Komatsu D575A-2 Bull Dozer Operation and Maintenance Manual SEAMN02501

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: SEAMN02501

- Format: PDF

- Size: 13.1MB

- Number of Pages: 260

-

Model List:

- D575A-2 Bull Dozer

- 1. COVER

- 2. FOREWORD

- 3. SAFETY INFORMATION

- 4. INTRODUCTION

- 4.1. INTENDED USE

- 4.2. FEATURES

- 4.3. BREAKING IN THE MACHINE

- 5. LOCATION OF PLATES,TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 5.1. MACHINE SERIAL NO. PLATE POSITION

- 5.2. ENGINE SERIAL NO. PLATE POSITION

- 5.3. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 6. CONTENTS

- 7. SAFETY

- 7.1. GENERAL PRECAUTIONS

- 7.2. PRECAUTIONS DURING OPERATION

- 7.2.1. BEFORE STARTING ENGINE

- 7.2.2. AFTER STARTING ENGINE

- 7.2.3. BATTERY

- 7.3. PRECAUTIONS FOR MAINTENANCE

- 7.3.1. BEFORE CARRYING OUT MAINTENANCE

- 7.3.2. DURING MAINTENANCE

- 7.4. POSITION FOR ATTACHING SAFETY LABELS

- 8. OPERATION

- 8.1. GENERAL VIEW

- 8.1.1. GENERAL VIEW OF MACHINE

- 8.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 8.2. EXPLANATION OF COMPONENTS

- 8.2.1. FRONT RANEL

- 8.2.2. SWITCHES

- 8.2.3. CONTROL LEVERS AND PEDALS

- 8.2.4. FUSE BOX

- 8.2.5. DOOR LOCK

- 8.2.6. CAP WITH LOCK

- 8.2.7. HANDLING OF ENGINE OIL FILTER CAP

- 8.2.8. OPERATING THE CAR STEREO

- 8.2.9. OPERATING THE AIR CONDITIONER

- 8.2.10. CONTROLLER

- 8.3. OPERATION

- 8.3.1. CHECK BEFORE STARTING ENGINE

- 8.3.2. STARTING ENGINE

- 8.3.3. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 8.3.4. MOVING MACHINE

- 8.3.5. SHIFTING GEAR

- 8.3.6. SHIFTING BETWEEN FORWARD AND REVERSE

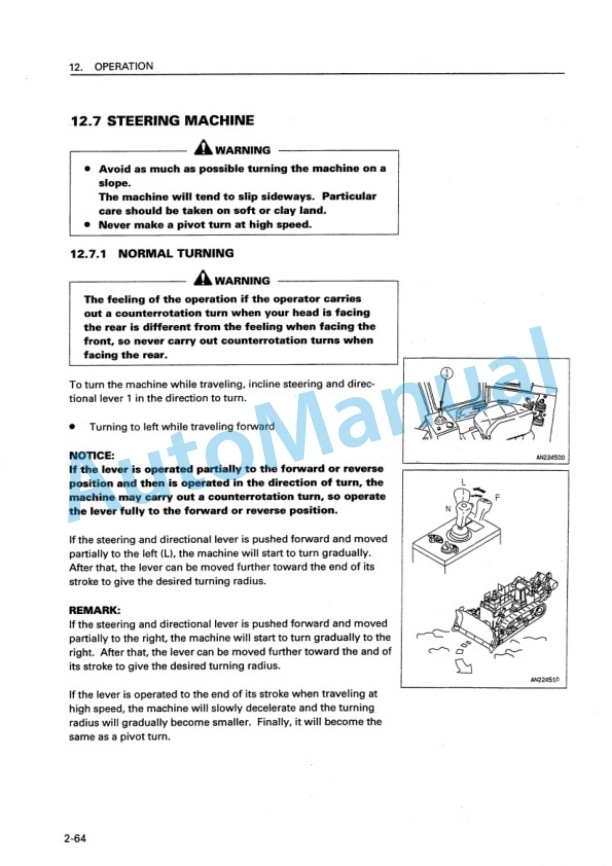

- 8.3.7. STEERING MACHINE

- 8.3.8. STOPPING MACHINE

- 8.3.9. PRECAUTIONS FOR OPERATION

- 8.3.10. WORK POSSIBLE USING BULLDOZER

- 8.3.11. EFFECTIVE METHOD OF OPERATION FOR DUAL TILT DOZER

- 8.3.12. OPERATING RIPPER

- 8.3.13. ADJUSTMENT OF WORK EQUIPMENT

- 8.3.14. PARKING MACHINE

- 8.3.15. CHECK AFTER FINISHING WORK

- 8.3.16. STOPPING ENGINE

- 8.3.17. CHECK AFTER STOPPING ENGINE

- 8.3.18. LOCKING

- 8.3.19. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 8.4. HANDLING ACCUMULATOR

- 8.4.1. RELEASING REMAINING PRESSURE IN ACCUMULATOR CIRCUIT

- 8.5. COLD WEATHER OPERATION

- 8.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 8.5.2. AFTER COMPLETION OF WORK

- 8.5.3. AFTER COLD WEATHER

- 8.6. LONGTERM STORAGE (MODE THAN ONE MONTH)

- 8.6.1. BEFORE STORAGE

- 8.6.2. DURING STORAGE

- 8.6.3. AFTER STORAGE

- 8.7. TROUBLESHOOTING

- 8.7.1. AFTER RUNNING OUT OF FUEL

- 8.7.2. IF BATTERY IS DISCHARGED

- 8.7.3. OTHER TROUBLE

- 8.7.4. WHEN MODE SELECTION SYSTEM CAUTION LAMP FLASHES

- 9. MAINTENANCE

- 9.1. GUIDES TO MAINTENANCE

- 9.2. OUTLINES OF SERVICE

- 9.2.1. OUTLINE OF OIL,FUEL,COOLANT

- 9.2.2. RELATING TO ELECTRIC SYSTEM

- 9.3. WEAR PARTS LIST

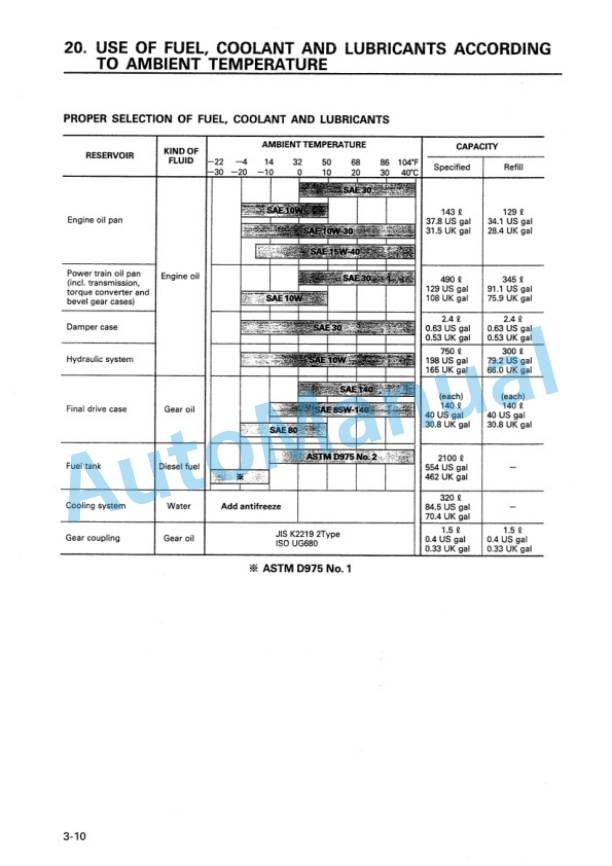

- 9.4. USE OF FUEL,COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 9.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 9.5.1. INTRODUCTION OF NECESSARY TOOLS

- 9.5.2. TORQUE LIST

- 9.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 9.7. MAINTENANCE SCHEDULE CHART

- 9.7.1. MAINTENANCE SCHEDULE CHART

- 9.8. SERVICE PROCEDURE

- 9.8.1. INITIAL 250 HOURS SERVICE

- 9.8.2. WHEN REQUIRED

- 9.8.3. CHECK BEFORE STARTING

- 9.8.4. EVERY 250 HOURS SERVICE

- 9.8.5. EVERY 500 HOURS SERVICE

- 9.8.6. EVERY 1000 HOURS SERVICE

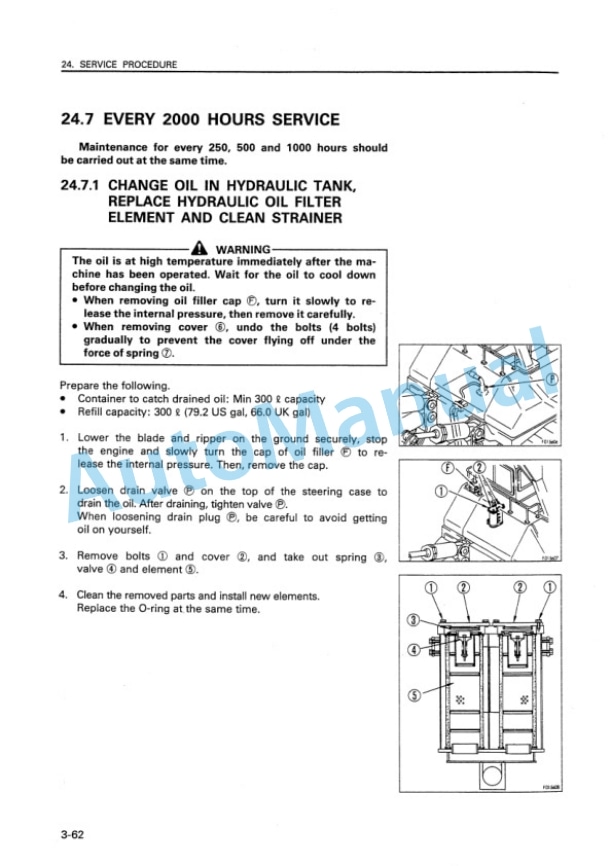

- 9.8.7. EVERY 2000 HOURS SERVICE

- 9.8.8. EVERY 4000 HOURS SERVICE

- 10. SPECIFICATIONS

- 10.1. SPECIFICATIONS

- 11. OPTIONS,ATTACHMENTS

- 11.1. GENERAL PRECAUTIONS

- 11.1.1. PRECAUTIONS RELATED TO SAFETY

- 11.2. USING SEAT BELT

- 11.2.1. FASTEN THE BELT AND REMOVE IT IN THE FOLLOWING MANNER

- 12. RADIOCONTROLLED BULLDOZER

- 12.1. RADIOCONTROLLED BULLDOZER

- 12.1.1. TO THE USER

- 12.1.2. GENERAL LOCATIONS

- 12.1.3. INSTRUMENTS AND CONTROLS

- 12.1.4. MAIN COMPONENTS OF RADIO CONTROL

- 12.1.5. TRANSMITTER CONTROL PANEL (OPERATING PANEL)

- 12.1.5.1. BATTERY

- 12.1.5.2. OPERATING SWITCHES

- 12.1.6. RECEIVER CONTROL DEVICE (RECEIVER)

- 12.1.6.1. GENERAL LOCATIONS OF RECEIVER

- 12.1.6.2. POWER SOURCE AND FUSE RELATED PARTS FOR RADIO CONTROL SYSTEM

- 12.1.6.3. RECEPTION ANTENNA

- 12.1.6.4. ANTENNA CABLE

- 12.1.7. RECEIVER CHECKER LED OPERATION TABLE

- 12.1.8. WIRELESS SYSTEM USING TRANSMITTER AND RECEIVER

- 12.1.9. CHARGER,ADAPTER

- 12.1.10. AUTOMATIC MACHINE SUPERVISOR AND ALARMS

- 12.1.11. PROTECTIVE AND SAFETY FUNCTIONS

- 12.1.12. METHOD OF FITTING CONTROL PANEL

- 12.1.13. PROCEDURE FOR RADIOCONTROLLED OPERATION

- 12.1.14. POINTS TO REMEMBER FOR RADIOCONTROLLED OPERATION

- 12.1.15. TROUBLESHOOTING DEVICE FOR RADIO CONTROL SYSTEM (OK MONITOR)

- 12.1.16. TROUBLESHOOTING LAMPS FOR CONTROL PANEL

- 12.1.17. TROUBLESHOOTING OF RECEIVER

- 12.1.18. SWITCHING BETWEEN RADIOCONTROLLED OPERATION AND DIRECT OPERATION

- 12.1.18.1. PROCEDURE FOR RADIOCONTROLLED OPERATION

- 12.1.18.2. PROCEDURE FOR DIRECT OPERATION

- 12.1.19. RADIO CONTROL OPERATIONS

- 12.1.19.1. PRECAUTIONS BEFORE STARTING OPERATION

- 12.1.19.2. PROCEDURE FOR RADIOCONTROLLED OPERATION

- 12.1.19.3. MOVING MACHINE

- 12.1.19.4. EFFECTIVE METHOD OF WING MODE SELECTION SYSTEM

- 12.1.19.5. MISCELLANEOUS CONTROL

- 12.1.20. INSPECTION AND MAINTENANCE OF RADIO CONTROL DEVICE

- 12.1.20.1. PERIODIC MAINTENANCE TABLE

- 12.1.20.2. EVERY 250 HOURS SERVICE

- 12.1.20.3. EVERY 1000 HOURS SERVICE

- 12.1.21. TROUBLESHOOTING GUIDE

- 12.1.22. SPECIFICATIONS

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM020001