Claas LEXION 600 (589) Combine Assembly Instruction DE

$30.00

- Model: LEXION 600 (589) Combine

- Type Of Manual: Assembly Instruction

- Language: DE

- Format: PDF(s)

- Size: 32.3 MB

File List:

– 00 0293 252 1.pdf

– 00 0293 776 0.pdf

– 00 0293 778 0.pdf

– 00 0293 947 1.pdf

– 00 0293 949 0.pdf

– 00 0293 951 0.pdf

– 00 0294 649 1.pdf

– 00 0294 812 0.pdf

00 0293 252 1.pdf

Table of Content:

6 1 Introduction

6.1 1.1 General information

7 2 Security

7.1 2.1 Note

8 3 Scope of delivery

8.1 3.1 Retrofit kits 000 517 640 0 and 91014142

9 4 Cultivation

9.1 4.1 Install CLAAS LASER-PILOT

10 5 Before commissioning

10.1 5.1 Setting and operating CLAAS LASER-PILOT (from mach. no. …)

10.2 5.2 CLAAS autopilot (grain cutter)

11 1 Introduction

11.1 1.1 General Information

12 2 Safety precautions

12.1 2.1 Important

13 3 Package list

13.1 3.1 Supplementary kits 000 517 640 0 and 91014142

14 4 Mounting

14.1 4.1 Installing the CLAAS LASER PILOT

15 5 Prior to operation

15.1 5.1 Adjusting and using the CLAAS LASER-PILOT (from serial no. …)

15.2 5.2 CLAAS Autopilot (Grain cutterbar)

16 1 Introduction

16.1 1.1 General Councils

17 2 Security Councils

17.1 2.1 Observer !

18 3 pieces fournies

18.1 3.1 Ultra assembly kits 000 517 640 0 and 91014142

19 4 Assembly

19.1 4.1 Pose of LASER-PILOT CLAAS

20 5 Avant la mise en service

20.1 5.1 Rglage and utilization of the LASER-PILOT CLAAS (part of the machine N. …)

20.2 5.2 Autopilot CLAAS (tablier de coupe crales)

21 1 Introduction

21.1 1.1 General indications

22 2 Medidas de seguridad

22.1 2.1 Observar

23 3 Conjunto de suministro

23.1 3.1 Rear equipment games 000 517 640 0 and 91014142

24 4 Montaje

24.1 4.1 Montar el CLAAS LASER-PILOT

25 5 Antes de la puesta en marcha

25.1 5.1 Adjust and operate the CLAAS LASER-PILOT (a part of the machine no. …)

25.2 5.2 Autopilot CLAAS (mecanismo de cort?? ????????? ?????? CLAAS

30 5 ????? ?????? ? ???????????

30.1 5.1 ????????? ? ???????????? ????????? ?????? CLAAS (??????? ? ????? ? …)

30.2 5.2 ????????? CLAAS (???????? ?????)

00 0293 776 0.pdf

Table of Content:

1 LEXION 600

2 Installation instructions

3 license plate lighting

4 Fitting Instructions

5 Number-plate illumination

6 Notice of assembly

7 ?clairage de plaque d’immatriculation

Read and observe 8 safety instructions!

9 Please read and follow the safety instructions!

10 Respect and read the security consignments !

10.2 1 Introduction

10.3 2 Safety instructions

10.4 3 Scope of delivery

10.5 4 Cultivation

10.6 1 Introduction

10.7 2 Safety information

10.8 3 Package list

10.9 4 Mounting

10.10 1 Introduction

10.11 2 Security Councils

10.12 3 pieces fournies

10.13 4 Montage

10.14 1 Introduction

10.15 2 Safety instructions

10.16 1 Introduction

10.17 2 Safety information

10.18 1 Introduction

10.19 2 Security Councils

00 0293 778 0.pdf

Table of Content:

1 LEXION 600 – 510

2 Installation instructions

3 Quantimeter

4 Fitting Instructions

5 Quantimeter

6 Notice of assembly

7 Quantimtre

Read and observe 8 safety instructions!

9 Please read and follow the safety instructions!

10 Respect and read the security consignments !

10.2 1 Introduction

10.3 2 Safety instructions

10.4 3 Scope of delivery

10.5 4 Cultivation

10.6 1 Introduction

10.7 2 Safety information

10.8 3 Package list

10.9 4 Mounting

10.10 1 Introduction

10.11 2 Security Councils

10.12 3 pieces fournies

10.13 4 Montage

10.14 1 Introduction

10.15 2 Safety instructions

10.16 3 Scope of delivery

10.17 3.1 Quantimeter scope of delivery

10.19 1666

10.21 4 cultivation

10.22 4.1 Add Quantimeter

10.23 1706

10.24 4.1.1 Install yield sensor

(D) on both sides of the grain elevator. The sealing lids are omitted.

10.29 (Fig. 1)

10.32 1671

10.33 – Screw the pre-assembled light barrier transmitter (1, red) to the rear side of the elevator with screws (2), contact washer (3), washer (4), compression spring (5) and washer (6). Fasten the cable to the elevator with the existing clamp (S).

10.34 (Fig. 2)

10.37 1672

10.38 – Screw the pre-assembled light barrier receiver (7, yellow) to the front side of the elevator with the nut (8) and contact washers (9). Fasten the cable to the elevator with the existing clamp (K).

10.39 (Fig. 3)

10.40 1673

10.44 1674

10.45 – Lock the pre-assembled clamping bolt (S) on the swivel holder (W). Pretension of the clamping bolt (S) with nut and lock nut…

10.46 (Fig. 4, 5)

10.47 1707

10.48 4.1.2 Install hydraulic chain tension

10.51 1675

10.52 Attachment of the hydraulic chain tensioning device only required if not already available

10.53 – Remove pipe (L) of the chain tensioner. Relax the chain by loosening the nut (M). Unscrew the screws (S) and remove the pipe (L).

10.54 (Fig. 6)

10.57 1676

10.58 – Slide angle (11) onto pipe (12).

10.59 – Connect pipe (12 and cylinder (13) with bolt (14).

10.60 – Slide on washer (15) and secure bolt (14) with cotter pin (16).

10.61 (Fig. 7)

10.64 1677

10.67 1678

10.68 – Insert the hydraulic cylinder (13) into the existing guide hole of the old tensioning device. Screw the bracket (11) onto the existing threaded bolts on the elevator shaft with nuts (17). Fasten pipe (12) at the top with existing screws (S).

10.69 (Fig. 8, 9)

10.70 1708

10.71 4.1.3 Install moisture sensor (18)

10.74 1669

10.75 – Use special tool (V) to create negative pressure in the hydraulic oil tank (P) or drain hydraulic oil.

10.76 – Special tool: valve combination for generating vacuum ET no. 181 619.1

10.77 (Fig. 10)

10.80 1679

10.81 – On machines with 3-D, unscrew both angle connectors (W).

10.82 (Fig. 11)

10.85 1680

10.86 – On machines without 3-D, unscrew both blind plugs (T).

10.87 (Fig. 12)

10.90 1681

10.91 – Unscrew the sealing cover (V) on the grain elevator.

10.92 (Fig. 13)

10.95 1682

10.96 – Humidity sensor (18) pre-assembled.

10.97 – Up to mach. no. … use the hydraulic hoses (H).

10.98 – From mach. no. … use the hydraulic lines (21) and (22).

10.99 (Fig. 14)

10.101 1683

10,105 1684

10.106 – Screw the moisture sensor (18) to the grain elevator with nuts (19) and existing nuts.

10.107 – Screw on pipes, angles and T-pieces according to Figures 15 and 16:

10.108 – L-piece (20), pipe (21), pipe (22), pipe (23), pipe (24), T-piece (25), angle (26), hose line (27).

10.109 – Screw on pipes (21) and (22) with clamp (28) and screw (29).

10,110 (Fig. 16)

10,113 1685

10,116 1686

10.117 – Machines with 3-D: Connect the hydraulic line (T) to the distributor at (D). Connect the hydraulic line (P) to the distributor at (B).

10.118 – Pipe (R) only LEXION Montana

10.119 – Hose line (T) chain tension cylinder

10.120 – Remove special tool for generating vacuum or fill up hydraulic oil.

10,121 (Fig. 17, 18)

10,122 1709

10.123 4.1.4 Install tilt sensor

10,126 1687

10.127 – Screw the tilt sensor (30) to the console (32) with screws (31). Fasten cable (K) with clamp (33).

10,128 (Fig. 19)

10,131 1688

10.132 – Unscrew the lower screws (S).

10,133 (Fig. 20)

10,136 1689

10.137 – Screw on the console (32) using the existing screws. Align console (32) parallel to the axis!

10,138 (Fig. 21)

10,141 1690

10.142 – Remove right drive wheel.

10.143 – Remove protection (S).

10,144 (Fig. 22)

10,147 1691

10.148 – Remove protection (K).

10,149 (Fig. 23)

10,152 1692

10.153 – Connect the cable set (34) to the solenoid valve (M) and to the humidity sensor cable (F). Fasten the cable set (34) with cable clamps (33).

10,154 (Fig. 24)

10,156 1693

10.157 – Connect the plug from the cable set (34) to the plug from the light barrier receiver and light barrier transmitter (see arrow).

10,158 (Fig. 25)

10,161 1694

10.162 – Screw on the cable set (34) with pipe clamps (35) and screws (39).

10,163 (Fig. 26)

10,166 1695

10.167 – Screw on the holders (37) using the existing screws. Screw the cable set (34) with pipe clamps (38) to the holder (37).

10,168 (Fig. 27)

10,171 1696

10.172 – Screw on the cable set (34) with pipe clamps (38).

10,173 (Fig. 28)

10,176 1697

10.177 – Screw on cable set (34) with pipe clamp (38).

10,178 (Fig. 29)

10,180 1698

10.181 – Lay the branch of the cable set (34) downwards to the inclination sensor.

10.182 – Screw on the cable set (34) with pipe clamps (35) and existing screws (see arrows).

10,183 (Fig. 30)

10,186 1699

10.187 – Screw on the cable set (34) with the pipe clamp (35) and the existing screw.

10,188 (Fig. 31)

10,191 1700

10.192 – Screw on the cable set (34) with pipe clamps (35) and screw (39).

10.193 – Fasten cable set (34) with cable tie (40).

10,194 (Fig. 32)

10,197 1701

10.198 – Screw on the cable set (34) with pipe clamps (35) and screw (36).

10.199 – Fasten the cable set (34) with cable ties (40).

10,200 (Fig. 33)

10.203 1702

10.204 – Connect the cable set (34) to the cable set of the inclination sensor

10.205 – Fasten cable set (34) with cable tie (40).

10.206 (Fig. 34)

10.209 1703

10.210 – Screw on the cable set (34) with pipe clamps (35) and existing screws (see arrows).

10,211 (Fig. 35)

10,214 1704

10.215 – Unscrew the footplate (T).

10,216 (Fig. 36)

10,219 1705

10.220 – Lay cable set (34) to the central electrical system.

10.221 – Screw the footplate back on.

10,222 (Fig. 37)

10,225 1706

10.226 – Open the screw lock (D) and latch (R).

10.227 – Open the central electrics.

10,228 (Fig. 38)

10,231 1707

10.232 – Unscrew sealing plate (B).

10,233 (Fig. 39)

10,236 1708

10.237 – Remove blind plug (C).

10.238 – Guide cable set (34) through at (C).

10.239 – Insert the cable grommet of the cable set (34) at (C).

10,240 (Fig. 40)

10,243 1709

10.244 – Screw on cable set (34) with pipe clamp (35) and nut (41).

10,245 (Fig. 41)

10,248 1710

10.249 – Fasten the cable set (34) with the clamp (L).

10,250 (Fig. 42)

10,253 1711

10.254 – Insert connector holder (42) so that it locks.

10,255 (Fig. 43)

10,258 1712

10.259 – Insert the plug from the cable set (34) into the plug holder.

10,260 (Fig. 44)

10,262 1713

10.263 – Central electrics up to mach. no. …

10.264 – Plug the second plug from the cable set (34) into the plug location (MP) (see arrow) and secure it with a cable tie (40).

10,265 (Fig. 45)

10,267 1714

10.268 – Central electrics from mach. no. …

10.269 – Plug the second plug from the cable set (34) into the plug location (MP) (see arrow) and secure it with a cable tie (40).

10,270 (Fig. 46)

10,273 1715

10.274 – Insert LEM module (43).

10.275 – Fasten modules with the bracket (H).

10,276 (Fig. 47)

10,277 1712

10.278 4.1.5 Carry out a test run

10,280 1716

10.281 – Close and lock the central electrical circuit board. Reinstall protective panels. Screw the drive wheel back on. For the tightening torque of the wheel nuts, see the combine harvester operating instructions.

10.282 – Close and lock the central electrics. Start the engine and operate the control valve by hand. Cylinder of the humidity sensor m…

10,283 (Fig. 48)

10,284 1 Introduction

10,285 2 Safety information

10,286 1 Introduction

10,287 2 Security Councils

00 0293 947 1.pdf

Table of Content:

2 7 Maintenance

2.1 7.1 Important maintenance instructions

2.2 7.2 Maintenance tables

00 0293 949 0.pdf

Table of Content:

4 1 Introduction

4.1 1.1 General information

5 2 Safety instructions

5.1 2.1 Note

6 3 Scope of delivery

6.1 3.1 Retrofit kit 000 014 922 0

7 4 cultivation

7.1 4.1 Attachment of additional work lighting

8 1 Introduction

8.1 1.1 General Information

9 2 Safety precautions

9.1 2.1 Important

10 3 Package list

10.1 3.1 Retrofit kit 000 014 922 0

11 4 Mounting

11.1 4.1 Installation of additional work lights

12 1 Introduction

12.1 1.1 General Councils

13 2 Security Councils

13.1 2.1 Observer !

14 3 pieces fournies

14.1 3.1 Ultra-equipment kit 000 014 922 0

15 4 Assembly

15.1 4.1 Montage de l’clairage de travail supplmentaire

00 0293 951 0.pdf

Table of Content:

6 1 Introduction

6.1 1.1tivation

9.1 4.1 Telematics

10 1 Introduction

10.1 1.1 General Information

11 2 Safety precautions

11.1 2.1 Important

12 3 Package list

12.1 3.1 Telematics

13 4 Mounting

13.1 4.1 Telematics

14 1 Introduction

14.1 1.1 General Councils

15 2 Security Councils

15.1 2.1 Observer !

16 3 pieces fournies

16.1 3.1 Telematics

17 4 Assembly

17.1 4.1 Telematics

18 1 Introduction

18.1 1.1 General indications

19 2 Medidas de seguridad

19.1 2.1 Observar

20 3 Conjunto de suministro

20.1 3.1 Telematics

21 4 Montaje

21.1 4.1 Telematics

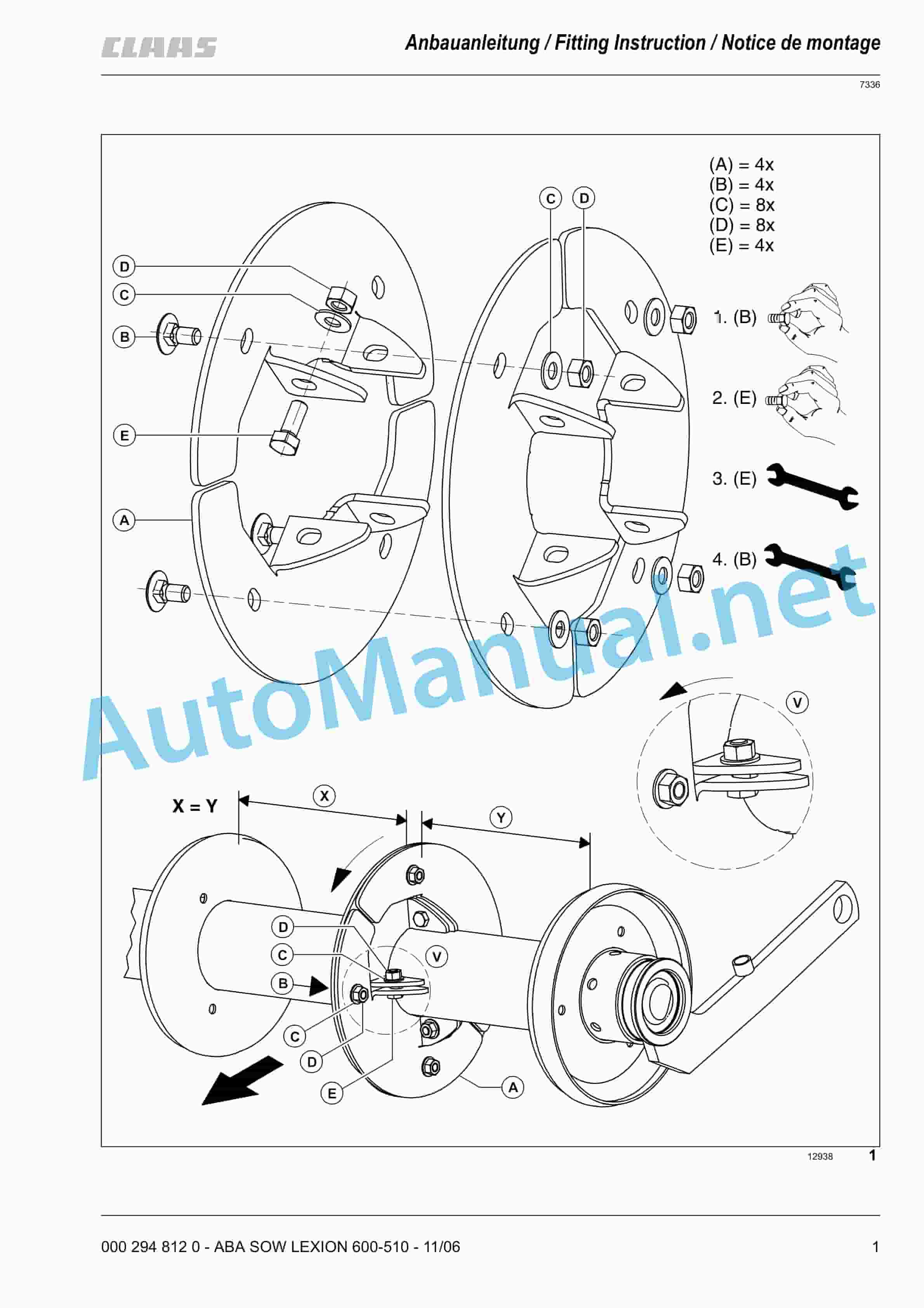

22 1 1N 560 Terra-Trac

4 3 Security

4.1 3.1 Note

4.2 3.2 Warning symbol

5 4 Scope of delivery

5.1 4.1 Rubber half-track

6 5 Cultivation

6.1 5.1 Rubber half-track

7 6 Work input

7.1 6.1 Operation

8 7 Maintenance

8.1 7.1 Important maintenance instructions

8.2 7.2 Maintenance tables

9 8 Lubrication plan

9.1 8.1 Lubrication points

John Deere Parts Catalog PDF

John Deere Tractors 7500 Parts Catalog CPCQ26568 30 Jan 02 Portuguese

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

John Deere Parts Catalog PDF

John Deere Tractors 6300, 6500, and 6600 Parts Catalog CQ26564 (29SET05) Portuguese

John Deere Repair Technical Manual PDF

John Deere Diesel Engines POWERTECH 2.9 L Component Technical Manual CTM126 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF