- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW200-7H, PW220-7H Wheeled Excavator Operation and Maintenance Manual VEAM370101

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: VEAM370101

- Format: PDF

- Size: 9.1MB

- Number of Pages: 408

-

Model List:

- PW200-7H Wheeled Excavator

- PW220-7H Wheeled Excavator

- 1. FOREWORD

- 2. SAFETY INFORMATION

- 2.1. SAFETY MESSAGES

- 2.2. NOISE

- 2.3. VIBRATION

- 2.3.1. Guide to Reduce Vibration Levels on Machine

- 2.4. EMERGENCY STEERING

- 2.5. EMERGENCY BRAKING

- 3. INTRODUCTION

- 3.1. INTENDED USE

- 3.2. FEATURES

- 3.3. BREAKING IN YOUR NEW MACHINE

- 4. LOCATIONS OF PLATES, TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 4.1. MACHINE SERIAL NO. PLATE POSITION

- 4.2. ENGINE SERIAL NO. PLATE POSITION

- 4.3. TABLE TO ENTER SERIAL NO. AND DISTRIBUTOR

- 4.4. MACHINE SERIAL PLATES

- 4.4.1. STANDARD SERIAL PLATE

- 5. SAFETY

- 5.1. GENERAL PRECAUTIONS

- 5.2. PRECAUTION DURING OPERATION

- 5.2.1. BEFORE STARTING ENGINE

- 5.2.2. OPERATING MACHINE

- 5.2.3. TRANSPORTATION

- 5.2.4. BATTERY

- 5.2.5. TOWING

- 5.2.6. BUCKET WITH HOOK OR BUCKET LINK WITH LIFTING EYE

- 5.2.7. HANDLING OF FLUIDS

- 5.3. PRECAUTIONS FOR MAINTENANCE

- 5.3.1. BEFORE CARRYING OUT MAINTENANCE

- 5.3.2. DURING MAINTENANCE

- 5.4. POSITION FOR ATTACHING SAFETY LABELS

- 5.4.1. POSITION FOR ATTACHING SAFETY LABELS

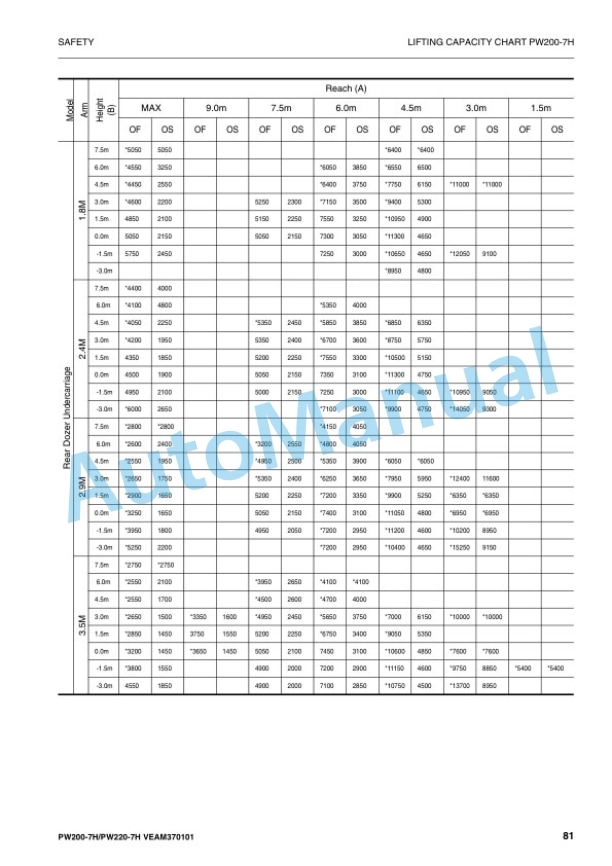

- 5.5. LIFTING CAPACITY CHART PW2007H

- 5.5.1. ONE PIECE BOOM Lift capacity tables for 2.5 metre undercarriage

- 5.5.2. ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage

- 5.5.3. TWO PIECE BOOM Lift capacity tables for 2.5 metre undercarriage

- 5.5.4. TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage

- 5.6. LIFTING CAPACITY CHART PW2207H

- 5.6.1. ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight.

- 5.6.2. ONE PIECE BOOM Lift capacity tables for 2.75 metre undercarriage

- 5.6.3. TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage and heavy duty counterweight

- 5.6.4. TWO PIECE BOOM Lift capacity tables for 2.75 metre undercarriage

- 6. OPERATION

- 6.1. GENERAL VIEW

- 6.1.1. GENERAL VIEW OF MACHINE

- 6.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 6.2. EXPLANATION OF COMPONENTS

- 6.2.1. MACHINE MONITOR

- 6.2.2. BASIC CHECK ITEMS

- 6.3. SWITCHES

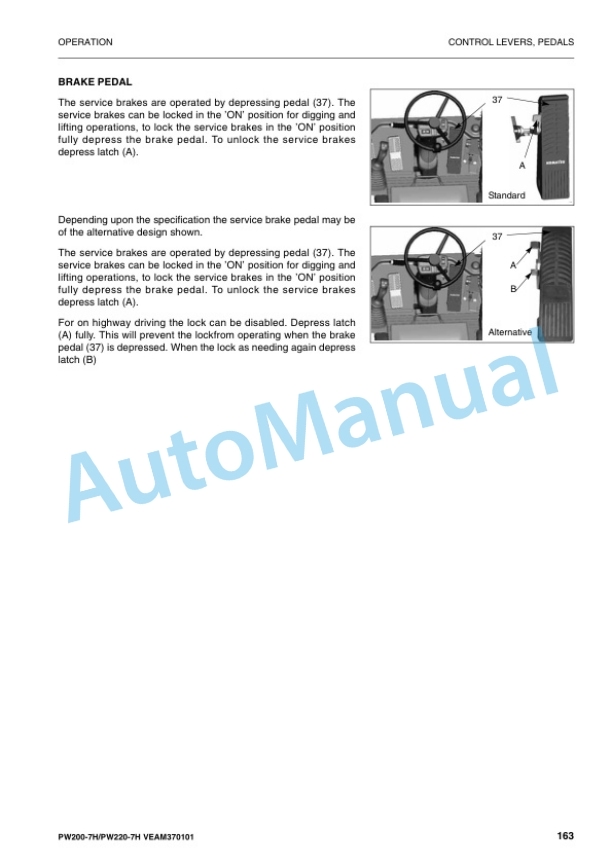

- 6.4. CONTROL LEVERS, PEDALS

- 6.4.1. FRONT WINDOW

- 6.4.2. EMERGENCY EXIT FROM OPERATORS CAB

- 6.4.3. CAP, COVER WITH LOCK

- 6.4.4. FUSE

- 6.4.5. LUGGAGE TRAY

- 6.4.6. ASHTRAY

- 6.4.7. CUP HOLDER

- 6.4.8. HOT AND COOL BOX

- 6.4.9. CAB RADIO

- 6.4.10. POWER PICKUP PORT

- 6.4.11. HANDLING AIR CONDITIONER

- 6.4.12. FUSIBLE LINK

- 6.4.13. CONTROLLER

- 6.4.14. TOOL BOX

- 6.4.15. REFUELLING PUMP

- 6.4.16. WARNING LAMPS

- 6.4.17. HANDLING ACCUMULATORS

- 6.5. OPERATION

- 6.5.1. CHECK BEFORE STARTING ENGINE

- 6.6. OPERATIONS AND CHECKS BEFORE STARTING ENGINE

- 6.6.1. STARTING ENGINE

- 6.6.2. MOVING MACHINE OFF

- 6.6.3. STEERING

- 6.6.4. TRAVELLING ON PUBLIC HIGHWAY

- 6.6.5. STOPPING PARKING

- 6.6.6. SWINGING (Slewing the upper carriage)

- 6.6.7. OPERATION OF WORK EQUIPMENT

- 6.6.8. WORKING MODE SELECTION

- 6.6.9. PROHIBITIONS FOR OPERATION

- 6.6.10. PRECAUTIONS FOR OPERATION

- 6.6.11. RECOMMENDATIONS FOR TRAVELLING

- 6.6.12. PRECAUTIONS WHEN TRAVELLING UP OR DOWN HILLS

- 6.6.13. HOW TO ESCAPE FROM MUD

- 6.6.14. WORK POSSIBLE USING HYDRAULIC EXCAVATOR

- 6.6.15. REPLACEMENT AND INVERSION OF BUCKET

- 6.6.16. STOPPING ENGINE

- 6.6.17. CHECK AFTER FINISHING WORK

- 6.7. CHECK AFTER STOPPING ENGINE

- 6.7.1. LOCKING

- 6.7.2. OVERLOAD WARNING DEVICE

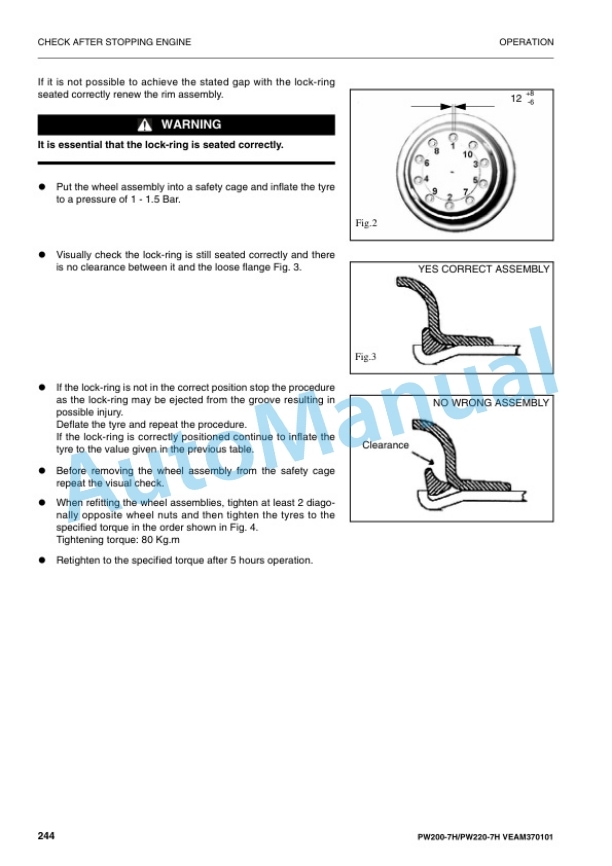

- 6.7.3. HANDLING THE WHEELS

- 6.8. TRANSPORTATION

- 6.8.1. LOADING, UNLOADING WORK

- 6.8.2. PRECAUTIONS FOR LOADING

- 6.8.3. PRECAUTIONS FOR TRANSPORTATION

- 6.8.4. TRAVELLING POSTURE

- 6.9. COLD WEATHER OPERATION

- 6.9.1. PRECAUTIONS FOR LOW TEMPERATURE

- 6.9.2. PRECAUTIONS AFTER COMPLETION OF WORK

- 6.9.3. AFTER COLD WEATHER

- 6.10. LONGTERM STORAGE

- 6.10.1. BEFORE STORAGE

- 6.10.2. DURING STORAGE

- 6.10.3. AFTER STORAGE

- 6.10.4. STARTING MACHINE AFTER LONGTERM STORAGE

- 6.11. TROUBLESHOOTING

- 6.11.1. PHENOMENA THAT ARE NOT FAILURES

- 6.11.2. METHOD OF TOWING MACHINE

- 6.11.3. PRECAUTIONS ON PARTICULAR JOBSITES

- 6.11.4. DISCHARGED BATTERY

- 6.11.5. OTHER TROUBLE

- 7. MAINTENANCE

- 7.1. GUIDES TO MAINTENANCE

- 7.2. OUTLINE OF SERVICE

- 7.2.1. USE OF BIODEGRADEABLE OIL

- 7.2.2. OUTLINE OF OIL, FUEL, COOLANT

- 7.2.3. OUTLINE OF ELECTRIC SYSTEM

- 7.2.4. OUTLINE OF HYDRAULIC SYSTEM

- 7.3. WEAR PARTS LIST

- 7.4. USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 7.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 7.5. USE FUEL, COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE CONT.

- 7.6. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 7.6.1. INTRODUCTION OF NECESSARY TOOLS

- 7.7. TIGHTENING TORQUE SPECIFICATIONS

- 7.7.1. TIGHTENING TORQUE LIST

- 7.8. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 7.8.1. SAFETY CRITICAL PARTS

- 7.9. MAINTENANCE SCHEDULE CHART

- 7.9.1. KEY TO LUBRICATION POINTS

- 7.10. SERVICE PROCEDURE

- 7.10.1. INITIAL 50 HOURS SERVICE

- 7.10.2. CHECK AND TIGHTEN WHEEL NUTS

- 7.10.3. INITIAL 250 HOURS SERVICE

- 7.10.4. WHEN REQUIRED

- 7.10.5. CHECKING COOLANT LEVEL

- 7.10.6. CHECK AND TIGHTEN WHEEL NUTS

- 7.10.7. CHECK ELECTRICAL INTAKE AIR HEATER

- 7.10.8. CHECK ALTERNATOR

- 7.10.9. REPLACE BUCKET SIDE CUTTERS

- 7.10.10. REPLACE BUCKET TEETH

- 7.10.11. ADJUST BUCKET CLEARANCE

- 7.10.12. CHECK WINDOW WASHER FLUID LEVEL, ADD FLUID

- 7.10.13. CHECK AND ADJUST AIR CONDITIONER

- 7.10.14. DRAIN ENGINE BREATHER OIL CATCHER

- 7.10.15. CHECK BEFORE STARTING

- 7.10.16. CHECK COOLANT LEVEL, ADD WATER

- 7.10.17. EVERY 50 HOURS

- 7.10.18. EVERY 100 HOURS SERVICE

- 7.10.19. EVERY 250 HOURS MAINTENANCE

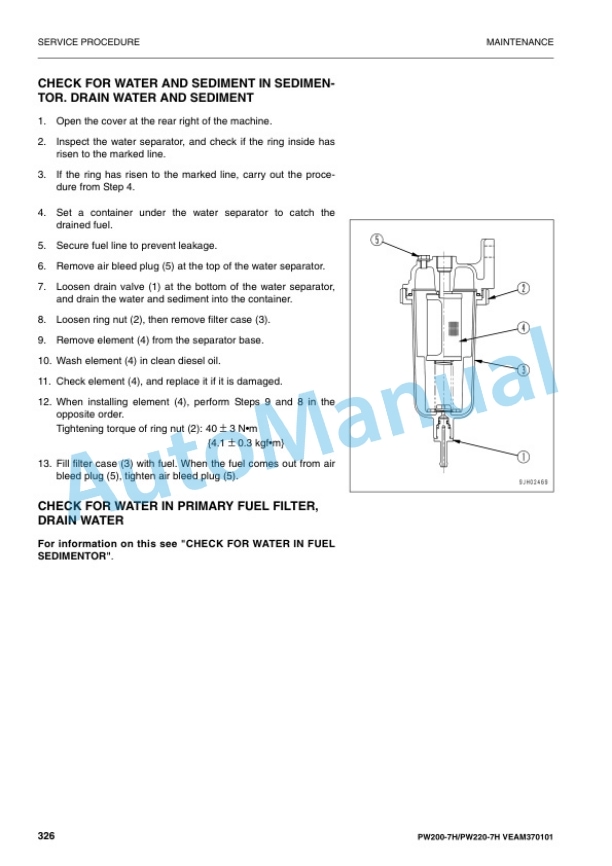

- 7.10.20. EVERY 500 HOURS SERVICE

- 7.10.21. EVERY 1000 HOURS SERVICE

- 7.10.22. EVERY 2000 HOURS SERVICE

- 7.10.23. EVERY 4000 HOURS SERVICE

- 7.10.24. EVERY 5000 HOURS SERVICE

- 8. SPECIFICATIONS

- 8.1. SPECIFICATIONS

- 8.1.1. PIECE BOOM

- 8.1.2. PIECE BOOM

- 8.1.3. WORKING RANGE ONE PIECE BOOM

- 8.1.4. WORKING RANGE TWO PIECE BOOM

- 9. OPTIONS, ATTACHMENTS

- 9.1. GENERAL PRECAUTIONS

- 9.1.1. PRECAUTIONS RELATED TO SAFETY

- 9.2. PRECAUTIONS WHEN INSTALLING ATTACHMENTS

- 9.3. HANDLING BUCKET WITH HOOK

- 9.3.1. CHECKING FOR DAMAGE TO BUCKET WITH HOOK

- 9.3.2. PROHIBITED OPERATIONS

- 9.3.3. PRECAUTIONS DURING OPERATIONS

- 9.4. MACHINES READY FOR ATTACHMENTS

- 9.4.1. GENERAL LOCATIONS

- 9.4.2. HANDLING THE CLAMSHELL BUCKET

- 9.4.3. OPERATION

- 9.4.4. METHOD FOR RELEASING PRESSURE IN CONTROL CIRCUIT OF MACHINES EQUIPPED WITH ACCUMULATOR

- 9.4.5. LONGTERM STORAGE

- 9.5. INTRODUCTION OF ATTACHMENTS AND EXTENDING MACHINE SERVICE LIFE

- 9.5.1. HYDRAULIC BREAKER

- 9.5.2. POWER RIPPER

- 9.5.3. FORK GRAB

- 9.5.4. GRAPPLE BUCKET

- 9.5.5. SCRAP GRAPPLE

- 9.5.6. CRUSHER SMASHER

- 9.5.7. HYDRAULIC PILE DRIVER

- 9.5.8. HYDRAULIC EXCAVATOR WITH MULTIPURPOSE CRANE

- 10. INDEX

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG692

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF