Komatsu PC3000-11 T4 Hydraulic Mining Excavator Field Assembly Manual 06373up-xD-GD-1

$20.00

- Type Of Manual: Field Assembly Manual

- Manual ID: 06373up-xD-GD-1

- Format: PDF

- Size: 28.0MB

- Number of Pages: 288

-

Model List:

- PC3000-11 T4 Hydraulic Mining Excavator

- 1. Frontcover

- 2. Foreword

- 2.1. Foreword

- 2.2. Precautions for field assembly

- 2.2.1. How to work

- 2.2.2. Preparation and check of protective gear, slings and tools

- 2.2.3. Check during actual work

- 2.3. Disposal of removed parts

- 3. SAFETY

- 3.1. Safety information

- 3.2. Overview

- 3.2.1. Normal operations

- 3.2.2. Regular maintenance

- 3.2.3. Troubleshooting, adjustments and repair

- 3.2.4. Additional safety precautions

- 3.3. Sound pressure and vibration levels in the operators cab

- 3.3.1. Sound

- 3.3.2. Vibration

- 3.4. General precautions common to operation on the excavator

- 3.4.1. Understanding the excavator

- 3.4.2. Precautions before starting operation on the excavator

- 3.4.3. Preparations for safe operation

- 3.4.4. Fire prevention

- 3.4.5. Precautions when getting on or off the excavator

- 3.4.6. Burn prevention

- 3.4.7. Precautions when cleaning cab glass

- 3.4.8. Precautions related to protective structures

- 3.4.9. Precautions related to airborne and ejected debris

- 3.4.10. Electromagnetic comparability (EMC)

- 3.4.11. Precautions at jobsite

- 3.4.12. Starting motor

- 3.4.13. Operation

- 3.5. Precaution for maintenance

- 3.5.1. Isolate the excavator using the transfer pump

- 3.5.2. Isolate the excavator

- 3.5.3. Deisolate the excavator

- 3.5.4. General precaution

- 3.5.5. Precautions for inspection and maintenance

- 3.5.6. Precautions with high pressure fluid

- 3.6. Additional safety information for troubleshooting and adjustments

- 3.6.1. Inspection of the hydraulic system

- 3.6.2. Two workers only when the excavator is running during adjustments

- 3.6.3. Areas of potential danger around the excavator

- 3.7. Special safety equipment

- 3.7.1. Front guard protective structure FOPS for operators cab

- 3.7.2. Object handling

- 3.7.3. Lighting

- 3.7.4. Warning beacon

- 3.7.5. Safety harness in conformity with EN 361 (European standard)

- 3.8. Additional safety precautions

- 3.8.1. When assembling the excavator

- 3.8.2. When disassembling the excavator

- 4. GENERAL

- 4.1. General

- 4.1.1. Delivery of the excavator

- 4.1.2. Assembling the excavator

- 4.1.3. Lifting and transportation

- 4.1.4. Electrical energy

- 4.1.5. Electromagnetic compatibility (EMC)

- 4.1.6. Monitoring system of the machine

- 4.2. Assembly site requirements

- 4.2.1. Configuration of components on erection site (example)

- 4.2.2. Required crane

- 4.2.3. Manpower / assembly time

- 4.2.4. Tools and equipment for assembly

- 4.3. Standard application torque chart

- 4.3.1. Metric standard thread

- 4.3.2. Metric fine thread

- 4.4. Special tightening torques

- 4.5. Torque charts for flange joints

- 4.6. Tightening torque for hydraulic hose connection nut

- 4.7. General installation procedures for hydraulic hose lines

- 4.8. General installation instructions for attachment pins

- 4.8.1. Preparations for assembly

- 4.9. Transportation postures

- 5. ASSEMBLY SEQUENCE

- 5.1. Assembly sequence of the face shovel excavators

- 5.1.1. ASSEMBLY SEQUENCE UNDER CONSIDERATION OF THE MACHINES STABILITY

- 5.2. Assembly sequence of the backhoe excavators

- 5.2.1. ASSEMBLY SEQUENCE UNDER CONSIDERATION OF THE MACHINES STABILITY

- 5.3. Assembling of the undercarriage (tracks, center body, track frames)

- 5.3.1. Assembling of center body to crawler carrier

- 5.3.2. DETERMINING THE TIGHTENING TORQUE

- 5.3.3. Connecting the hydraulic lines to the travel motors

- 5.4. Assembling of the travel gear protection and final assembly

- 5.4.1. Assembling of the travel gear box protection

- 5.4.2. Final assembly of undercarriage

- 5.5. Assembling of the machinery house

- 5.5.1. Assembling of the handrails

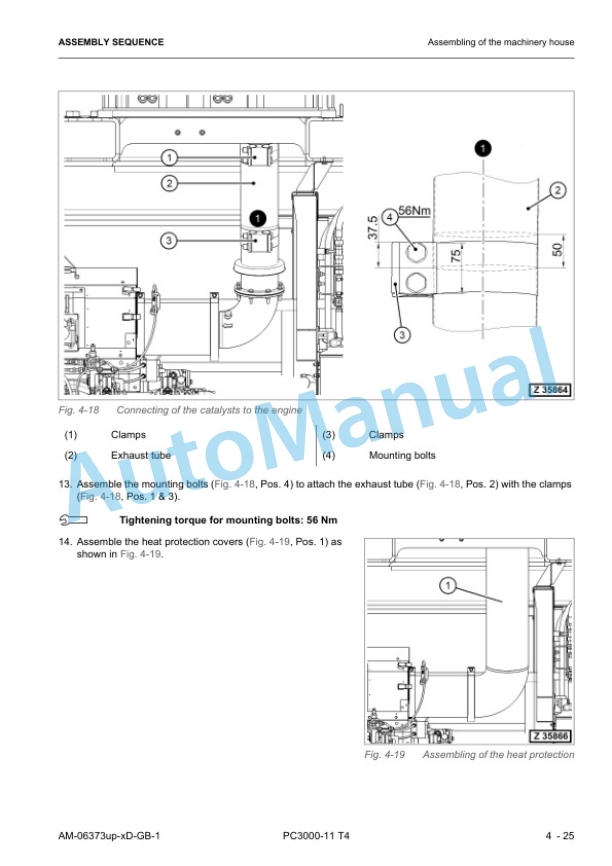

- 5.5.2. Assembling of the traverse with SCR catalyst and def tank

- 5.5.3. Assembling of the air cleaner assembly

- 5.6. Assembling of the superstructure platform

- 5.7. Connecting engine oil reserve system

- 5.8. Assembling of the fuel tank

- 5.9. Assembling of the access platform and stairway

- 5.9.1. Assembling of the access platform and the stairway cylinder

- 5.9.2. Assembling of the stairway and the attachment point

- 5.9.3. Assembling of the fuel tank step

- 5.9.4. Assembling of the fuel tank grids and hand rails

- 5.9.5. Assembling of the fuel cooler

- 5.9.6. routing and connecting the hydraulic hose of the stairway cylinder

- 5.10. Assembling of the bha boom

- 5.10.1. Assembling of boom cylinder to the boom (BHA)

- 5.10.2. Assembling of stick cylinder to the boom (BHA)

- 5.10.3. Assembling of boom assembly to superstructure platform (bha)

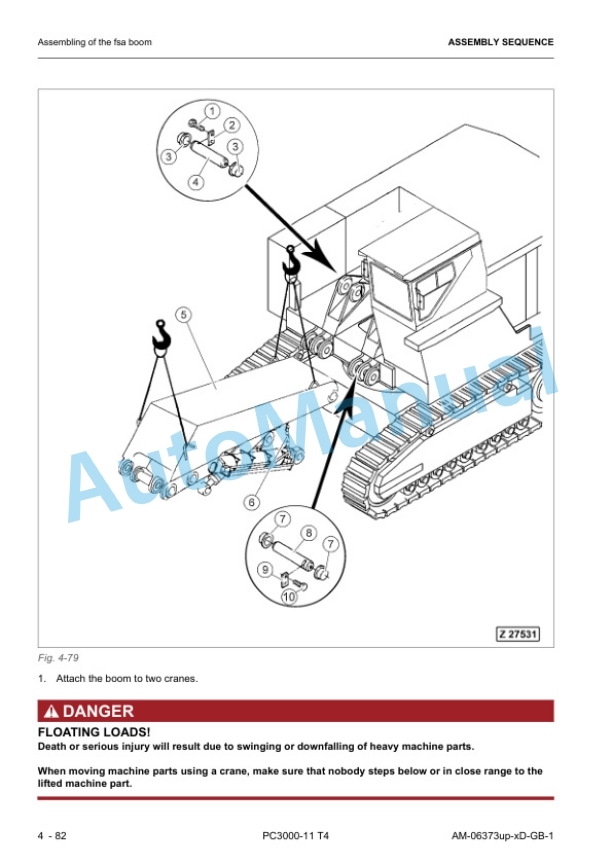

- 5.11. Assembling of the fsa boom

- 5.11.1. Assembling of boom cylinder and stick cylinder to the boom (FSA attachment)

- 5.11.2. Assembling of the boom assembly

- 5.12. Assembling of the counterweight

- 5.13. Assembling of the cab base

- 5.13.1. Connect cables from the machinery house to cab base

- 5.14. Assembling of the operators cab

- 5.15. Assembling of hydraulic oil cooler assembly

- 5.16. Assembling of the handrails, catwalks and steps

- 5.16.1. Assembling of the catwalk between machinery house and control block frame

- 5.16.2. Assembling of the emergency escape ladder at the cab base

- 5.16.3. Assembling of the emergency escape ladder assembly at the machinery house

- 5.16.4. Assembling of the ladder cylinder

- 5.17. Assembling of additional equipment

- 5.17.1. Assembling of the lubrication pinion assembly

- 5.17.2. Connecting grease lines of the slew circle system

- 5.18. Connecting the central refilling system

- 5.19. Prechecks before initial engine start

- 5.20. Filling and bleeding the hydraulic system

- 5.20.1. FILLING THE HYDRAULIC SYSTEM

- 5.20.2. Bleeding of the suction oil tank

- 5.20.3. Bleeding the main mumps

- 5.20.4. Bleeding the auxiliary pumps PC3000

- 5.20.5. Rebleeding the main pumps after main drive start

- 5.20.6. Bleeding Checklist PC3000

- 5.20.7. Bleeding the hydraulic oil tank

- 5.20.8. Bleeding the slew parking brake

- 5.20.9. Bleeding the travel parking brake

- 5.20.10. Dynamic bleeding

- 5.21. Assembling of the backhoe attachment

- 5.21.1. Assembling of the stick to the boom (BHA attachment)

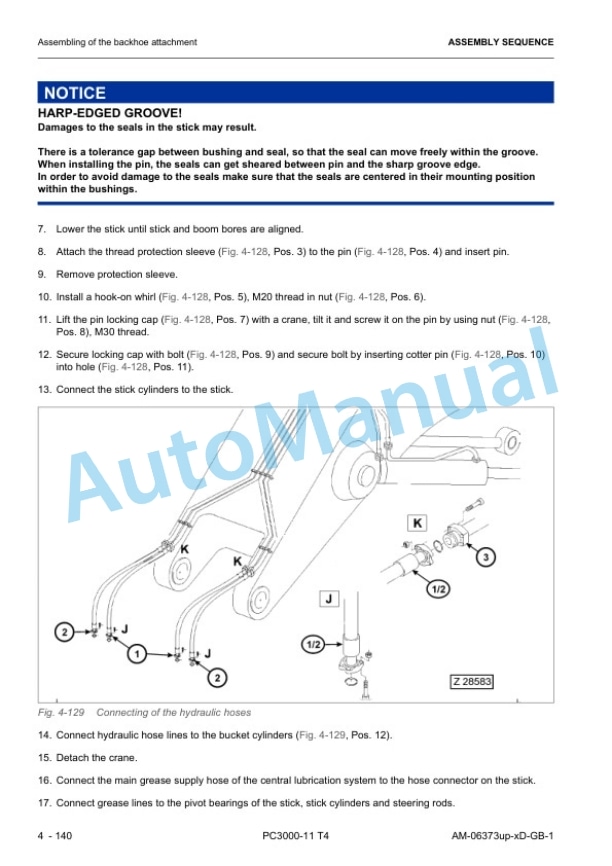

- 5.21.2. Connecting the hose lines from boom to bucket cylinders

- 5.21.3. Bleeding the bucket cylinder

- 5.21.4. Assembling of the bucket (bha attachment)

- 5.22. Assembling of the face shovel attachment

- 5.22.1. Attach the bucket cylinder to the boom

- 5.22.2. Assembling the stick to the boom

- 5.22.3. Assembling of the bull clam bucket

- 5.22.4. Assembling of the clam

- 5.23. Bleeding of the track tensioning system

- 5.24. Bleeding the slew circuit

- 5.25. Bleeding air from track system

- 6. DISASSEMBLY OF THE MACHINE

- 6.1. Disassembly sequence of the face shovel excavators

- 6.1.1. SAFETY PRECAUTIONS FOR DISASSEMBLING THE MACHINE

- 6.2. Disassembly sequence of the backhoe excavators

- 6.2.1. SAFETY PRECAUTIONS FOR DISASSEMBLING THE MACHINE

- 6.2.2. DISPOSAL OF WASTE MATERIAL

- 7. FINAL CHECKS AND ADJUSTMENTS

- 7.1. COMMISSIONING CHECK LIST

- 7.2. ADJUSTMENT OF AUTOMATIC LUBRICATION SYSTEMS

- 7.2.1. ADJUSTMENT OF AUTOMATIC LUBRICATION SYSTEMS

- 7.2.2. MAIN PUMP ADJUSTMENT IN RELATION TO ALTITUDE AT THE MINE SITE

- 7.2.3. PRESSURE COMPENSATION OF SEALED COMPONENTS

- 7.3. Air conditioning unit

- 7.3.1. COMMISSIONING OF THE AIR CONDITIONING

- 7.3.2. AIR CONDITIONING FOR OPERATORS CAB

- 7.4. PERFORM THE PMCLINIC ACCORDING TO THE PMCLINIC MANUAL

- 7.4.1. VISUAL INSPECTION

- 7.4.2. TRAVELLING INSTRUCTIONS

- 7.5. HANDLING OF DOCUMENTATION AFTER ASSEMBLY AND COMMISSIONING

- 8. ORBCOMM INITIALIZATION

- 8.1. ORBCOMM terminal activation

- 8.1.1. Application form for terminal activation

- 8.2. WebCARE basic information for machine registration

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615