- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA250-3 Wheel Loader Operation and Maintenance Manual CEAM000503

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM000503

- Format: PDF

- Size: 8.0MB

- Number of Pages: 361

-

Model List:

- WA250-3 Wheel Loader

- 1. INTRODUCTION

- 1.1. FOREWORD

- 1.2. SAFETY INFORMATION

- 1.3. APPROVED AND NONAPPROVED USES

- 1.3.1. Approved Functions

- 1.3.2. NonApproved Functions

- 1.4. VISIBILITY STANDARD

- 1.4.1. Visibility in Immediate Area

- 1.4.2. M Radius Visibility

- 1.5. PRODUCT IDENTIFICATION

- 1.5.1. Machine

- 1.5.2. Service Meter Location

- 1.5.3. Directions of Machine

- 1.5.4. Machine Serial Number/Product Identification Number (PIN)

- 1.5.5. Engine Serial Number, EPA Regulations

- 1.6. SERIAL NUMBERS AND DEALER INFORMATION

- 1.6.1. Model WA2506

- 1.7. TABLE OF CONTENTS

- 2. SAFETY

- 2.1. SAFETY AND WARNING DECALS

- 2.1.1. Location of the Safety Labels

- 2.1.2. Safety Labels

- 2.2. GENERAL SAFETY RULES AND PRECAUTIONS

- 2.2.1. General Safety Rules

- 2.2.2. Safety at Job Site

- 2.2.3. Safety Features

- 2.2.4. Clothing and Protective Equipment

- 2.2.5. Keep Machine Clean

- 2.2.6. Fire and Explosion Prevention

- 2.2.7. Action if Fire Occurs

- 2.2.8. Fire Extinguisher and First Aid Kit

- 2.2.9. Mounting and Dismounting

- 2.2.10. Inside Operators Compartment

- 2.2.11. Emergency Escape from Operators Cab

- 2.2.12. Precautions When Standing Up from Operators Seat

- 2.2.13. Leaving Operators Compartment

- 2.2.14. Parking the Machine

- 2.2.15. Precautions When Using ROPS

- 2.2.16. Unauthorized Modification

- 2.2.17. Precautions for Attachments and Options

- 2.2.18. Precautions When Cleaning Cab Glass

- 2.2.19. Asbestos Hazard Alert

- 2.2.20. Crush or PinchPoint Dangers

- 2.2.21. Precautions for Ventilation Exhaust Gas

- 2.3. PRECAUTIONS BEFORE STARTING OPERATIONS

- 2.3.1. PreOperational Checks

- 2.3.2. Precautions for Job Site

- 2.4. RULES FOR ROAD TRAVEL

- 2.4.1. Travel Precautions

- 2.4.2. Traveling on Slopes

- 2.4.3. Using the Brakes

- 2.4.4. Traveling in Reverse

- 2.4.5. Operating on Snow or Frozen Surfaces

- 2.5. PRECAUTIONS DURING INSPECTION AND MAINTENANCE

- 2.5.1. Warning Tags

- 2.5.2. Workplace Environment

- 2.5.3. Systems Equipped with ECSS

- 2.5.4. Equipment Storage

- 2.5.5. Working Under the Machine

- 2.5.6. Using Drop Lamps

- 2.5.7. Using Proper Tools

- 2.5.8. Keeping the Machine Clean

- 2.5.9. Precautions When Welding

- 2.5.10. Precautions When Using Hammer

- 2.5.11. Noise

- 2.5.12. Stopping Engine During Inspection and Maintenance

- 2.5.13. Running the Machine During Maintenance

- 2.5.14. Rules for Refueling the Machine

- 2.5.15. Cooling System Precautions

- 2.5.16. Window Washer Fluid

- 2.5.17. Battery Information

- 2.5.18. HighPressure Precautions

- 2.5.19. HighTemperature Precautions

- 2.5.20. High Voltage

- 2.5.21. Accumulator and Gas Spring

- 2.5.22. Inflating Tires

- 2.5.23. Storing Tires

- 2.5.24. Using Compressed Air

- 2.5.25. Disposal of Waste Materials

- 2.5.26. Critical Parts

- 2.5.27. Maintenance of Air Conditioner

- 3. OPERATION

- 3.1. GENERAL VIEW

- 3.1.1. General View of Machine

- 3.1.2. General View of Controls and Gauges

- 3.2. EXPLANATION OF COMPONENTS

- 3.2.1. Machine Monitor

- 3.2.2. Types of Warnings

- 3.2.3. Character Display Portion

- 3.2.4. Emergency Stop Items

- 3.2.5. Caution Items

- 3.2.6. Inspection and Maintenance Items

- 3.2.7. Pilot Display Portion

- 3.2.8. Meter Display Portion

- 3.3. OTHER FUNCTIONS OF MACHINE MONITOR

- 3.3.1. Overall Menu

- 3.4. SWITCHES AND CONTROLS

- 3.4.1. General View

- 3.5. CONTROL LEVERS, PEDALS

- 3.5.1. General View

- 3.6. SECURITY LOCKS AND SAFETY FEATURES

- 3.6.1. Steering Tilt Lock Lever

- 3.6.2. Frame Lock Bar

- 3.6.3. Caps and Covers with Lock

- 3.6.4. Backup Alarm

- 3.7. MACHINE FEATURES

- 3.7.1. Towing Pin

- 3.7.2. Grease Pump

- 3.7.3. Cab Door

- 3.8. WORK OPERATIONS

- 3.8.1. WalkAround Check

- 3.8.2. Precautions Before Starting Work Operations

- 3.8.3. Check Before Starting Engine

- 3.8.4. Adjustments

- 3.8.5. Final Checks Before Starting Engine

- 3.8.6. Starting Engine

- 3.8.7. Operations and Checks After Starting Engine

- 3.8.8. Stopping Engine

- 3.8.9. Moving the Machine (Directional, Speed), Stopping the Machine

- 3.8.10. Operation of Work Equipment

- 3.8.11. Work Possible Using Wheel Loader

- 3.8.12. Loading Operations

- 3.8.13. Precautions During Work Operations

- 3.8.14. Adjusting Work Equipment

- 3.8.15. Measuring Dump Angle

- 3.8.16. Parking the Machine

- 3.8.17. Checks After Completion of Operation

- 3.8.18. Locking the Machine

- 3.9. HANDLING TIRES

- 3.9.1. Precautions When Handling Tires

- 3.10. TRANSPORTATION

- 3.10.1. Transportation Procedure

- 3.10.2. Loading and Unloading Trailers

- 3.11. LIFTING MACHINE

- 3.11.1. Lifting Position

- 3.11.2. Lifting Procedure

- 3.12. COLD WEATHER OPERATION

- 3.12.1. Precautions for Low Temperature

- 3.13. LONGTERM STORAGE

- 3.13.1. Before Storage

- 3.13.2. During Storage

- 3.13.3. After Storage

- 3.14. AUTOMATIC AIR CONDITIONER

- 3.14.1. Control Panel

- 3.14.2. Method of Operation

- 3.14.3. Precautions When Using Air Conditioner

- 3.14.4. Inspection and Maintenance

- 3.14.5. Cool Box

- 3.15. KOMTRAX

- 3.15.1. Basic Precautions

- 3.16. TROUBLESHOOTING

- 3.16.1. When Machine Runs Out of Fuel

- 3.16.2. Towing the Machine

- 3.16.3. If Battery is Discharged

- 3.16.4. Starting Engine With Booster Cables

- 3.16.5. Lowering Work Equipment When Engine Has Stopped

- 3.16.6. Other Troubleshooting

- 4. MAINTENANCE

- 4.1. GUIDES TO MAINTENANCE

- 4.1.1. Check Service Meter

- 4.1.2. Komatsu Genuine Replacement Parts

- 4.1.3. Komatsu Genuine Oils

- 4.1.4. Always Use Clean Washer Fluid

- 4.1.5. Always Use Clean Oil and Grease

- 4.1.6. Checking for Foreign Materials in Drained Oil and On Filters

- 4.1.7. Fuel Strainer

- 4.1.8. Welding Instructions

- 4.1.9. Do Not Drop Things Inside Machine

- 4.1.10. Dusty Work Sites

- 4.1.11. Avoid Mixing Oil

- 4.1.12. Locking Inspection Covers

- 4.1.13. Bleeding Air from Hydraulic Circuit

- 4.1.14. Precautions When Installing Hydraulic Hoses

- 4.1.15. Checks After Inspection and Maintenance

- 4.2. OUTLINES OF SERVICE

- 4.2.1. Handling Oil, Fuel, Coolant, and Performing Oil Clinic

- 4.2.2. Performing KOWA (Komatsu Oil Wear Analysis)

- 4.2.3. Outline of Electric System

- 4.3. WEAR PARTS

- 4.3.1. Wear Parts List

- 4.4. RECOMMENDED FUEL, COOLANT, AND LUBRICANTS

- 4.4.1. Fuel, Coolant, and Lubricant Ambient Temperature Chart

- 4.4.2. Recommended Brands, Other Than Komatsu Genuine Oil

- 4.4.3. Biodiesel Usage

- 4.5. STANDARD TIGHTENING TORQUES FOR BOLTS AND NUTS

- 4.5.1. Torque List

- 4.6. PERIODIC REPLACEMENT OF SAFETY CRITICAL PARTS

- 4.6.1. Safety Critical Parts List

- 4.7. MAINTENANCE SCHEDULE CHART

- 4.8. SERVICE PROCEDURE

- 4.8.1. Initial 10 Hours Service

- 4.8.2. Initial 250 Hours Service

- 4.8.3. Initial 1000 Hours Service

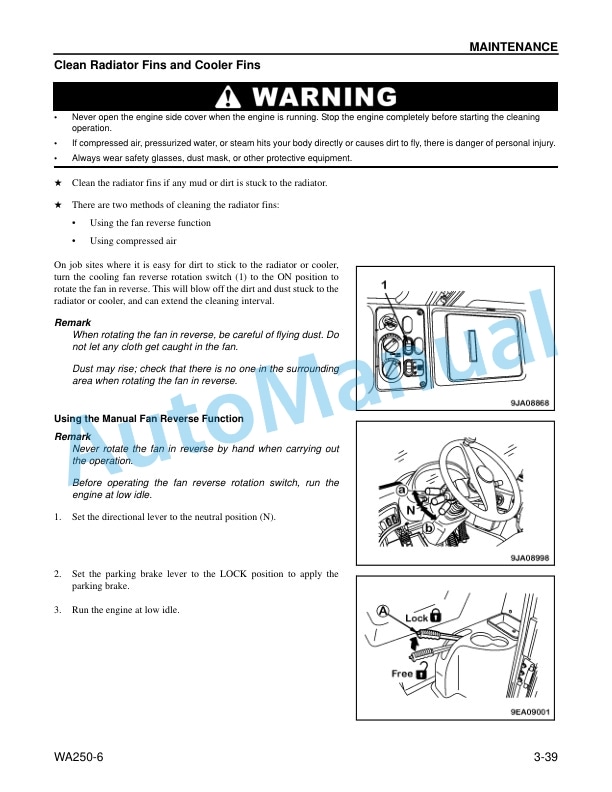

- 4.8.4. When Required

- 4.8.5. Check Before Starting

- 4.8.6. Every 50 Hours Service

- 4.8.7. Every 100 Hours Service

- 4.8.8. Every 250 Hours Service

- 4.8.9. Every 500 Hours Service

- 4.8.10. Every 1000 Hours Service

- 4.8.11. Every 2000 Hours Service

- 4.8.12. Every 4000 Hours Service

- 4.8.13. Every 8000 Hours Service

- 5. SPECIFICATIONS

- 5.1. SPECIFICATIONS

- 6. OPTIONS, ATTACHMENTS

- 6.1. BUCKET AND TIRES

- 6.2. AM/FM RADIO CASSETTE STEREO SOUND SYSTEM

- 6.2.1. Sound System Components

- 6.2.2. Method of Operation

- 6.2.3. Precautions When Using

- 6.2.4. Handling Cassette Tape

- 6.3. HYDRAULIC QUICK COUPLER

- 6.3.1. Removing Attachment

- 6.3.2. Installing Attachment

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 515C, 520C Operation and Maintenance Manual OM515C520C99-1E

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG729

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF