Komatsu CK30-1 Compact Track Loader Operation and Maintenance Manual CEAM017102

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM017102

- Format: PDF

- Size: 21.7MB

- Number of Pages: 253

-

Model List:

- CK30-1 Compact Track Loader

- 1. INTRODUCTION

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.3. APPROVED AND NON APPROVED USES

- 1.3.1. Approved

- 1.3.2. Non Approved

- 1.4. PRODUCT INFORMATION

- 1.4.1. Main Features

- 1.4.2. Break In Period

- 1.5. PRODUCT IDENTIFICATION

- 1.5.1. Machine Serial Number

- 1.5.2. Machine Identification Plate And Product Identification Number (Pin)

- 1.5.3. Engine Serial Number And Emission Plate

- 1.5.4. Travel Reduction Gear Serial Number

- 1.5.5. Cab Serial Number

- 1.6. SERIAL NUMBERS AND DISTRIBUTOR INFORMATION

- 1.6.1. Model CK301

- 1.7. TABLE OF CONTENTS

- 2. SAFETY

- 2.1. SAFETY LABELS

- 2.1.1. Example Of Safety Label Using Words

- 2.1.2. Example Of Safety Label Using Pictogram

- 2.2. SAFETY AND WARNING DECALS

- 2.2.1. Location Of The Safety Decals

- 2.2.2. Decals Defined

- 2.3. SAFETY RULES AND PRECAUTIONS

- 2.3.1. General Safety Rules

- 2.3.2. Safety Features

- 2.3.3. Personal Protective Equipment

- 2.3.4. Unauthorized Modifications

- 2.3.5. Leaving The Operators Seat

- 2.3.6. Mounting And Dismounting

- 2.3.7. Checking The Rearview Mirrors (If Installed)

- 2.3.8. Fire Prevention For Fuel And Oil

- 2.3.9. Preventing Burns

- 2.3.10. Asbestos Dust Hazard Precautions

- 2.3.11. Preventing Accidents Caused By Improper Operation Of The Work Equipment

- 2.3.12. Fire Extinguisher And First Aid Kit

- 2.3.13. Precautions Concerning The Cab Structure

- 2.3.14. Precautions When Using ROPS

- 2.3.15. Precautions Concerning The Equipment

- 2.4. PRECAUTIONS BEFORE STARTING THE ENGINE

- 2.4.1. Safety On The Work Site

- 2.4.2. Fire Prevention

- 2.4.3. Precautions To Be Taken For The Operators Cab

- 2.4.4. Room Ventilation

- 2.4.5. Precautions To Be Taken For The Lights (If Installed)

- 2.4.6. Cleaning The Windows And The Rearview Mirrors Checking The Windshield Wiper Blades

- 2.5. PRECAUTIONS TO BE TAKEN WHEN WORKING

- 2.5.1. Starting The Engine

- 2.5.2. Rules For Traveling In Reverse

- 2.5.3. Moving The Machine

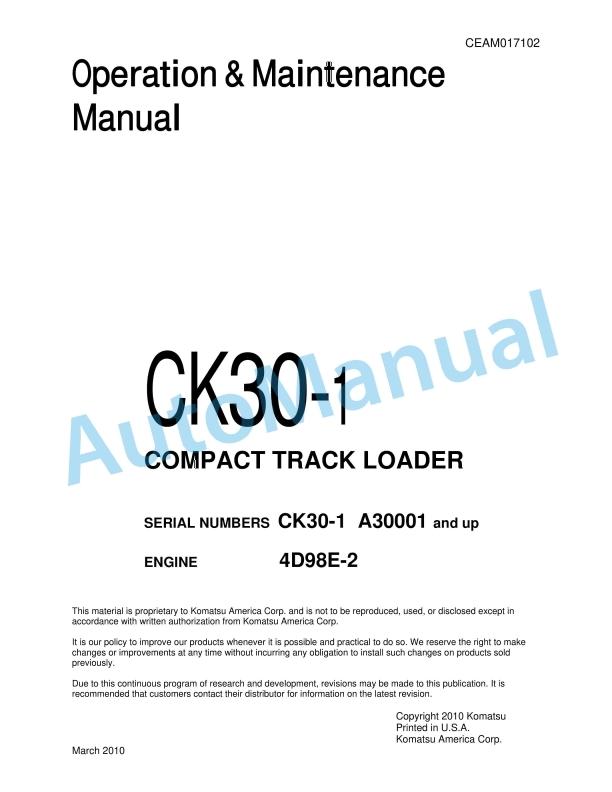

- 2.5.4. Working On Slopes

- 2.5.5. Preventing Electrocution

- 2.5.6. Visibility

- 2.5.7. Working On Icy Or Snowcovered Surfaces

- 2.5.8. Preventing Accidents Caused By The Improper Operation Of The Work Equipment

- 2.5.9. Working On Loose Ground

- 2.5.10. Parking The Machine

- 2.6. TRANSPORTING THE MACHINE

- 2.6.1. Loading And Unloading The Machine

- 2.6.2. The Route

- 2.7. BATTERY

- 2.7.1. Safety Precautions For Work On Batteries

- 2.7.2. Starting With Booster Cables

- 2.7.3. Precautions For Emergency Recovery

- 2.8. PRECAUTIONS DURING MAINTENANCE

- 2.8.1. Warning Tags

- 2.8.2. Tools

- 2.8.3. Personnel

- 2.8.4. Equipment Storage

- 2.8.5. Working Under The Machine

- 2.8.6. Keeping The Machine Clean

- 2.8.7. Engine Operation During Maintenance

- 2.8.8. Critical Parts

- 2.8.9. Stop The Engine Before Carrying Out Any Maintenance Operation Or Inspection

- 2.8.10. Rules For Refueling The Machine

- 2.8.11. Cooling System Precautions

- 2.8.12. Using Lamps

- 2.8.13. Precautions Concerning The Battery And Alternator

- 2.8.14. Precautions Concerning The Starter

- 2.8.15. Precautions Concerning High Pressure Hoses

- 2.8.16. Precautions For Working On High Pressure Systems

- 2.8.17. Precautions For Maintenance Work Involving High Temperatures And Pressures

- 2.8.18. Rotating Parts

- 2.8.19. Precautions To Be Taken When Using Highpressure Grease To Adjust The Rubber Track Tension

- 2.8.20. Do Not Remove The Shock Absorbing Spring From The Shock Absorber Unit

- 2.8.21. Hydraulic Accumulator

- 2.8.22. Disposal Of Waste Materials

- 2.8.23. Hydraulic Environmental Ester Synthetic (HEES) Oil

- 3. OPERATION

- 3.1. SAFETY LOCKS

- 3.1.1. Loader Arm Support

- 3.2. GENERAL VIEWS

- 3.2.1. Front View Of Machine

- 3.2.2. Rear View Of Machine

- 3.2.3. Inside View Of Cab

- 3.3. INSTRUMENTS AND CONTROLS

- 3.3.1. Instruments

- 3.3.2. Indicator Lights

- 3.3.3. Switches And Push Buttons

- 3.3.4. Electrical Accessories

- 3.3.5. Machine Controls

- 3.3.6. ISO Pattern Control System

- 3.3.7. Optional Pattern Control System

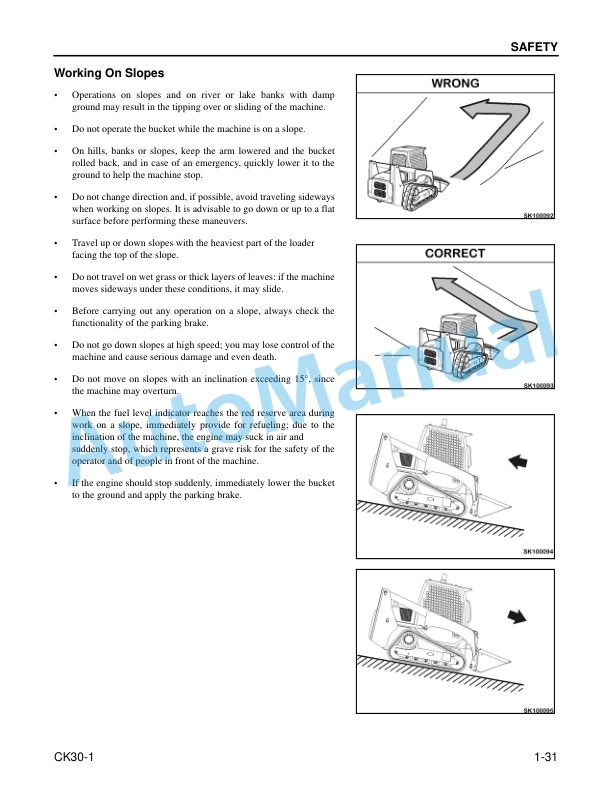

- 3.3.8. Auxiliary Hydraulic Kit Control Pedal (If Installed)

- 3.3.9. Battery Disconnect Switch

- 3.3.10. Fuses And Relays

- 3.4. GUARDS AND OPERATORS SEAT

- 3.4.1. Engine Hood

- 3.4.2. Rear Panel

- 3.5. OPERATING THE MACHINE

- 3.5.1. Checks Before Starting The Engine

- 3.5.2. Starting The Engine

- 3.5.3. Starting The Engine

- 3.5.4. Warming The Engine

- 3.5.5. Heating The Hydraulic Oil

- 3.5.6. Moving The Machine (Iso Pattern Control System)

- 3.5.7. How To Move The Machine (Optional Pattern Control System)

- 3.5.8. Hand And Foot Control System

- 3.5.9. Travel And Steering Control Joysticks

- 3.6. PARKING THE MACHINE

- 3.6.1. Parking On Level Ground

- 3.6.2. Parking On Slopes

- 3.7. STOPPING THE ENGINE

- 3.8. TRANSPORTING THE MACHINE

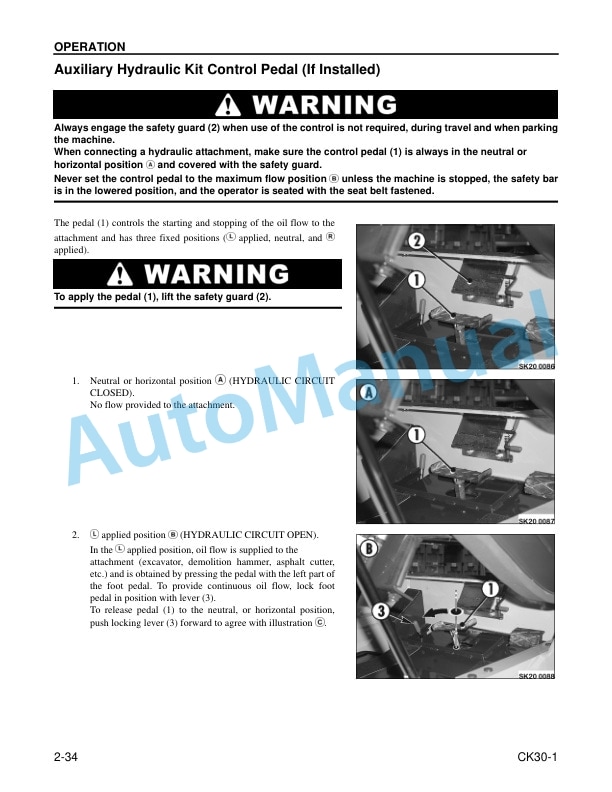

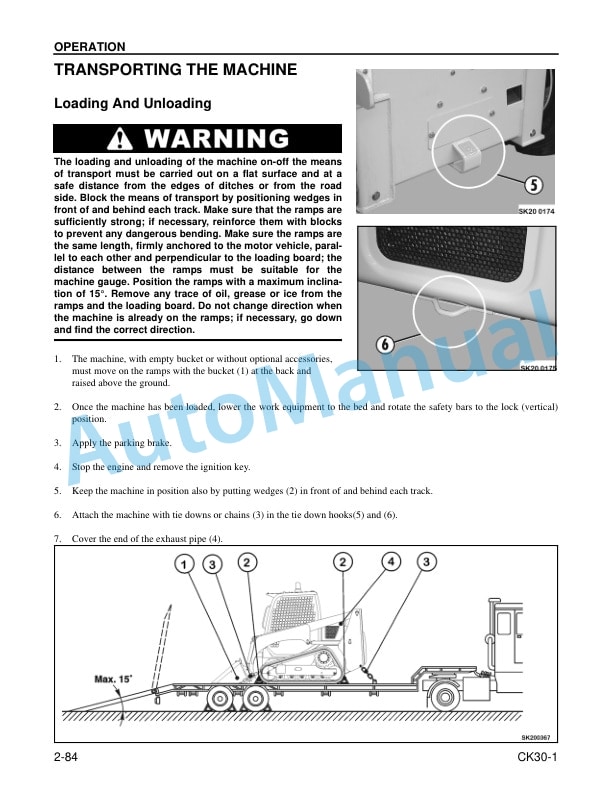

- 3.8.1. Loading And Unloading

- 3.8.2. Transport

- 3.9. HOW TO LIFT THE MACHINE

- 3.10. COLD WEATHER PRECAUTIONS

- 3.10.1. Fuel And Lubricants

- 3.10.2. Coolant

- 3.10.3. Battery

- 3.10.4. Other Precautions

- 3.10.5. Precautions To Be Taken At The End Of Work

- 3.11. WARM WEATHER PRECAUTIONS

- 3.12. OPERATING THE WORK EQUIPMENT

- 3.12.1. Lowering The Equipment In Case Of Machine Failure

- 3.12.2. Organizing The Work Area

- 3.12.3. Loading Heaped And Level Material

- 3.12.4. Loading Operations On Slopes

- 3.12.5. Digging Method

- 3.12.6. Changing The Bucket Or Attachment With Standard Quick Coupler

- 3.12.7. Using The Rubber Tracks

- 3.12.8. Long Periods Of Inactivity

- 3.13. TROUBLESHOOTING

- 3.13.1. How To Move The Machine

- 3.13.2. If The Fuel Has Been Completely Depleted

- 3.13.3. Battery Is Exhausted

- 3.13.4. Other Troubles

- 4. MAINTENANCE

- 4.1. GUIDE TO MAINTENANCE

- 4.2. MAINTENANCE NOTES

- 4.2.1. Notes Regarding The Engine

- 4.2.2. Notes Regarding The Hydraulic System

- 4.2.3. Notes Regarding The Electrical System

- 4.2.4. Notes Regarding Lubrication

- 4.2.5. Parts Subject To Wear That Periodically Need Changing

- 4.3. FUEL, COOLANT AND LUBRICANTS

- 4.3.1. Selection According To The Ambient Temperature

- 4.3.2. Grease

- 4.4. APPROVED SYNTHETIC BIODEGRADABLE LUBRICANTS TYPE HEES

- 4.5. LUBRICATION DIAGRAMS

- 4.5.1. General

- 4.6. PERIODIC REPLACEMENT OF COMPONENTS FOR SAFETY

- 4.6.1. Critical Parts For Safety

- 4.6.2. Super Flow Hydraulic System

- 4.7. TIGHTENING TORQUE

- 4.7.1. Standard Torque For Bolts And Nuts

- 4.7.2. Specific Torques

- 4.8. MAINTENANCE PLAN

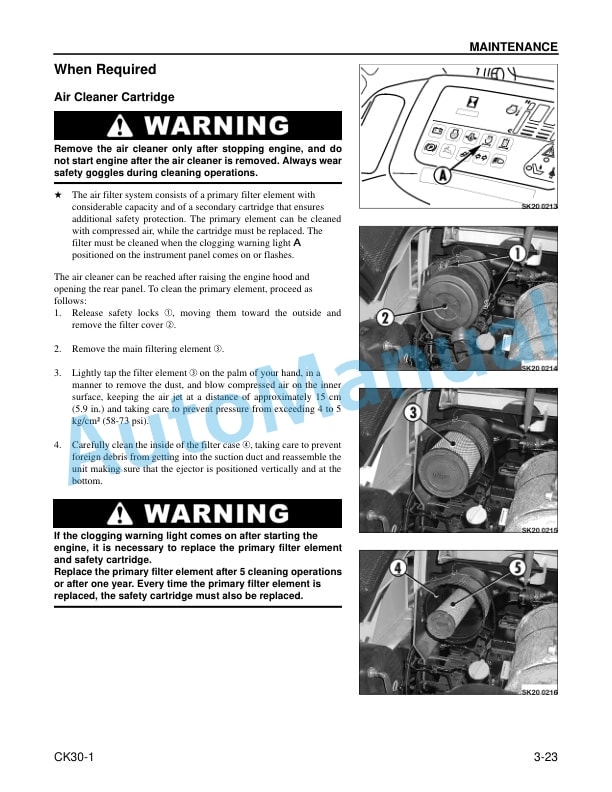

- 4.8.1. When Required

- 4.8.2. Checks Before Starting

- 4.8.3. After The First 50 Hours Of Operation

- 4.8.4. Every 50 Hours Of Operation

- 4.8.5. Maintenance After The First 250 Hours Of Operation

- 4.8.6. Every 250 Hours Of Operation

- 4.8.7. After The First 500 Hours Of Operation

- 4.8.8. Every 500 Hours Of Operation

- 4.8.9. Every 1000 Hours Of Operation

- 4.8.10. Every 2000 Hours Of Operation

- 4.8.11. When Required

- 4.8.12. Checks Before Starting

- 4.8.13. Maintenance After The First 50 Hours Of Operation

- 4.8.14. Maintenance Every 50 Hours Of Operation

- 4.8.15. First 250 Hours Of Operation

- 4.8.16. Every 250 Hours Of Operation

- 4.8.17. Maintenance After The First 500 Hours Of Operation

- 4.8.18. Maintenance Every 500 Hours Of Operation

- 4.8.19. Maintenance Every 1000 Hours Of Operation

- 4.8.20. Maintenance Every 2000 Hours Of Operation

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 5.1.1. Standard Machine Overall Dimensions

- 5.1.2. Technical Specifications

- 6. OPTIONS, ATTACHMENTS

- 6.1. AVAILABLE OPTIONAL ATTACHMENTS

- 6.1.1. Basic Precautions

- 6.1.2. Precautions Regarding The Installation Of Attachments

- 6.1.3. Characteristics Of The Standard Machine With Optional (Factory Supplied) Equipment

- 6.1.4. Characteristics Of The Optional (Factory Supplied) Equipment For The Machine With High Flow And Superflow Hydraulic Systems

- 6.1.5. Changing The Available Attachments

- 6.1.6. Connecting The Hydraulic Circuit

- 6.1.7. Connecting The Return Circuit With Direct Drainage Into The Tank

- 6.1.8. Preparing The Machine For Use With The Excavator

- 6.1.9. Using The Machine With The Excavator

- 6.1.10. Pallet Forks

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716