

Installation

00 0290 380 0.pdf:

Contents

1 Introduction

1.1 General information

1.1.1 Validity of manual

2 Feed rake conveyor

2.1 Feed rake conveyor

2.1.1 Replacing the HP feed rake conveyor anti-slip strips

3 Straw discharge

3.1 Chaff spreader

3.1.1 Overview of chaff spreader / chaff spreader fan LEXION 600 – 560 (type 589 – 584)

3.1.2 Overview of radial spreader LEXION 600 – 560 (type 589 – 584)

3.2 Straw spreader

3.2.1 Overview of straw spreader

4 Drives

4.1 Drive belts / drive chains

4.1.1 Drive diagram, left side (LEXION 600 with JET STREAM cleaning system)

4.1.2 Drive diagram, right side (LEXION 600 with JET STREAM cleaning system)

4.1.3 Drive diagram, left side (LEXION 580 with standard cleaning system)

4.1.4 Drive diagram, right side (LEXION 580 with standard cleaning system)

4.1.5 Drive diagram, left side (LEXION 570 with standard cleaning system)

4.1.6 Drive diagram, right side (LEXION 570 with standard cleaning system)

4.1.7 Drive diagram, left side (LEXION 570 with JET STREAM cleaning system)

4.1.8 Drive diagram, right side (LEXION 570 with JET STREAM cleaning system)

4.1.9 Drive diagram, left side (LEXION 560 – 510 with standard cleaning system)

4.1.10 Drive diagram, right side (LEXION 560 – 510 with standard cleaning system)

4.1.11 Removing belt (R26)

4.1.12 Installing belt (R26)

4.1.13 Adjusting belt (R26)

4.2 Fan drive of JET STREAM cleaning system LEXION 570

4.2.1 Overview of fan variable-speed drive (electric) from serial no. …

4.2.2 Overview of fan variable-speed drive (spring-loaded) from serial no. …

4.2.3 Overview of fan variable-speed drive from serial no. …

4.3 Special tool for fan drive of JET STREAM cleaning system LEXION 570

4.3.1 Disassembling the fan variable-speed drive (spring-loaded) from serial no. …

4.3.2 Disassembling the fan variable-speed drive (spring-loaded) from serial no. …

4.4 Front attachment drive

4.4.1 Overview of belt (R2)

4.4.2 Removing the drive pulley of belt (R2) from serial no. …

4.4.3 Overview of drive pulley of belt (R2) from serial no. …

4.4.4 Installing drive pulley of belt (R2) from serial no. …

4.4.5 Overview of belt (R3) (with front attachment variable-speed drive)

4.4.6 Removing the front attachment variable- speed drive (hydraulic) from serial no. …

4.4.7 Overview of front attachment variable-speed drive (hydraulic) from serial no. …

4.4.8 Installing the front attachment variable- speed drive (hydraulic) from serial no. …

4.4.9 Overview of belt (R3) (with front attachment step drive)

4.4.10 Overview of belt (R26)

4.4.11 Removing drive pulley of belt (R26)

4.4.12 Overview of drive pulley of belt (R26)

4.4.13 Installing the drive pulley of belt (R26)

4.4.14 Removing the driven pulley of belt (R26)

4.4.15 Overview of driven pulley of belt (R26)

4.4.16 Installing the driven pulley of belt (R26)

4.4.17 Overview of jockey pulley of belt (R26)

4.5 Special tools for front attachment drive

4.5.1 Installing drive pulley of belt (R2) from serial no. …

4.5.2 Removing the front attachment variable- speed drive (hydraulic) from serial no. …

4.5.3 Installing the front attachment variable- speed drive (hydraulic) from serial no. …

4.5.4 Installing the drive pulley of belt (R26)

4.5.5 Removing the driven pulley of belt (R26)

4.5.6 Installing the driven pulley of belt (R26)

4.6 Impeller drive

4.6.1 Removing the driven pulley of belt (R5) from serial no. …

4.6.2 Overview of driven pulley of belt (R5) from serial no. …

4.6.3 Installing the driven pulley of belt (R5) from serial no. …

4.7 Special tool for impeller drive

4.7.1 Removing the driven pulley of belt (R5) from serial no. …

5 Axles, tyres

5.1 Steering Axle

5.1.1 Removing the rear axle / CLAAS 4-Trac axle with standard cleaning system

5.1.2 Installing the rear axle / CLAAS 4-Trac axle with standard cleaning system

5.1.3 Removing the rear axle / CLAAS 4-Trac axle / ACTIVE TRAC axle with JET STREAM cleaning system

5.1.4 Installing the rear axle / CLAAS 4-Trac axle / ACTIVE TRAC axle with JET STREAM cleaning system

5.1.5 Overview of rear axle (10 t, adjustable)

5.1.6 Overview of rear axle (9.5 t, adjustable)

5.1.7 Overview of rear axle (9 t, adjustable)

5.1.8 Overview of rear axle (9 t, rigid)

5.1.9 Overview of rear axle (8.5 t, adjustable)

5.1.10 Overview of rear axle (7.5 t rigid / adjustable)

5.1.11 Overview of rear axle (7 t, adjustable)

5.2 Rear drive axle

5.2.1 Removing the motor retainer of the ACTIVE TRAC axle (11 t)

5.2.2 Overview of motor retainer of ACTIVE TRAC axle (11 t)

5.2.3 Installing the motor retainer of ACTIVE TRAC axle (11 t)

5.2.4 Removing the gearbox of ACTIVE TRAC axle (11 t)

5.2.5 Installing the gearbox of ACTIVE TRAC axle (11 t)

5.2.6 Overview of ACTIVE TRAC axle (11 t)

5.2.7 Overview of CLAAS 4-Trac axle (11 t)

5.2.8 Overview of CLAAS 4-Trac axle (9 t / 10 t)

5.2.9 Overview of CLAAS 4-Trac axle (9.5 t)

5.3 Special tool for rear drive axle

5.3.1 Installing the motor retainer of ACTIVE TRAC axle (11 t)

6 Hydraulic system

6.1 General

6.1.1 Venting the hydrostatic system with mechano-hydraulic ground drive

6.1.2 Venting the hydrostatic system with electro-hydraulic ground drive

6.1.3 Venting the CLAAS 4-Trac system with mechano-hydraulic ground drive

6.2 Special tool for general hydraulic system

6.2.1 Venting the hydrostatic system with mechano-hydraulic ground drive

6.2.2 Venting the hydrostatic system with electro-hydraulic ground drive

6.3 Hydraulic motors

6.3.1 Removing the radial spreader motor (241 / 242)

6.3.2 Installing the radial spreader motor (241 / 242)

6.3.3 Removing the CLAAS 4-Trac axle motor (203 / 204)

6.3.4 Installing the CLAAS 4-Trac axle motor (203 / 204)

6.3.5 Removing the motor of ACTIVE TRAC axle (2063 / 2064)

6.3.6 Installing the motor of ACTIVE TRAC axle (2063 / 2064)

6.3.7 Overview of steering hydraulic cylinder (twin piston rod cylinder) (323)

6.4 Special tool for hydraulic motors

6.4.1 Installing the radial spreader motor (241 / 242)

6.5 Hydraulic cylinder

6.5.1 Overview of steering hydraulic cylinder (twin piston rod cylinder) (323)

7 Engine

7.1 Transfer gearbox

7.1.1 Disassembling the transfer box

7.1.2 Overview of transfer gearbox

7.2 Special tool for transfer gearbox

7.2.1 Disassembling the transfer gearbox

7.2.2 Disassembling the transfer gearbox

7.2.3 Assembling the transfer gearbox

7.2.4 Assembling the transfer gearbox

00 0295 424 0.pdf:

Contents

1 Introduction

1.1 General Information

1.1.1 Using the manual

Texts and figures

Document structure based on subassemblies

Search and find

Directions

1.2 General repair instructions

1.2.1 Specifications

1.2.2 Reason of damage

1.2.3 Spare parts

1.2.4 Diesel engine

1.2.5 Gearboxes

1.2.6 Alternator

1.2.7 Welding Work

1.2.8 Tensioning the steel roller chains

1.2.9 Taper ring fasteners

1.2.10 Self-locking bolts with micro-encapsulated adhesive

1.2.11 Liquid locking compound

1.2.12 Lock collar bearing

1.2.13 Adapter sleeve bearing

1.2.14 Ferrule fittings on hydraulic lines

1.2.15 Progressive ring fittings on hydraulic lines

1.2.16 Taper fittings on hydraulic lines

1.2.17 Hydraulic hoses

1.2.18 Some advice for speedy and correct repair work:

1.3 Torque settings

1.3.1 Tightening torques for metric standard threads

1.3.2 Tightening torques for metric fine threads

1.3.3 Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

1.3.4 Tightening torques for hydraulic screw fittings and air conditioner fittings with a sealing cone and O-ring DIN 3865

1.3.5 Tightening torques for hydraulic male connector DIN 3901

1.3.6 Tightening torques for direction-adjustable hydraulic male connectors ISO 6149-2 / ISO 11926-2 (3)

1.3.7 Tightening torque for hydraulic swivelling screw fittings

1.3.8 Tightening torques for hollow screws DIN 7643

1.3.9 Tightening torques of brake line screw fittings

1.3.10 Tightening torques for screw thread clamps

1.3.11 Tightening torque for tyres

1.4 Specifications

1.4.1 Lubricants

2 Safety precautions

2.1 General information

2.1.1 Important notice

2.1.2 Identification of warning and danger signs

2.1.3 General safety and accident prevention regulations

2.1.4 General safety and accident prevention regulations for combine harvesters

2.1.5 Crop / straw discharge

2.1.6 Leaving the machine

2.1.7 Grain tank

2.1.8 Combine harvester chopper unit

2.1.9 Adjustment and maintenance work

2.1.10 Danger of injury due to escaping hydraulic liquid

2.1.11 Air conditioner

2.1.12 Pressure accumulator

2.1.13 First aid measures

2.1.14 Battery isolating switch

2.1.15 Installing the feed rake conveyor safety lock

2.1.16 Jack up the machine

2.1.17 Putting the machine out of action

3 Chassis

3.1 Crawler

3.1.1 Crawler (from serial no. …) Overview

3.1.2 Arm (from serial no. …) Overview

3.1.3 Crawler drive (from serial no….) Overview

3.1.4 Support wheels, mounted (from serial no. …) Overview

3.1.5 Crawler (up to serial no. …) Overview

3.1.6 Arm (up to serial no. …) Overview

3.1.7 Crawler drive (up to serial no. …) Overview

3.1.8 Support wheels, mounted (up to serial no. …) Overview

3.2 Terra Trac manual gearbox (type 589)

3.2.1 Manual gearbox (type 589) Overview

3.2.2 Differential (type 589) Overview

3.3 Terra Trac manual gearbox (type 589) special tools

3.3.1 Disassembling the Terra Trac manual gearbox (type 589)

3.3.2 Disassembling the Terra Trac manual gearbox (type 589)

3.3.3 Assembling the Terra Trac manual gearbox (type 589)

3.3.4 Assembling the Terra Trac manual gearbox (type 589)

3.4 Terra Trac manual gearbox (type 586 / 585 / 584)

3.4.1 Manual gearbox (type 586 / 585 / 584 from serial no. …) Overview

3.4.2 Differential (type 586 / 585 / 584 from serial no. …) Overview

3.4.3 Manual gearbox (type 586 / 585 / 584 up to serial no. …) Overview

3.4.4 Differential (type 586 / 585 / 584 up to serial no. …) Overview

3.5 Terra Trac manual gearbox (type 586 / 585 / 584) special tools

3.5.1 Disassembling the manual gearbox (type 586 / 585 / 584 from serial no. …)

3.5.2 Assembling the manual gearbox (type 586 / 585 / 584 from serial no. …)

3.5.3 Disassembling the manual gearbox (type 586 / 585 / 584 up to serial no. …)

3.5.4 Assembling the manual gearbox (type 586 / 585 / 584 from serial no. …)

4.1 Service brake / Parking brake (type 589)

4.1.1 Overview of spring accumulator combination cylinder

4.1.2 Installing and adjusting the spring-type accumulator combination cylinder

4.1.3 Plain disc brake overview

00 0296 400 0.pdf:

TERRA TRAC track roller unitGeneration II

Table of contents

Introduction

General information

Validity of manual

Handling of this manual

Texts and figures

Document structure based on subassemblies

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on economic repairs

Self-locking bolts

Liquid locking compound

Ferrule fittings

Screwing in

Non-tight ferrule connection

Sealing cone fittings

Hydraulic hose lines

Hose placement

Spare parts

Torque settings

Tightening torques for metric standard threads

Tightening torque for metric fine threads

Tightening torques for hydraulic screw fittings with ferrule DIN 3861

Tightening torques for hydraulic screw fittings and air conditioner screw fittings with O-ring and sealing cone DIN 3865

Tightening torques for SDS hydraulic male connectors

Tightening torques for direction-adjustable SDE hydraulic male connectors

Tightening torques for hydraulic swing fittings

Tightening torques for hollow screws DIN 7643

Tightening torques for brake line screw fittings

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

General information

Of special importance

Identification of warning and danger signs

General safety and accident prevention regulations

First aid measures

Risk of injury from hydraulic fluid

Leaving the machine

Putting the machine out of operation

Jacking up the machine

Adjustment and maintenance operations

Hydraulic accumulators

Battery isolating switch

Welding work

03 Chassis

0355 Track roller unit

Overview of TERRA TRAC track roller unit

Removal/Installation

Overview of TERRA TRAC track roller unit

Removal/Installation

TERRA TRAC track roller unit rubber tracks

Work preparation

Installation

TERRA TRAC track roller unit rubber tracks

Work preparation

Special tool

Installation

TERRA TRAC track roller unit support wheels

Work preparation

Disassembly

Assembly

Installation

TERRA TRAC track roller unit support wheels

Work preparation

Disassembly

Assembly

Installation

TERRA TRAC track roller unit bearing unit

Work preparation

Installation

TERRA TRAC track roller unit rocker arm

Work preparation

Disassembly

Assembly

Installation

TERRA TRAC track roller unit gearbox

Work preparation

Special tool

Disassembly

Assembly

Installation

Rubber track tension hydraulic cylinder (3071)

Work preparation

Special tool

Removing the hydraulic cylinder

Installing the hydraulic cylinder

00 0302 218 2.pdf:

LEXION 780-405

Table of contents

Introduction

General information

Validity of manual

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

Tightening torques

Tightening torques for metric standard threads

Tightening torques for metric fine thread

Tightening torques for hydraulic screw fittings with ferrule according to DIN 3861

General information

Important

Hazard signs

Signal word

General safety and accident prevention regulations

Combine-harvester safety and accident prevention regulations

First aid measures

Crop / straw discharge

Leaving the machine

Adjusting and maintenance work

Danger of injury from hydraulic liquid

Battery isolating switch

Putting the machine out of operation

08 Drives

0841 Threshing mechanism drive

Driven pulley of belt (R52)

Technical specifications

Work preparation

Special tool

Disassembly

Assembly

Installation

Lubricating interval

0842 Separation drive

Driven pulley of belt (R41)

Technical specifications

Work preparation

Special tool

Disassembly

Assembly

Installation

Lubricating interval

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF