Claas Tucano 340 (834) Combines Technical System EN

$300.00

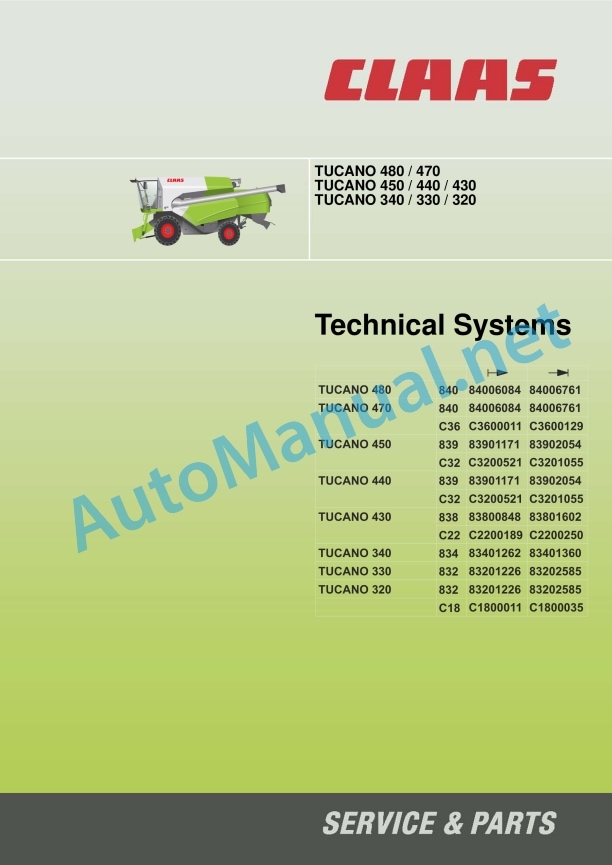

- Model: Tucano 340 (834) Combines

- Type Of Manual: Technical System

- Language: EN

- Format: PDF(s)

- Size: 250 MB

File List:

00 0290 242 0.pdf

00 0290 641 1.pdf

00 0291 027 2.pdf

00 0292 119 1.pdf

00 0295 562 3.pdf

00 0302 343 1.pdf

00 0302 565 2.pdf

CHP-numbers for connectors CLAAS HARNESS PARTS.pdf

00 0290 242 0.pdf:

TUCANO 480 / 470

TUCANO 450 / 440 / 430

TUCANO 340 / 330 / 320

Table of contents

CCN explanation

CCN (CLAAS Component Number)

Electric system standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

CCN Index

Introduction

General instructions

Important safety and hazard information

Validity of manual

01 Engine

0125 Injection – / Fuel system

Fuel system

Measured values table

Description of function

0150 Engine attachment parts

Starting the diesel engine, diesel engine speed adjustment – Caterpillar (CAT)

Measured values table

Description of function

Caterpillar speed table

Starting the diesel engine, diesel engine speed adjustment – Daimler (MTU)

Measured values table

Description of function

Daimler speed table

0155 Engine control

Diesel engine monitoring – Caterpillar (CAT)

Measured values table

Description of function

Diesel engine fault code – J 1939 / Engine diagnosis / Component position – CAT

Diesel engine monitoring – Daimler (MTU)

Measured values table

Description of function

Diesel engine fault code – J 1939 / Engine diagnosis / Position of components – Daimler (MTU)

0165 Exhaust gas treatment

Compressed air system MTU TIER 4i

Description of function

SCR system – urea heater and injection

Description of function

Combined filling level / urea temperature sensor

Description of function

Urea pump unit

Description of function

Reduction catalyst temperature sensors

Description of function

Dosing unit

Description of function

NOx sensor

Description of function

Combined intake air moisture and temperature sensor

Description of function

03 Chassis

0330 Driven steering axle, rear

Measured values table

Description of function

4-Trac hydraulic circuit diagram

0335 Ground drive

Hydrostatic ground drive

Function overview graphic / CAT diesel engine

Function overview graphic / Daimler diesel engine

Description of function

Wiring diagram

Pump unit (HPV)

Description of function

Servo-control valve

Description of function

Multifunction valve (7013/7014)

Description of function

Ground drive fixed-displacement motor (HMF)

Description of function

Testing – measuring

04 Brake

0405 Service brake

Brake hydraulics circuit diagram

05 Steering

0505 Steering

Steering system

Neutral function diagram

Steering-actuated function diagram

Checking the steering system

Description of function

0510 Automatic steering

AUTOPILOT / Sensing system

Measured values table

Description of function

Checking the AUTOPILOT system

AUTOPILOT / LASER PILOT

Measured values table

Description of function

Checking the AUTOPILOT system

Basic machine GPS steering system

Measured values table

Description of function

Checking the AUTOPILOT system

EGNOS GPS steering system

Description of function

OMNISTAR HP GPS steering system

Description of function

RTK GPS steering system

Description of function

GPS Pilot with RTK

RTK NET GPS steering system

Description of function

BASELINE HD GPS steering system

Description of function

09 Hydraulic system

0920 Valves

Main valve

Description of function

AUTOCONTOUR / reversing valve block

Front attachment dampening valve block

Steering (Orbitrol) valve block

Autopilot valve block

Description of function

Low-pressure hydraulic system valve block

Low-pressure hydraulic system valve block

Low-pressure hydraulic system valve block (left chopper drive, type 83x)

Description of function

Reel drive valve block

Grain tank unloading tube valve block

Threshing drum variable-speed drive valve block

0980 Hydraulic circuit diagram

Vehicle hydraulic system circuit diagrams

Working hydraulics, steering hydraulics

Testing the working hydraulics

Low-pressure hydraulic system circuit diagram, hydraulic reel drive type – 83x

Testing the low-pressure hydraulic system and the reel drive

Low-pressure hydraulic system circuit diagram, hydraulic reel drive – type 840

Testing the low-pressure hydraulic system and the reel drive

Hydrostatic ground drive (type 832 – 839)

Hydrostatic ground drive (type 840)

Brake hydraulics circuit diagram

Front attachment hydraulics circuit diagrams

Cutterbar C370-C490 (type 527)

VARIO cutterbar V540-V900 (type 716)

Rape cutter – Drive / VARIO cutterbar V540-V1050 (type 716)

Folding cutterbar 450-540 (type 713)

Conspeed 6-row

Conspeed 8-row

Sunspeed (type 443) hydraulic circuit diagram

10 Electrical / Electronic equipment

1010 Central electrics

Basis of central terminal compartment

Fuse assignment

Relay assignment

Connector designations

Roof central terminal compartment

Fuse assignment

Relay assignment

Connector designations

Patch field

Key to diagram

1012 Modules / sensors

Module overview

Installation position of modules

Module A006 – Automatic air conditioner (ACM)

Key to diagram

Module A007 – Cab fan (CFC)

Key to diagram

Module A009 – AUTOPILOT (ATP)

Key to diagram

Module A015 – Engine control (ECM) – CATERPILLAR (CAT C13, C9)

Key to diagram

Module A015 – electronic engine control (ECM) – Daimler (OM 906, OM 926 TIER 3)

Key to diagram

Module A015 – electronic engine control (ECM) – Daimler (OM 906, OM 926 TIER 4i)

Key to diagram

Module A017 – Engine adaption (ADM) – Daimler (OM 906, OM 926 TIER 3)

Key to diagram

Module A017 – Engine adaption (ADM) – Daimler (OM 906, OM 926 TIER 4i)

Key to diagram

Module A021 – Yield measuring (YMM)

Key to diagram

Module A025 – Sieve adjustment (SAM)

Key to diagram

Module A026 – Deflector adjustment (DAM)

Key to diagram

Module A027 – VARIO cutterbar (VAR)

Key to diagram

Module A032 – Reduction catalyst (SCR) – Daimler (OM 926)

Key to diagram

Module A069 – Vehicle base module (VBM)

Module A069 – Vehicle base module (VBM – 1/3) – Sensors part 1

Module A069 – Vehicle base module (VBM- 2/3) – Sensors part 2

Module A069 – Vehicle base module (VBM- 3/3) – Actuators

Key to diagram A069

Module A075 – Operating panel (OPM)

Key to diagram

Module A130 – Front attachment

Key to diagram

Module A137 – AUTOCONTOUR multisensor

Key to diagram

1015 Wiring harnesses

Wiring looms

Front attachment multicoupler connection

Description of function

Rear drive axle wiring loom

Autopilot wiring loom (cab)

Autopilot wiring loom (rear drive axle)

Trailer hitch wiring loom

Earth wiring loom

Axle wiring loom

Main wiring loom, left

Main wiring loom, right

Engine wiring loom

Rear hood / rotor wiring loom

Rear hood / straw walker wiring loom

Dashboard wiring loom

Operator’s platform lighting wiring loom

Earth / roof central terminal compartment wiring loom

Cab B-column wiring loom

Cab, Vehicle Base Module wiring loom

Cab, lighting wiring loom

Cab, front operating panel wiring loom

Cab, rear control panel wiring loom

Steering column wiring loom

Multicoupler wiring loom

Yield measuring wiring loom

Inclination sensor wiring loom

Heater / ventilation wiring loom

Feed rake conveyor wiring loom

RIO wiring loom – module extension

Deflector plate adjustment wiring loom

Chopper (straw walker) wiring loom

Chopper (rotor) wiring loom

Tine spreader wiring loom

Chaff spreader wiring loom

1035 Operation / Multifunction control lever

T signal function

Measured values table

Description of function

Road travel – fieldwork function

Description of function

1040 Yield measuring

Yield measuring

Description of function

1080 Electronic circuit diagram

Introduction into circuit diagrams

Overview of designations

CLAAS cable marking

Wire colours

Overview of CAN Bus system

Machine circuit diagrams

SCM 01 – Multicoupler

SCM 02a – Power supply / Starting the diesel engine (12 Volt) – Applies to: CAT

SCM 02a – Power supply / Starting the diesel engine (12 Volt) – Applies to: MTU TIER 3

SCM 03a – Battery earth (12 Volt) – MTU TIER 3 – CAT TIER 3

SCM 03b – Power supply / Starting the diesel engine (24 Volt) – MTU TIER 4i

SCM 04 – Road travel – Applies to: All types

SCM 05a – Power supply of modules I – Applies to: CAT TIER 3

SCM 05b – Power supply of modules I – Applies to: MTU TIER 3

SCM 05c – Power supply of modules I – Applies to: MTU TIER 4i

SCM 06 – Power supply of modules

SCM 08 – Power supply of sensors – Applies to: All types

SCM 09a – Engine monitoring, speed regulation – Applies to: Caterpillar TIER 3

SCM 09b – Engine monitoring, speed regulation – Applies to: MTU TIER 3

SCM 09c – Engine monitoring, speed regulation – Applies to: MTU TIER 4i

SCM 10a – CAN0 (vehicle CAN) part 1 – Applies to: All types

SCM 10b – CAN0 (vehicle CAN) part 1 – With yield measuring – Applies to: All types

SCM 11 – CAN0 (vehicle CAN) part 2 – Applies to: All types

SCM 12a – CAN1 (J1939 CAN) – Applies to: CAT TIER 3

SCM 12b – CAN1 (J1939 CAN) – Applies to: CAT TIER 3, with yield measuring

SCM 12c – CAN1 (J1939 CAN) – Applies to: MTU TIER 3

SCM 12d – CAN1 (J1939 CAN) – Applies to: MTU TIER 3, with yield measuring

SCM 12e – CAN1 (J1939 CAN) – Applies to: MTU TIER 4i

SCM 12f – CAN1 (J1939 CAN) – Applies to: MTU TIER 4i, with yield measuring

SCM 13 – CAN2 (Front CAN)

SCM 14 – Threshing mechanism

SCM 15 – Engaging the front attachment clutch, reversing

SCM 16a – Machine monitoring – Applies to: Rotor machines

SCM 16b – Machine monitoring – Applies to: Straw walker machines

SCM 17 – Master valve, hydraulic system monitoring

SCM 18 – Ground drive – Applies to: All types

SCM 19a – Air conditioner

SCM 19b – Automatic air conditioner

SCM 20 – Threshing drum speed

SCM 21 – Fan speed

SCM 22 – Throughput monitoring

SCM 23a – Straw chopper – Hydraulic without tine spreader

SCM 23b – Straw chopper – Hydraulic with tine spreader

SCM 23c – Straw chopper – Mechanical without tine spreader

SCM 23d – Straw chopper – Mechanical with tine spreader

SCM 24 – Raise / lower front attachment – AUTO CONTOUR

SCM 25 – Reel adjustment

SCM 26 – Grain tank unloading

SCM 27 – Grain tank full indicator, warning beacons

SCM 28 – 4-Trac – Applies to: All types

SCM 29 – Brake system – Applies to: All types

SCM 30 – Folding the front attachment

SCM 31 – Rape cutter – Applies to: All types

SCM 32 – AUTOLPILOT – Applies to: All types

SCM 33 – Windscreen wiper/washer, horn

SCM 34 – Turn indicator system

SCM 35 – Main lighting circuit, side light

SCM 36 – Drive lights

SCM 37 – Instrument panel illumination – Applies to: All types

SCM 38 – Maintenance light

SCM 39 – Sidefinder

SCM 40a – Work lights main circuit

SCM 40b – Work lights main circuit with Xenon

SCM 41 – Grain tank, returns, sieve pan work lights

SCM 42 – Cab equipment – Applies to: All types

SCM 43 – Mirror adjustment

SCM 44 – Service sockets

SCM 45 – Table adjustment

SCM 46 – Sieve adjustment

SCM 47a – Deflector plate adjustment, straw chopper

SCM 47b – Deflector plate adjustment, Special Cut straw chopper

SCM 48 – Options

SCM 50 – Yield measuring

SCM 51 – T signal

SCM 52 – Rear-mounted camera

SCM 53 – Urea injection

SCM 54a CAN3 (Steering CAN) GPS Pilot BASIC

SCM 54b CAN3 (Steering CAN) GPS Pilot II

SCM 54c CAN3 (Steering CAN) GPS Pilot II with RTK

SCM 54d CAN3 (Steering CAN) GPS Pilot II with RTK NET

SCM 55a – Oveview of modules I CAT and MTU TIER3

SCM 55b – Overview of modules I MTU TIER4i

SCM 56a – Overview of modules II CAT TIER3

SCM 56b – Overview of modules II MTU TIER3

SCM 56c – Overview of modules II MTU TIER4i

SCM 57 – Overview of connectors

SCM 58 – Earth supply – Applies to: All types

Front attachment circuit diagrams – Soybean cutterbar (type 438)

T438 01 – Multicoupler

T438 02 – Reel

T438 03 – Autocontour

T438 04 – Lighting

T438 05 – AUTOPILOT

Front attachment circuit diagrams – Sirius – Flexhead – Cutterbar (type 441)

T441 01 – Multicoupler

T441 02 – Reel

T441 03 – Cutting table adjustment

T441 04 – Autocontour

T441 05 – Lighting

T441 06 – AUTOPILOT

Front attachment circuit diagrams – Sirius – Rigidhead – Cutterbar (type 442)

T442 01 – Multicoupler

T442 02 – Reel

T442 03 – Autocontour

T442 04 – Lighting

T442 05 – AUTOPILOT

Front attachment circuit diagrams – Standard – Cutterbar (type 527)

T527 01 – Multicoupler

T527 02 – Reel

T527 03 – Autocontour

T527 04 – AUTOPILOT

Front attachment circuit diagrams – VARIO – Cutterbar (type 529)

T529 01 – Multicoupler

T529 02 – Power supply of modules / CAN Bus

T529 03 – Reel

T529 04 – Cutting table adjustment

T529 05 – Rape cutter

T529 06 – Autocontour

T529 07 – AUTOPILOT

T529 08 – Flashlights

T529 09 – Overview of modules

Front attachment circuit diagrams – rigid cutterbar (type 529)

T529 01 – Multicoupler

T529 02 – Reel

T529 03 – Autocontour

T529 04 – AUTOPILOT

T529 05 – Flashlights

Front attachment circuit diagrams – Flexhead (type 531)

T531 01 – Multicoupler

T531 02 – Power supply of modules / CAN Bus

T531 03 – Reel

T531 04 – Cutting table adjustment

T531 05 – Rape cutter

T531 06 – Autocontour

T531 07 – AUTOPILOT

T531 08 – Flashlights

Front attachment circuit diagrams – MAXFLO (type 537, 538)

T537 T538 01 – Multicoupler

T537, T538 02 – Power supply of modules / CAN Bus

T537, T538 03 – Reel

T537, T538 04 – Cutting table adjustment

T537, T538 05 – Rape cutter

T537, T538 06 – Autocontour

T537, T538 07 – AUTOPILOT

T537, T538 08 – Flashing position light

T537, T538 09 – Overview of modules

Front attachment circuit diagrams – Folding cutterbar (type 713)

T713 01 – Multicoupler

T713 02 – Reel

T713 03 – Folding the front attachment

T713 04 – Autocontour

T713 05 – Lighting

T713 06 – AUTOPILOT

Front attachment circuit diagrams – Standard – Cutterbar (type 715)

T715 01 – Multicoupler

T715 02 – Reel

T715 03 – Rape cutter

T715 04 – Autocontour

T715 05 – AUTOPILOT

Front attachment circuit diagrams – VARIO – Cutterbar (type 716)

T716 00 – Overview of modules

T716 01 – Multicoupler

T716 02 – Power supply of modules / CAN Bus

T716 03 – Reel

T716 04 – Cutting table adjustment

T716 05 – Rape cutter

T716 06 – Autocontour

T716 07 – AUTOPILOT

Circuit diagrams of CONSPEED (types 907, 908, I00, I01)

T907, T908, TI00, TI01 – Multicoupler

T907, T908, TI00, TI01 – Snapper plates

T907, T908, TI00, TI01 – AUTO CONTOUR

T907, T908, TI00, TI01 – Lighting

T907, T908, TI00, TI01 – AUTOPILOT

Front attachment circuit diagrams – Sunspeed (type 443)

T443 01 – Multicoupler

T443 02 – Reel

1081 Overview of Connectors

Connector database (CHP CLAAS)

Example of representation of key numbers (CHP)

Connector representation (CHP)

1085 Networks

BUS systems (CAN) – Basic machine

Description of function

BUS systems (CAN) – Front attachment

Description of function

12 Cab / Operator’s platform

1230 Seat

Seat contact

Measured values table

Description of function

1240 Air condition

Air conditioner function

Measured values table

Description of function

Test menu:

Controls

Test menu operation

Test menu access

Menu item 1

Menu item 2

Menu item 3

Menu item 4

Menu item 5

Menu item 6

Menu item 7

Menu item 8

Menu item 9

Menu item 10

Menu item 11

Menu item 12

20 Crop feeding

2002 Front attachment

Raise / lower front attachment

Measured values table

Description of function

Main valve

Description of function

Front attachment ON / OFF

Measured values table

Description of function

Front attachment reversing

Measured values table

Description of function

Front attachment dampening

Measured values table

Description of function

Front attachment dampening valve

Accumulator pressure filling instructions

Manual cross levelling

Measured values table

Description of function

AUTOCONTOUR / reversing valve block

2010 Cutterbar table

VARIO cutting table adjustment

Measured values table

Reel adjustment function description

2015 Reel / Crop guard

Raise / lower reel, automatic reel height adjustment

Measured values table

Reel adjustment function description

Horizontal reel adjustment

Measured values table

Reel adjustment function description

Reel speed adjustment, automatic reel speed

Measured values table

Reel adjustment function description

26 Ground guidance

2605 Auto-Contour

AUTOCONTOUR (CAC)/Contour

Measured values table

Description of function

AUTOCONTOUR / reversing valve block

Accumulator pressure filling instructions

41 Threshing mechanism

4100 Threshing mechanism

Engaging the threshing mechanism

Measured values table

Description of function

4120 Threshing drum

Threshing drum speed adjustment

Measured values table

Description of function

43 Cleaning system

4320 Sieves / Sieve pan

Sieve adjustment – Upper sieve

Measured values table

Description of function

Sieve adjustment – Lower sieve

Measured values table

Description of function

4325 Cleaning fan

Fan speed adjustment

Measured values table

Description of function

60 Crop discharge / straw discharge

6010 Straw chopper

Chopping / swath discharge (left chopper drive, type 83x)

Measured values table

Description of function

Deflector adjustment

Measured values table

Description of function

61 Grain delivery

6120 Grain tank unloading

Swinging the grain tank unloading tube

Measured values table

Description of function

Grain tank unloading

Measured values table

Description of function

Diagnosis by fault codes

FMI failure code (Failure Mode Indicator)

FMI failure code (Failure Mode Indicator)

FMI 00 (Signal too high)

FMI 01 (Signal too low)

FMI 02 (Erratic signal)

FMI 03 (Voltage too high)

FMI 04 (Voltage too low)

FMI 05 (Current too low)

FMI 06 (Current too high)

FMI 07 (Mechanical failure)

FMI 08 (Abnormal frequency signal)

FMI 09 (Communication error)

FMI 10 (Rate of signal change too fast)

FMI 11 (multiple faults)

FMI 12 (ECU defective)

FMI 13 (Signal outside of calibration range)

FMI 16 (Parameter not available)

FMI 17 (ECU not responding)

FMI 18 (Power supply failure)

FMI 19 (Software conditions not met)

FMI 95 (no signal change)

FMI 96 (CAN Bus system defective)

FMI 97 (Erratic condition)

FMI 98 (Warning)

FMI 99 (Info)

Machine fault code

Machine fault code list (DTC)

Diesel engine fault code

Diesel engine fault code list (SPN)

Position of components

Hydraulic system

Main assembly groups (I to XI)

1001- 1999 Oil reservoir / filter / oil cooler

2001- 2999 Pump / motor

3001- 3999 Hydraulic cylinder

4001- 4999 Restrictor / orifice plate

5001- 5999 Accumulator

6001- 6999 Valve, mechanically actuated

7001- 7999 Valve, hydraulically actuated

8001- 8999 Couplings / connections

9001- 9999 Measuring point / indicating instrument

Electric system

A Terminal / modules

B Sensors

C Electrical / electronic devices

E Lighting

G Voltage sources

H Signal devices / light

K Relays

M Motor (electric)

R Potentiometer / resistor

S Switch / pushbutton – Cab operation

U Switch – External operation

V Electronic components

Y Solenoid coil

Z Actual value switch

Earth points

Central terminal compartment

00 0290 641 1.pdf:

Contents

CCN explanations

CCN (CLAAS Component Number)

Electric system standard

Overview

Hydraulic system standard

Overview

CCN (CLAAS Component Number)

Introduction

Validity of the manual

Overview

3D visualisations

Flash Player

Adobe Reader

Starting the DAIMLER diesel engine, diesel engine monitoring

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Diesel engine fault code – Fault code list J 1939 / Engine diagnosis / Component position

Fault code list J 1939 / Engine diagnosis

03 Chassis

Hydrostatic ground drive

Graphic overview of functions

Description of function

Pump unit (HPV)

Key to diagram

Description of function

Servo-control valve

Key to diagram

Description of function

Multifunction valve (7013/7014)

Key to diagram

Description of function

Ground drive fixed-displacement motor (HMF)

Key to diagram

Description of function

Maintenance

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

05 Steering

Steering system

Hydraulic circuit diagram

Legend for overview of functions

Measured value table

Description of function

Description of function

Function diagram, neutral

Graphics

Key to diagram

Description of function

Function diagram, actuated by steering

Graphics

Key to diagram

Description of function

Testing the steering system

Description of function

09 Hydraulic system

Valve blocks

Main valve

Designations

Autocontour / Reversing valve block

Front attachment dampening valve block

Steering (Orbitrol) valve block

Autopilot valve block

Low-pressure hydraulic system valve block

Reel drive valve block

Grain tank unloading tube valve block

Threshing drum variable-speed drive valve block

Vehicle hydraulic system circuit diagrams

Working hydraulics, steering hydraulics

Designations

Testing the working hydraulics

Low pressure hydraulics, hydraulic reel drive

Testing the low-pressure hydraulic system and the reel drive

Brake hydraulics

Hydrostatic ground drive, type 832 – 839

Front attachment hydraulics circuit diagrams

Cutterbar C370-C490 (Type 527)

Vario cutterbar V540-V900 (Type 716)

Rape cutter – Drive / Vario cutterbar V540-V1050 (Type 716)

Folding cutterbar 450-540 (Type 713)

10 Electric system

Road travel – fieldwork function

Graphic overview of functions

Legend for overview of functions

Description of function

Seat contact function

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

CAN function (Daimler-Benz)

Graphic overview of functions

Legend for overview of functions

Description of function

T signal function

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Central terminal compartment

Basis of central terminal compartment

Designations

Fuse assignment

Roof-mounted central terminal compartment

Designations

Fuse assignment

Patch field

Designations

Module overview

Designations

Module A009 – Autopilot (ATP)

Designations

Module A025 – Sieve adjustment (SAM)

Designations

Module A026 – Deflector adjustment (DAM)

Designations

Module A027 – Vario adjustment (VAR)

Designations

Module A069 – Vehicle base module (VBM- 1/3) – Sensors part 1

Module A069 – Vehicle base module (VBM- 2/3) – Sensors part 2

Module A069 – Vehicle base module (VBM- 3/3) – Actuators

Key to diagram A069

Module A075 – Operating panel (OPM)

Designations

Introduction into circuit diagrams

Overview of designations

Overview of CAN Bus system

CLAAS cable marking

Power supply

Actuators

*Correction of cable lettering

Communication

Standards

Electric circuit diagrams of machine (SCM)

TUCANO 450 – 430 / 340 – 320

SCM 01 – Multicoupler

SCM 02 – Electric power supply – Starting the diesel engine

SCM 03 – Road travel

SCM 04 – Power supply of modules 1

SCM 05 – Power supply of modules 2

SCM 06 – Power supply of sensors

SCM 07a – Diesel engine speed adjustment / Diesel engine monitoring

SCM 07b – Diesel engine speed adjustment / Diesel engine monitoring

SCM 08 – CAN BUS

SCM 09 – Threshing mechanism

SCM 10 – Engage front attachment (front attachment quick stop) / reverse front attachment

SCM 11 – Machine monitoring

SCM 12 – Master valve, hydraulic system monitoring

SCM 13 – Ground drive

SCM 14 – Air conditioner

SCM 15 – Threshing drum speed

SCM 16 – Fan speed

SCM 17 – Throughput monitoring

SCM 18 – Straw chopper

SCM 19 – Raise / lower front attachment / CLAAS AUTOCONTOUR (CAC)

SCM 20 – Reel adjustment

SCM 21 – Grain tank unloading

SCM 22 – Grain tank extension / Grain tank full indicator / Warning beacons

SCM 23 – 4-wheel drive

SCM 24 – Brake system

SCM 25 – Folding the front attachment

SCM 26 – Rape cutter

SCM 27 – Autopilot

SCM 28 – Windscreen wiper, windscreen washer, horn

SCM 29 – Turn indicator system

SCM 30 – Lights / parking light main circuit

SCM 31 – Drive lights

SCM 32 – Instrument lighting

SCM 33 – Maintenance light

SCM 34 – Sidefinder

SCM 35 – Work lights main circuit

SCM 36 – Sieve pan, returns and grain tank lights

SCM 37 – Cab equipment

SCM 38 – Mirror adjustment

SCM 39 – Service sockets

SCM 40 – Table adjustment

SCM 41 – Sieve adjustment

SCM 42 – Deflector adjustment

SCM 43 – Spare

SCM 44 – Axle control Hillside

SCM 45 – T signal (clock signal)

SCM 46 – Earth supply

SCM 47 – Overview of modules – part 1

SCM 48 – Overview of modules – part 2

SCM 49 – Overview of connectors

SCM 50 – Vehicle CAN (CAN 0)

SCM 51 – J1939-CAN (CAN 1)

SCM 52 – Front CAN (CAN 2)

Electric circuit diagrams of front attachments (SCM)

Soybean cutterbar (type 440)

SCM 01 – Multicoupler

SCM 02 – Reel

SCM 03 – Autocontour

SCM 04 – Lighting

SCM 05 – Autopilot

Standard cutterbar (type 527)

SCM 01 – Multicoupler

SCM 02 – Reel

SCM 03 – Autocontour

SCM 04 – Autopilot

Draper cutterbar (type 538)

SCM 01 – Multicoupler

SCM 02 – Modules power supply / CAN Bus

SCM 03 – Reel

SCM 04 – Table adjustment

SCM 05 – Rape cutter

SCM 06 – Autocontour

SCM 07 – Autopilot

SCM 08 – Flashlights

SCM 09 – Overview of modules

Folding cutterbar (type 713)

SCM 01 – Multicoupler

SCM 02 – Reel

SCM 03 – Folding the front attachment

SCM 04 – Autocontour

SCM 05 – Lighting

SCM 06 – Autopilot

Standard cutterbar (type 715)

SCM 01 – Multicoupler

SCM 02 – Reel

SCM 03 – Rape cutter

SCM 04 – Autocontour

SCM 05 – Autopilot

Vario cutterbar (type 716)

SCM 00 – Overview of modules

SCM 01 – Multicoupler

SCM 02 – Power supply of modules / CAN Bus

SCM 03 – Reel

SCM 04 – Table adjustment

SCM 05 – Rape cutter

SCM 06 – Autocontour

SCM 07 – Autopilot

Connector representation

Key number (CHP)

Contact overview

20 Crop feeding

Raise / lower front attachment

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Main valve

Front attachment ON/OFF

Graphic overview of functions

Legend for overview of functions

Description of function

Reverse front attachment

Graphic overview of functions

Legend for overview of functions

Description of function

Raise / lower reel, automatic reel height adjustment

Graphic overview of functions

Legend for overview of functions

Measured value table

Reel adjustment function description

Horizontal reel adjustment

Graphic overview of functions

Legend for overview of functions

Measured value table

Reel adjustment function description

Reel speed adjustment, automatic reel speed

Graphic overview of functions

Legend for overview of functions

Measured value table

Reel adjustment function description

Vario cutting table adjustment

Graphic overview of functions

Legend for overview of functions

Measured value table

Reel adjustment function description

Manual cross levelling

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Autocontour / reversing valve block

Front attachment dampening

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Front attachment dampening valve

Accumulator pressure filling instructions

26 Ground guidance

Auto-Contour (CAC)/Contour

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Autocontour / reversing valve block

Accumulator pressure filling instructions

41 Threshing mechanism

Engaging the threshing mechanism

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Threshing drum speed adjustment

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

43 Cleaning

Fan speed adjustment

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Sieve adjustment – Upper sieve

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

Sieve adjustment – Lower sieve

Graphic overview of functions

Legend for overview of functions

Measured value table

Description of function

61 Grain delivery

Swinging the grain tank unloading tube

Graphic overview of functions

Legend for overview of functions

Measured value

John Deere Repair Technical Manual PDF

John Deere 16, 18, 20 and 24HP Onan Engines Component Technical Manual CTM2 (19APR90)

John Deere Repair Technical Manual PDF

John Deere DF Series 150 and 250 Transmissions (ANALOG) Component Technical Manual CTM147 05JUN98

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Application List Component Technical Manual CTM106819 24AUG20

John Deere Repair Technical Manual PDF

John Deere Transmission Control Unit Component Technical Manual CTM157 15JUL05

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

New Holland Service Manual PDF