Komatsu 860E-1KT Dump Truck Field Assembly Instruction CEAW005702

$20.00

- Type Of Manual: Field Assembly Instruction

- Manual ID: CEAW005702

- Format: PDF

- Size: 11.1MB

- Number of Pages: 290

-

Model List:

- 860E-1KT Dump Truck

- 1. COVER

- 2. FOREWORD

- 3. TABLE OF CONTENTS

- 4. SAFETY RULES, TOOLS EQUIPMENT

- 4.1. SAFETY RULES

- 4.2. TOOLS AND EQUIPMENT FOR ASSEMBLY

- 4.3. LIFTING SLING GENERAL INFORMATION

- 4.4. HYDRAULIC SYSTEM FLUSHING TOOLS

- 4.5. HYDRAULIC SYSTEM VACUUM PUMP

- 5. TRUCK COMPONENTS AND SPECIFICATIONS

- 5.1. Truck And Engine

- 5.2. Main Alternator

- 5.3. AC Induction Traction Motorized Wheels

- 5.4. Suspension

- 5.5. Operators Cab

- 5.6. Power Steering

- 5.7. Dynamic Retarding

- 5.8. Brake System

- 5.9. SPECIFICATIONS

- 5.9.1. ENGINE

- 5.9.2. AC ELECTRIC DRIVE SYSTEM

- 5.9.3. DYNAMIC RETARDING

- 5.9.4. BATTERY ELECTRIC SYSTEM

- 5.9.5. SERVICE CAPACITIES

- 5.9.6. HYDRAULIC SYSTEMS

- 5.9.7. SERVICE BRAKES

- 5.9.8. STEERING

- 5.9.9. TIRES

- 5.9.10. STANDARD DUMP BODY CAPACITIES AND DIMENSIONS

- 5.9.11. WEIGHT DISTRIBUTION

- 6. MAJOR COMPONENT WEIGHTS

- 6.1. CHASSIS

- 6.2. DECK AND DECK SUPPORT COMPONENTS

- 6.3. POWER MODULE

- 6.4. HYDRAULIC COMPONENTS

- 6.5. FRONT AXLE COMPONENTS

- 6.6. REAR AXLE COMPONENTS

- 7. FIELD WELDING FOR ASSEMBLY OR REPAIR

- 7.1. WELDER QUALIFICATION AND TRAINING

- 7.2. WELD PROCEDURES

- 7.3. APPROVED CONSUMABLES

- 7.4. WELD QUALITY REQUIREMENTS

- 7.5. MATERIALS, CONTROLS, AND PRECAUTIONS

- 7.6. WELD INSPECTION

- 7.7. RECORDS

- 7.8. ANNEX A

- 7.9. ANNEX B

- 7.9.1. TOE HAMMER PEENING

- 7.9.1.1. Procedure

- 7.9.2. TOE GRINDING WITH A ROTARY BURR

- 7.9.2.1. Procedure

- 7.10. BIBLIOGRAPHY

- 7.10.1. SPECIAL PRECAUTIONS WHEN SERVICING AN AC DRIVE SYSTEM TRUCK

- 7.10.1.1. Engine Shutdown Procedure Before Welding or Performing Maintenance

- 7.10.1.2. Precautions Before Welding or Performing Maintenance

- 8. RECEIVING ASSEMBLY PREPARATION

- 8.1. Color Coded Boxes

- 8.2. ASSEMBLY LAYOUT

- 9. CHASSIS ASSEMBLY

- 9.1. RECOMMENDED ASSEMBLY DATA

- 9.2. BASIC ASSEMBLY PROCEDURE

- 9.3. ORDER OF ASSEMBLY

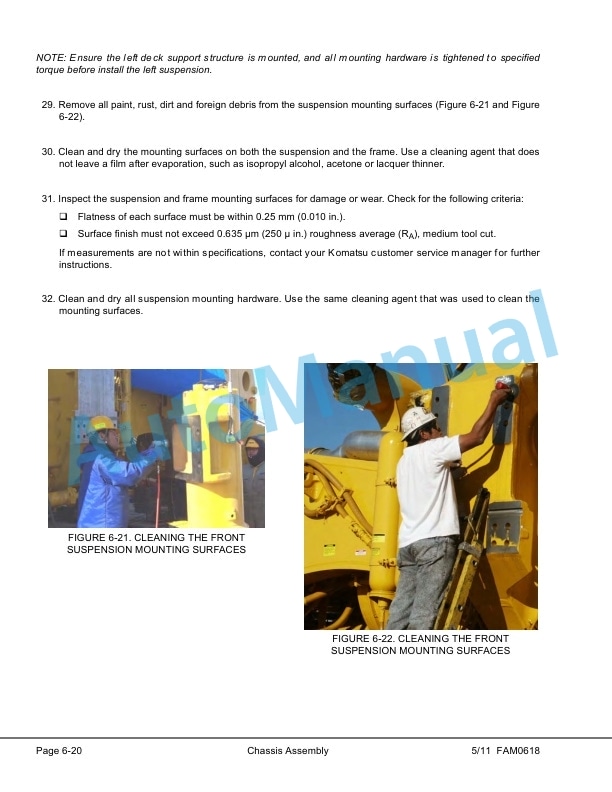

- 9.4. CHASSIS ASSEMBLY

- 9.5. GENERAL PRECAUTIONS AND INSTRUCTION

- 9.5.1. Upper Mounting Joint 60 Advance

- 9.5.2. Front Wheel Installation

- 9.5.3. Rear Wheel Installation

- 10. DUMP BODY ASSEMBLY

- 10.1. GENERAL INFORMATION

- 10.2. BODY WELDING INFORMATION

- 10.3. BODY ASSEMBLY

- 11. FINAL ASSEMBLY

- 11.1. SAFETY

- 11.2. BEFORE STARTING THE ENGINE

- 12. FINAL CHECKOUT

- 13. APPENDIX

- 13.1. LUBRICATION CHART

- 13.1.1. LUBRICATION CHART

- 13.2. OILING AND CHARGING PROCEDURE

- 13.2.1. GENERAL

- 13.2.2. EQUIPMENT LIST

- 13.2.3. HYDRAIR CHARGING KIT

- 13.2.3.1. Installation of Charging Kit

- 13.2.3.2. Removal of Charging Kit

- 13.2.4. SUPPORT BLOCKS FOR OILING AND CHARGING DIMENSIONS

- 13.2.5. FRONT SUSPENSION

- 13.2.5.1. Front Suspension Oiling

- 13.2.5.2. Front Suspension Nitrogen Charging

- 13.2.6. REAR SUSPENSION

- 13.2.6.1. Rear Suspension Oiling

- 13.2.6.2. Rear Suspension Nitrogen Charging

- 13.2.7. OIL AND NITROGEN SPECIFICATIONS CHART

- 13.3. TOEIN ADJUSTMENT

- 13.4. AUTOMATIC LUBRICATION SYSTEM CHECKOUT PROCEDURE

- 13.4.1. GREASE REQUIREMENTS

- 13.4.1.1. Required Lubricant

- 13.4.2. SYSTEM PRIMING

- 13.4.2.1. Pump Pressure Control

- 13.4.2.2. Pressure Control Valve Adjustment

- 13.4.2.3. Flow Control Valve Adjustment

- 13.4.3. PUMP HOUSING OIL

- 13.4.4. SYSTEM CHECKOUT

- 13.4.4.1. Lubrication Cycle Operation

- 13.4.5. PREVENTATIVE MAINTENANCE

- 13.4.5.1. Daily Lubrication System Inspection

- 13.4.5.2. SYSTEM TROUBLESHOOTING CHART

- 13.5. RESERVE OIL SYSTEM CHECKOUT PROCEDURE

- 13.6. A/C CHECKOUT PROCEDURE

- 13.7. A/C DRIVE BELT ADJUSTMENT PROCEDURE

- 13.8. HYDRAULIC SYSTEM CHECKOUT PROCEDURE

- 13.9. BRAKE SYSTEM CHECKOUT PROCEDURE

- 13.10. VHMS SETUP PROCEDURE

- 13.11. VHMS CHECKOUT PROCEDURE

- 13.12. INTERFACE MODULE CHECKOUT PROCEDURE

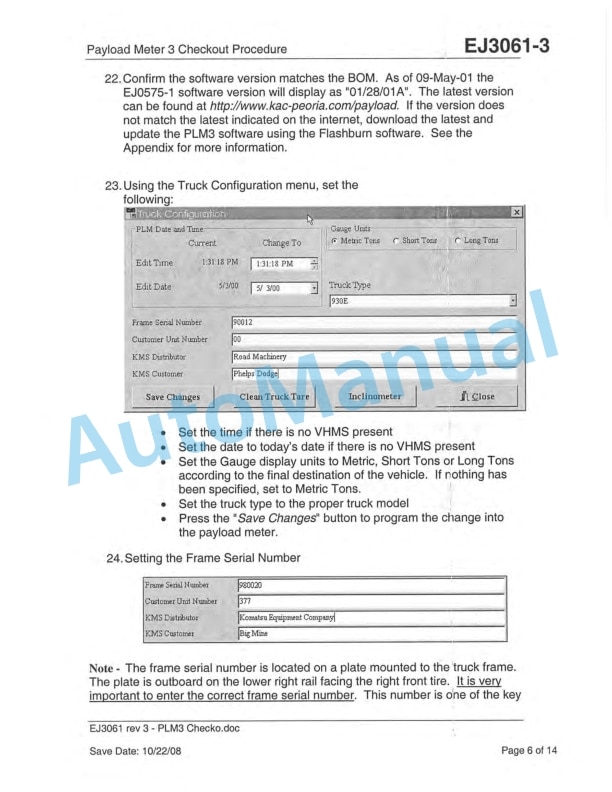

- 13.13. PLM III CHECKOUT PROCEDURE

- 13.14. ELECTRICAL CHECKOUT PROCEDURE

- 13.15. KOMATSU HAUL TRUCK COMMISSIONING PROCEDURE

- 13.16. STANDARD TORQUE CHARTS AND CONVERSION TABLES

- 13.16.1. EFFECT OF SPECIAL LUBRICANTS On Fasteners and Standard Torque Values

- 13.16.2. STANDARD ASSEMBLY TORQUES For 12Point, Grade 9 Cap Screws (SAE)

- 13.16.3. STANDARD ASSEMBLY TORQUES For Class 10.9 Capscrews Class 10 Nuts

- 13.17. HYDRAULIC SYSTEM FLUSHING PROCEDURE

- 13.17.1. SYSTEM FLUSHING

- 13.17.1.1. Hydraulic System Flushing Procedure

- 13.18. FIELD ASSEMBLY INSPECTION REPORT

- 13.19. HOUR POST COMMISSIONING CHECKSHEET

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702