Komatsu 730E-10 Dump Truck Operation and Maintenance Manual CEAM034506

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM034506

- Format: PDF

- Size: 14.1MB

- Number of Pages: 238

-

Model List:

- 730E-10 Dump Truck

- 1. Contents

- 2. INTRODUCTION

- 2.1. Foreword

- 2.2. Safety Alert Symbol and Signal Words

- 2.3. Basic Machine Introduction

- 2.4. Visibility

- 2.5. Noise And Vibration

- 2.6. Exhaust Gas Regulations

- 2.7. Declaration of Conformity

- 2.8. Komatsu Machine Operator Privacy Policy

- 2.9. Product Information

- 3. SAFETY

- 3.1. Safety Labels

- 3.1.1. Locations of Safety Labels

- 3.1.2. Illustrations of Safety Labels

- 3.2. General Precautions Common to Operation and Maintenance

- 3.2.1. Preparations for Safe Operation

- 3.2.2. Fire and Explosion Prevention

- 3.2.3. Precautions When Getting On or Off the Machine

- 3.2.4. Precautions for Cab and Working Around Machine

- 3.2.5. Precautions for Diesel Exhaust Fluid (DEF)

- 3.3. Operation Precautions

- 3.3.1. Precautions at Jobsite

- 3.3.2. Precautions in Starting Engine

- 3.3.3. Precautions During Operation

- 3.4. Maintenance Precautions

- 3.4.1. Precautions Before Inspection and Maintenance

- 3.4.2. Precautions During Inspection and Maintenance

- 4. OPERATION

- 4.1. Visual Overview of Machine

- 4.1.1. Machine Components Front And Rear Views

- 4.1.2. Machine Components Inside Frame View

- 4.1.3. Machine Components Left Side View

- 4.1.4. Machine Components Right Side View

- 4.1.5. Exterior Lights

- 4.1.6. Cab Interior View

- 4.2. Steering Wheel and Controls

- 4.3. Pedals

- 4.4. Center Console Controls

- 4.5. Instrument Panel Gauges

- 4.6. Instrument Panel Indicator Lamps

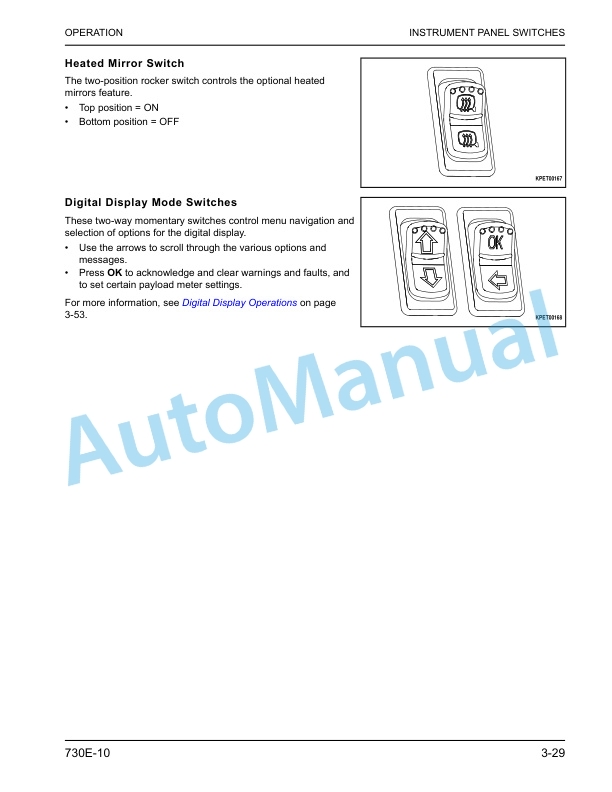

- 4.7. Instrument Panel Switches

- 4.8. Heater and Air Conditioner Controls

- 4.9. Seat Heater/Ventilation System (HVS)

- 4.10. Retractable Ladder Operations

- 4.11. Radio Operations

- 4.11.1. AM/FM RADIO / MP3 / USB / iPOD / AUX PLAYER

- 4.11.1.1. USB Connection Port

- 4.11.1.2. Phone/Bluetooth Button

- 4.11.1.3. Digital Display

- 4.11.1.4. DISP (Display) Button

- 4.11.1.5. SRC/PWR/ESC (Source/Power/Escape) Button

- 4.11.1.6. Volume Knob/OK Button

- 4.11.1.7. NEXT Button

- 4.11.1.8. PREV (Previous) Button

- 4.11.1.9. Preset Buttons

- 4.11.1.10. RDM (Random) Button

- 4.11.1.11. RPT (Repeat) Button

- 4.11.1.12. Mute/Play/Pause Button

- 4.11.1.13. Browse Button

- 4.11.1.14. SCAN/ASCN (Scan/Autoscan) Button

- 4.11.1.15. Auxiliary Jack Port

- 4.12. KomVision

- 4.12.1. KomVision Monitor Panel

- 4.12.2. KomVision Monitor Display

- 4.12.3. KomVision Object Detection

- 4.13. Cab Connectors

- 4.14. Vehicle Information Display (VID) Panel

- 4.15. Digital Display Operations

- 4.16. Digital Display Menus

- 4.17. KOMTRAX

- 4.18. Payload Meter IV

- 4.18.1. Payload Meter IV Communication Module

- 4.18.2. Payload Lights/Scoreboard

- 4.18.3. Haul Cycle

- 4.18.4. Payload Calculations

- 4.18.5. Clean Truck Tare

- 4.18.6. Viewing and Downloading Data

- 4.19. Battery Disconnect Switches

- 4.20. Ground Level Shutdown Switch

- 4.21. Preparations Before Operating the Machine

- 4.21.1. WalkAround Inspection

- 4.21.1.1. Zone 1 In Front of Left Front Tire

- 4.21.1.2. Zone 2 Behind Left Front Tire

- 4.21.1.3. Zone 3 In Front of Left Rear Tires

- 4.21.1.4. Zone 4 Rear of Truck

- 4.21.1.5. Zone 5 In Front of Right Rear Tires

- 4.21.1.6. Zone 6 Behind Right Front Tire

- 4.21.1.7. Zone 7 In Front of Right Front Tire

- 4.21.1.8. Zone 8 Front of Truck

- 4.21.1.9. Zone 9 Decks and Cab

- 4.21.2. PreShift Brake Tests

- 4.21.3. Emergency Steering Test

- 4.21.4. Adjusting the Mirrors

- 4.21.5. Adjusting the Cab Seat

- 4.21.5.1. Seat Adjustment Controls, Earlier Models

- 4.21.5.2. Seat Adjustment Controls, Later Models

- 4.21.6. KomVision StartUp Inspection

- 4.22. Starting the Engine

- 4.23. Checks After Starting the Engine

- 4.24. Operating the Machine

- 4.24.1. Traveling on a Haul Road

- 4.24.2. Initial Propulsion on a Grade

- 4.24.3. Retarding on a Grade

- 4.24.3.1. Dynamic Retarding Operation

- 4.24.4. Loading the Dump Body

- 4.24.4.1. Overload Speed Limit Function

- 4.24.5. Dumping the Load

- 4.25. Shutting Down the Machine

- 4.26. Disabled Machine Operations

- 4.26.1. Stopping the Machine After Loss of Power

- 4.26.2. Dumping the Load From a Disabled Machine

- 4.26.3. Towing a Disabled Machine

- 4.26.3.1. Enabling the Steering and Braking Circuits

- 4.26.3.2. Releasing the Parking Brake

- 4.26.3.3. Towing Procedure

- 4.26.4. Jump Starting a Disabled Machine

- 4.27. Engine Emissions AfterTreatment System Operations

- 5. MAINTENANCE

- 5.1. Rules for Maintenance

- 5.2. Recommended Fuel, Coolant, and Lubricant

- 5.3. Lubrication Chart

- 5.4. Oil Clinic Inspection

- 5.5. Remote Fill Service Centers

- 5.6. Torque Specifications

- 5.7. Maintenance Schedule

- 5.7.1. Wheel Motor Maintenance Intervals

- 5.7.2. Engine Maintenance Intervals

- 5.7.3. Safety Critical Parts

- 5.7.4. Maintenance Schedule Table

- 5.8. Maintenance Procedures as Required

- 5.8.1. Replace Engine Air Cleaner Filter Elements

- 5.8.2. Maintain Correct Hydraulic Oil Level

- 5.8.3. Maintain Correct Coolant Level

- 5.8.4. Replace Autolube Filter Element

- 5.8.5. Fuses, Diodes and Relays

- 5.9. Maintenance For First 500 Hours

- 5.9.1. Initial 50 Hours Maintenance

- 5.9.2. Initial 100 Hours Maintenance

- 5.9.3. Initial 250 Hours Maintenance

- 5.9.4. Initial 500 Hours Maintenance

- 5.10. Every 250 Hours Maintenance

- 5.10.1. Clean Cab External Air Filter

- 5.10.2. Lubricate Pump Driveshaft

- 5.10.3. Collect Wheel Motor Oil Sample

- 5.10.4. Collect Hydraulic Oil Sample

- 5.10.5. Check Automatic Lubrication (Autolube) System

- 5.10.6. Check Retractable Ladder

- 5.11. Every 500 Hours Maintenance

- 5.11.1. Clean HVAC Recirculation Air Filter

- 5.11.2. Clean A/C Condenser

- 5.11.3. Check A/C Drain Hose

- 5.11.4. Lubricate Pedals

- 5.11.5. Clean Control Cabinet Interior

- 5.11.6. Check Tie Rod

- 5.11.7. Check Engine Air Intake Piping

- 5.11.8. Check Dump Body Up and Hoist Limit Switches

- 5.11.9. Replace Hydraulic Tank Breather Elements

- 5.11.10. Cooling System Service

- 5.11.11. Fuel System Service

- 5.11.12. Check Automatic Lubrication (Autolube) System Pump Oil Level

- 5.12. Every 1000 Hours Maintenance

- 5.12.1. Change Hydraulic Oil

- 5.12.2. Replace Hydraulic Filter Elements

- 5.12.3. Replace DEF System Filters

- 5.12.4. Lubricate Retractable Ladder

- 5.12.5. Check Dump Body Pads

- 5.12.6. Check/Lubricate Hoist Lever

- 5.12.7. Check Cab Seat Suspension

- 5.13. Every 2000 Hours Maintenance

- 5.13.1. Change Automatic Lubrication (Autolube) System Pump Oil

- 5.14. Every 2500 Hours Maintenance

- 5.14.1. Change Front Wheel Hub Oil

- 5.14.2. Lubricate Electronic Fan Clutch

- 5.15. Every 3000 Hours Maintenance

- 5.16. Every 5000 Hours Maintenance

- 5.16.1. Check Engine Air Cleaner Vacuator Valves

- 5.16.2. Check Steering Wheel Retaining Nut

- 5.17. Every 6500 Hours Maintenance

- 5.17.1. Lubricate Traction Alternator Bearing

- 6. SPECIFICATION

- 6.1. Specifications 730E10

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103