- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

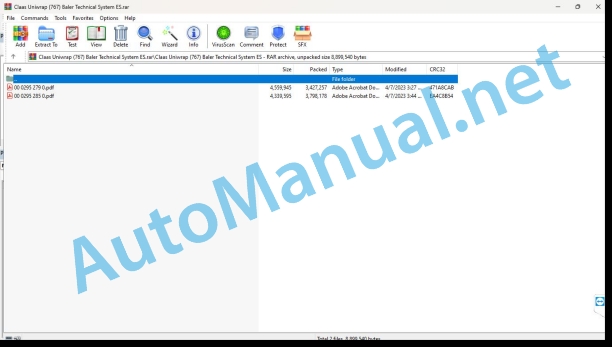

Claas Uniwrap (767) Baler Technical System ES

$300.00

- Model: Uniwrap (767) Baler

- Type Of Manual: Technical System

- Language: ES

- Format: PDF(s)

- Size: 6.9 MB

File List:

00 0295 279 0.pdf

00 0295 285 0.pdf

00 0295 279 0.pdf:

1. Introduction

Structure of the electrical installation documentation

Connection diagram

Connection List

CLAAS standardization:

2 Central electrical system

UNIWRAP central electrical system

Denominations

3 Modules

Representation of ROLLANT modules

Denominations

Representation of the UNIWRAP bale wrapper modules

Denominations

Denominations

Module occupancy

Module A020 - CLAAS Control Unit (CCU)

Module A022 – Uniwrap bale wrapper (X100 plug pin assignment)

4 Connection diagrams

01st main power supply Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Occupation of the sockets

Connection List

04a Rollant 355 Comfort circulation block valve type 766 with UNIWRAP type 767

Connection diagrD3)

Denominations

Table of measured values

Function Description

Occupation of the sockets

Connection List

06a CAN-Bus, module voltage supply. Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Table of measured values ISO 11783 CAN BUS

Function Description

Occupation of the sockets

Connection List

07a Rotocut Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Function description – sensor adjustment

Occupation of the sockets

Connection List

Automatic rotor reversing process

11th shot of the Rollant 355 Comfort type 766 bundle with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Function description – setting sensors/switches actual value

Occupation of the sockets

Connection List

Threaing process diagram (Comfort) 1 / 2

Denominations

Function Description

Thread tying process diagram (Comfort) 2 / 2

Denominations

Function Description

Mesh tied process diagram (Comfort) 1/2

Denominations

Function Description

Mesh tied process diagram (Comfort) 2/2

Denominations

Function Description

12th open/close tailgate Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Occupation of the sockets

Connection List

19a load / unload the Rollant 355 Comfort bale type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Function description – sensor adjustment

Packaging process diagram

Occupation of the sockets

Connection List

20th raise / lower the Rollant 355 Comfort Pick-up type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Occupation of the sockets

Connection List

21a rotate the wrapping arm Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Function description – switch setting, sensors

Packaging process diagram

Occupation of the sockets

Connection List

22a open/close plastic tape scissors, control of plastic tape breakage Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Table of measured values

Function Description

Function description – sensor adjustment

Packaging process diagram

Occupation of the sockets

Connection List

32nd lighting Rollant 355 Comfort type 766 with UNIWRAP type 767

Connection diagram (DIN A3)

Denominations

Function Description

Occupation of the sockets

Connection List

5 Location of components

Summary (DIN A3)

Representation

Alphabetical index

00 0295 285 0.pdf:

1. Introduction

Animations

General indications

Flash Player

Adobe Reader

2 Overall hydraulic system

ROLLANT UNIWRAP 355 hydraulic connection diagram (with options)

Global wiring diagram

Denominations

Option: 3-level stepped restrictor (6045)

Function Description

Option: electromagnetic coil packing table speed 50% (Y377)

Function Description

Table of measured values

ROLLANT UNIWRAP 355 hydraulic connection diagram (without options)

Global wiring diagram

Denominations

3 General hydraulic system

Preliminary conditions for use

UNIWRAP operation

Connecting the tractor hydraulic system

Function Description

4 ROLLANT 355 RC Comfort hydraulic system

Global hydraulic system

Hydraulic connection diagram (DIN A3)

Denominations

Function Description

Valve block II – pressing pressure limiting valve, pressing chamber service valve

Denominations

Denominations

Valve block III – reverse rotor

Denominations

Valve block V – circulation blocking valve, open/close tailgate

Denominations

Unilateral check throttle valve

Denominations

5 Hydraulic system of the bale wrapper

Valve block VI – UNIWRAP

Denominations

Function Description

Hydraulic connection diagram

Denominations

Function Description

Valve block VII – plastic tape scissors

Denominations

Function Description

Divider valve plastic tape scissors (7069)

Construction

Function Description

Function

Function Description

Function

Function Description

Function

Function Description

Function

Function Description

Check the adjustments of the taping arm motor valve block (IX)

Secure the wrapper

Necessary material

Pressure gauge assembly

Hydraulic unit settings

Hydraulic unit and valves

Adjustment of pressure limiting valve, taping arm motor drive 7064

Pressure limiting valve adjustment braking wrapping arm motor 7065

7066 Wrapping Arm Motor Lowering Brake Valve Adjustment

Setting up the wrapping machine

Alphabetical index

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

New Holland Service Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere Repair Technical Manual PDF

John Deere 18-Speed PST Repair Manual Component Technical Manual CTM168 10DEC07

John Deere Repair Technical Manual PDF

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF