Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OM515C520C99-1E

- Format: PDF

- Size: 5.0MB

- Number of Pages: 205

-

Model List:

- 515C

- 520C

- 1. MAIN MENU

- 2. COVER

- 3. SECTION INDEX

- 4. SECTION CONTENTS

- 5. SECTION 1 INTRODUCTION

- 5.1. INTRODUCTION

- 5.1.1. INTRODUCTION

- 5.1.2. SERIAL NUMBERS

- 6. SECTION 2 SAFETY PRECAUTIONS

- 6.1. SAFETY PRECAUTSIONS

- 6.1.1. GENERAL

- 6.1.2. BEFORE STARTING ENGINE

- 6.1.3. OPERATING THE MACHINE

- 6.1.4. GENERAL MAINTENANCE PRECAUTIONS

- 6.1.5. WHEN PARKING

- 6.1.6. SAFETY GRAPHICS LOCATION

- 6.1.6.1. SAFETY GRAPHICS

- 6.1.6.2. SAFETY GRAPHICS (VERSION CE)

- 7. SECTION 3 STORAGE AND SHIPPING

- 7.1. MACHINE TRANSPORT AND STORAGE

- 7.1.1. MACHINE TRANSPORT

- 7.1.1.1. GENERAL

- 7.1.1.2. TRANSPORTATION ON TRAILER, RAILWAY CAR OR BY SEA

- 7.1.1.3. TRANSPORTATION BY MACHINE OWN DRIVE

- 7.1.2. LIFTING ON SLINGS

- 7.1.3. MOVING A DISABLED MACHINE

- 7.1.4. MACHINE STORAGE

- 7.1.4.1. PREPARING FOR STORAGE

- 7.1.4.2. SERVICING DURING STORAGE

- 7.1.4.3. PREPARING FOR OPERATION AFTER STORAGE

- 8. SECTION 4 OPERATING

- 8.1. OPERATING

- 8.1.1. GENERAL

- 8.1.2. UNIVERSAL SYMBOLS FOR INSTRUMENTS AND CONTROLS

- 8.1.3. INSTRUMENTS AND CONTROLS

- 8.1.4. CAB DOOR AND WINDOWS

- 8.1.5. OPERATORS SEAT

- 8.1.6. SEAT BELT

- 8.1.7. CAB HEATING AND VENTILATION

- 8.1.7.1. DEFROSTER FAN

- 8.1.7.2. HEATER

- 8.1.7.3. AIR CONDITIONER

- 8.1.8. AIR CLEANER SERVICE INDICATOR

- 8.1.9. ELECTRIC SYSTEM MASTER SWITCH

- 8.1.10. DOME LIGHT WITH SWITCHES

- 8.1.11. STARTING AND STOPPING THE ENGINE

- 8.1.11.1. NORMAL START (AMBIENT TEMPERATURE ABOVE 0 (C))

- 8.1.11.2. COLD WEATHER START (USING ETHER INJECTOR, AMBIENT TEMPERATURE BELOW 0 C)

- 8.1.11.3. STOPPING THE ENGINE

- 8.1.12. DRIVING THE MACHINE

- 8.1.13. SHIFTING GEARS

- 8.1.14. STEERING

- 8.1.15. STOPPING THE MACHINE

- 8.1.16. PARKING THE MACHINE

- 8.1.17. LOADER OPERATIONS

- 8.1.17.1. BOOM CONTROL LEVER POSITIONS

- 8.1.17.2. AUTOMATIC BOOM KICKOUT

- 8.1.17.3. BUCKET CONTROL LEVER POSITIONS

- 8.1.17.4. AUTOMATIC LEVELER

- 8.1.17.5. MULTIPURPOSE BUCKET CONTROL LEVER POSITIONS (IF EQUIPPED)

- 8.1.18. LOADER TECHNIQUES

- 8.1.18.1. LOADING, TRANSPORTING AND PILING

- 8.1.18.2. DIGGING, CLEARING AND LEVELING

- 8.1.19. ECONOMICAL OPERATION OF MACHINE

- 8.1.20. QUICKCOUPLING

- 8.1.20.1. QUICKCOUPLING WITH 3SPOOL VALVE

- 8.1.20.2. QUICKCOUPLING WITH 2SPOOL VALVE

- 8.1.21. RIDE STABILIZING MECHANISM

- 8.1.21.1. DRIVING A MACHINE WITH RSM SYSTEM

- 8.1.22. HIGHDUMP BUCKET

- 8.1.22.1. HIGHDUMP BUCKET CONTROL

- 8.1.22.2. OPERATING THE HIGHDUMP BUCKET

- 9. SECTION 5 MAINTENANCE

- 9.1. MAINTANENCE

- 9.1.1. GENERAL PRECAUTIONS

- 9.1.2. SCHEDULED MAINTENANCE GUIDE

- 9.1.2.1. GROUND LEVEL INSPECTION

- 9.1.3. MAINTENANCE AND SERVICE CHART

- 9.1.3.1. SERVICE POINTS

- 9.1.4. LUBRICATION

- 9.1.4.1. WHEN SHIPPED

- 9.1.4.2. WHEN SERVICED

- 9.1.4.3. LUBRICANT SELECTION

- 9.1.4.4. VISCOSITIES

- 9.1.4.5. REFILL SPECIFICATIONS AND CAPACITIES

- 9.1.4.6. LUBRICANT, COOLANT AND FUEL EQUIVALENTS

- 9.1.4.7. LUBRICATING FITTINGS (LUBRICATED WITH SOLID GREASE)

- 9.1.5. SEASONAL PREPARATION

- 9.1.5.1. FUEL SYSTEM

- 9.1.5.2. COOLING SYSTEM

- 9.1.5.3. ELECTRICAL SYSTEM

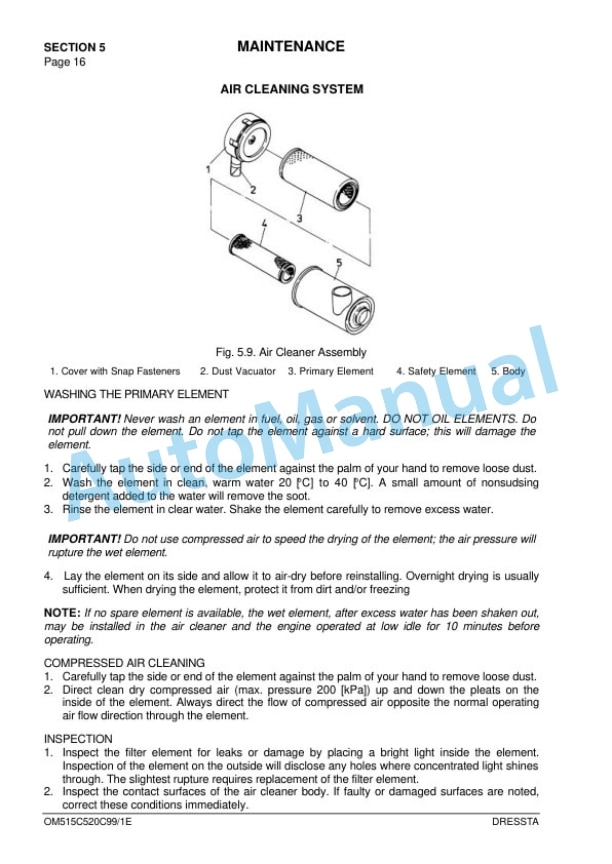

- 9.1.6. AIR CLEANING SYSTEM

- 9.1.6.1. AIR CLEANER

- 9.1.6.2. PRIMARY (OUTER) FILTER ELEMENT

- 9.1.6.3. SAFETY (INNER) FILTER ELEMENT

- 9.1.6.4. PRECLEANER SCREEN

- 9.1.6.5. DUST VACUATOR VALVE

- 9.1.6.6. CHECKING AIR INTAKE SYSTEM FOR LEAKS

- 9.1.7. BRAKES

- 9.1.7.1. SERVICE BRAKE SYSTEM

- 9.1.7.2. CHECKING THE BRAKE FLUID LEVEL

- 9.1.7.3. CHANGING THE BRAKE FLUID

- 9.1.7.4. FILLING AND VENTING THE SYSTEM

- 9.1.7.5. PARKING BRAKE

- 9.1.8. COOLING SYSTEM

- 9.1.8.1. WATER

- 9.1.8.2. ANTIFREEZE

- 9.1.8.3. RADIATOR CAP

- 9.1.8.4. CHECKING THE COOLANT LEVEL

- 9.1.8.5. DRAINING THE SYSTEM

- 9.1.8.6. CLEANING THE SYSTEM

- 9.1.8.7. FILLING THE SYSTEM

- 9.1.8.8. CLEANING THE RADIATOR

- 9.1.9. DRIVE AXLES

- 9.1.9.1. CHECKING THE OIL LEVEL

- 9.1.9.2. SERVICING THE BREATHER

- 9.1.9.3. CHANGINE THE OIL

- 9.1.10. ELECTRICAL SYSTEM

- 9.1.10.1. ELECTRIC WIRES

- 9.1.10.2. CIRCUIT BREAKERS

- 9.1.10.3. BULB OR LAMP REPLACEMENT

- 9.1.10.4. BATTERIES

- 9.1.11. ENGINE

- 9.1.11.1. CHECKING THE CRANKCASE OIL LEVEL

- 9.1.11.2. CHANGING THE CRANKCASE OIL AND FILTER

- 9.1.11.3. CHECKING THE CONDITION AND TENSION OF BELTS

- 9.1.11.4. CHECKING THE CONDITION OF FAN AND HUB

- 9.1.11.5. INSPECTION OF IDLER PULLEY

- 9.1.11.6. ADJUSTMENT OF ENGINE VALVES

- 9.1.12. ETHER INJECTOR

- 9.1.13. FUEL SYSTEM

- 9.1.13.1. FUEL TANK

- 9.1.13.2. CHANGING THE FUEL FILTERS

- 9.1.13.3. FUEL FILTER WITH WATER SEPARATOR

- 9.1.13.4. VENTING THE FUEL SYSTEM

- 9.1.14. HYDRAULIC SYSTEM

- 9.1.14.1. CHECKING THE RESERVOIR OIL LEVEL

- 9.1.14.2. CHANGING THE HYDRAULIC SYSTEM OIL

- 9.1.14.3. CHANGING THE HYDRAULIC OIL RETURN FILTER

- 9.1.14.4. SERVICING THE HYDRAULIC RESERVOIR BREATHER

- 9.1.15. SEAT BELT

- 9.1.16. STEERING GEAR

- 9.1.17. TIRES AND RIMS

- 9.1.18. TRANSMISSION SYSTEM

- 9.1.18.1. CHECKING THE OIL LEVEL

- 9.1.18.2. CHANGING THE OIL

- 9.1.18.3. CHANGING THE TRANMISSION PRESSURE FILTER

- 9.1.18.4. CLEANING THE TRANSMISSION SUCTION STRAINER

- 9.1.18.5. SERVICING THE BREATHER

- 9.1.19. ROPS CAB AND ROPS CANOPY

- 9.1.20. HOOD ASSEMBLY AND RADIATOR GRILL

- 9.1.21. LOADER EQUIPMENT

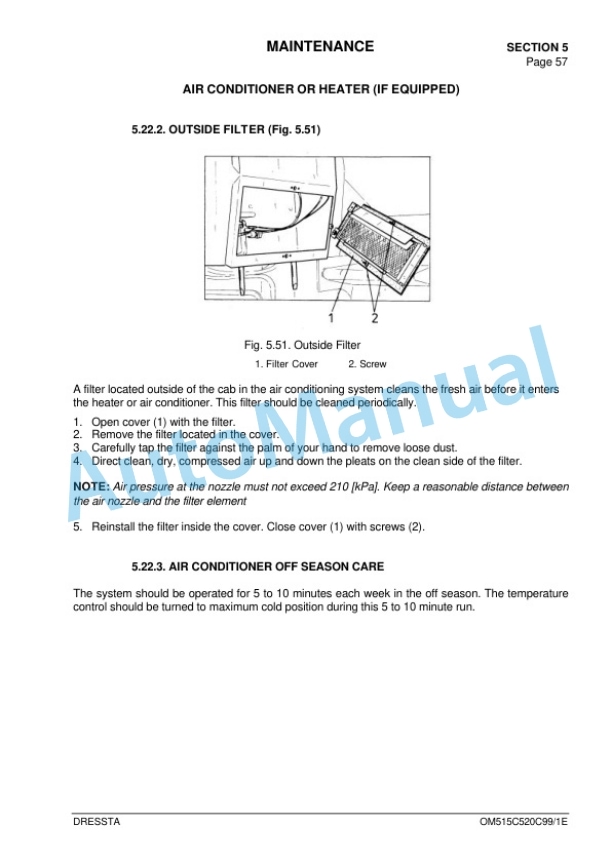

- 9.1.22. AIR CONDITIONER OR HEATER (IF EQUIPPED

- 9.1.22.1. INSIDE FILTER

- 9.1.22.2. OUTSIDE FILTER

- 9.1.22.3. AIR CONDITIONER OFF SEASON CARE

- 10. SECTION 6 SPECIFICATIONS

- 10.1. SPECIFICATIONS

- 10.1.1. APPLICATION

- 10.1.2. TECHNICAL DESCRIPTION

- 10.1.3. SCHEMATIC OF 515C AND 520C WHEEL LOADERS DRIVE TRAIN

- 10.1.4. SCHEMATICS OF TRANSMISSION HYDRAULIC SYSTEM

- 10.1.5. LOADER EQUIPMENT AND STEERING HYDRAULIC SCHEMATIC

- 10.1.6. WIRING DIAGRAMS

- 10.1.7. BRAKE HYDRAULIC SYSTEM SCHEMATIC

- 10.1.8. SPECIFICATIONS

- 10.1.8.1. GENERAL SPECIFICATIONS OF 515C AND 520C LOADERS

- 10.1.8.2. CAPACITIES

- 10.1.8.3. ENGINE

- 10.1.8.4. ELECTRICAL SYSTEM

- 10.1.8.5. TRANSMISSION

- 10.1.8.6. TORQUE CONVERTER

- 10.1.8.7. DRIVE AXLES

- 10.1.8.8. TIRES

- 10.1.8.9. RIMS

- 10.1.8.10. BRAKES

- 10.1.8.11. LOADER HYDRAULIC SYSTEM

- 10.1.8.12. STEERING SYSTEM

- 10.1.8.13. DRIVE TRAIN

- 10.1.8.14. CYCLE TIMES

- 10.1.8.15. FUEL CONSUMPTION

- 10.1.9. AND 520C LOADERS EQUIPMENT

- 10.1.9.1. QUICKCOUPLING

- 10.1.9.2. BUCKETS FOR QUICKCOUPLING

- 10.1.9.3. FORKLIFT FOR QUICKCOUPLING 520C

- 10.1.9.4. MULITPURPOSE BUCKET

- 10.1.9.5. LOADER HIGHDUMP BUCKET

- 10.1.10. TORQUE VALUES FOR STANDARD METRICK FASTENERS

- 10.1.11. TORQUE VALUES FOR STANDARD ENGLISH FASTENERS

- 10.1.12. TORQUE VALUES FOR SPLIT FLANGE CONNECTIONS

- 10.1.13. TORQUE VALUES FOR HYDRAULIC TUBES AND FITTINGS

- 10.1.14. TORQUE VALUES FOR HOSE CLAMPS

- 10.1.15. TORQUE VALUES FOR AIR CONDITIONING TUBES AND FITTINGS

- 10.1.16. TORQUE VALUES FOR AIR CONDITIONING ORING CONNECTIONS

- 10.1.17. SPECIAL TORQUES

- 10.1.18. LIST OF SERVICE TOOLS

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1