Komatsu PC290LC-10 Hydraulic Excavator Operation and Maintenance Manual CEAM025305

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM025305

- Format: PDF

- Size: 24.1MB

- Number of Pages: 394

-

Model List:

- PC290LC-10 Hydraulic Excavator

- 1. Operation and Maintenance Manual, PC290LC10

- 1.1. Contents

- 1.2. INTRODUCTION

- 1.2.1. Foreword

- 1.2.2. Safety Alert Symbol and Signal Words

- 1.2.3. Basic Machine Introduction

- 1.2.4. Product Information

- 1.3. SAFETY

- 1.3.1. Safety Labels

- 1.3.1.1. Location of Safety Labels

- 1.3.2. General Precautions Common to Operation and Maintenance

- 1.3.2.1. Precautions Before Starting Operation

- 1.3.2.2. Preparations for Safe Operation

- 1.3.2.3. Fire and Explosion Prevention

- 1.3.2.4. Precautions When Getting On or Off the Machine

- 1.3.2.5. Precautions for Cab and Working Around Machine

- 1.3.3. Operation Precautions

- 1.3.3.1. Precautions at Jobsite

- 1.3.3.2. Precautions in Starting Engine

- 1.3.3.3. Precautions During Operation

- 1.3.3.4. Transportation Safety

- 1.3.3.5. Lifting Objects With Bucket

- 1.3.4. Maintenance Precautions

- 1.3.4.1. Precautions Before Inspection and Maintenance

- 1.3.4.2. Precautions During Inspection and Maintenance

- 1.4. OPERATION

- 1.4.1. Visual Overview of Machine

- 1.4.1.1. General Machine View

- 1.4.1.2. General View of Cab

- 1.4.1.3. Controls and Gauges

- 1.4.1.4. Machine Monitor Overview

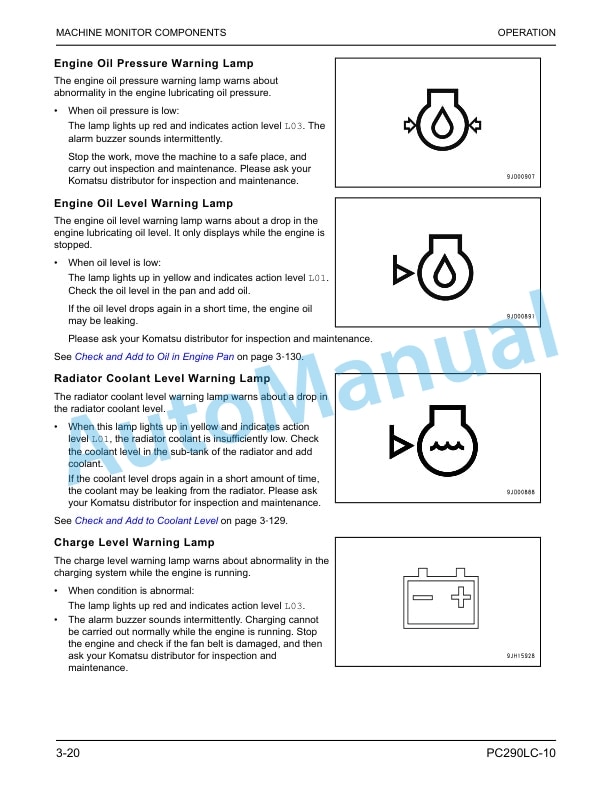

- 1.4.2. Machine Monitor Components

- 1.4.2.1. Basic Operation of Machine Monitor

- 1.4.2.2. Warning Lamps

- 1.4.2.3. Pilot Display

- 1.4.2.4. Gauge and Meter Display

- 1.4.2.5. Monitor Switches

- 1.4.2.6. User Menu

- 1.4.3. Operator Cab Switches

- 1.4.4. Control Levers and Pedals

- 1.4.5. Air Conditioner Operations

- 1.4.5.1. Air Conditioner Control Switches and Sensor

- 1.4.5.2. Using A/C in Auto Mode

- 1.4.5.3. Using A/C in Manual Mode

- 1.4.5.4. Blowing Cold Air to Face, Warm Air to Feet

- 1.4.5.5. Using Defrost Mode

- 1.4.6. Radio Operations

- 1.4.6.1. Radio Buttons and Display

- 1.4.6.2. Radio Setting and Adjusting

- 1.4.7. Auxiliary Electric Power

- 1.4.8. Fuses

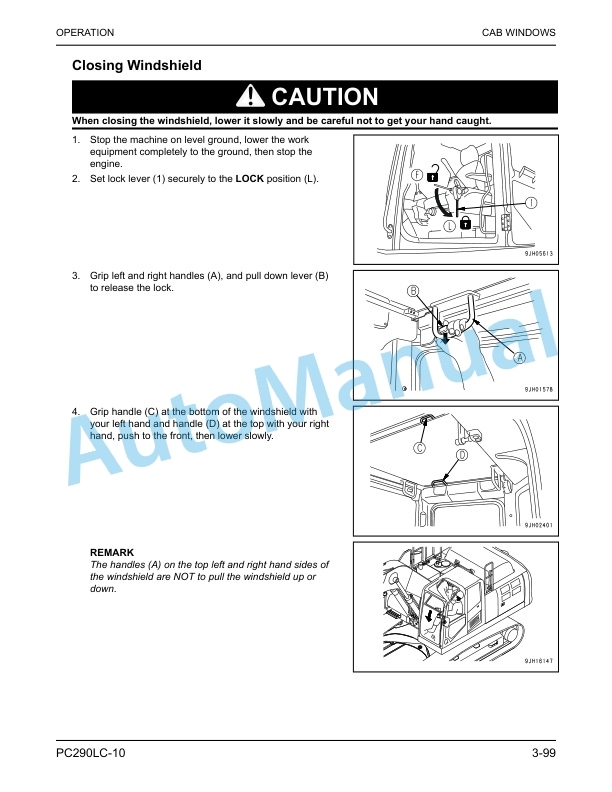

- 1.4.9. Cab Windows

- 1.4.9.1. Opening and Closing Roof Window

- 1.4.9.2. Opening and Closing Windshield

- 1.4.10. Cab Door

- 1.4.11. Containers and Fire Extinguisher

- 1.4.12. Engine Hood

- 1.4.12.1. Opening Engine Hood

- 1.4.12.2. Closing Engine Hood

- 1.4.13. Caps and Covers with Lock

- 1.4.13.1. Open and Close Caps with Locks

- 1.4.13.2. Open and Close Covers with Locks

- 1.4.13.3. Lock and Unlock Engine Hood

- 1.4.13.4. Lock and Unlock the Cab Door

- 1.4.14. Battery Disconnect Switch

- 1.4.15. System Operating Lamp

- 1.4.16. Komatsu Diesel Particulate Filter (KDPF)

- 1.4.16.1. Manual Stationary Regeneration Procedure

- 1.4.16.2. KDPF Regeneration Disable Procedure

- 1.4.16.3. Canceling KDPF Regeneration Disable

- 1.4.17. Komatsu Closed Crankcase Ventilation (KCCV)

- 1.4.18. KOMTRAX

- 1.4.19. Daily Checks and Preparations Before Starting Engine

- 1.4.19.1. WalkAround Checks

- 1.4.19.2. Drain Water and Sediment from Fuel Tank

- 1.4.19.3. Drain Water and Sediment in Water Separator

- 1.4.19.4. Check and Add to Oil Level in Hydraulic Tank

- 1.4.19.5. Check and Add to Coolant Level

- 1.4.19.6. Check and Add to Oil in Engine Pan

- 1.4.19.7. Check Electrical Wiring

- 1.4.19.8. Check and Add to Fuel Level

- 1.4.19.9. Check Working Lamp Switch

- 1.4.19.10. Check Horn Function

- 1.4.19.11. Preparing to Use Operators Cab

- 1.4.20. Starting the Engine

- 1.4.20.1. Turbo Protect Function

- 1.4.21. Operations and Checks After Starting the Engine

- 1.4.21.1. Engine WarmUp

- 1.4.21.2. Hydraulic System WarmUp

- 1.4.22. Stopping the Engine

- 1.4.23. Moving and Steering Machine

- 1.4.23.1. Moving Machine Forward

- 1.4.23.2. Moving Machine Backwards

- 1.4.23.3. Stopping the Machine

- 1.4.23.4. Steering the Machine

- 1.4.23.5. Swinging the Machine

- 1.4.24. Operating Work Equipment

- 1.4.25. Working Mode

- 1.4.25.1. Operating the Working Mode Selector Switch

- 1.4.26. Prohibited Operations

- 1.4.27. Rules for Traveling

- 1.4.27.1. Traveling on Slopes

- 1.4.28. Recommended Applications

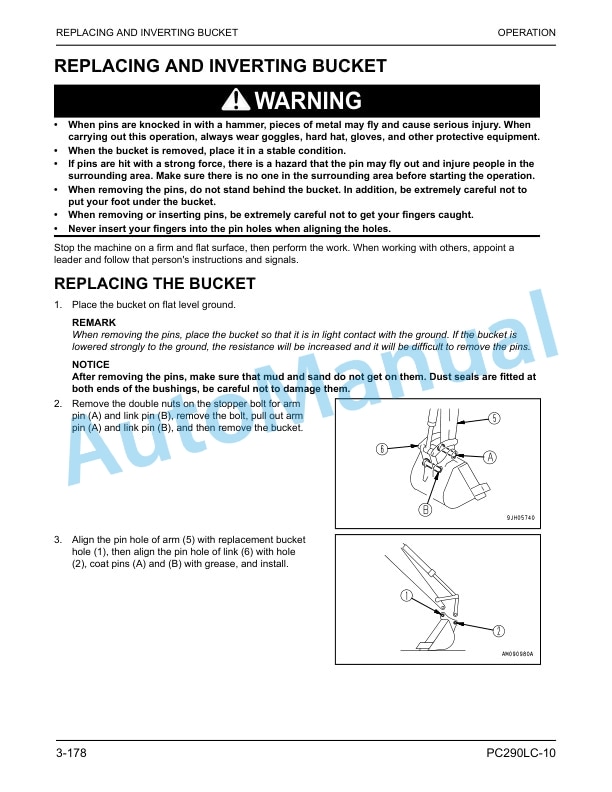

- 1.4.29. Replacing and Inverting Bucket

- 1.4.29.1. Replacing the Bucket

- 1.4.29.2. Inverting the Bucket

- 1.4.30. Parking Machine

- 1.4.31. After Finishing Work

- 1.4.31.1. Checks After Finishing Daily Work

- 1.4.31.2. Locking the Machine

- 1.4.32. Transporting the Machine

- 1.4.32.1. Loading and Unloading with Trailer

- 1.4.32.2. Lifting Machine

- 1.4.33. Cold Weather Operation

- 1.4.34. LongTerm Storage of Machine

- 1.4.35. Common Phenomena That are Not Failures

- 1.4.36. Towing Machine

- 1.4.37. Towing with Machine

- 1.4.38. Disconnect and Charge Battery

- 1.4.39. Jumper Cables to Start Engine

- 1.4.39.1. Attaching Jumper Cables to Machine

- 1.4.39.2. Start Engine with Jumper Cables Attached

- 1.4.39.3. Disconnect Jumper Cables from Machine

- 1.4.40. Troubleshooting Common Troubles and Actions to Take

- 1.4.40.1. Error List Screen

- 1.5. MAINTENANCE

- 1.5.1. Rules for Maintenance

- 1.5.2. Outline of Service

- 1.5.2.1. Handling Oil, Fuel, Coolant, and Performing Oil Clinic

- 1.5.2.2. Handling Electrical Components

- 1.5.3. Wear Parts

- 1.5.4. Safety Critical Parts

- 1.5.5. Torque Specifications

- 1.5.6. Recommended Fuel, Coolant, and Lubricant

- 1.5.7. Hydraulic Breaker Maintenance Interval

- 1.5.8. Maintenance Schedule

- 1.5.8.1. Maintenance Schedule Table

- 1.5.9. Maintenance Procedures

- 1.5.9.1. New Machine Maintenance

- 1.5.9.2. Air Cleaner Element Maintenance

- 1.5.9.3. Cooling System Cleaning

- 1.5.9.4. Track Shoe Bolts

- 1.5.9.5. Track Tension Inspection

- 1.5.9.6. Track Tension Increase

- 1.5.9.7. Track Tension Decrease

- 1.5.9.8. Vertical Pin Bucket Teeth Replacement

- 1.5.9.9. Horizontal Pin Bucket Teeth Replacement

- 1.5.9.10. Bucket Clearance Adjustment

- 1.5.9.11. Window Washer Fluid Level And Mixture Ratio

- 1.5.9.12. Air Conditioner Maintenance

- 1.5.9.13. Washable Cab Floor and Floor Mat

- 1.5.9.14. Setting Machine at Angle

- 1.5.9.15. Gas Spring Maintenance

- 1.5.9.16. Bleeding Air From Hydraulic System

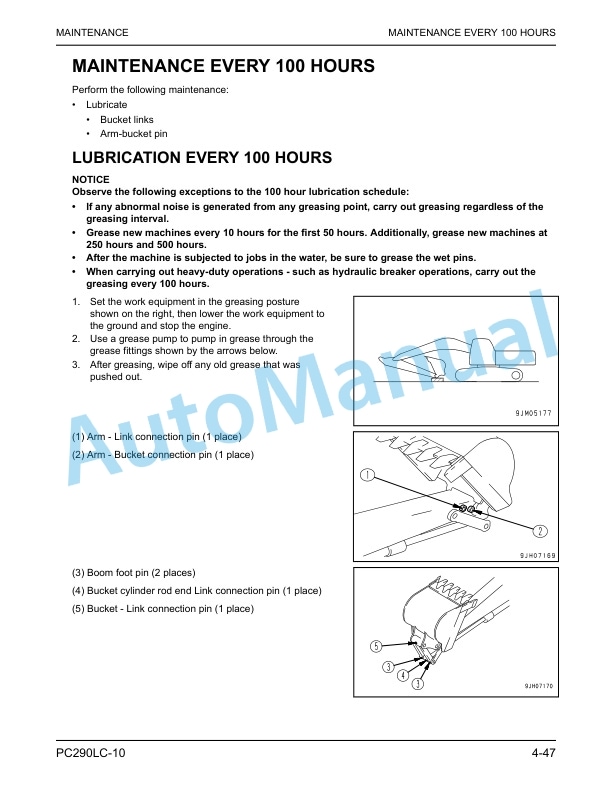

- 1.5.10. Maintenance Every 100 Hours

- 1.5.10.1. Lubrication Every 100 Hours

- 1.5.11. Maintenance Every 250 Hours

- 1.5.11.1. Battery Electrolyte Level Check

- 1.5.11.2. Air Conditioner Compressor Belt Check and Tension Adjustment

- 1.5.12. Maintenance Every 500 Hours

- 1.5.12.1. Lubrication Every 500 Hours

- 1.5.12.2. Engine Oil and Filter Cartridge Replacement

- 1.5.12.3. Fuel Prefilter Cartridge Replacement

- 1.5.12.4. Swing Pinion Grease Level

- 1.5.12.5. Radiator, Cooler, and Condenser Fins Maintenance

- 1.5.12.6. Recirculated Filter and Fresh Air Filter Maintenance

- 1.5.12.7. Hydraulic Tank Breather Element Replacement

- 1.5.12.8. Swing Machinery Case Oil Level

- 1.5.12.9. Final Drive Case Oil Level

- 1.5.13. Maintenance Every 1000 Hours

- 1.5.13.1. Hydraulic Oil Filter Element Replacement

- 1.5.13.2. Swing Machinery Case Oil Change

- 1.5.13.3. Damper Case Oil Level

- 1.5.13.4. Fuel Main Filter Cartridge Replacement

- 1.5.14. Maintenance Every 2000 Hours

- 1.5.14.1. Final Drive Case Oil Change

- 1.5.14.2. Hydraulic Tank Strainer Cleaning

- 1.5.14.3. Accumulator Nitrogen Gas Pressure

- 1.5.14.4. KCCV Filter Element Replacement

- 1.5.15. Maintenance Every 4000 Hours

- 1.5.15.1. Water Pump Check

- 1.5.15.2. Vibration Damper Check

- 1.5.15.3. Accumulator Replacement (Control Circuit)

- 1.5.15.4. High Pressure Mounting Checks

- 1.5.15.5. Fuel Spray Prevention Cap Check

- 1.5.16. Maintenance Every 4500 Hours

- 1.5.17. Maintenance Every 5000 Hours

- 1.5.17.1. Hydraulic Tank Oil Change

- 1.5.18. Maintenance Every 8000 Hours

- 1.6. SPECIFICATIONS

- 1.6.1. Specifications

- 1.7. OPTIONS, ATTACHMENTS

- 1.7.1. General Precautions for Safety

- 1.7.2. Machine Options

- 1.7.2.1. Straight Travel Pedal

- 1.7.2.2. Machine Control Pattern

- 1.7.3. Machine Attachments

- 1.7.3.1. Explanation of Attachment Components

- 1.7.3.2. Hydraulic Circuit

- 1.7.3.3. Attachment Guide

- 1.7.3.4. Attachment Operations

- 1.8. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103