- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Claas Torion 1812 (K58) Wheel Loaders Repair Manual EN

$300.00

- Model: Torion 1812 (K58) Wheel Loaders

- Type Of Manual: Repair Manual

- Language: EN

- Format: PDF(s)

- Size: 55.5 MB

File List:

00 0302 512 3.pdf

Diesel engine TORION 1914 TORION 1812.pdf

Liebherr LH-D934 A7 LH-D944 A7 Stage V TORION 1914 TORION 1812.pdf

Liebherr LH-D934 A7 LH-D944 A7 Stage IV TORION 1914 TORION 1812.pdf

Service Instructions Webasto Water heater Thermo Pro 90 Thermo Pro 90 HDD.pdf

00 0302 512 3.pdf:

Repair Manual

Table of contents

Introduction

General information

Validity of manual

Using the manual

Text and figures

Document structure based on sub-assemblies

Search and find

Directions

Abbreviations

Technical terms

General repair instructions

Technical specifications

Information on technically correct repairs

Self-locking bolts

Liquid locking compound

Steel roller chains

Tensioning

Chain connector

Chain connector type E with spring

Chain connector type G with wire

Chain connector type S with cotter pins

Taper ring fasteners

Dismounting

Installing

Gib head key connections

Dismounting

Installing

Lock collar bearing

Dismounting

Installing

Adapter sleeve bearing

Dismounting

Installing

Chuck bushing

Removing

Dismounting of version A

Dismounting of version B

Installing

Chuck bushing version A

Chuck bushing version B

Circlips

Ferrule fittings

Screwing in

Leaky ferrule fittings

Sealing cone fittings

Hydraulic hoses

Hose placement

Treatment of sealing faces

Spare parts

Operating materials

Tightening torques

Tightening torques for metric standard and fine threads

Tightening torques for hydraulic fittings with ferrule

Tightening torques for screwed pipe connections with sealing cone joint and hydraulic threaded joints with soft core seal

Tightening torques for hydraulic male connectors SDS shape B and E

Tightening torques for hydraulic swivel screw fittings

Tightening torque for hollow screws (with copper sealing ring)

Tightening torques for hydraulic male connectors SDE shape H, with adjustable direction

Tightening torques for brake line screw fittings

Tightening torque for tubes with O-ring and union nuts

Tightening torques for worm drive hose clamps

Tightening torques for hose clamps with round pins

General tightening torques for Mannesmann-Rexroth

General tightening torques ZF

CCN explanation

CCN (CLAAS Component Number)

Electric systems standard

Hydraulic system standard

CCN (CLAAS Component Number)

General information

Safety and hazard information

Important

Signal word

General safety and accident prevention regulations

First-aid measures

Danger of injury from hydraulic liquid

Leaving the machine

Putting the machine out of operation

Jacking up the machine

Adjusting and maintenance work

Welding work

01 Engine

0102 Complete component

Diesel engine

Technical specifications

Work preparation

Removing

Installing

0125 Injection / Fuel system

Fuel tank

Technical specifications

Removing

Installing

Fuel filter

Technical specifications

Removing

Installing

Fuel cooler

Technical specifications

Removing

Installing

0135 Cooling system

Engine radiator

Technical specifications

Removing

Installing

Compensating tank

Technical specifications

Removing

Installing

Gear pump

Technical specifications

Removing

Installing

0145 Air intake

Air filter housing

Technical specifications

Removing

Installing

Charge air cooler

Technical specifications

Removing

Installing

Air cooler

Technical specifications

Removing

Installing

0150 Engine attachment parts

Electric starting motor

Technical specifications

Alternator

Technical specifications

Compressed-air compressor

Technical specifications

Work preparation

Removing

Installing

0165 Exhaust gas aftertreatment

Exhaust gas treatment – General

Work preparation

Special tool

Checking the purity of the urea solution

Checking the density of the urea solution

SCR catalytic converter

Technical specifications

Work preparation

Removing

Installing

Urea tank

Technical specifications

Removing

Installing

Withdrawal module

Technical specifications

Removing

Installing

Dosing unit

Technical specifications

Special tool

Removing

Installing

02 Gearbox / Clutch / Universal drive shaft

0202 Complete component

Technical specifications

Work preparation

Special tool

Removing

Installing

Technical specifications

Removing

Installing

Control unit

Technical specifications

Special tool

Removing

Installing

Speed sensors

Technical specifications

Removing

Installing

Pressurized oil pump

Technical specifications

Special tool

Removing

Installing

Drive and output flanges

Technical specifications

Special tool

Removing

Installing

Hydrostatic module

Technical specifications

Removing

Installing

0230 Mechanical gearbox

Pump transfer gearbox

Technical specifications

Work preparation

Removing

Installing

0255 Gearbox cooling system

Gearbox oil cooler

Technical specifications

Removing

Installing

0260 Universal drive shaft

Front axle universal drive shaft

Technical specifications

Removing

Installing

Rear axle universal drive shaft

Technical specifications

Removing

Installing

Gearbox drive universal drive shaft

Technical specifications

Special tool

Removing

Installing

03 Chassis

0316 Drive axle, front

Front drive axle

Technical specifications

Removing

Installing

Wheel bolts

Special tool

Installation instructions

Wheel hub

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Axle body

Technical specifications

Special tool

Removing

Installing

Differential gear

Technical specifications

Work preparation

Special tool

Disassembling

Assembling

Differential

Technical specifications

Special tool

Removing

Disassembling

Assembling

Installing

Determining the shims for installation

0316 Drive axle, front

Front drive axle

Technical specifications

Removing

Installing

Wheel bolts

Special tool

Installation instructions

Wheel hub

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Axle body

Technical specifications

Special tool

Removing

Installing

Differential gear

Technical specifications

Work preparation

Special tool

Disassembling

Assembling

Differential

Technical specifications

Special tool

Removing

Disassembling

Assembling

Installing

Determining the shims for installation

0317 Drive axle, rear

Rear drive axle

Technical specifications

Removing

Installing

Wheel bolts

Special tool

Installation instructions

Wheel hub

Technical specifications

Work preparation

Special tool

Removing

Disassembling

Assembling

Installing

Axle body

Technical specifications

Special tool

Removing

Installing

Differential gear

Technical specifications

Work preparation

Special tool

Disassembling

Assembling

Differential

Technical specifications

Special tool

Removing

Disassembling

Assembling

Installing

Determining the shims for installation

0340 Front wheels

Front wheels

Special tool

Installation

0345 Rear wheels

Rear wheels

Special tool

Installation

04 Brake

0405 Service brake

Service brake

Technical specifications

Installation instructions

Checking the tightness of the brake hydraulics

Checking the wear of brake discs

Brake pedal

Technical specifications

Removing

Installing

0415 Parking brake

Parking brake

Technical specifications

Removing

Installing

Venting the parking brake

Stop venting the parking brake

05 Steering

0505 Steering

Steering column

Technical specifications

Special tool

Removing

Disassembling

Assembling

Installing

Orbitrol

Technical specifications

Removing

Installing

Steering hydraulic cylinder

Technical specifications

Removing

Installing

Emergency steering pump

Technical specifications

Removing

Disassembling

Assembling

Installing

06 Lift device

0625 Tools

Technical specifications

Removing

Installing

0630 Lift arms

Lift arms

Technical specifications

Removing

Installing

Link plate

Technical specifications

Removing

Installing

Lift cylinder

Technical specifications

Special tool

Work preparation

Removing

Installing

Tipping cylinder

Technical specifications

Special tool

Work preparation

Removing

Installing

Guide lever

Technical specifications

Removing

Installing

Rotary angle sensor for lift arms

Technical specifications

Removing

Installing

Rotary angle sensor for tipping cylinder

Technical specifications

Removing

Installing

08 Drives

0800 Drive diagram

Drive diagram

09 Hydraulic system

0900 Hydraulic system – General

Hydraulic system – General

Special tool

Filling the accumulator

0905 Hydraulic oil tank

Hydraulic oil tank

Technical specifications

Special tool

Removing

Installing

Generating a vacuum

Stopping generating a vacuum

0907 Hydraulic oil cooler

Hydraulic oil cooler

Technical specifications

Removing

Installing

0910 Pumps

Working hydraulics pump

Technical specifications

Work preparation

Removing

Installing

Steering hydraulic pump

Technical specifications

Work preparation

Removing

Installing

10 Electrical / Electronic equipment

1005 Power supply

Technical specifications

Removing

Installing

1010 Central electrics

Central terminal compartment

Technical specifications

Removing

Installing

1020 Driving lights

Front drive lights

Technical specifications

Removing

Installing

Rear drive lights

Technical specifications

Removing

Installing

1025 Working lights

Work light

Technical specifications

Removing

Installing, left side

1030 Board computer / Indicators

Rear compartment monitoring

Technical specifications

Removing

Installing

1035 Operation / Multifunction control lever

Control lever

Technical specifications

Removing

Installing

Control panel

Technical specifications

Removing

Disassembling

Assembling

Installing

12 Cab / Operator’s platform

1210 Cab

Technical specifications

Removing

Installing

Roof covering

Technical specifications

Removing

Installing

Door lock / locking device

Technical specifications

Removing

Installing

Front windscreen wiper

Technical specifications

Removing

Installing

Rear wiper

Removing

Installing

1230 Seat

Driver’s seat

Technical specifications

Removing

Installing

1235 Cab heater

Heater/air conditioning unit

Technical specifications

Work preparation

Removing

Installing

1240 Air condition

Air conditioner compressor

Technical specifications

Removing

Installing

Anti-icing protection sensor

Removing

Installing

75 Central lubrication system

7505 Reservoir / Pump

Grease container

Technical specifications

Removing

Installing

7510 Distributor

Lubricant distributor

Technical specifications

Removing

Installing

80 Various components / Machine body

8015 Access

Cab access

Technical specifications

Removing, left side

Removing, right side

Installing, left side

Installing, right side

8025 Panellings / Hoods

Engine bnet

Technical specifications

Removing

Instaing

Engine bonnet linear motor

Technical specifications

Removing

Installing

Side panel

Technical specifications

Removing the left side panel

Installing the left side panel

Removing the right side panel

Installing the right side panel

Protecting covers

Technical specifications

Removing

Installing

8030 Mud guards

Wheel case extension

Removing

Installing

8035 Ballast / Additional weight

Ballast weight

Technical specifications

Removing the left ballast weight

Installing the left ballast weight

Removing the right ballast weight

Installing the right ballast weight

95 Maintenance parts overview

9599 Maintenance jobs

Maintenance position 1

Maintenance position 2

Adjusting the valve lash

Special tool

Bleeding the fuel system

Replacing the fuel prefilter insert

Changing the fuel fine filter element

Changing the diesel engine oil

Draining oil

Topping up oil

Changing the diesel engine oil filter

Replacing the filter element of the diesel engine oil separator

Changing the coolant

Draining the coolant

Topping up coolant

Checking the V-belt of the diesel engine

Changing the diesel engine belt

Checking the intake system and the exhaust system

Checking the intake system

Checking the exhaust system

Checking the exhaust system with diesel particulate filter

Check the fastening of diesel engine control units and the cable connections.

Changing the diesel engine heater flange

Cleaning the filter module of the diesel particulate filter

Checking the urea tank ventilation

Changing the gear oil and the gearbox oil filter

Work preparation

Changing the hydrostatic oil filter of the gearbox

Changing the pump transfer gearbox oil

Draining oil

Topping up oil

Testing and measuring the ground drive

Checking the universal drive shafts

Changing the axles’ oil

Draining oil

Topping up oil

Checking the wear of service brake discs

Checking the parking brake wear

Work preparation

Checking the brake lining wear

Checking the operating clearance

Replacing the brake linings

Adjusting the operating clearance

Checking the parking brake emergency operation

Testing and measuring the brake system

Testing and measuring the steering system

Checking the bucket bearing sleeves on the lift arms

Checking the bucket stops

Check the bucket stops when installing directly

Checking the bucket stops on the quick-hitch plate

Performing a hydraulic oil analysis

Changing the hydraulic oil

Draining the hydraulic oil

Topping up hydraulic oil

Changing the hydraulic oil tank fresh air filter element

Changing the hydraulic oil tank return line filter cartridge

Drain the condensate and sediment from the hydraulic oil tank

Checking and measuring the working hydraulics

Checking the liquid level of batteries

Replacing the forward/reverse control rocker switch and the multifunction handle cap

Checking the compressed-air system

Changing the compressed-air system air dryer

Liebherr LH-D934 A7 LH-D944 A7 Stage V TORION 1914 TORION 1812.pdf:

Repair instructions

Only for the United States

Change history

About the document

Work instructions

Spare parts

Lubricating and operating fluids

Usage instructions

Graphic symbols in these instructions

Changes, conditions, copyright

Contents

1 Product description

1.1 Technical description

1.1.1 Engine components

1.1.2 Exhaust aftertreatment system SCRFilter (single-flow)

1.1.3 Reduction agent pump

1.1.4 Engine type itemization

1.1.5 Firing order, cylinder designation and engine serial number

1.1.6 Direction of rotation

1.1.7 Company nameplate

1.1.8 Engine control unit type plate ECU3

1.1.9 Exhaust aftertreatment system type plate

1.2 Technical data

1.2.1 Cylinder liner projection

1.2.2 Valve clearance

1.2.3 Piston ring end gap

1.2.4 Thermostat start of opening

1.3 Functional description

1.3.1 Fuel system

1.3.2 Lubrication system

1.3.3 Cooling system

1.3.4 Assignment of the channels in the crankcase and cylinder head

1.3.5 Exhaust aftertreatment system SCRFilter (single-flow)

1.3.6 Reduction agent pump

2 Safety

2.1 Labeling of warnings

2.1.1 Additional labels

2.2 Target group

2.3 Intended use

2.4 Foreseeable misuse

2.5 General safety instructions

2.6 Preventing personal injuries

2.6.1 Bruises

2.6.2 Burns and scalds

2.6.3 Fires and explosions

2.6.4 Poisoning

2.6.5 High-pressure injection (liquids at high pressure can squirt out)

2.6.6 Electrical energy

2.6.7 Danger due to noise

2.7 Personal protective equipment

2.8 Operating areas and maintenance areas

2.8.1 Safety instructions

2.8.2 Operating areas

2.8.3 Maintenance areas

2.8.4 Securing and releasing the diesel engine against accidental start-up

2.8.5 Emergency stop

2.9 Signage

2.10 Preventing property damage

3 Repair work

3.1 Removing and installing the cover (variant 1)

3.1.1 Removing the cover

3.1.2 Installing the cover

3.2 Removing and installing the cover (variant 2)

3.2.1 Removing the cover

3.2.2 Installing the cover

3.3 Cylinder head cover

3.3.1 Removing and installing the cylinder head cover

3.4 Cylinder head

3.4.1 Checking and setting the valve clearance

3.4.2 Rocker arm bracket and push rods

3.4.3 Removing and installing the valve bridges

3.4.4 Removing and installing the cylinder head

3.4.5 Valves and valve stem seal

3.4.6 Removing and installing the roller plunger

3.4.7 Removing and installing the camshaft

3.5 Driving gear

3.5.1 Piston with connecting rod

3.5.2 Piston rings

3.5.3 Removing and installing the cylinder liner

3.5.4 Checking the projection of the cylinder liners

3.5.5 Removing and installing the belt pulley

3.5.6 Ancillary support housing side radial shaft sealing ring

3.5.7 Removing and installing the ancillary support housing

3.5.8 Flywheel

3.5.9 Removing and installing the flywheel housing (variant 1)

3.5.10 Removing and installing the flywheel housing (variant 2)

3.5.11 Removing and installing the flywheel housing (variant 3)

3.5.12 Removing and installing the flywheel housing (variant 4)

3.5.13 Crankshaft

3.6 Fuel system

3.6.1 Safety instructions for working on the fuel system

3.6.2 Removing and installing the fuel lines

3.6.3 Removing and installing the fuel return line

3.6.4 Reducing the pressure in the fuel system

3.6.5 Removing and installing the fuel injection pipe

3.6.6 Removing and installing the injection pipes

3.6.7 Removing and installing the fuel rail

3.6.8 Removing and installing the pressure pipe socket and injector

3.6.9 Fuel high pressure pump

3.6.10 Drive for high pressure pump

3.7 Belt drive

3.7.1 Removing and installing the V-ribbed belt

3.7.2 Remove and install the tension pulley (self-tensioning)

3.7.3 Removing and installing the deflection pulley

3.8 Charge air system

3.8.1 Removing and installing the charge air pipe

3.8.2 Removing and installing the intermediate flange

3.8.3 Air intake manifold

3.8.4 Removing and installing the intake manifold

3.9 Exhaust system

3.9.1 Exhaust gas stub

3.9.2 Exhaust gas turbocharger

3.10 Engine oil system

3.10.1 Removing and installing the end control valve

3.10.2 Removing and installing the oil mist separator return line

3.10.3 Crankcase ventilation

3.10.4 Oil cooler

3.10.5 Oil pan

3.10.6 Engine oil pump

3.10.7 Removing and installing the oil pump

3.10.8 Removing and installing the piston cooling nozzle

3.11 Cooling system

3.11.1 Removing and installing the pipeline and coolant venting pipe

3.11.2 Coolant manifold

3.11.3 Coolant pump

3.11.4 Thermostat

3.12 Auxiliary output

3.12.1 Air conditioning compressor (optional)

3.12.2 Air compressor (optional)

3.12.3 Removing and installing power take off 1

3.12.4 Removing and installing power take off 3

3.12.5 Removing and installing power take off 4

3.13 Electrical system

3.13.1 Removing and installing the heating flange

3.13.2 Alternator

3.13.3 Removing and installing the starter motor

3.13.4 Installing the starter motor

3.13.5 Engine control unit

3.13.6 Sensors

3.13.7 Cable harness

3.14 SCRF exhaust aftertreatment system

3.14.1 Removing and installing the SCRF inlet module (single-flow)

3.14.2 Removing and installing the SCRF outlet module (single-flow)

3.14.3 Removing the pressure measurement lines

3.14.4 Removing the filter module (single-flow)

3.14.5 Installing the filter module (single-flow)

3.14.6 Installing the pressure measurement line

3.14.7 Exhaust regulation sensors

3.14.8 Removing and installing the reduction agent pump

3.14.9 Removing and installing the mixing pipe

3.14.10 Removing and installing the reduction agent injector

3.14.11 Removing and installing the diesel oxidation catalyst

3.14.12 Removing and installing the sensor pipe

4 Tools and devices

4.1 Tools

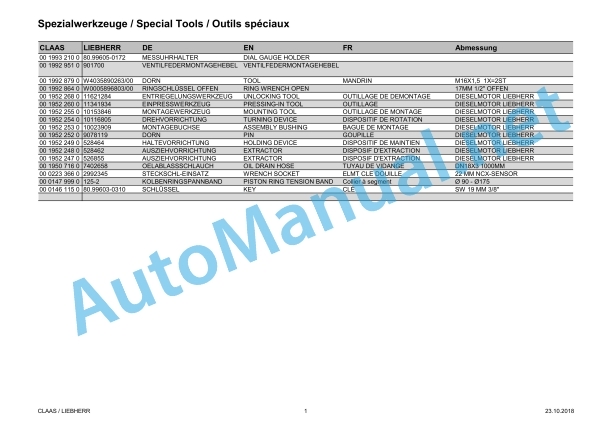

4.1.1 Special tools

4.1.2 Diagnostic tools

4.2 Devices

4.2.1 Lifting traverse with two-point-raising (basic version)

4.2.2 Lifting traverse with two-point-raising

4.2.3 Engine assembly stand

4.2.4 Engine assembly stand and adapter

4.2.5 Transport device

5 Assembly agents

6 Appendix

6.1 Tightening torques

6.1.1 For hex bolts / cylinder screws / external hex bolts

6.1.2 For locking screws and banjo bolts

6.1.3 Standard torques for metric flange connections

6.1.4 Metric screw connection series L (light) (up to 500 bar/7252 Psi)

6.1.5 Metric screw connection series S (heavy) (up to 800 bar/11603 Psi)

6.1.6 Inch screw connection series L (light) (up to 500 bar/7252 Psi)

6.1.7 Inch screw connection series S (heavy) (up to 800 bar/11603 Psi)

6.1.8 Metric thread unit series L (light) (up to 500 bar/7252 Psi) for aluminum

Liebherr LH-D934 A7 LH-D944 A7 Stage IV TORION 1914 TORION 1812.pdf:

1 General information

1.1 Structure of this manual

1.2 Important notes in this manual

1.2.1 Identification of operational safety instructions

1.2.2 Additional identifications

1.3 Safety instructions

1.3.1 General safety instructions

1.3.2 Preventing personal injuries

1.3.3 Preventing property damage

1.4 Safety instructions for working on the fuel and injection system

1.4.1 General safety instructions

1.4.2 Preventing personal injuries

1.4.3 Preventing property damage

1.5 Safety instructions for working on the exhaust after-treatment system (SCR system)

Definition of terms

1.5.1 Reducing agent

1.5.2 General safety instructions

1.5.3 Preventing personal injuries

1.5.4 Preventing property damage

1.6 Engine diagrams and engine components

Flywheel side view

Unit carrier side view

6-cylinder wheel drive view

4-cylinder wheel drive view

1.7 Technical data

1.7.1 Engine, general

1.7.2 Standard torques for screw connections

1.7.3 Standard torques for screw plugs and banjo screws

1.7.4 Standard torques for metric screw fittings

1.7.5 Standard torques for imperial screw fittings

1.7.6 Standard torques for cutting ring screw fittings

1.7.7 Standard torques for triple-lock screw fittings

1.7.8 Standard torques for VSTI screw plugs

1.8 Special torques, tensioning instructions, instructions for mounting and installation instructions

1.8.1 Cleaning and locking agents, greases

1.8.2 Special torques for cylinder head engine control unit and valves

Tensioning instruction for rocker arm bracket

Installation and tensioning instruction for cylinder head

Tensioning instruction for injector sleeve

Tensioning instruction for camshaft gear

1.8.3 Special torques for the engine

Tensioning instruction for crank

Tensioning instruction for crankshaft attachments

Tensioning instruction for unit carrier

Tensioning instruction for flywheel

Tensioning instruction for flywheel

Tensioning instruction for flywheel housing

Tensioning instruction for main bearing

1.8.4 Special torques for fuel and injection system

Tensioning instruction for injection lines

Installation and tensioning instruction for injector and pressure pipe branch

Tensioning instruction for fuel fine filter

Tensioning instruction for fuel high pressure pump

1.8.5 Special torques for charge air and exhaust system

Tensioning instruction for exhaust pipe

Tensioning instruction for exhaust branch

Tensioning instruction for turbocharger and flange on turbocharger

Tensioning instruction for SCR catalytic converter

Tensioning instruction for air compressor nut

Tensioning instruction for air compressor M6 screw

Tensioning instruction for reducing agent extraction module

Tensioning instruction for SCR injector

Tensioning instruction for SCR profile clip

Instructions for mounting high temperature sensor

Instructions for mounting lambda NOx sensor

Instructions for mounting NH3 sensor

Instructions for mounting outside temperature sensor

Instructions for mounting humidity sensor

1.8.6 Special torques for the electrical system

Tensioning instruction for heating flange

Tensioning instruction for alternator electrical connection

Tensioning instruction for starter individual operation

Tensioning instruction for sensors

Tensioning instruction for engine control units attachment

1.8.7 Special torques for the lubrication system

Tensioning instruction for oil cooler housing screws

Cold start valve

Tensioning instruction for valve

Tensioning instruction for cold start valve default setting

Tensioning instruction for piston cooling injector

1.8.8 Special torques for the auxiliary output, air compressor

Tensioning instruction for proximity switch switchable auxiliary output

Tensioning instruction for M52x1.5 ring auxiliary output

Tensioning instruction for M40x1.5 ring auxiliary output

1.9 Fuel diagram

1.10 Lubricating oil diagram

1.11 Coolant diagram

1.11.1 Coolant diagram, general overview

1.11.2 Coolant circuit, engine

Coolant circuit, unit carrier side view

Coolant circuit, cylinder head

1.12 Assigning the channels in the crankcase and the cylinder head

1.13 Transport device and fastening parts

1.13.1 Removing and installing the transport device and fastening parts

1.14 Tools

1.14.1 Special tools

Lifting traverse

Engine assembly stand

Lifting device for flywheels (SAE0, SAE1 and SAE2)

Turning devices

Assembly bolt

Pivot bracket devices

Torx tools

Removing and installing the cylinder liner

Checking the cylinder liners’ projection

Removing and installing the unit carrier

Removing and installing the flywheel housing

Removing and installing the front crankshaft seal

Removing and installing the crankshaft

Removing and installing the piston with crank and piston rings

Removing and installing the piston rings

Removing and installing the valve stem seal, valve springs, valves

Removing and installing the mass balancing shafts

Removing and installing the camshaft

Removing and installing the injection line

Removing and installing the pressure pipe branch and injector

Removing and installing the injector sleeve

Removing and installing the flywheel

Removing and installing the rear crankshaft seal

Reducing agent pump

Auxiliary outputs

2 Cylinder head, engine control unit and valves

2.1 Removing and installing the cylinder head cover

2.2 Removing and installing the rocker arm bracket and push rods

2.3 Removing and installing the valve bridge (engines with and without ABS)

2.4 Removing and installing the cylinder head

Installation and tensioning instruction for cylinder head

2.5 Removing and installing the injector sleeve

Tensioning instruction for injector sleeve

2.6 Removing and installing the valve stem seal, valve springs, valves

2.6.1 Remove

2.6.2 Installing

2.6.3 Removing and installing the valve stem seal without removing the cylinder head

2.7 Removing and installing the roller tappet (valve controller)

2.8 Removing and installing the camshaft

Tensioning instruction for camshaft gear

2.8.1 Remove

If present: Gear wheel on the unit carrier side

2.8.2 Installing

If present: Gear wheel on the unit carrier side

3 Driving gear

3.1 Removing and installing the piston with crank and piston rings

3.1.1 Overview

3.1.2 A: Removing and installing the piston with crank from the engine

Tensioning instruction for crank

Installing

3.1.3 B: Removing and installing the piston rings

Installing

3.1.4 C: Removing and installing the pistons

3.2 Removing and installing the cylinder liner

Note on the special tools

3.2.1 Checking the cylinder liners’ projection

3.3 Removing and installing the crankshaft attachments

Tensioning instruction for crankshaft attachments

3.4 Removing and installing the front crankshaft seal

3.4.1 General instructions

3.4.2 Remove

3.4.3 Installing

3.5 Removing and installing the unit carrier

Tensioning instruction for unit carrier

3.6 Removing and installing the flywheel

Flywheel without membranes

Flywheel with membranes

Tensioning instruction for flywheel

Tensioning instruction for flywheel

3.6.1 Remove

3.6.2 Installing

Checking rotation

3.6.3 Removing and installing the starting gear ring

3.7 Removing and installing the rear crankshaft seal

3.7.1 General instructions

3.7.2 Remove

3.7.3 Installing

3.8 Removing and installing the flywheel housing

Tensioning instruction for flywheel housing

3.9 Removing and installing the top right intermediate wheel

3.10 Removing and installing the top middle intermediate wheel

3.11 Removing and installing the crankshaft

Tensioning instruction for main bearing

3.11.1 Remove

3.11.2 Installing

Checking the crankshaft’s axial play

3.12 Removing and installing the crankshaft gear wheel

4 Fuel and injection sy

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere POWERTECH E 4.5 and 6.8 L Diesel Engines TECHNICAL MANUAL 25JAN08

John Deere Repair Technical Manual PDF

John Deere Parts Catalog PDF

John Deere Harvesters 8500 and 8700 Parts Catalog CPCQ24910 Spanish

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere PowerTech M 10.5 L and 12.5 L Diesel Engines COMPONENT TECHNICAL MANUAL CTM100 10MAY11

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF