Komatsu 830E-1AC Dump Truck Field Assembly Instruction CEAW008001

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: CEAW008001

- Format: PDF

- Size: 7.2MB

- Number of Pages: 304

-

Model List:

- 830E-1AC Dump Truck

- 1. COVER

- 2. FOREWORD

- 3. TABLE OF CONTENTS

- 4. SAFETY RULES, TOOLS EQUIPMENT

- 4.1. SAFETY RULES

- 4.1.1. Use of TieOff Anchor During Maintenance and Repair

- 4.1.2. BODYUP RETENTION CABLE

- 4.2. NITROGEN CHARGING VALVE

- 4.3. ROLLOUT ASSEMBLY

- 4.4. SLEEVE ALIGNMENT TOOLS

- 4.5. QUICK DISCONNECT COUPLING

- 4.6. HARNESS

- 4.7. SEAL INSTALLATION RING

- 4.8. SOCKETS AND ADAPTERS

- 4.9. DUST CAPS

- 4.10. HYDRAULIC SYSTEM FLUSHING TOOLS

- 4.11. KOMVISION CALIBRATION TOOLS

- 4.12. MISCELLANEOUS SERVICE TOOLS

- 4.13. PAYLOAD DATA MANAGER

- 4.14. HYDRAULIC SYSTEM VACUUM PUMP

- 4.15. BRAKE PISTON TOOL

- 4.16. HIGH VOLTAGE TOOLS

- 4.17. VDC CUSTOM METER KIT (58B0600800)

- 4.18. BODY PAD SPACER TOOL

- 5. TRUCK COMPONENTS AND SPECIFICATIONS

- 5.1. Truck And Engine

- 5.2. AC Induction Traction Motorized Wheels

- 5.3. Suspension

- 5.4. Operators Cab

- 5.5. Power Steering

- 5.6. Dynamic Retarding

- 5.7. Brake System

- 6. SPECIFICATIONS

- 6.1. REAR AXLE COMPONENTS

- 7. FIELD WELDING FOR ASSEMBLY OR REPAIR

- 7.1. WELDER QUALIFICATION AND TRAINING

- 7.2. WELD PROCEDURES

- 7.3. APPROVED CONSUMABLES

- 7.4. WELD QUALITY REQUIREMENTS

- 7.5. MATERIALS, CONTROLS, AND PRECAUTIONS

- 7.6. WELD INSPECTION

- 7.7. RECORDS

- 7.8. ANNEX A

- 7.9. ANNEX B

- 7.9.1. TOE HAMMER PEENING

- 7.9.1.1. Procedure

- 7.9.2. TOE GRINDING WITH A ROTARY BURR

- 7.9.2.1. Procedure

- 7.10. BIBLIOGRAPHY

- 7.10.1. SPECIAL PRECAUTIONS WHEN SERVICING AN AC DRIVE SYSTEM TRUCK

- 7.10.1.1. Engine Shutdown Procedure before Welding or Performing Maintenance

- 8. RECEIVING ASSEMBLY PREPARATION

- 8.1. Preparation

- 8.1.1. Inspection, Cleaning, Setup

- 8.1.2. Color Coded Boxes

- 8.2. ASSEMBLY LAYOUT

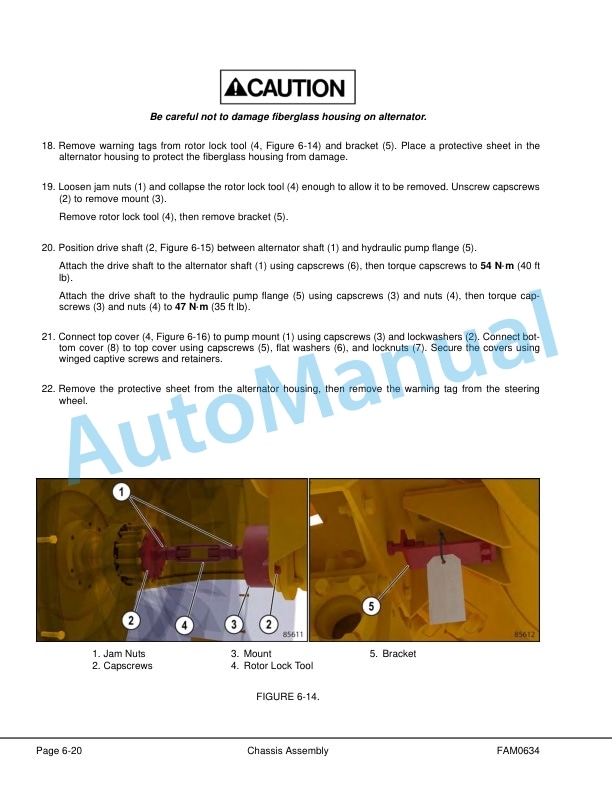

- 9. CHASSIS ASSEMBLY

- 9.1. RECOMMENDED ASSEMBLY DATA

- 9.2. BASIC ASSEMBLY PROCEDURE

- 9.2.1. ORDER OF ASSEMBLY

- 9.2.2. LEVEL 1

- 9.2.3. LEVEL 2

- 9.2.4. LEVEL 7

- 9.3. GENERAL PRECAUTIONS AND INSTRUCTION

- 9.3.1. Angle Advance Tightening Procedure

- 9.3.2. Upper Mounting Joint 60 Advance

- 9.3.3. Lower Mounting Joint 90 Advance

- 9.3.4. Inspection

- 9.4. GENERAL INFORMATION

- 9.5. BODY ASSEMBLY

- 9.6. BODY WELDING

- 10. FINAL ASSEMBLY

- 10.1. Body Pad Shimming Procedure

- 11. APPENDIX

- 11.1. LUBRICATION CHART

- 11.2. OILING AND CHARGING PROCEDURE

- 11.2.1. GENERAL

- 11.2.2. EQUIPMENT LIST

- 11.2.3. HYDRAIR CHARGING KIT

- 11.2.3.1. Installation of Charging Kit

- 11.2.3.2. Removal of Charging Kit

- 11.2.4. SUPPORT BLOCKS FOR OILING AND CHARGING DIMENSIONS

- 11.2.5. FRONT SUSPENSION

- 11.2.5.1. Front Suspension Oiling

- 11.2.5.2. Front Suspension Nitrogen Charging

- 11.2.6. REAR SUSPENSION

- 11.2.6.1. Rear Suspension Oiling

- 11.2.6.2. Rear Suspension Nitrogen Charging

- 11.3. OIL AND NITROGEN SPECIFICATIONS CHART

- 11.4. TOEIN ADJUSTMENT

- 11.5. AUTO LUBE SYSTEM

- 11.5.1. Lincoln Flow master Phase I Auto Lube System with fixed Hydraulic Controls

- 11.5.2. Lube Pump Startup / Purging Procedure

- 11.5.3. Truck Lube System Purging Procedure After lube pump has been primed with grease.

- 11.5.4. INJECTOR SETTINGS

- 11.5.5. TIMER

- 11.5.6. WARNING SYSTEM

- 11.6. AIR CONDITIONING SYSTEM CHECKOUT PROCEDURE

- 11.7. KOMTRAX PLUS SETUP PROCEDURE

- 11.7.1. Purpose

- 11.7.2. Preliminary Procedures

- 11.7.3. Necessary Equipment

- 11.7.4. Check for KOMTRAX Plus System Faults

- 11.7.5. KOMTRAX Plus Setup

- 11.7.6. Begin KOMTRAX Plus Setup

- 11.8. KOMTRAX PLUS CHECKOUT PROCEDURE

- 11.8.1. Purpose

- 11.8.2. Preliminary Procedures

- 11.8.3. Necessary Equipment

- 11.8.4. Check for KOMTRAX Plus System Faults

- 11.8.5. Checkout Procedure

- 11.9. IM CHECKOUT 830E1AC WITH DIGITAL DISPLAY

- 11.9.1. Purpose

- 11.9.2. Necessary Equipment

- 11.9.3. Install the application code

- 11.9.4. How to use the IM Realtime Data Monitor Software

- 11.9.5. Check for Fault Codes Associated with the Interface Module.

- 11.9.6. Interface Module I/O

- 11.9.7. Check Digital Inputs to the Interface Module

- 11.9.8. Check Analog Inputs to the Interface Module

- 11.9.9. Check Serial Interfaces to the IM

- 11.9.10. Check Outputs from the Interface Module

- 11.10. PAYLOAD METER IV CHECKOUT PROCEDURE

- 11.10.1. Necessary Equipment

- 11.10.2. Install the Application Code

- 11.10.3. General Instructions

- 11.10.4. Appendix A

- 11.10.4.1. Guide to Connect to Payload Meter IV

- 11.10.4.2. Configuring a PCs Static IP Address

- 11.10.5. Appendix B

- 11.10.5.1. Installing Payload Meter IV Truck Application Software via USB

- 11.10.6. Payload Meter IV Checkout Procedure Confirmation

- 11.11. Electric Checkout Procedure

- 11.11.1. Scope

- 11.11.2. General Description

- 11.11.3. General Precautions

- 11.11.4. Normal shutdown procedure

- 11.11.5. AC Drive System Description

- 11.11.6. Test equipment needed to fully test AC system

- 11.11.7. Visual Inspection

- 11.11.8. Resistance Check Preparation

- 11.11.9. Resistance Check

- 11.11.10. Voltage Check

- 11.11.11. Key Switch OFF Checks

- 11.11.12. Key Switch ON Check

- 11.11.13. GE Control Switch ON Check

- 11.11.14. Truck Function Check

- 11.11.15. Key Switch OFF

- 11.11.16. Key Switch ON

- 11.11.17. Interface Module (IM) System

- 11.11.18. Komtrax Plus (VHMS) Checkout

- 11.11.19. Payload Meter Checkout

- 11.11.20. GE Vehicle Test Instructions (VTI)

- 11.11.21. Digital I/O to GE

- 11.11.22. Engine Shutdown Smart Timer Check

- 11.11.23. Body Hoist Limit

- 11.11.24. Truck Function Check

- 11.12. RESERVE OIL SYSTEM R2000DF W/AUTO FILL

- 11.12.1. AFC Control StartUp / Fast Fill Procedure

- 11.12.2. Reserve pump R2000DF startup and led description.

- 11.13. AUTOMATIC LUBRICATION SYSTEM

- 11.13.1. GENERAL DESCRIPTION

- 11.13.2. SYSTEM COMPONENTS

- 11.13.2.1. Filter

- 11.13.2.2. Hydraulic Motor and Pump

- 11.13.2.3. Grease Reservoir

- 11.13.2.4. Pressure Reducing Valve

- 11.13.2.5. Flow Control Valve

- 11.13.2.6. Solenoid Valve

- 11.13.2.7. Vent Valve

- 11.13.2.8. Over Pressure Cut Off Switch

- 11.13.2.9. Grease Pressure Failure Switch

- 11.13.2.10. Injectors

- 11.13.2.11. Interface Module

- 11.13.2.12. Relief Valve (unloader valve)

- 11.13.3. SYSTEM OPERATION

- 11.13.3.1. Normal Operation

- 11.13.3.2. Lubricant Required For System

- 11.13.3.3. Filter Assembly

- 11.13.4. LUBRICANT PUMP

- 11.13.4.1. Pump Housing Oil Level

- 11.13.4.2. Pump Pressure Control

- 11.13.5. SYSTEM CHECKOUT

- 11.13.5.1. Lubrication Cycle Operation

- 11.14. SYSTEM TROUBLESHOOTING CHART

- 11.15. STANDARD TORQUE CHARTS AND CONVERSION TABLES

- 11.15.1. EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

- 11.15.2. STANDARD ASSEMBLY TORQUES Grade 9 Capscrews (SAE)

- 11.15.3. STANDARD ASSEMBLY TORQUES For Class 10.9 Capscrews Class 10 Nuts

- 11.16. HYDRAULIC SYSTEM FLUSHING PROCEDURE

- 11.16.1. SYSTEM FLUSHING

- 11.16.1.1. Hydraulic System Flushing Procedure

- 11.17. STATIC BRAKE SYSTEM CHECKOUT

- 11.17.1. STATIC BRAKE SYSTEM CHECKOUT

- 11.17.1.1. Events

- 11.17.1.2. OPERATION

- 11.17.1.2.1. Description

- 11.17.1.2.2. Brake Test Exit Criteria

- 11.17.1.3. PERFORMING THE BRAKE TESTS

- 11.17.1.3.1. Setup

- 11.17.1.3.2. Service Brake Test

- 11.17.1.3.3. Parking Brake Test

- 11.17.1.3.4. Retard System Test

- 11.18. KOMVISION CHECKOUT PROCEDURE

- 11.18.1. Necessary Equipment

- 11.18.2. STEP 1 Settings

- 11.19. Wireless Bridge Checkout procedure

- 11.19.1. Purpose

- 11.19.2. Necessary Equipment

- 11.19.3. Communication Setup

- 11.19.4. Appendix A

- 11.19.5. Setting The Computer Subnet Mask And IP Address

- 11.19.6. Windows 2000

- 11.19.7. Windows XP

- 11.19.8. Windows Vista

- 11.19.9. Windows 7

- 11.19.10. Appendix B Troubleshooting

- 11.20. FIELD ASSEMBLY INSPECTION REPORT

- 11.21. HOUR CHECKSHEET

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000