Komatsu PC210-10, PC210LC-10, PC210-10 Demolition Base Spec, PC210LC-10 Demolition Base Spec Hydraulic Excavator Operation and Maintenance Manual UENAM00902

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: UENAM00902

- Format: PDF

- Size: 37.5MB

- Number of Pages: 458

-

Model List:

- PC210-10 Demolition Base Spec PC210LC-10 Demolition Base Spec Hydraulic Excavator

- PC210LC-10 Demolition Base Spec PC210LC-10 Demolition Base Spec Hydraulic Excavator

- PC210-10 Demolition Base Spec PC210LC-10 Demolition Base Spec Hydraulic Excavator

- 1. FOREWORD

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.3. INTRODUCTION

- 1.4. PRODUCT INFORMATION

- 1.5. Contents

- 2. SAFETY

- 2.1. Safety

- 2.2. SAFETY LABELS

- 2.3. General precautions common to operation and maintenance

- 2.4. Precautions for operation

- 2.5. SAFETY MACHINE OPERATION

- 2.6. Precautions for maintenance

- 3. OPERATION

- 3.1. General view

- 3.2. Explanation of components

- 4. Engine preheating monitor

- 5. Swing Lock Monitor

- 6. Wiper Monitor

- 7. Autodeceleration Monitor

- 8. Working mode monitor

- 9. Travel Speed Monitor

- 10. OneTouch Power Max. Monitor

- 11. Air Conditioner Monitor

- 12. MESSAGE MONITOR

- 13. SEAT BELT MONITOR

- 14. ENGINE STOP MONITOR

- 15. KDPF REGENERATION MONITOR

- 16. KDPF REGENERATION STOP MONITOR

- 17. ECO GUIDANCE

- 17.1. Gauges and Meter

- 18. Engine coolant temperature gauge

- 19. HYDRAULIC OIL TEMPERATURE GAUGE

- 20. FUEL GAUGE

- 21. Service meter or clock

- 22. ECO GAUGE

- 23. FUEL CONSUMPTION GAUGE

- 23.1. MONITOR SWITCH PORTION

- 23.2. HANDLING FUNCTION SWITCHES

- 23.3. USER MENU SELECTOR SWITCH

- 24. Attachment 2 Setting

- 24.1. KDPF REGENERATION

- 24.2. MAINTENANCE SCREEN SETTING

- 25. Monitor setting

- 26. SCREEN ADJUSTMENT

- 27. CLOCK ADJUSTMENT

- 28. LANGUAGE SELECTION

- 29. MESSAGE DISPLAY

- 29.1. SWITCHES

- 29.2. CONTROL LEVERS AND PEDALS

- 29.3. CEILING WINDOW

- 29.4. Opening and closing cab front window

- 29.5. Emergency escape hammer

- 29.6. Door lock

- 29.7. Cab door hinge

- 29.8. Opening and closing engine hood

- 29.9. Caps and covers with lock

- 29.10. Drink box

- 29.11. Magazine box

- 29.12. Cup holder

- 29.13. Ashtray

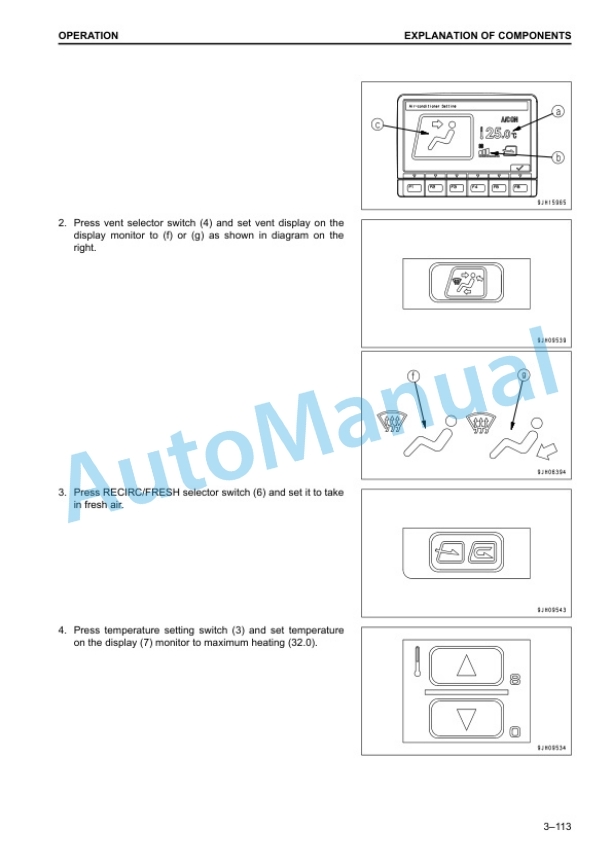

- 29.14. Handling air conditioner

- 29.15. Handling radio

- 29.16. SPACE FOR RADIO CASSETTE

- 29.17. Auxiliary electric power

- 29.18. Fuse

- 29.19. Fusible link

- 29.20. controller

- 29.21. Tool box

- 29.22. Grease pump holder

- 29.23. Fire extinguisher

- 29.24. BATTERY DISCONNECT SWITCH

- 29.25. System operating lamp

- 29.26. Handling KDPF

- 29.27. Handling KCCV

- 29.28. Handling machines equipped with KOMTRAX

- 29.29. Machine operations and controls

- 30. Adjusting drain valve

- 30.1. CHECK OIL LEVEL IN HYDRAULIC TANK, ADD OIL

- 30.2. CHECK COOLANT LEVEL, ADD COOLANT

- 30.3. CHECK OIL LEVEL IN ENGINE OIL PAN, ADD OIL

- 30.4. Check Electric Wiring

- 30.5. CHECK FUEL LEVEL, ADD FUEL

- 30.6. Check Working Lamp Switch

- 30.7. CHECK HORN FUNCTION

- 30.8. Adjustment

- 30.9. SEAT BELT

- 30.10. OPERATIONS AND CHECKS BEFORE STARTING ENGINE

- 30.11. STARTING ENGINE

- 30.12. OPERATIONS AND CHECKS AFTER STARTING ENGINE

- 30.13. STOPPING ENGINE

- 30.14. MACHINE OPERATION

- 30.15. Steering machine

- 30.16. SWINGING MACHINE

- 30.17. WORK EQUIPMENT CONTROLS AND OPERATIONS

- 30.18. WORKING MODE

- 30.19. Prohibited operations

- 30.20. RULES FOR OPERATION

- 30.21. Travelling on slopes

- 30.22. ESCAPE FROM MUD

- 30.23. RECOMMENDED APPLICATIONS

- 30.24. REPLACING AND INVERTING BUCKET

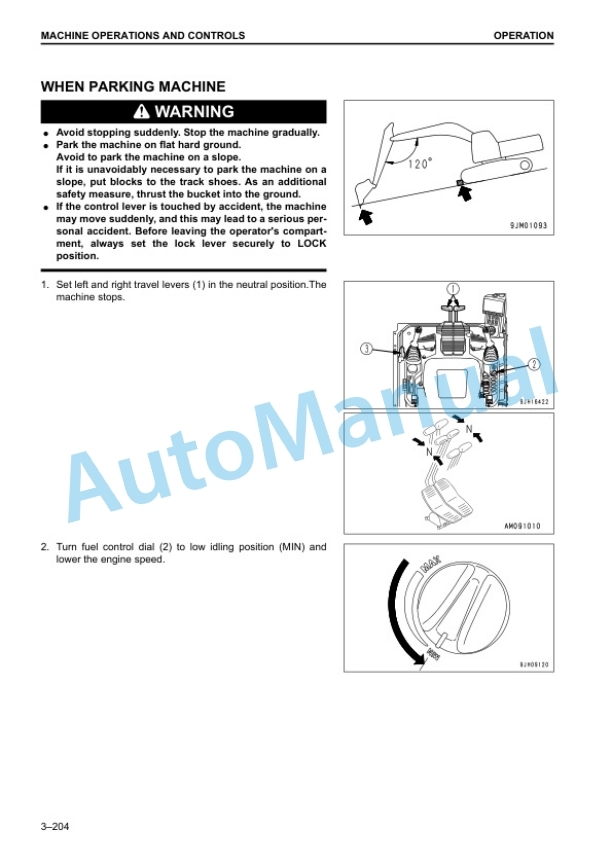

- 30.25. When parking machine

- 30.26. After daily work completion

- 30.27. LOCKING

- 30.28. TRANSPORTATION

- 30.29. COLD WEATHER OPERATION

- 30.30. LONGTERM STORAGE

- 30.31. Troubles and actions

- 31. MAINTENANCE

- 31.1. Rules for maintenance

- 31.2. Outline of service

- 31.3. Standard tightening torque for bolts and nuts

- 31.4. Maintenance schedule

- 31.5. MAINTENANCE SCHEDULE TABLE

- 32. Increase track tension

- 33. Loosen track tension

- 33.1. REPLACE BUCKET TEETH (VERTICAL PIN TYPE)

- 33.2. REPLACE BUCKET TEETH (HORIZONTAL PIN TYPE)

- 33.3. ADJUST BUCKET CLEARANCE

- 33.4. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 33.5. CHECK AND MAINTENANCE AIR CONDITIONER

- 33.6. WASH WASHABLE FLOOR

- 34. USE SLOPE

- 35. USE BLOCK

- 35.1. CHECK GAS SPRING

- 35.2. BLEED AIR FROM HYDRAULIC CIRCUIT

- 35.3. CHECKS BEFORE STARTING

- 35.4. EVERY 100 HOURS MAINTENANCE

- 35.5. EVERY 250 HOURS MAINTENANCE

- 35.6. EVERY 500 HOURS MAINTENANCE

- 35.7. EVERY 1000 HOURS MAINTENANCE

- 35.8. EVERY 2000 HOURS MAINTENANCE

- 35.9. EVERY 4000 HOURS MAINTENANCE

- 35.10. EVERY 4500 HOURS MAINTENANCE

- 35.11. EVERY 5000 HOURS MAINTENANCE

- 35.12. EVERY 8000 HOURS MAINTENANCE

- 35.13. END OF SERVICE LIFE

- 36. SPECIFICATIONS

- 36.1. SPECIFICATIONS

- 37. ATTACHMENTS AND OPTIONS

- 37.1. GENERAL PRECAUTIONS FOR SAFETY

- 37.2. HANDLING QUICK COUPLER

- 37.3. AUTOMATIC GREASE SYSTEM

- 37.4. Bucket with hook

- 37.5. Machine ready for installation of attachment

- 37.6. ATTACHMENTS AND OPTIONS

- 37.7. RECOMMENDED ATTACHMENT OPERATIONS

- 38. Replacement parts

- 38.1. SAFETY CRITICAL PARTS

- 38.2. Consumable parts

- 38.3. RECOMMENDED FUEL, COOLANT, AND LUBRICANT

- 39. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45