Komatsu PC3000-1 Hydraulic Mining Excavator Operation and Maintenance Manual OMPC30006202

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: OMPC30006202

- Format: PDF

- Size: 13.9MB

- Number of Pages: 378

-

Model List:

- PC3000-1 Hydraulic Mining Excavator

- 1. Main Menu

- 2. Cover

- 3. Introduction

- 4. Part 1 Operation Manual

- 4.1. Table of Contents Operation Manual

- 4.2. Section A Explanation of Abbreviations Used in this Manual

- 4.3. Section 1.0 Foreward

- 4.4. Section 2.0 Construction of the Excavator

- 4.4.1. Overall View

- 4.4.2. Superstructure

- 4.4.3. Attachment

- 4.5. Section 3.0 Safety Instructions

- 4.5.1. Fundamental Safety Instructions

- 4.5.2. Safety Harness

- 4.6. Section 3.1 Ladder, Walkways, and Access Doors

- 4.6.1. Superstructure

- 4.6.2. Sea Protection Covers

- 4.7. Section 3.2 Transport of Excavator

- 4.7.1. Short Transport with Calm Sea Conditions Drawing

- 4.7.2. Long Transport with Rough Sea Conditions Drawing

- 4.7.3. Location of Plug Socket for Hydraulic Oil Heating System

- 4.8. Section 3.3 Operators Seat

- 4.9. Section 4.0 Operators Cab Controls and Monitors

- 4.9.1. Control Levers and Control Pedals

- 4.9.2. Safety Circuit for Controls

- 4.9.3. Switch Board

- 4.9.4. Instruments and Pontoon Controls

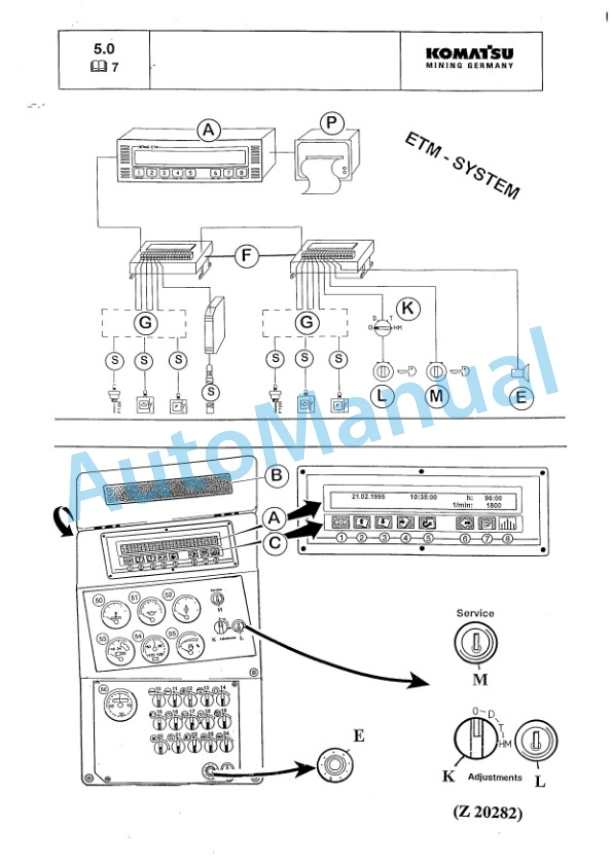

- 4.10. Section 5.0 Electronic Text Monitoring System Komatsu ETM

- 4.10.1. Introduction

- 4.11. Section 5.1 Power House Controls

- 4.12. Section 5.2 Electrical Equipment in Cab Base

- 4.12.1. Main Switch X2 in Cab Base

- 4.12.2. Diagnostic Fault Codes of Engine Centry System

- 4.12.3. Switch Box X7 for Cab Heating and Air Conditioning

- 4.13. Section 5.3 Preheating System for Hydraulic Oil

- 4.13.1. General

- 4.13.2. Operating the Heating System

- 4.14. Section 5.4 Engine Oil Management System

- 4.14.1. General

- 4.14.2. Centinel Diagnostic Lamps

- 4.14.3. Check Centinel Diagnostic Lamps for Faults

- 4.14.4. Clearing Active Faults and Reset the Centinel System

- 4.14.5. Resetting the Centinel System is Necessary

- 4.14.6. Check the Centinel System for Proper Operation

- 4.14.7. Calibration Plug for Engine Oil Quality

- 4.14.8. Oil Burning System Centinel Combined with Reverse System

- 4.14.9. Eliminator Engine Oil Filter

- 4.15. Section 5.5 Operators Cab Arrangement of Components

- 4.16. Section 6.1 Ceheck Before Starting the Engine

- 4.17. Section 6.2 Starting the Engine

- 4.17.1. Before Starting

- 4.17.2. Starting Procedure

- 4.17.3. Cold Weather Starting

- 4.17.4. After Starting

- 4.17.5. Automatic Engine ShutDown System (Safety Chain)

- 4.17.6. Untitled

- 4.17.7. Engine WarmUp

- 4.17.8. Hydraulic Oil WarmUp

- 4.17.9. Hydraulic Oil Viscosity and Temperature Chart

- 4.18. Section 6.3 Stopping the Engine

- 4.18.1. Stopping Procedure

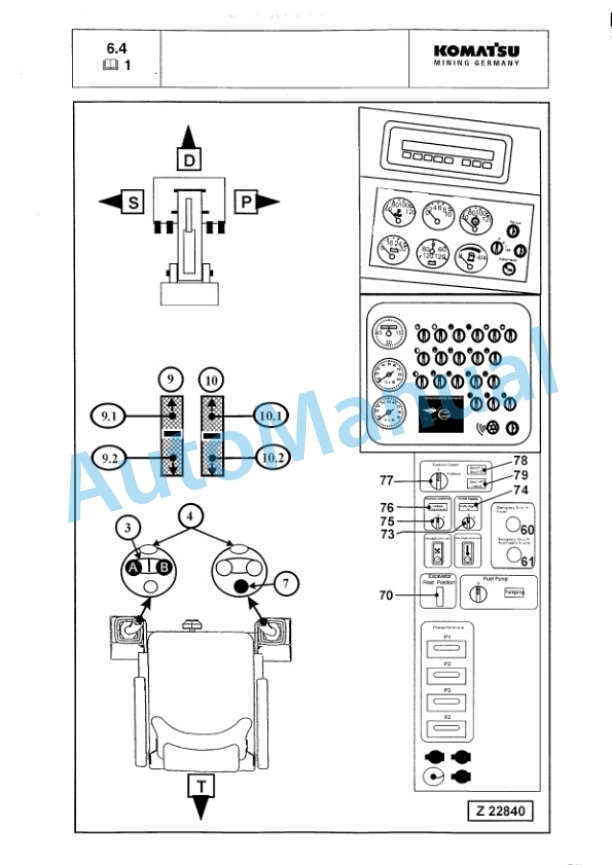

- 4.19. Section 6.4 Pontoon Operation

- 4.19.1. Warping of the Pontoon

- 4.19.2. Float Position of Backhoe Attachment

- 4.19.3. Determination of Directions

- 4.19.4. Shutoff Cocks for the Pontoon Hydraulic System

- 4.20. Section 6.5 Slewing and Braking the Superstructure

- 4.20.1. Rotating the Superstructure

- 4.20.2. Swing Angle Limitation System

- 4.20.3. Braking the Superstructure

- 4.20.4. Swing Parking Brake

- 4.21. Section 6.6 Working with the Attachment

- 4.22. Section 6.7 Combined Operation Cycles

- 4.23. Section 6.8 Operating the Heater, Ventilation, and Air Conditioning

- 4.23.1. Heating

- 4.23.2. Air Conditioning (Special Equipment

- 4.23.3. Combined Operation of Air Conditioning and Heating

- 4.24. Section 6.11 Automatic Lubrication Systems

- 4.24.1. Central Lubrication System and Swing Ring Gear Lubrication System

- 4.24.2. Controls of Automatic Lubrication Systems

- 4.24.3. Factory Adjustments

- 4.25. Section 6.13 Fire Detection and Suppression System (Special Equipment)

- 4.26. Section 6.15 Transfer Pump for Hydraulic Oil Reservoir

- 4.26.1. Functions of the Transfer Pump

- 4.26.2. Transfer Procedure

- 4.27. Section 7.0 Working Instructions

- 4.27.1. Excavator Operation

- 4.27.2. Barge Warping

- 4.27.3. Pontoon Warping

- 4.27.4. Maintaining the Pontoon in the Flow

- 4.27.5. Slowing Down Pontoon Motions

- 4.27.6. Working Ashore or at Banks from the Pontoon

- 4.27.7. Working in Shallow Waters

- 4.27.8. Depositing the Attachment During Working Breaks

- 4.28. Section 7.1 Emergency Operation System

- 4.29. Section 9.0 Refueling the Excavator

- 4.30. Section 10.0 Exchange of Attachment and/or Components

- 5. Part 2 Lubrication and Maintenance Manual

- 5.1. Table of Contents Lubrication and Maintenance Manual

- 5.2. Section 1.0 Foreward

- 5.2.1. Section Contents

- 5.2.2. Definitions

- 5.3. Section 1.1 Fire Prevention

- 5.4. Section 1.2 Repair Welding

- 5.5. Section 2.0 Safety Instructions

- 5.6. Section 3.0 Fuel and Lubricants

- 5.7. Section 4.0 Filling Capacities

- 5.8. Section 5.0 Lubrication and Maintenance Schedule

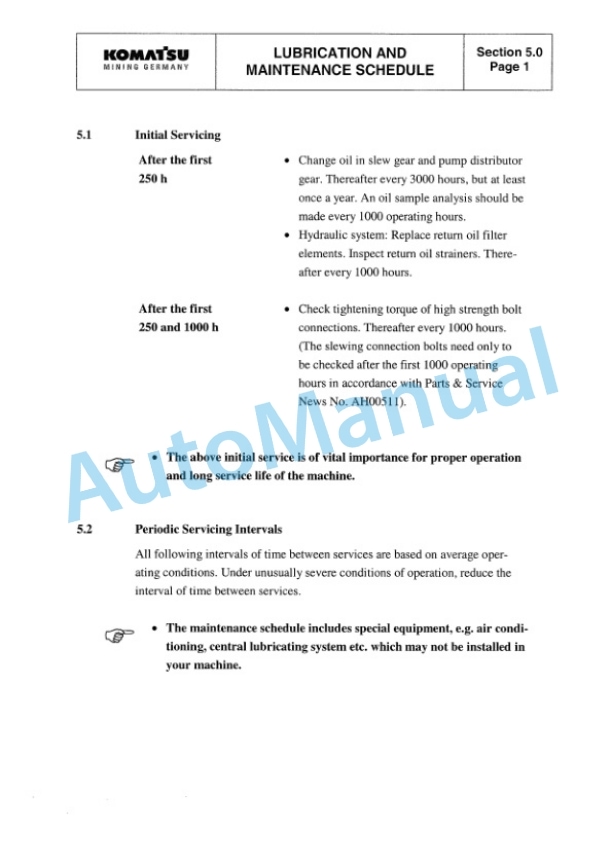

- 5.8.1. Initial Servicing

- 5.8.2. Periodic Servicing Intervals

- 5.8.3. Extended Service Intervals for Engines with Engine Oil Management System

- 5.8.4. Maintenance of Engine

- 5.8.5. Maintenance of Eliminator Oil Filtration System

- 5.8.6. Lubrication Point and Maintence Chart

- 5.9. Section 6.1 Every 10 Operating Hours or Daily

- 5.9.1. Visual Inspection

- 5.9.2. Maintenance of Engines

- 5.9.3. Lubrication of Attachment

- 5.9.4. Lubrication of Slewing Connection

- 5.9.5. Engine Air Cleaners

- 5.9.6. Not Used

- 5.9.7. Radiator Check Coolant Level

- 5.9.8. Track Groups

- 5.9.9. Fuel System, Water Separator

- 5.10. Section 6.2 Every 50 Operating Hours or Weekly

- 5.10.1. Slew Gear and Motor Adapter Housing

- 5.10.2. Not Used

- 5.10.3. Pump Distributor Geat (PTO) and Oil Reservoirs

- 5.10.4. Radiator and Hydraulic Oil Coolers

- 5.10.5. Air Conditioning

- 5.10.6. Maintenance of Engines

- 5.11. Section 6.3 Every 250 Operating Hours or Monthly

- 5.11.1. Engine

- 5.11.2. Drive Belts

- 5.11.3. Not Used

- 5.11.4. Not Used

- 5.11.5. Hydraulic Oil Cooler Lubricate Fan Bearings

- 5.11.6. Not Used

- 5.11.7. Not Used

- 5.11.8. Compressor for Signal Horn

- 5.11.9. Automatic Lubrication Systems, Clean InLineGreaseFilters

- 5.11.10. Air Cleaner for Operators Cab

- 5.11.11. Air Conditioning

- 5.11.12. Not Used

- 5.11.13. Not Used

- 5.11.14. Air Conditioning Refrigerant Compressor

- 5.12. Section 6.4 Every 500 Operating Hours or Every 3 Months

- 5.12.1. Engine

- 5.12.2. Batteries

- 5.12.3. Fuel Tank, Drain Water and Sediments

- 5.12.4. Flexible Drive Coupling

- 5.12.5. Rotary Distributor Lubrication

- 5.13. Section 6.5 Every 1000 Operating Hours or Every 6 Months

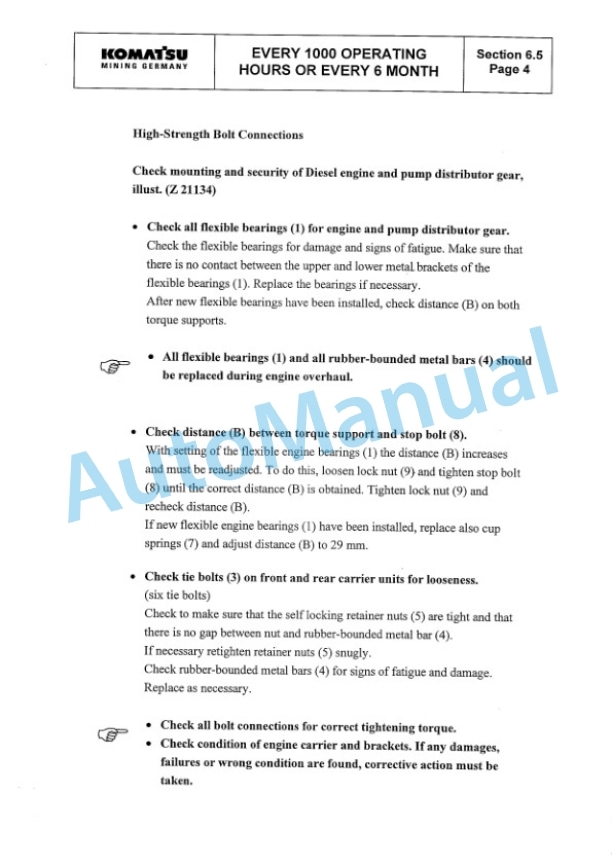

- 5.13.1. HighStrength Bolt Connections

- 5.13.2. Bolt Torque Chart

- 5.13.3. Maintenance of Engines

- 5.13.4. Hydraulic System

- 5.13.5. Pump Distributor Gears, Slew Gears, and Travel Gears

- 5.13.6. Compressor for Signal Horn

- 5.13.7. Not Used

- 5.13.8. Air Conditioning

- 5.14. Section 6.6 Every 2000 Operating Hours or Yearly

- 5.14.1. Hydraulic System

- 5.15. Section 6.7 Every 3000 operating operating Hours but at Least Once a Year

- 5.15.1. Slew Gear and Motor Adapter Housing

- 5.15.2. Pump Distributor Gear (PTO)

- 5.16. Section 6.8 When Necessary

- 5.16.1. Servicing the Engine Air Cleaners

- 5.16.2. Additional Fuel System Water Separator

- 5.16.3. Slew Gear

- 5.16.4. Automatic Lubrication Systems with Replaceable Grease Barrels

- 5.16.5. Not Used

- 5.16.6. Not Used

- 5.16.7. Not Used

- 5.16.8. Not Used

- 5.16.9. Hydraulic System

- 5.16.10. Cold Starting Aid, Replace Fluid Cylinder

- 5.16.11. Electrical Switch Board (X2)

- 5.17. Section 7.0 Excavator Storage

- 5.17.1. General

- 5.17.2. Preparing for Storage

- 5.17.3. One Month Repetitive Service Peroid

- 5.17.4. Six Month Repetitive Service Period

- 5.17.5. Preparing for Operation

- 5.18. Section 8.0 Troubleshooting

- 5.18.1. General

- 5.18.2. Engine

- 5.18.3. Hydraulic System

- 5.18.4. Travel and Slew Gears

- 5.18.5. Crawler Tracks

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103