Komatsu BR200R-1 Mobile Waste Recycler Operation and Maintenance Manual SEAM006500

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAM006500

- Format: PDF

- Size: 5.7MB

- Number of Pages: 179

-

Model List:

- BR200R-1 Mobile Waste Recycler

- 1. COVER

- 2. FOREWORD

- 3. SAFETY INFORMATION

- 4. TO THE USER

- 5. LOCATION OF PLATES,TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 6. CONTENTS

- 7. SAFETY

- 7.1. GENERAL PRECAUTIONS

- 7.2. PRECAUTIONS DURING OPERATION

- 7.2.1. BEFORE STARTING ENGINE

- 7.2.2. OPERATING MACHINE

- 7.2.3. CRUSHER (CRUSHING) OPERATIONS

- 7.2.4. TRANSPORTATION

- 7.2.5. BATTERY

- 7.3. PRECAUTIONS FOR MAINTENANCE

- 7.4. POSITION FOR ATTACHING SAFETY LABELS

- 8. OPERATION

- 8.1. GENERAL VIEW

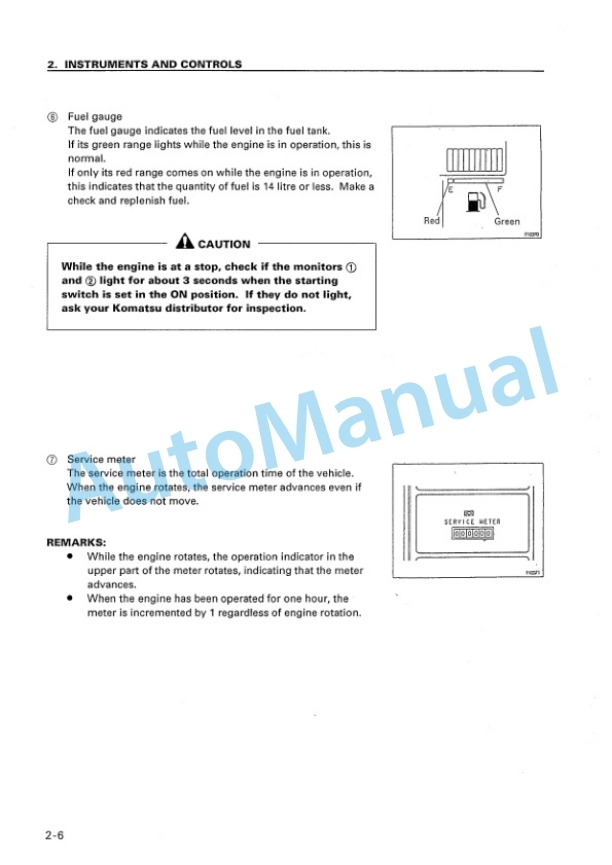

- 8.2. INSTRUMENTS AND CONTROLS

- 8.2.1. ELECTRONIC VEHICLE MONITORING SYSTEM

- 8.2.2. SWITCH UNIT

- 8.2.3. CAP WITH LOCK

- 8.2.4. DUST INDICATOR

- 8.2.5. FUSIBLE LINK

- 8.2.6. FUSE

- 8.2.7. HANDLING OF ACCUMULATOR

- 8.3. OPERATING PROCEDURES

- 8.3.1. ASSEMBLING AND DISASSEMBLING PROCEDURES OF FEED HOPPER

- 8.3.2. CHECKS BEFORE STARTING

- 8.3.3. STARTING THE ENGINE

- 8.3.4. AFTER STARTING THE ENGINE

- 8.3.5. STARTING THE VEHICLE

- 8.3.6. STEERING(CHANGING THE COURSE)

- 8.3.7. STOPPING THE VEHICLE

- 8.3.8. STARTING CRUSHER OPERATIONS

- 8.3.9. TYPE OF DEBRIS AND ADJUSTMENT OF ENGINE SPEED AND FEEDER SPEED

- 8.3.10. SPRINKLER

- 8.3.11. END OF OPERATION

- 8.3.12. AFTER END OF OPERATION

- 8.3.13. STOPPING THE ENGINE

- 8.3.14. INSPECTION AFTER STOP OF ENGINE

- 8.3.15. AUTOMATIC STOP OF BELT CONVEYOR

- 8.4. PRECAUTIONS DURING OPERATION OF CRUSHER

- 8.4.1. PRECAUTIONS CONCERNING ADHESION OF EARTH AND SAND AND STRIKING BOARD

- 8.4.2. GRAIN SIZE OF PRODUCT

- 8.4.3. OTHER PRECAUTIONS

- 8.5. TRANSPORTATION

- 8.6. LONGTERM STORAGE

- 9. MAINTENANCE

- 9.1. GENERAL INSTRUCTIONS ON MAINTENANCE OPERATIONS

- 9.2. AIR BLEEDING FROM CIRCUIT

- 9.2.1. AIR BLEEDING IN THE MAIN PUMP

- 9.2.2. AIR BLEEDING IN THE SUBPUMP

- 9.2.3. STARTING THE ENGINE

- 9.2.4. AIR BLEEDING IN THE CRUSHER MOTOR

- 9.2.5. AIR BLEEDING IN THE PLATE FEEDER MOTOR

- 9.2.6. AIR BLEEDING IN THE BELT CONVEYOR MOTOR

- 9.2.7. AIR BLEEDING IN THE TRAVEL MOTOR

- 9.2.8. STARTING OPERATIONS

- 9.3. OIL FILLER AND OIL LEVEL GAUGE

- 9.4. STANDARD BOLTS AND NUTS

- 9.5. MAINTENANCE TABLE

- 9.6. PERIODIC MAINTENANCE

- 9.6.1. CHECKS BEFORE STARTING

- 9.6.2. EVERY 100 HOURS SERVICE

- 9.6.3. EVERY 250 HOURS SERVICE

- 9.6.4. EVERY 500 HOURS SERVICE

- 9.6.5. MAINTENANCE EVERY 1000 HOURS

- 9.6.6. EVERY 2000 HOURS SERVICE

- 9.6.7. EVERY 4000 HOURS SERVICE

- 9.7. WHEN REQUIRED

- 9.7.1. CHECK,CLEANING AND REPLACEMENT OF AIR CLEANER

- 9.7.2. CLEANING OF THE INSIDE OF THE COOLING SYSTEM

- 9.7.3. TENSION CHECK AND ADJUSTMENT FOR THE TRACK SHOE

- 9.7.4. INSPECTION,ADJUSTMENT AND REPLACEMENT OF CRUSHER

- 9.7.5. INSPECTION AND ADJUSTMENT OF BELT CONVEYOR

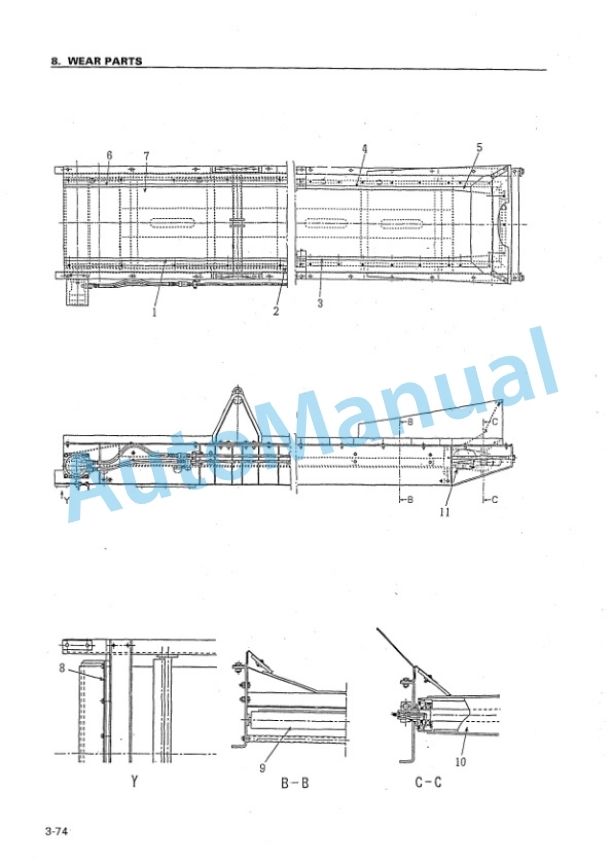

- 9.8. WEAR PARTS

- 9.8.1. WEAR PARTS RELATED TO THE BODY

- 9.8.2. PARTS RELATED TO CRUSHER

- 9.8.3. WEAR PARTS RELATED TO THE PRIMARY BELT CONVEYOR

- 9.9. USAGE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 9.10. PERIODIC REPLACEMENT OF SAFETY PARTS

- 9.11. TROUBLESHOOTING

- 9.11.1. CRUSHER

- 9.11.2. ELECTRICAL EQUIPMENT

- 9.11.3. ENGINE

- 9.11.4. ENGINE(CONTINUED FROM THE PREVIOUS PAGE)

- 9.11.5. BODY

- 9.11.6. BELT CONVEYOR

- 10. SPECIFICATIONS AND CIRCUIT DIAGRAMS

- 10.1. EXTERNAL VIEW

- 10.2. SPECIFICATIONS

- 10.3. HYDRAULIC CIRCUIT

- 10.4. ELECTRIC CIRCUIT

- 11. OPTIONS

- 11.1. HANDLING OF HYDRAULIC SECONDARY BELT CONVEYOR

- 11.1.1. SPECIFICATIONS

- 11.1.2. EXTERNAL VIEW

- 11.1.3. PROCEDURE FOR INSTALLING THE INCLINED LEG

- 11.1.4. PRECAUTIONS CONCERNING OPERATION

- 11.1.5. INSPECTION,MAINTENANCE AND ADJUSTMENT

- 11.1.6. TROUBLESHOOTING

- 11.1.7. DETAILS OF HYDRAULIC SECONDARY BELT CONVEYOR WEAR PARTS

- 11.2. HANDLING OF HYDRAULIC SORTER

- 11.2.1. SPECIFICATIONS

- 11.2.2. EXTERNAL VIEW

- 11.2.3. CAUTIONS ON SAFETY

- 11.2.4. PRECAUTIONS CONCERNING OPERATION

- 11.2.5. INSPECTION AND ADJUSTMENT

- 11.2.6. TROUBLESHOOTING

- 11.2.7. INSPECTION TABLE

- 11.2.8. WEAR PARTS LIST OF MAGNETIC SORTER

- 11.3. HYDRAULIC VIBRATING SCREEN

- 11.3.1. SPECIFICATION

- 11.3.2. EXTERNAL VIEW

- 11.3.3. CAUTIONS TO BE NOTED FOR SAFETY

- 11.3.4. PRECAUTIONS DURING OPERATION

- 11.3.5. TROUBLESHOOTING

- 11.3.6. CONSUMABLES

- 11.3.7. OTHERS

- 11.4. HYDRAULIC HAND BREAKER

- 11.5. CONNECTION OF OPTION HYDRAULIC HOSE

- 11.6. TROUBLESHOOTING OF OPTION SYSTEM

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729